Automatic die punching machine for lithium battery shell

An automatic punching and lithium battery technology, which is applied in product die cutting and industrial production, can solve problems such as low work efficiency, raw material transportation, and positioning difficulties, and achieve the effects of smooth surface, difficult transportation and positioning, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

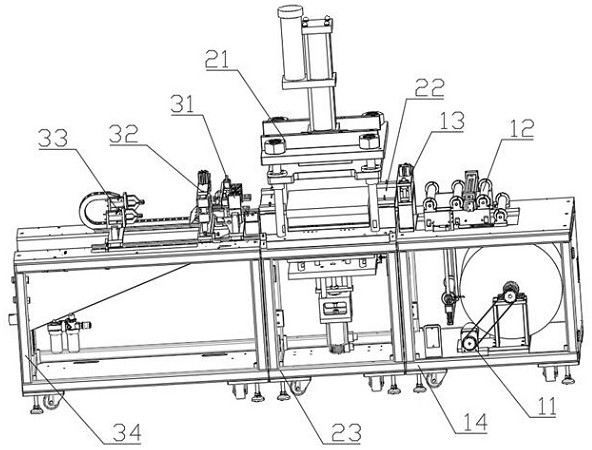

[0029] Embodiment 1: as figure 1 As shown, an automatic punching machine for a lithium battery shell is provided with a feeding mechanism, a die mechanism and a cutting and blanking mechanism, and the feeding mechanism is provided with a feeding motor assembly 11, a tension assembly 12, a pressing cylinder assembly 13 and a feeding frame 14. The die mechanism is provided with a die machine 21, a guide plate assembly and a die frame 24; the slitting and blanking mechanism is provided with a longitudinal slitting assembly 31, a transverse slitting assembly 32, a pulling assembly 33 and a blanking machine Rack 34.

[0030] The raw material is conveyed to the tension assembly 12 through the feeding motor assembly 11, and the tension assembly 12 stretches the raw material and then conveys it to the pressing cylinder assembly 13; the raw material enters the first guide plate 21 after passing through the pressing cylinder assembly 13; the raw material passes through the first guide p...

Embodiment 2

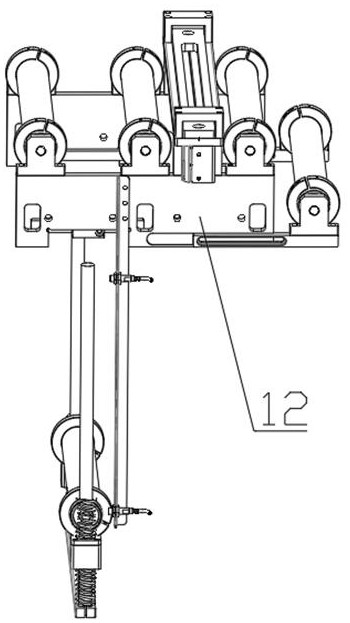

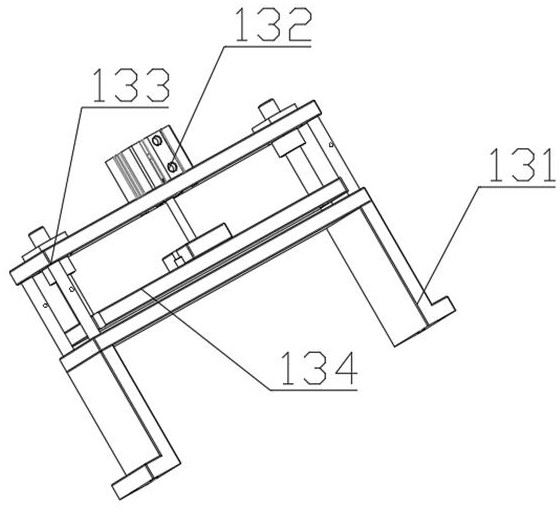

[0031] Embodiment 2: as figure 2 As shown, in order to ensure that the surface of the raw material entering the die machine 22 is smooth and wrinkle-free, a binder cylinder assembly 13 is provided. The binder cylinder assembly is provided with a support seat 131, a binder cylinder 132, a binder cylinder frame 133 and a binder plate 134; the support seat 131 is installed on the feeding frame 14, the pressing cylinder frame 133 is installed on the support seat 131; the pressing cylinder 132 is installed on the pressing cylinder frame 133; The pressing plate 134 is connected to the pressing cylinder 132, and the pressing plate 134 is located above the support seat 131; when the raw material enters the pressing cylinder assembly 13 from the tension assembly 12, the raw material passes through the supporting seat 131 and the press. Pass between the material plates 134; according to the thickness of the raw material, the pressing cylinder drives the pressing plate to move, and the ...

Embodiment 3

[0032] Embodiment 3: as image 3 As shown, in order to prevent the deviation of the raw material and the material after the die during the conveying process, a guide plate assembly is provided. The guide plate assembly is provided with a first guide plate and a second guide plate. The first guide plate There are supporting legs 221, flat plates 222, sliding blocks 223 and wing nuts 224; the supporting legs 221 are installed on the left and right sides of the fixed plate, and the flat plates 222 are installed on the supporting legs; An adjustment thread hole is provided, and a chute is provided on the sliding block 223, and the wing nut 224 passes through the adjustment thread hole and the chute to fix the sliding block 223 on the flat plate 222; The structure of the first guide plate is consistent with that of the second guide plate; the distance between the two slide blocks can be fine-tuned through the chute on the slide block, and the position of the adjustment thread hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com