Edge cutting device for paperboard processing and using method of edge cutting device

A cardboard and trimming technology, which is applied in metal processing and other directions, can solve the problems of low efficiency of trimming work, adjustment, and inability to follow up and adjust at any time, and achieve the effect of convenient long-distance observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

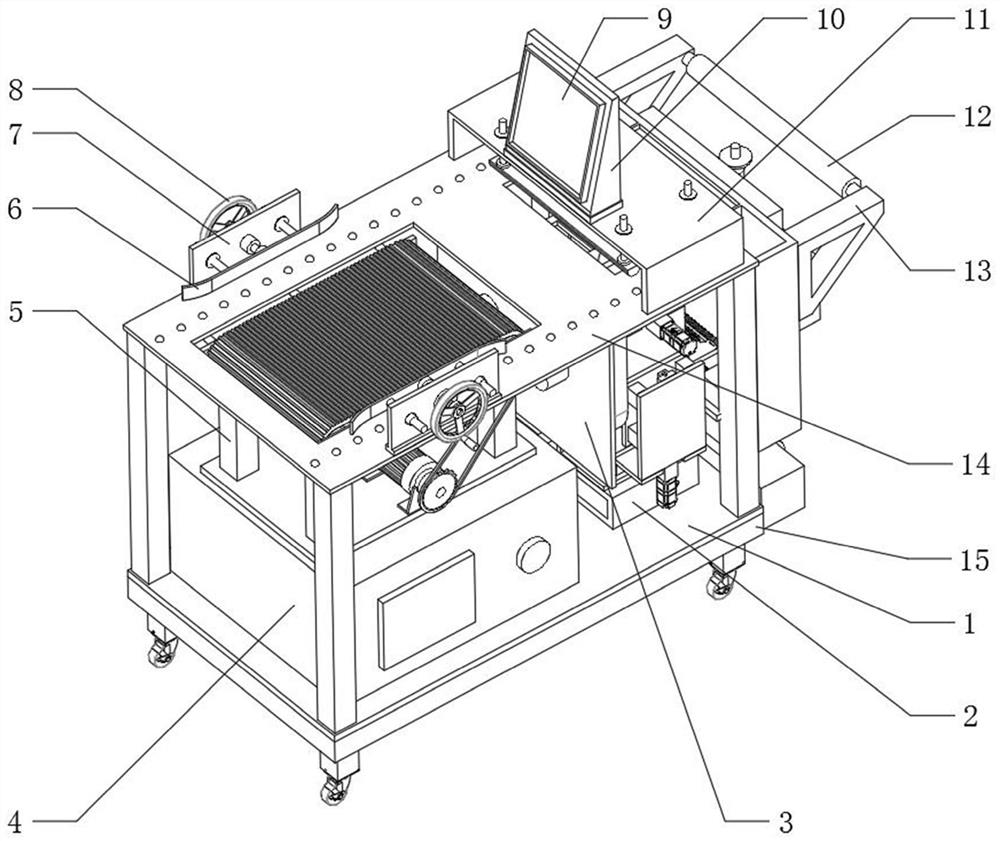

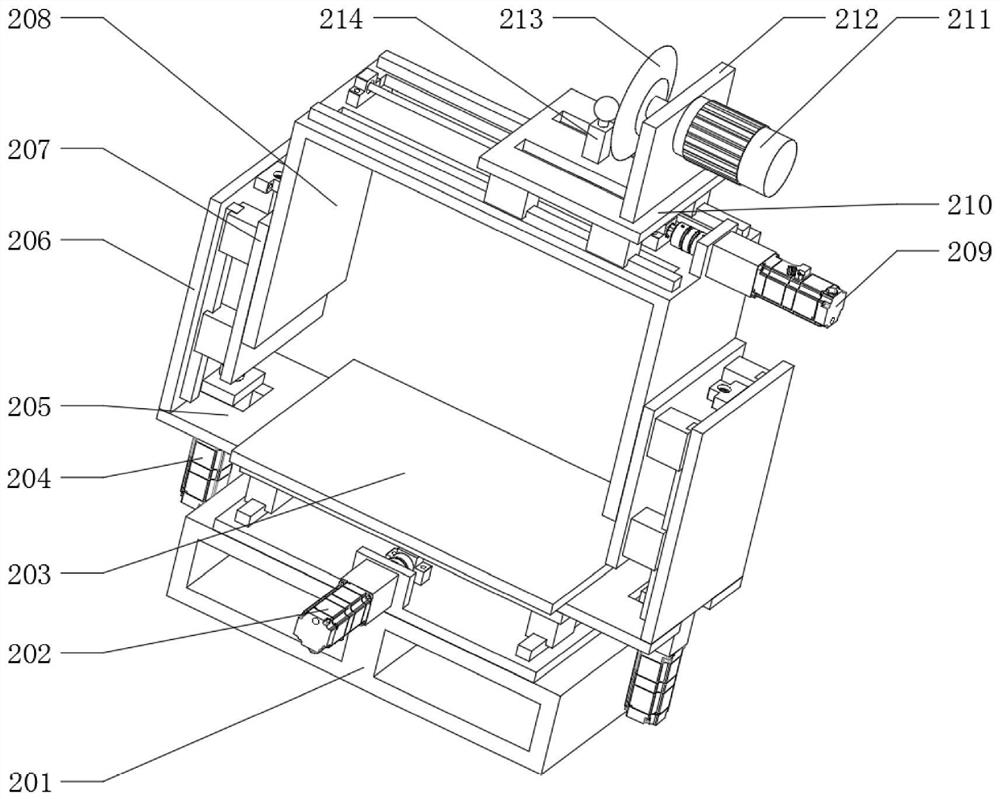

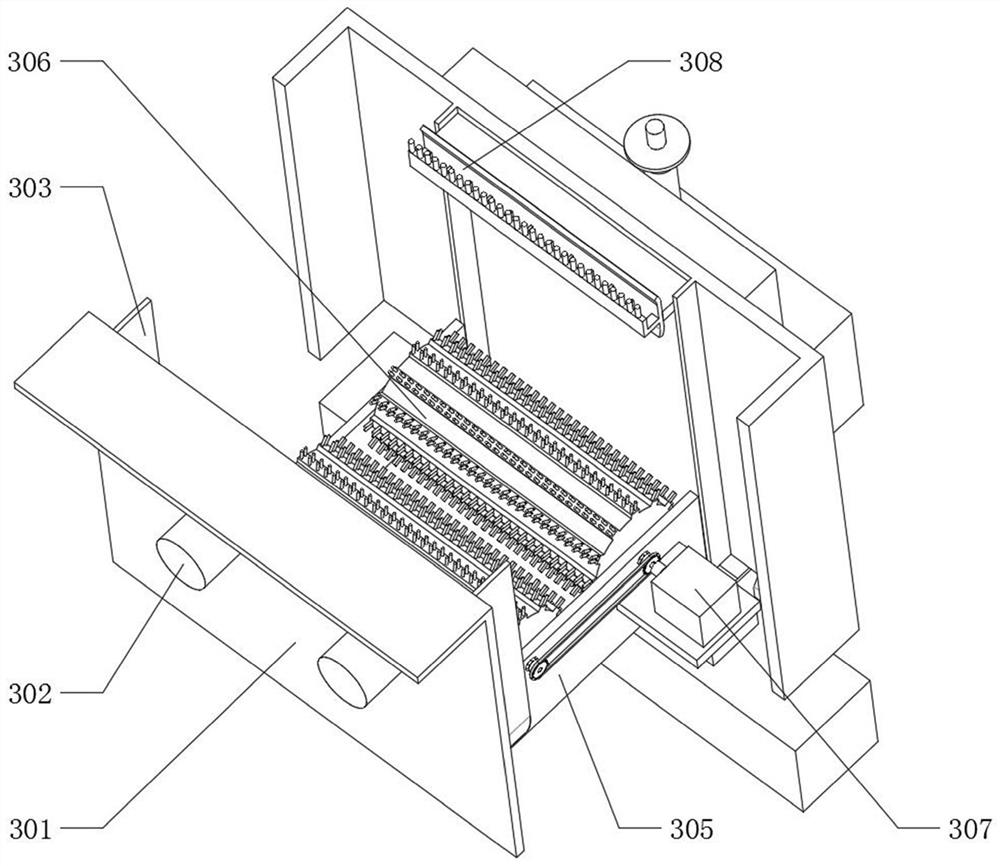

[0042] A trimming device for cardboard processing, such as Figure 1-6 As shown, it includes a base plate 1, a cutting assembly 2, a cleaning assembly 3, a feeding assembly 5, and a pressing assembly 11. The cutting assembly 2 includes a bracket 201 and a first motor 202, and the bottom outer wall of the bracket 201 is fixedly connected to the top outer wall of the base plate 1. , the top outer wall of the bracket 201 is fixedly connected with a backing plate, the first motor 202 is fixedly connected to the outer wall on one side of the backing plate, the top outer wall of the backing plate is provided with a slide rail 1, the slide rail 1 is used in conjunction with a slider 1, and the top outer wall of the slider 1 A first movable plate 205 is fixedly connected, a second motor 204 is fixedly connected to the outer wall of the bottom of the first movable plate 205, a first vertical plate 206 is fixedly connected to the outer wall of the top of the first movable plate 205, and ...

Embodiment 2

[0049] A method of using an edge trimming device for cardboard processing, such as Figure 1-7 As shown, the trimming device described in this embodiment is the trimming device in Embodiment 1, and its method of use includes the following steps;

[0050] S1: Move the device to the designated position through the universal wheel, turn on the power to start the device;

[0051] S2: Put the cardboard on the conveyor belt 504, the seventh motor 510 drives the second sprocket 509 to rotate, and then drives the second chain 508 to move, the second chain 508 drives the first sprocket 505 to rotate, and passes through the adjacent first chain 507 Drive remaining first sprocket wheel 505 to rotate, realize that conveyer belt 504 advances;

[0052] S3: When cutting, the first motor 202 is activated to enable the blade 213 to move back and forth relative to the cardboard, the second motor 204 is activated to enable the blade 213 to move up and down relative to the cardboard, the third m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com