Preparation method and equipment of fully water-soluble high imino partially methylated amino resin

An amino resin and water-soluble technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problems of saturation phenomenon, poor shock isolation effect, etc., and achieve convenient wiring, Good shock isolation effect and high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

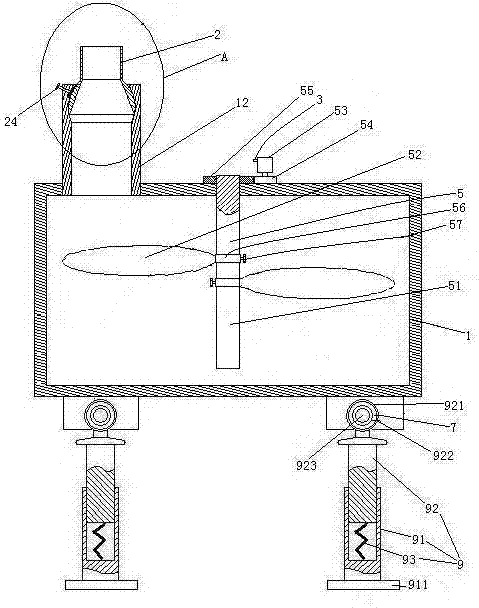

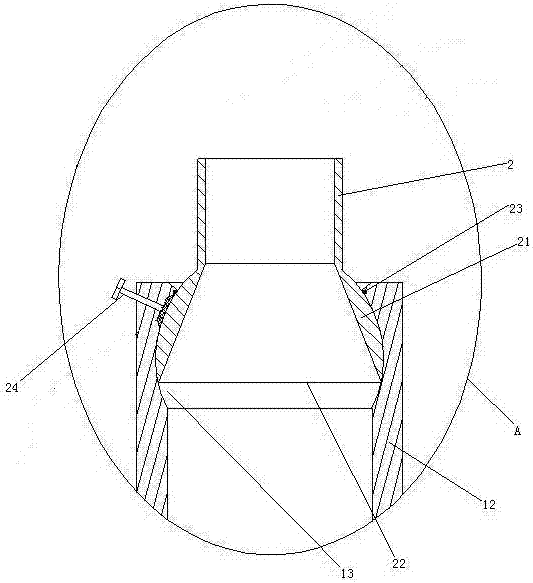

[0047] Embodiment one, see figure 1 , a water-soluble high imino partially methylated amino resin preparation equipment, including a container 1, a reversing tube 2, a tightening bolt 24 and a stirrer 5.

[0048] The container 1 is provided with a feed opening 12 .

[0049] The reversing pipe 2 is butted on the inlet end of the feed port 12 . The reversing pipe 2 is affixed together with the feed port 12 by tightening bolts 24 .

[0050] The agitator 5 includes a rotating shaft 51 , a stirring blade 52 , a motor 53 , a driving gear 54 and a driven gear 55 . The rotating shaft 51 is input into the container 1 . The rotating shaft 51 is rotatably connected to the container 1 . The rotating shaft 51 extends in the vertical direction. The stirring blade 52 is connected to the part of the rotating shaft 51 located in the container. The stirring blade 52 is a blade structure. The driven gear 55 is fixed on the upper end of the rotating shaft 51, and the driven gear 55 and the...

Embodiment 2

[0058] Embodiment two, the difference with embodiment one lies in the change of the structure of the preparation equipment of the water-soluble high imino part methylated amino resin, specifically changed as follows:

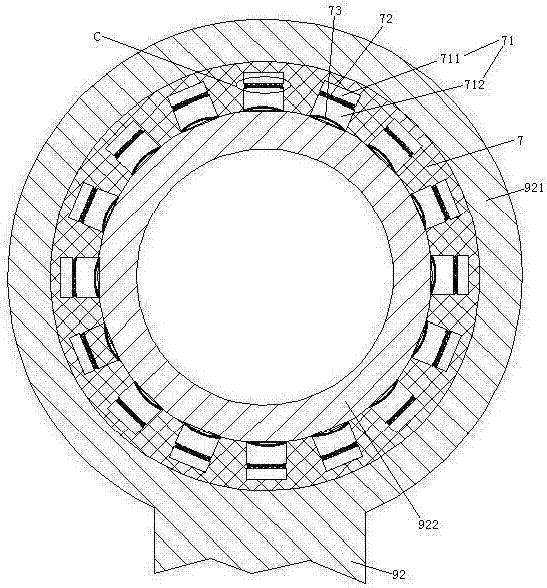

[0059] see Figure 6 , The shock-isolation foot 9 is also provided with a driving mechanism 6 . The inner ring 922 is rotatably connected to the rubber ring 7 , and the rubber ring 7 is fixedly connected with the connecting ring 921 .

[0060]The drive mechanism 6 includes a ratchet 61 , a pawl 62 for driving the ratchet, and a drive rod 63 . The ratchet 61 is coaxially connected with the inner ring 922 . The ratchet 61 is integrated with the inner ring 922 . The pawl 62 is fixedly connected to one end of the driving rod 63 . The upper section 92 is provided with a sliding hole 924 . The other end of the driving rod 63 can slide through the sliding hole 924 two-dimensionally. The lower end of the drive rod 63 is slidably hooked to the lower section 91 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com