Leather defect detecting conveying table

A defect detection and conveying table technology, which can be used in optical testing defects/defects, measuring devices, analyzing materials, etc., and can solve problems such as low efficiency of manual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

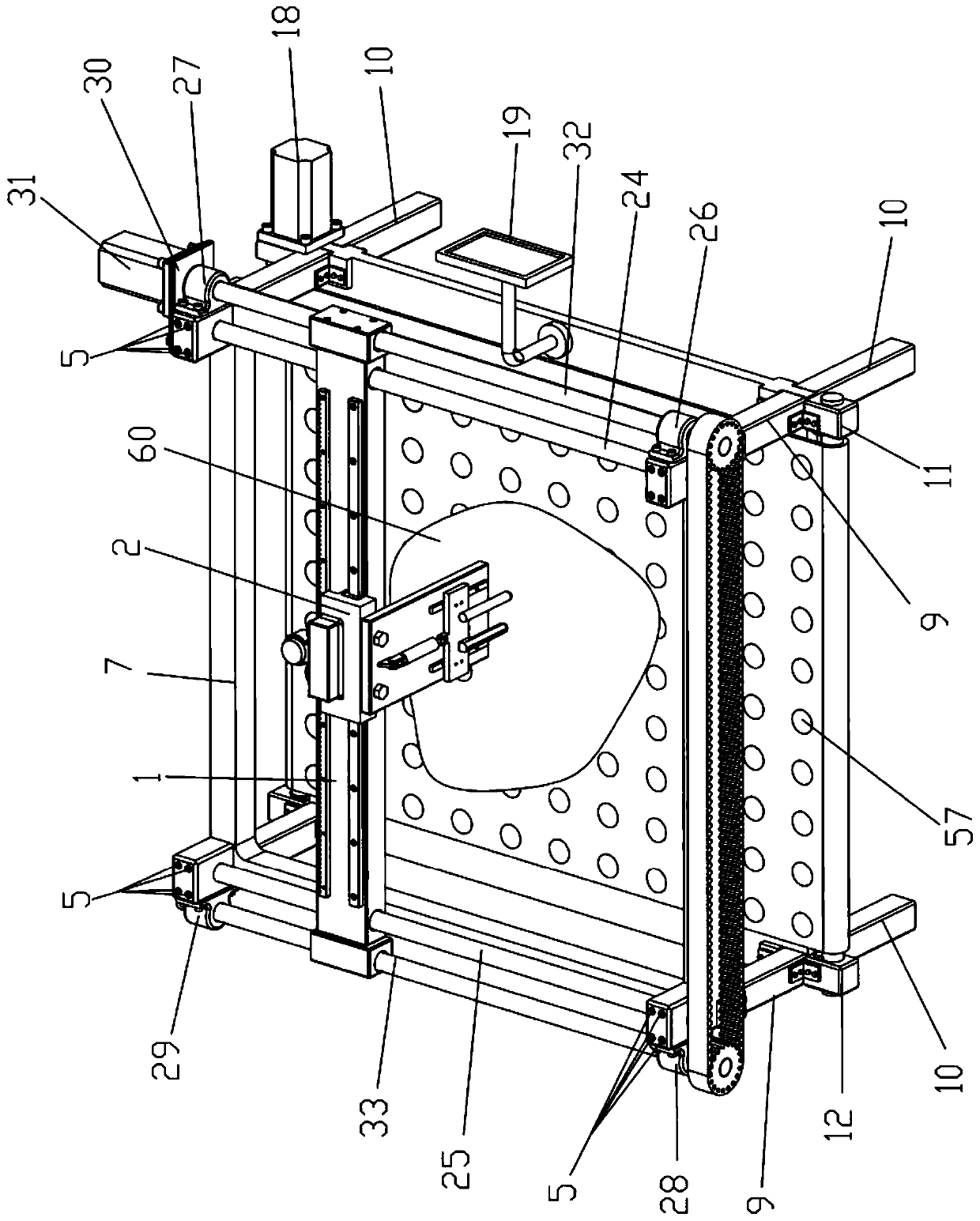

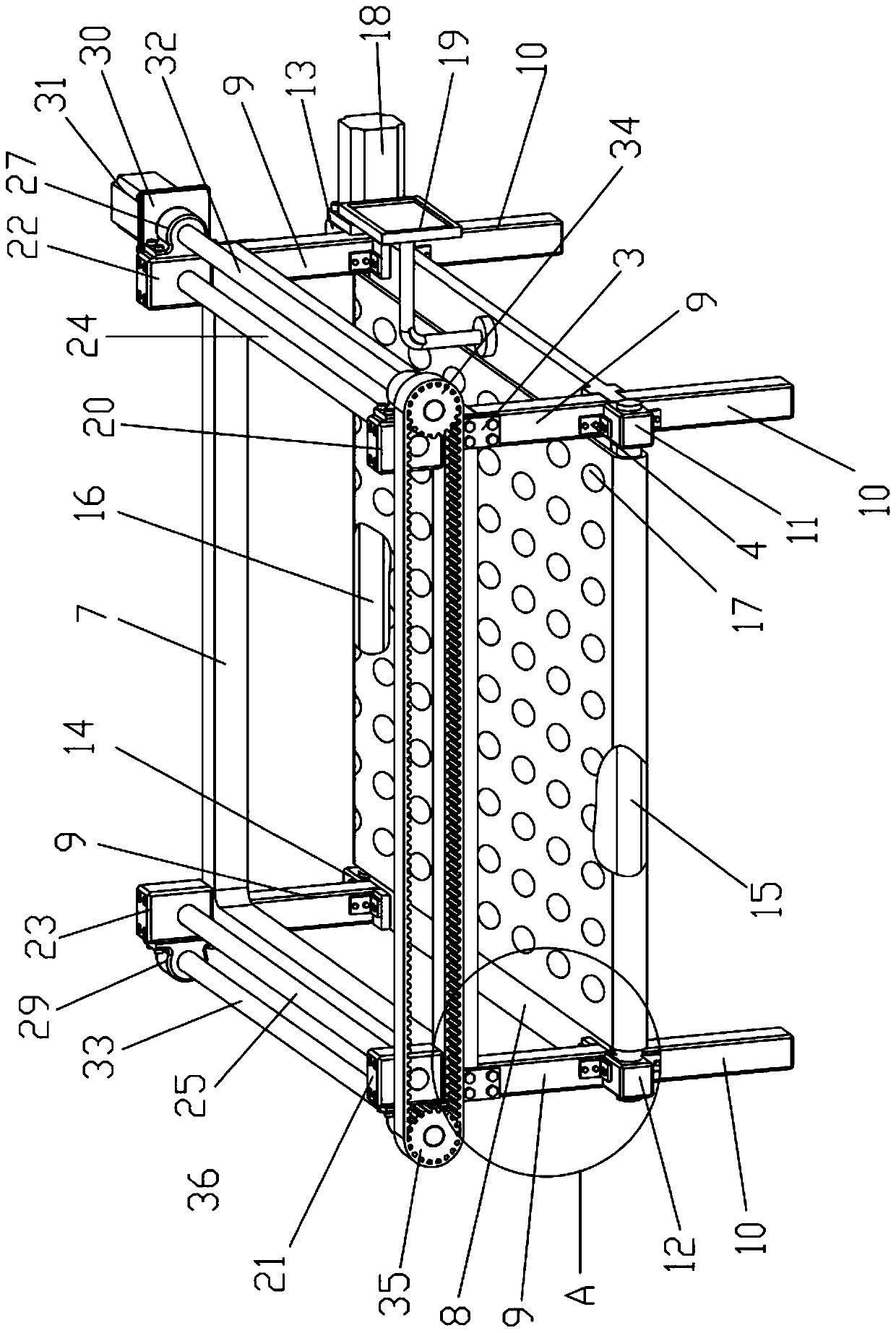

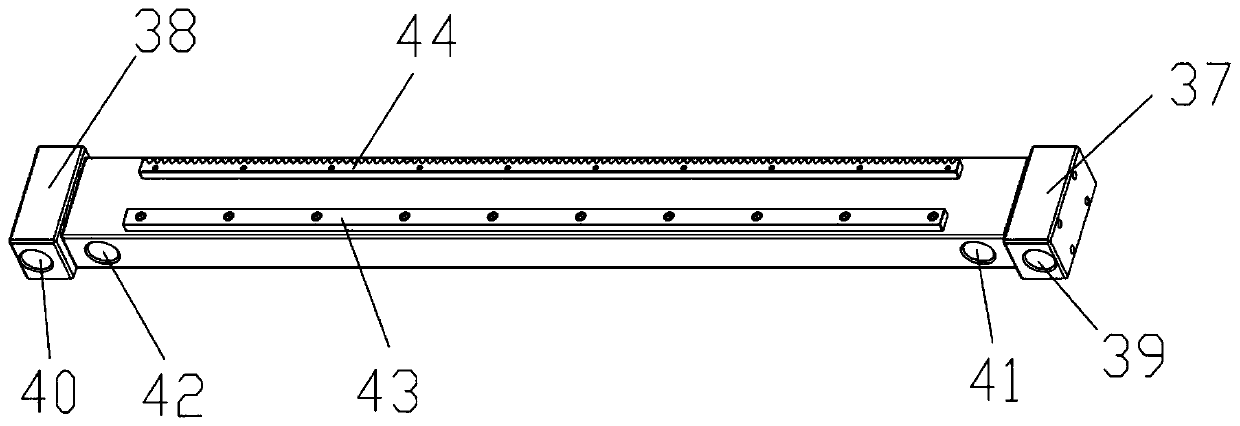

[0020] Embodiment: a kind of leather flaw detection conveyor platform, such as Figure 1-Figure 7As shown, it includes a Y-axis moving seat, an X-axis moving seat, several straight connecting plates, an upper mounting frame, a lower mounting frame, several L-shaped connecting plates, several inner hexagon screws and some outer hexagonal bolts. The upper mounting frame and The lower mounting frames are all square frame structures, and the four corners between the upper mounting frame and the lower mounting frame are provided with support rods, and the upper mounting frame and the support rods are fastened and connected by straight connecting plates. The lower mounting frame and the support rod are connected by an L-shaped connecting plate, the lower sides of the four corners of the lower mounting frame are provided with supporting legs, and the lower mounting frame and the supporting legs are connected by an L-shaped connecting plate Tightly connected, the right side of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com