Device for synchronously polishing in bulk with multiple working stations and same working procedure

A technology with the same process and multiple stations, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure of polishing device and platform, low reliability, low polishing efficiency, etc. The effect of batch automatic polishing processing, efficient automatic processing, and simple working procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

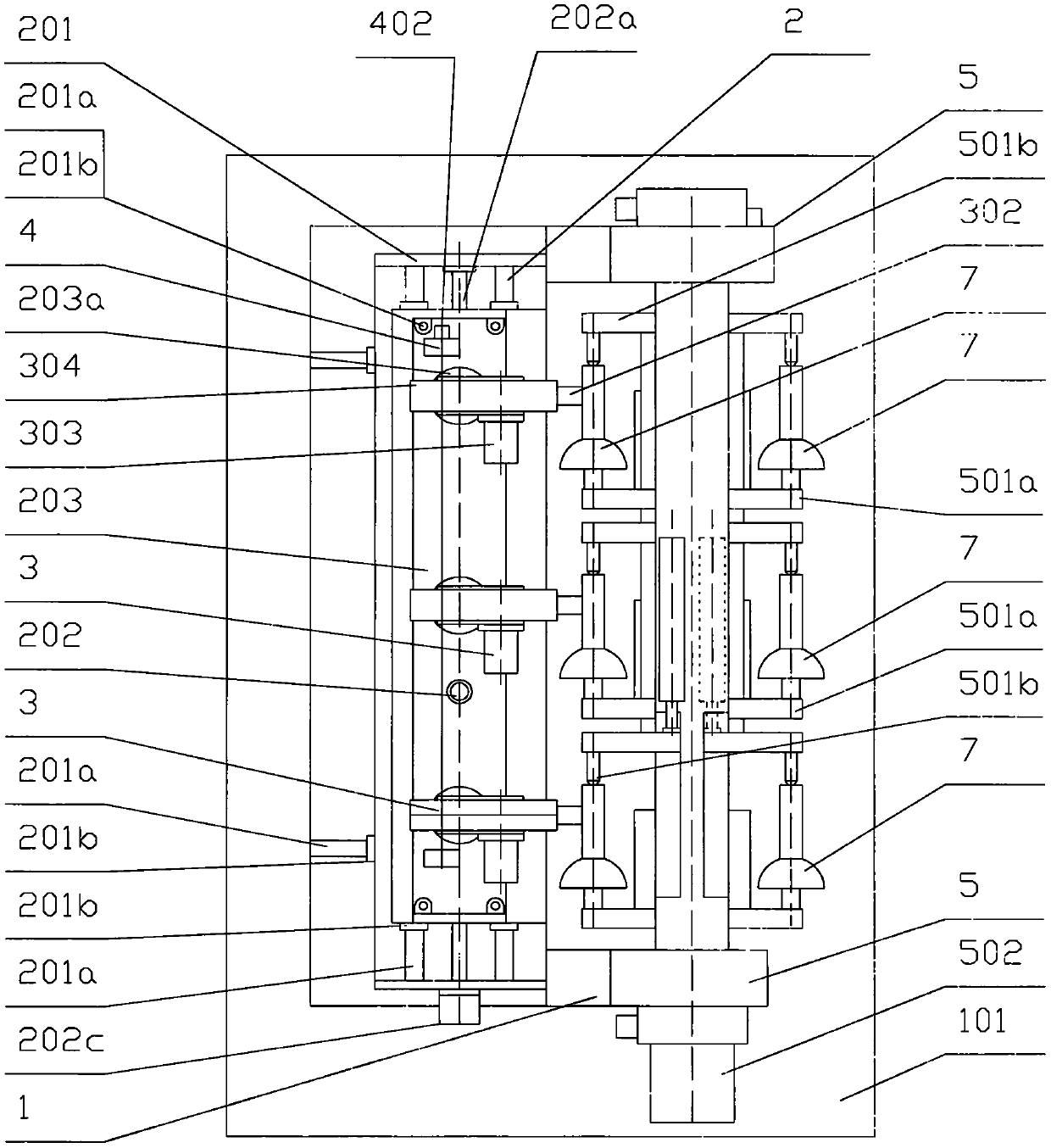

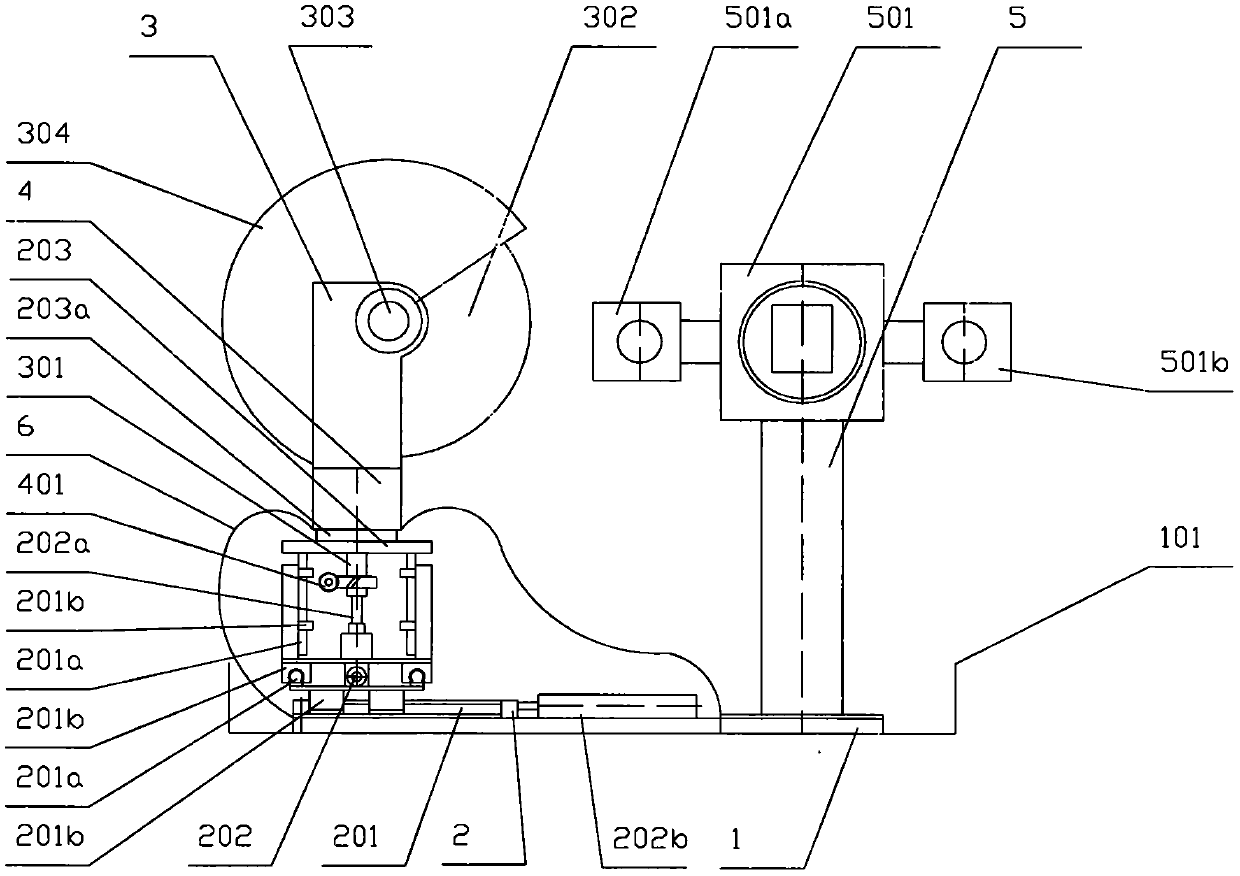

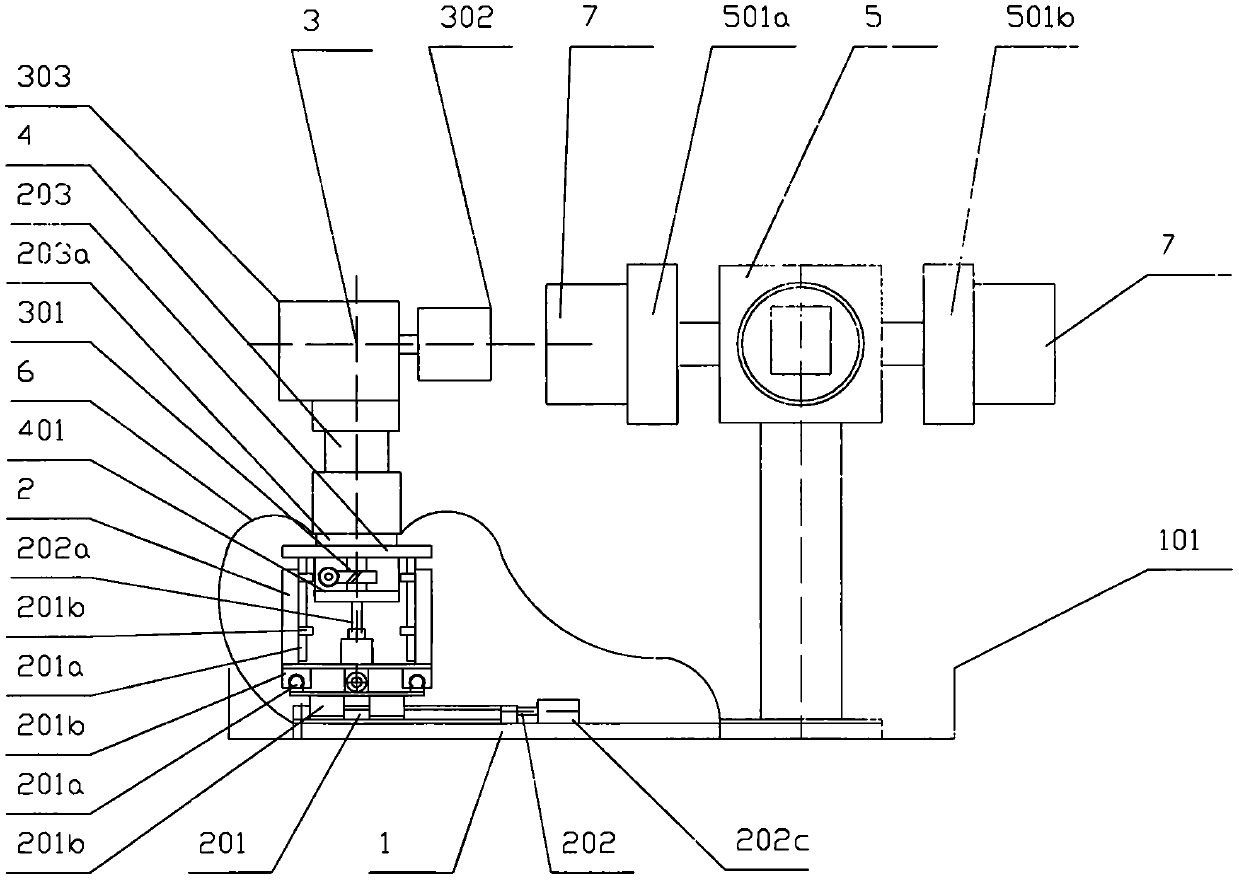

[0027] figure 1 The first embodiment relates to a wheel polishing device.

[0028] figure 1 Among them, Embodiment 1 includes a base 1 , a sliding mechanism 2 , two or more sets of polishing devices 3 , a synchronous swing mechanism 4 , and a workpiece clamping platform 5 .

[0029] The sliding mechanism 2 includes 2 sets or 3 sets of sliding devices 201, a sliding control device 202, and a multi-directional synchronous motion platform 203. The sliding device 201 includes guide rails 201a, sliding sleeves 201b, and 2 or 3 sets of guide rails 201a are perpendicular to each other. The direction of motion of the sliding sleeve 201b is perpendicular to each other; the sliding control device 202 includes a screw rod 202a and a servo motor 202c, and the screw rod 202a is assembled on the sliding mechanism 2; the multi-directional synchronous motion platform 203 is assembled on On the sliding device 201 at the top, the multi-directional synchronous motion platform 203 includes 2 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com