Conveyor Orientation Device and Conveyor Orientation Method for Conical Outer Tube Inserted with Yarn Tube

A technology of an orientation device and a conveying device, applied in the textile field, can solve the problems of low azimuth efficiency of a tapered core tube, and achieve the effects of low cost, high azimuth and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

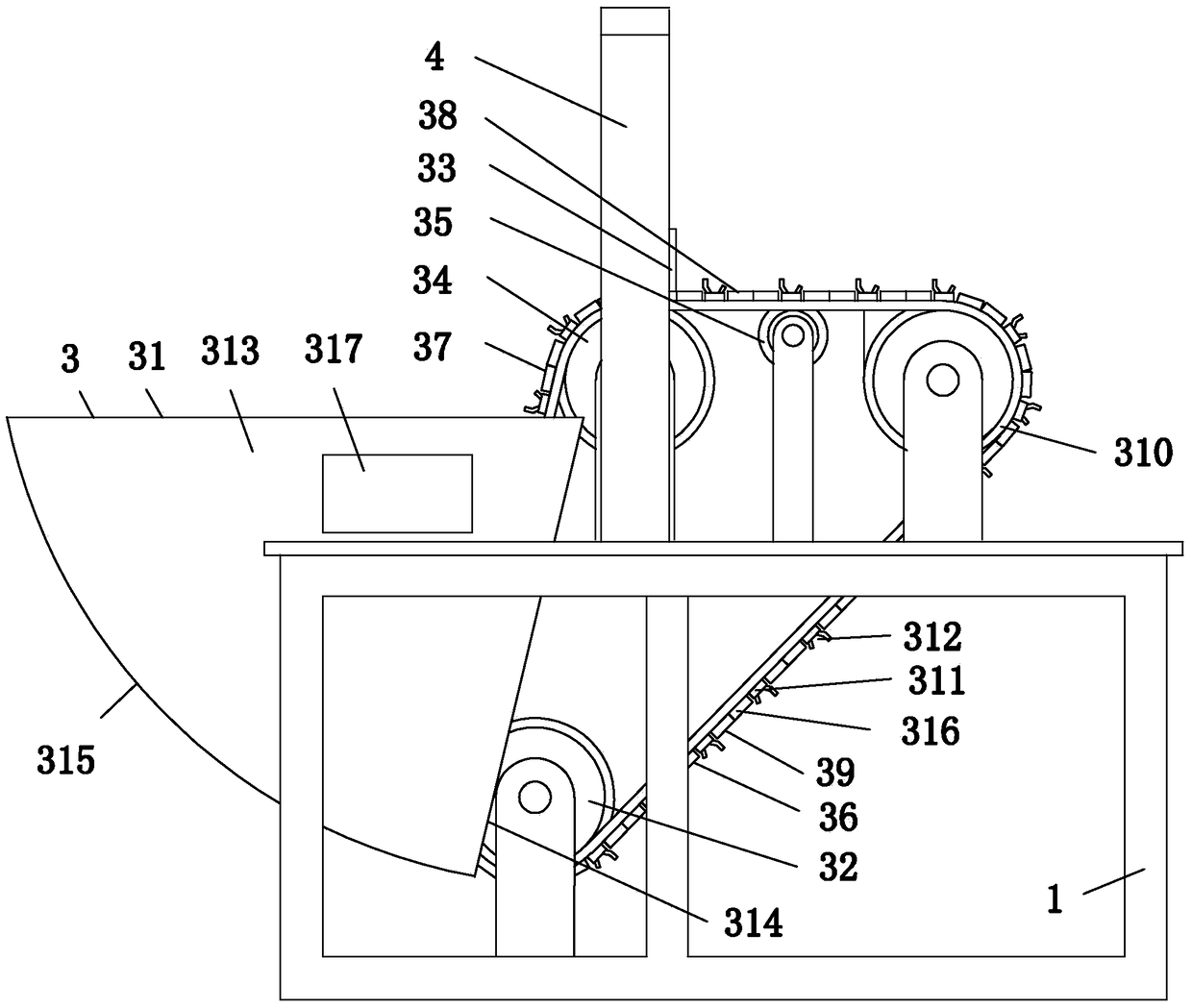

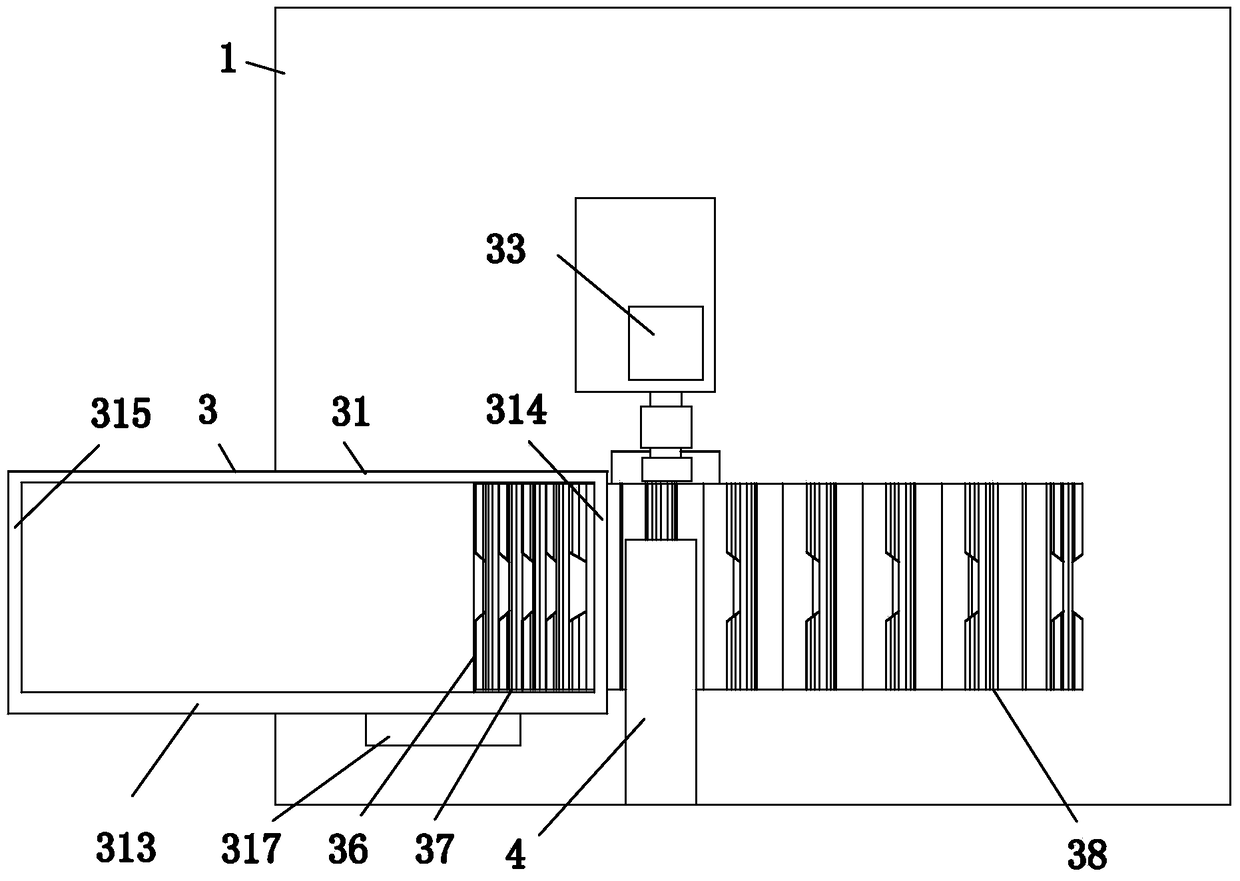

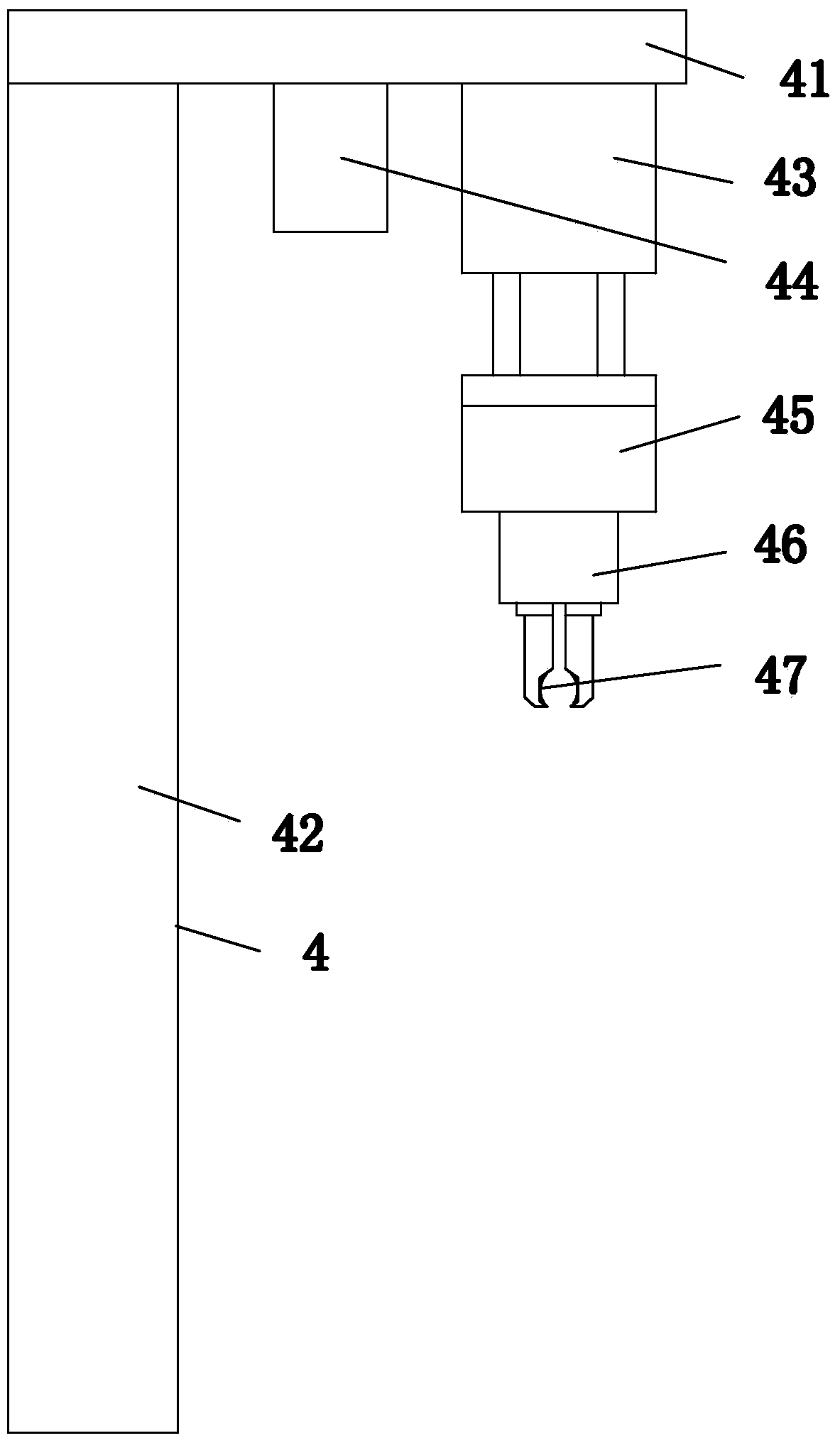

[0019] as attached figure 1 To attach image 3 Shown: a tapered outer tube conveying orienting device with a core embedded in the yarn tube, including a frame 1, a tapered outer tube conveying device 3 and a tapered outer tube orienting manipulator 4.

[0020] The tapered outer tube conveying device 3 includes: an outer tube hopper 31 with an open upper end, two transmission wheels 34 arranged side by side laterally, a reduction motor connected with the frame 1 by screws and the output shaft is keyed to a transmission wheel 34 33, the support wheel 35 between the two transmission wheels 34, the transition wheel 32 at a position lower than the transmission wheel 34, and the conveyor belt 36; the transition wheel 32, the support wheel 35 and the two transmission wheels 34 pass through the frame 1 respectively The bearing is pivotally connected; the conveyor belt 36 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com