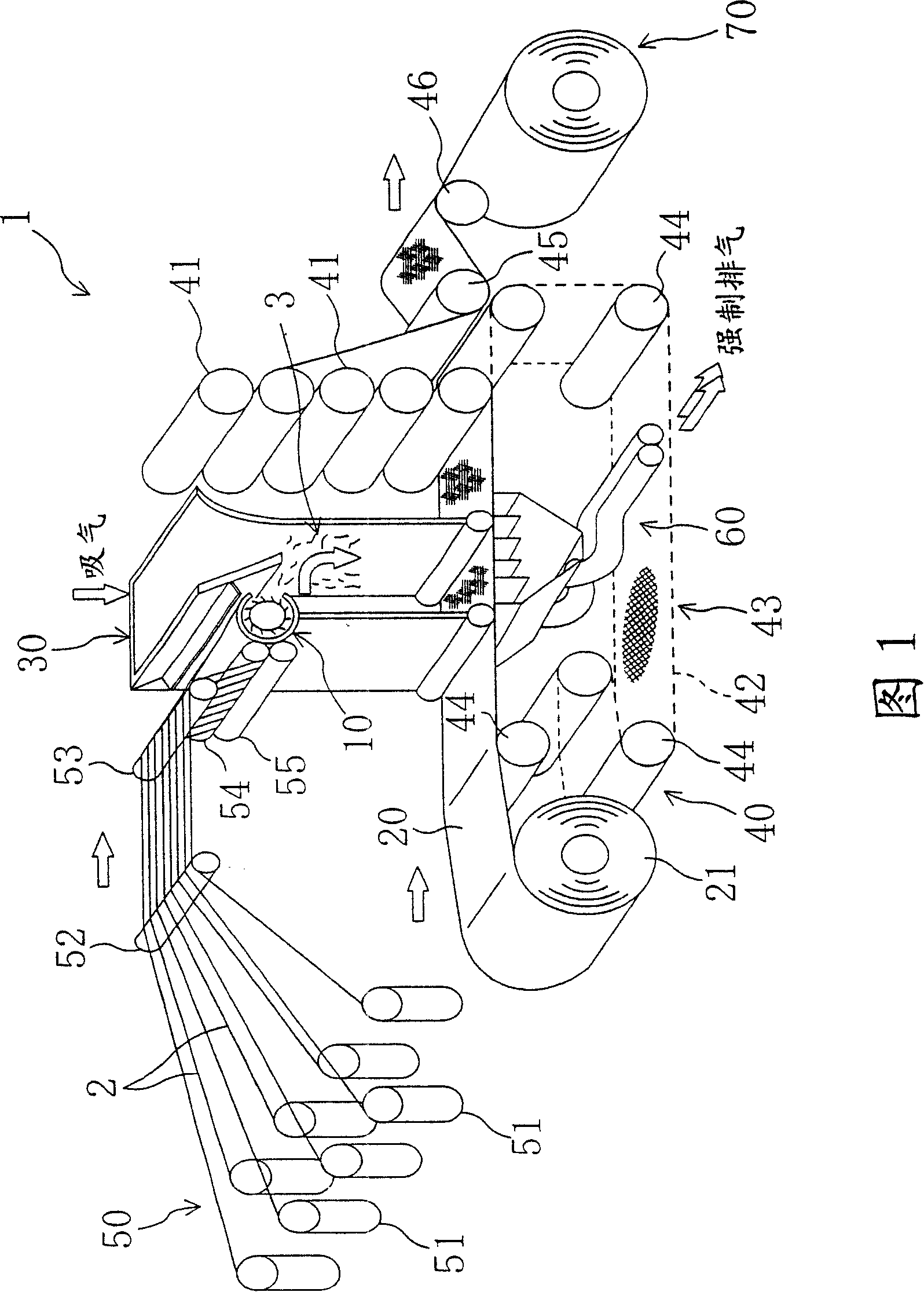

Needle blade roll for quasi-cotton producing device

A technology for manufacturing a device and a needle roller, which is applied in the field of needle rollers, can solve the problems of short fibers 102, short fibers 102 are not easily entangled, etc., and achieves the effects of uniform micronization and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

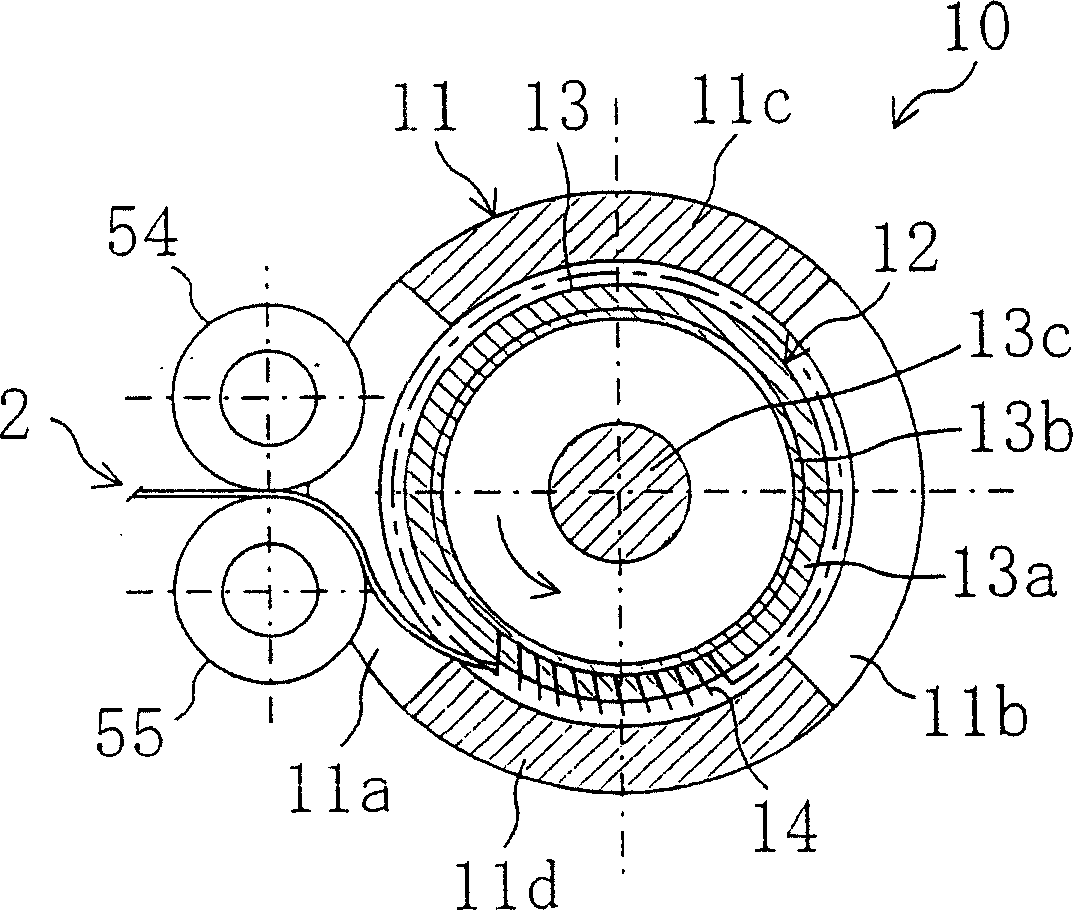

Examples

Deformed example 1

[0098] Figure 9 A first modified example of the above-mentioned embodiment is shown. In this example, the front-back direction of the wind tunnel 30 is reversed from that of the above-mentioned embodiment, and the roller unit 10 is fixed to the back panel 30b. In addition, the back panel 30b is constituted by reversing the same components as the front panel 30a of the above-mentioned embodiment back and forth, and the front panel 30a is constituted by reversing the same components as the back panel 30b of the above-mentioned embodiment back and forth. of. In addition, the short fiber agitating plate 32 is also arranged symmetrically with the above-mentioned embodiment, but the end portion 33a on the facing surface 30a side of the roller unit 10 is arranged lower than the end portion on the roller unit 10 side and the front end 34a of the vortex forming plate 34. , which is the same as the previous example.

[0099] Other structures and effects are the same as those of the ...

Deformed example 2

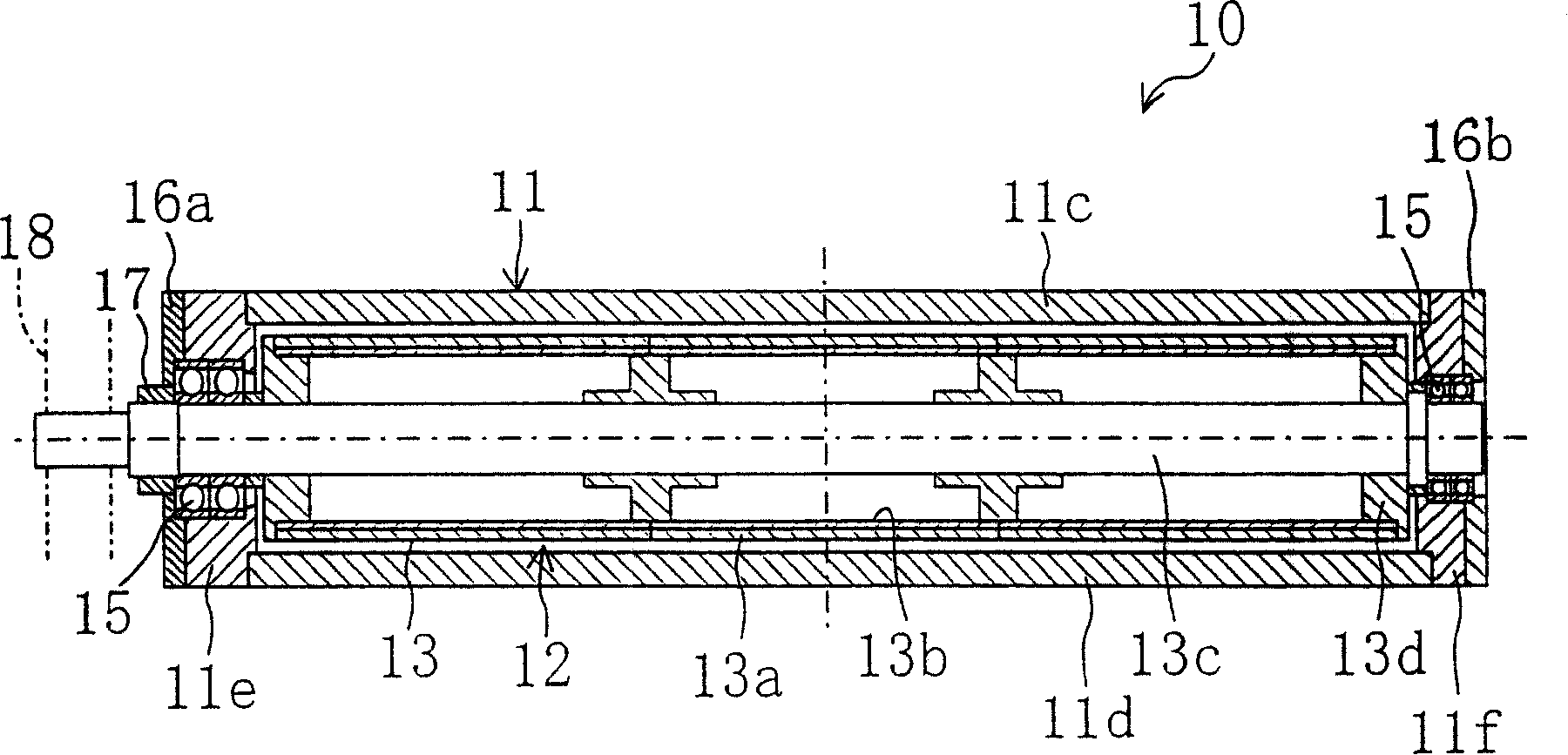

[0101] Figure 10 A second modified example of the above-mentioned embodiment is shown. In this example, as for the casing 11 of the roller unit 10, it is made into a structure in which the discharge port 11b is formed wider on the side of the upper casing 11c. Further, the second vortex forming plate 11g is fixed to the end portion of the upper case 11c on the discharge port 11b side so as to be substantially parallel to the front plate 30a of the wind tunnel 30 . That is, in this second modified example, the structure in which the second vortex forming plate 11g is provided on the upper portion of the roller unit 10 below the air inlet 30e of the wind tunnel 30 is configured.

[0102] Thus, by enlarging the discharge port 11b of the housing 11, the short fibers 3 can be easily discharged into the wind tunnel 30 even when the short fibers 3 are wound around the needle pieces 14, for example. On the other hand, if the discharge port 11b is simply enlarged, the short fibers 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com