Floor tile seam beautifying machine

A technology for beautiful sewing machines and floor tiles, applied in construction, building construction, etc., can solve the problems of manual labor and low work efficiency, and achieve the effect of reducing labor, precision and speed, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

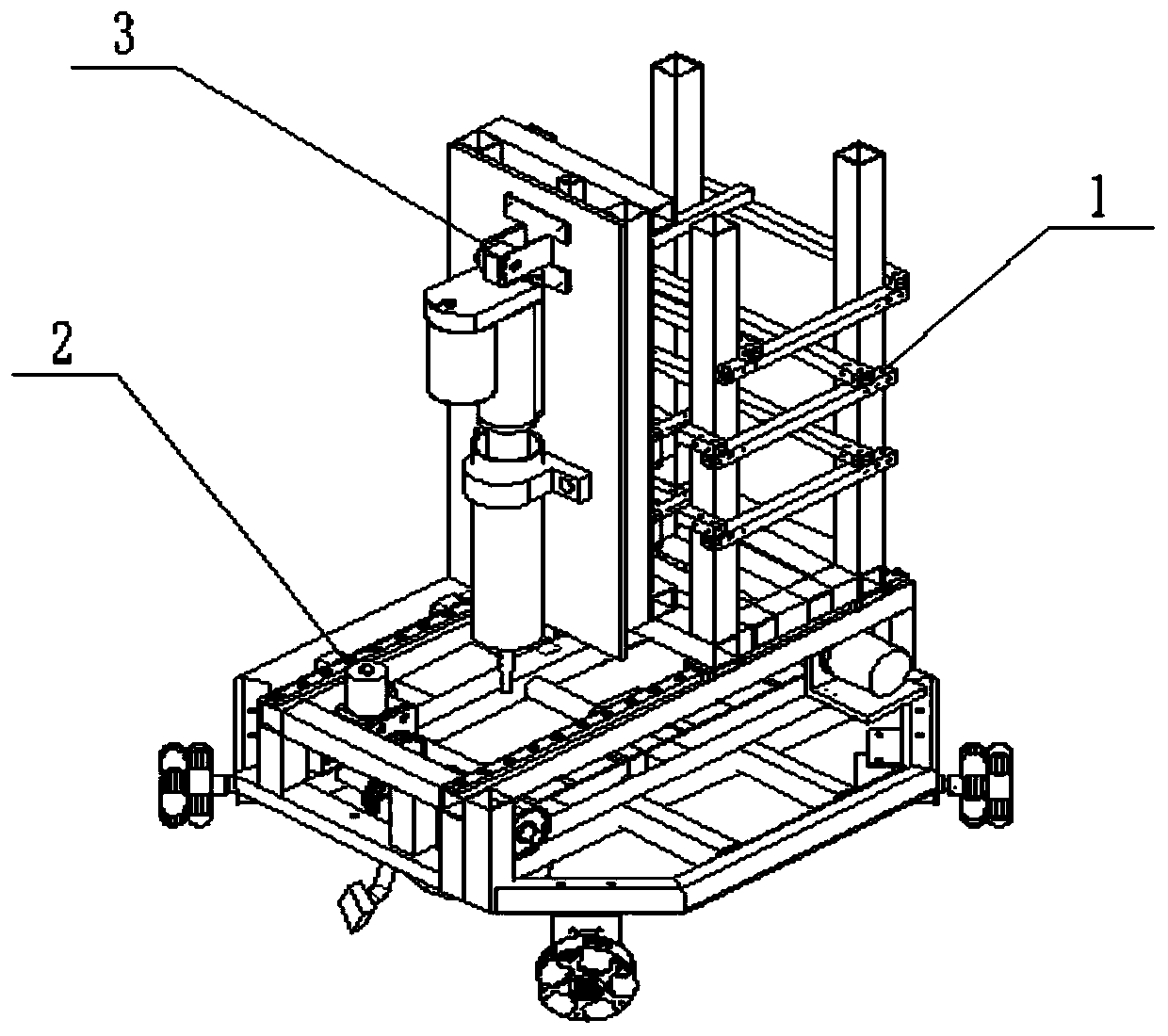

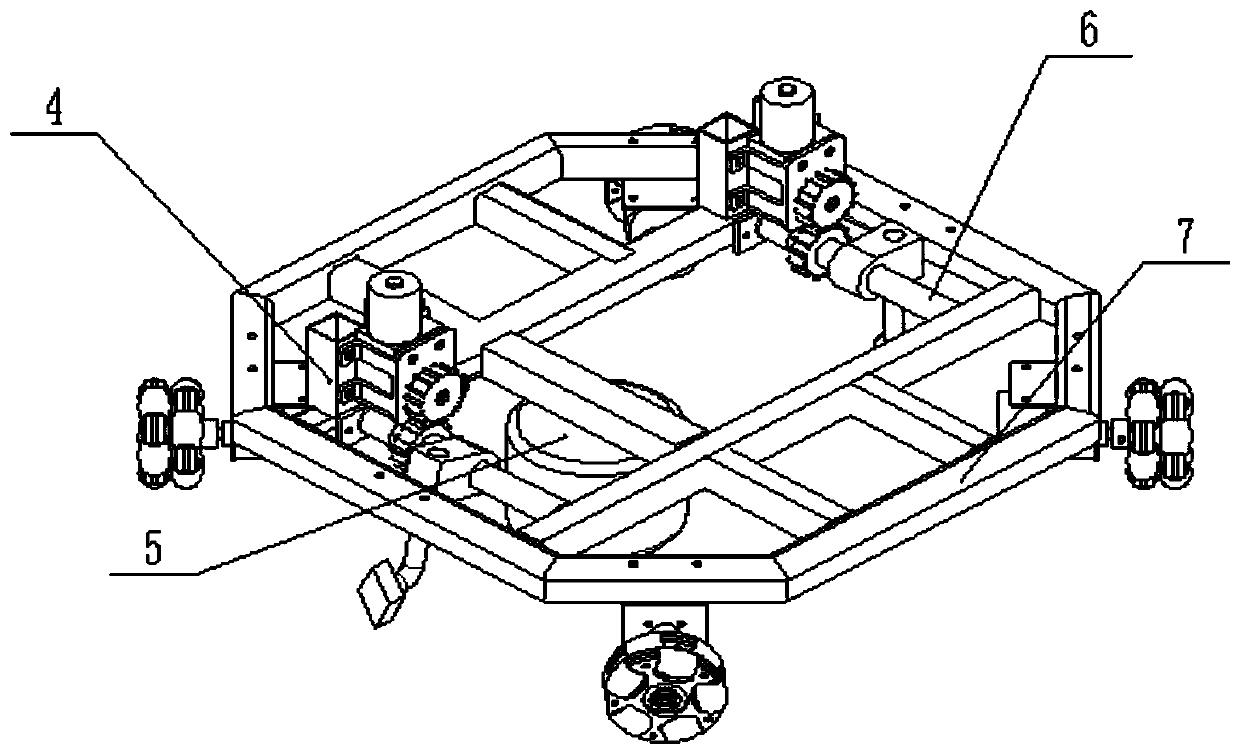

[0032] A floor tile beautifying sewing machine, which is composed of a lifting mechanism 1, a translation mechanism 2, a material extruding mechanism 3, a seam cleaning mechanism 4, a vacuum cleaner 5, a seam pressing mechanism 6 and a chassis walking mechanism 7, the material extruding mechanism 3 and the lifting mechanism 1 Connect together with bolts, the lifting mechanism 1 and the moving platform 201 of the translation mechanism 2 are welded together, the translation mechanism 2 is welded above the chassis traveling mechanism 7, the seam cleaning mechanism 4 is fixed on the front end of the chassis traveling mechanism 7 with bolts, and the vacuum cleaner 5 is fixed on the rear side of the seam cleaning mechanism 4 with screws, and the seam pressing mechanism 6 is fixed on the rear end of the chassis traveling mechanism 7 with bolts;

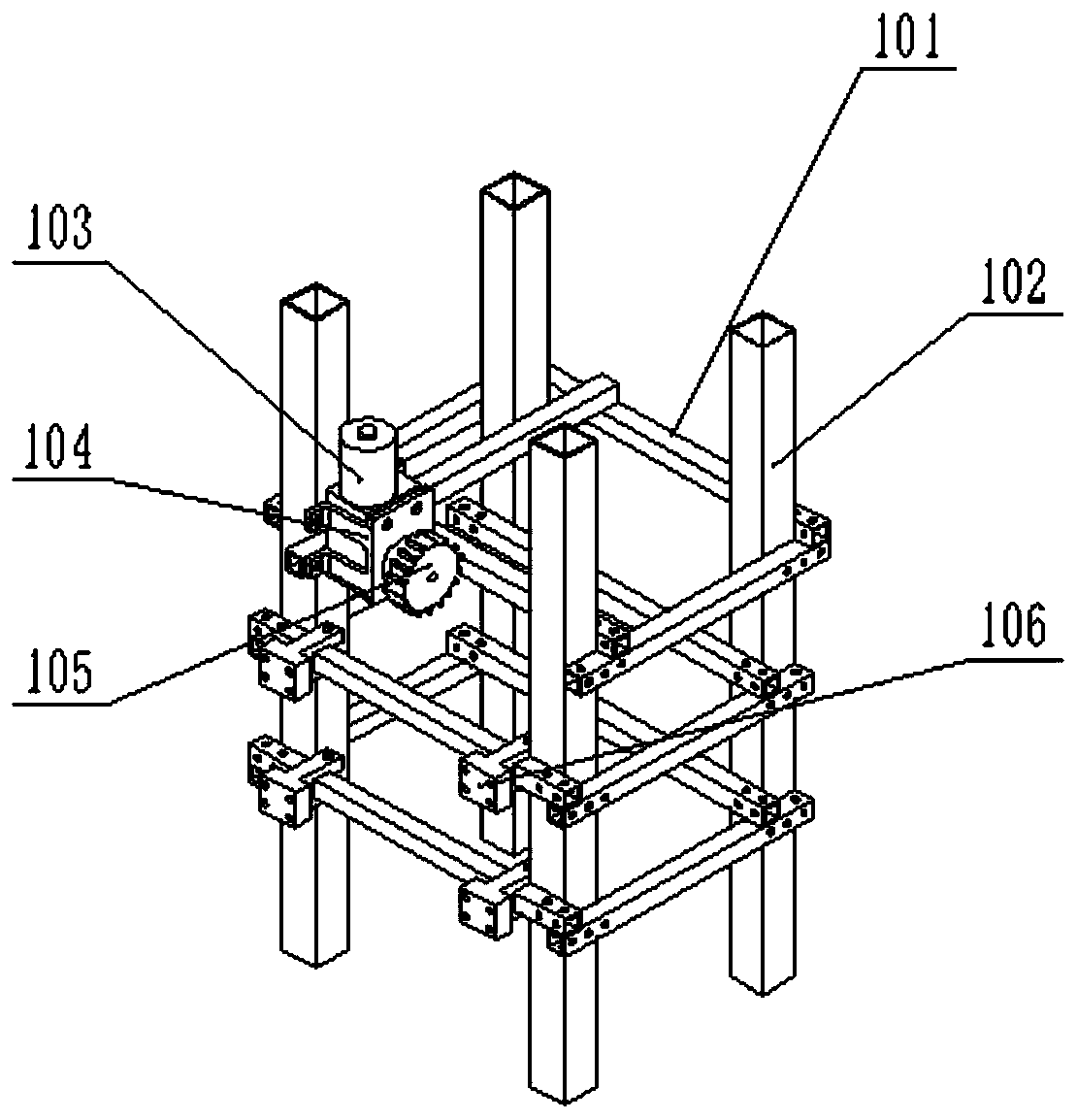

[0033] The lifting mechanism 1 is composed of thin aluminum tube 101, thick aluminum tube 102, motor one 103, motor seat one 104, gear one 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com