Automatically-rotating explosive machine

A technology of automatic rotation and medicine machine, which is applied in packaging and other directions, can solve problems such as not meeting safety standards, and achieve the effect of small size, simple structure, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

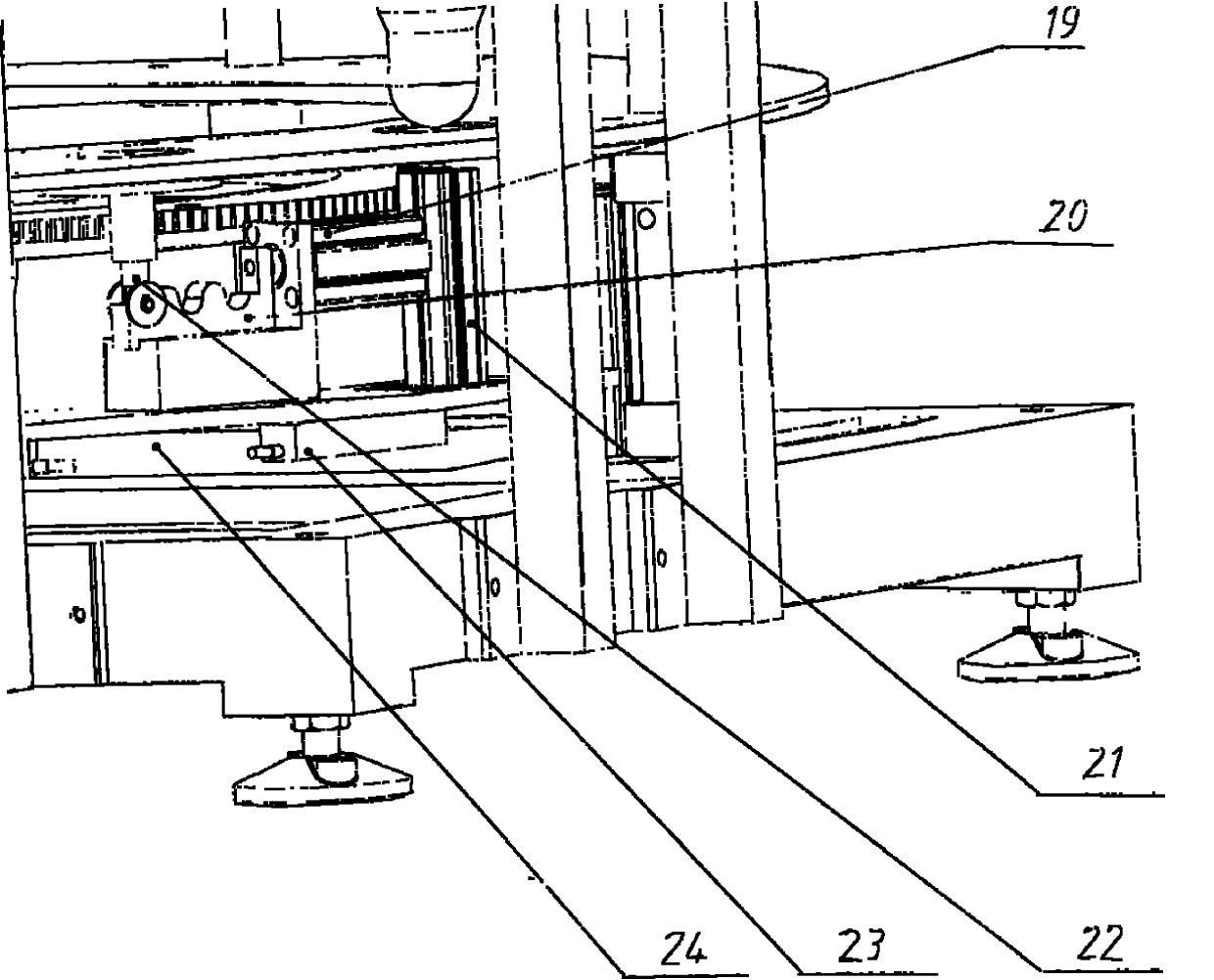

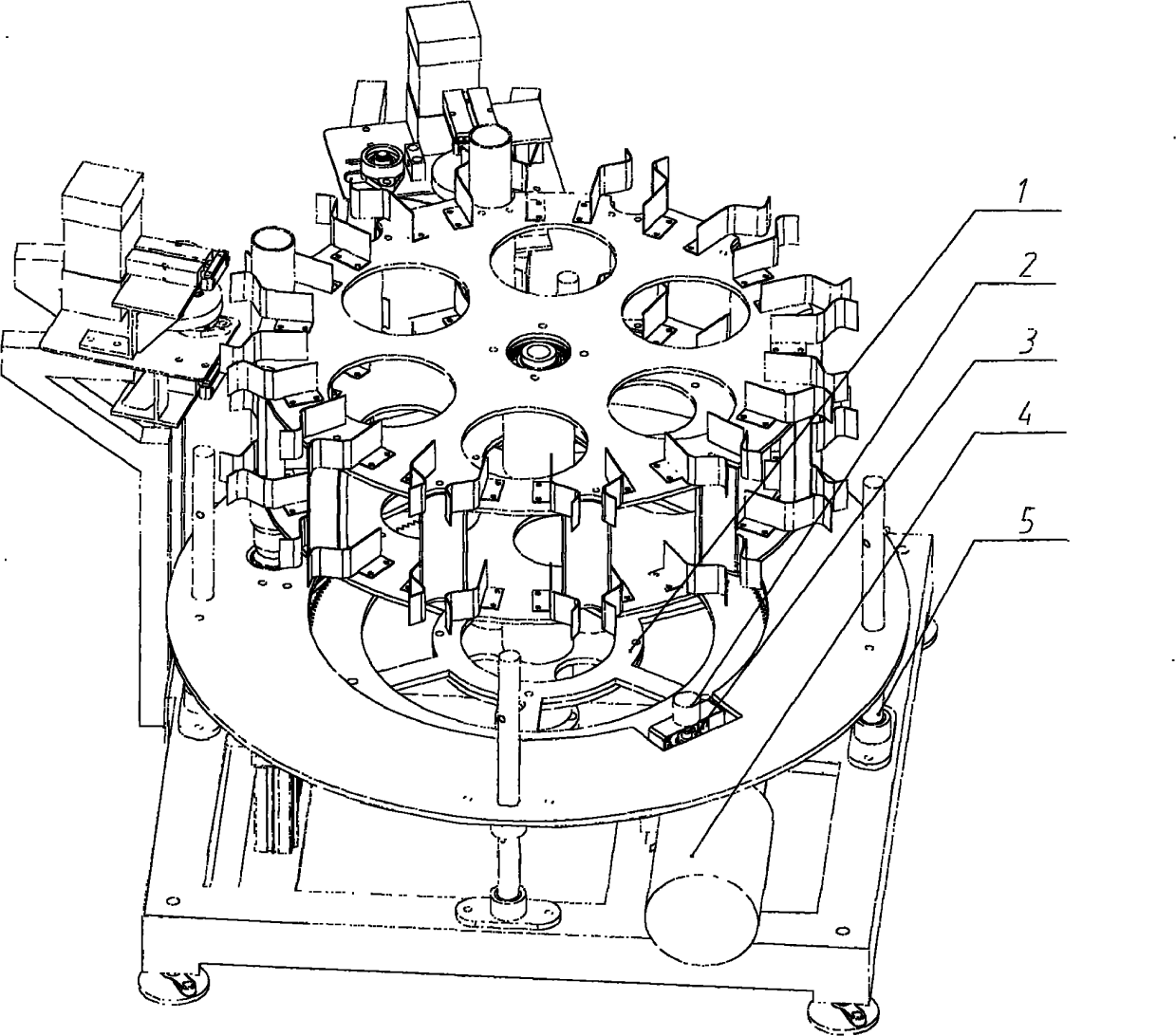

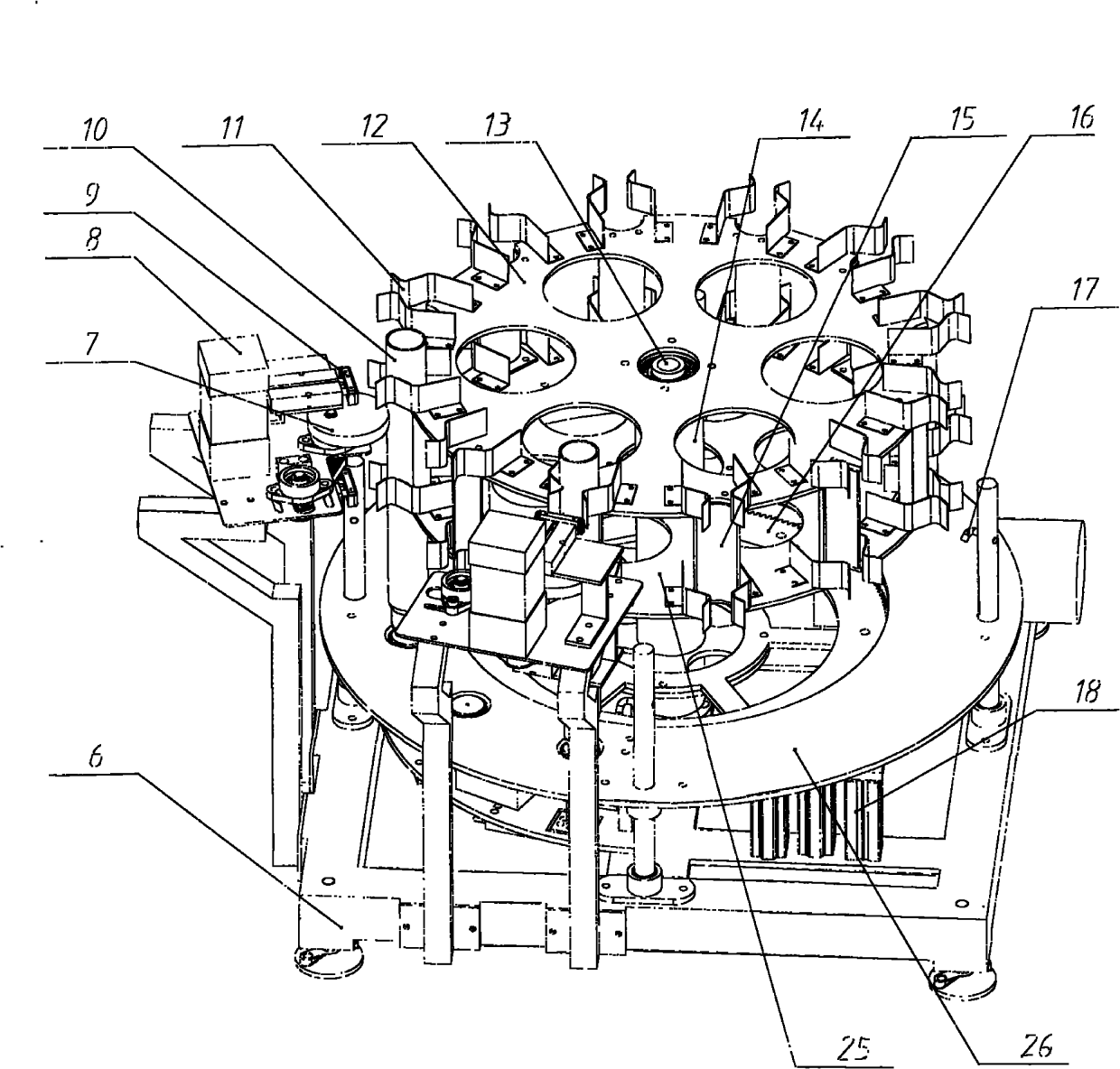

[0016] Such as figure 1 , figure 2 , image 3 Shown, the present invention comprises frame 6, pinion 3, bull gear 16, pillar 15, axle 13, rotating shaft 14, base plate 26, motor 4, upper turntable 12, lower turntable 25, 24 clips 11, combined cylinder 18, Rotary encoder 2, vibrating mechanism and card supporting mechanism, combined cylinder 18 are connected in series by three cylinders, rotating shaft 14, motor 4, vibrating mechanism and card supporting mechanism are installed on the frame 6 respectively, and base plate 26 is connected by sliding bearings On the four fixed shafts 5 on the frame 6, the combined cylinder 18 is installed on the frame 6 and below the base plate 26. When the piston rod of the combined cylinder 18 expands and contracts, it also drives the four fixed shafts 5 connected by sliding bearings. The bottom plate 26 on the top rises up and down to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com