Cave mining device of finishing-use granite

A granite and tunnel mining technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling and mining, etc., can solve the problems of low mining yield, huge initial investment, ecological environment damage, etc., to save manpower, protect The effect of environment and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

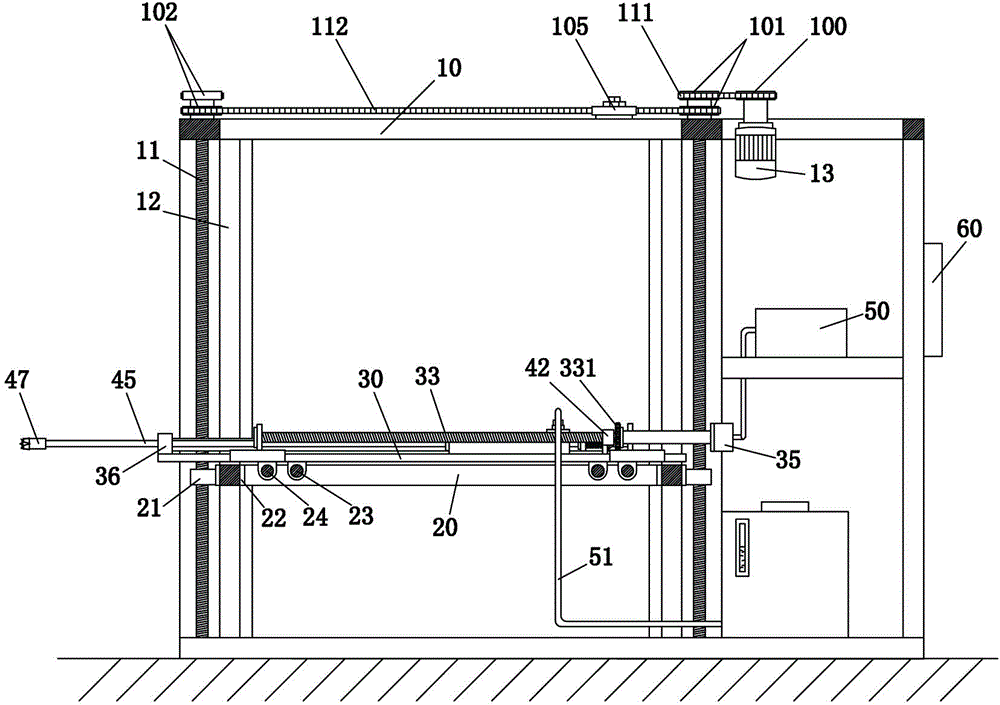

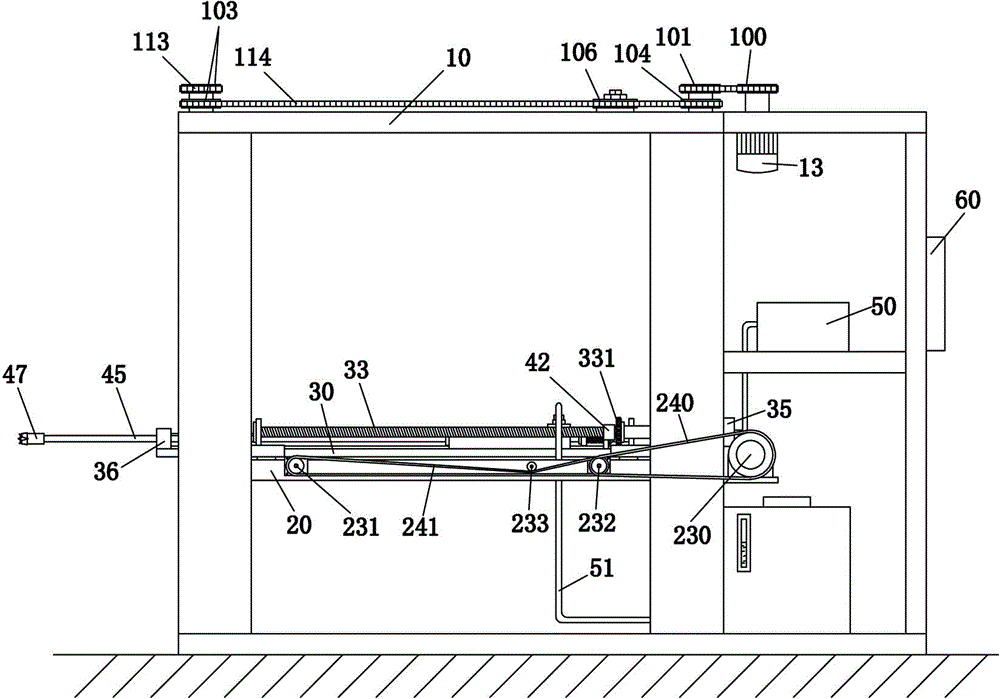

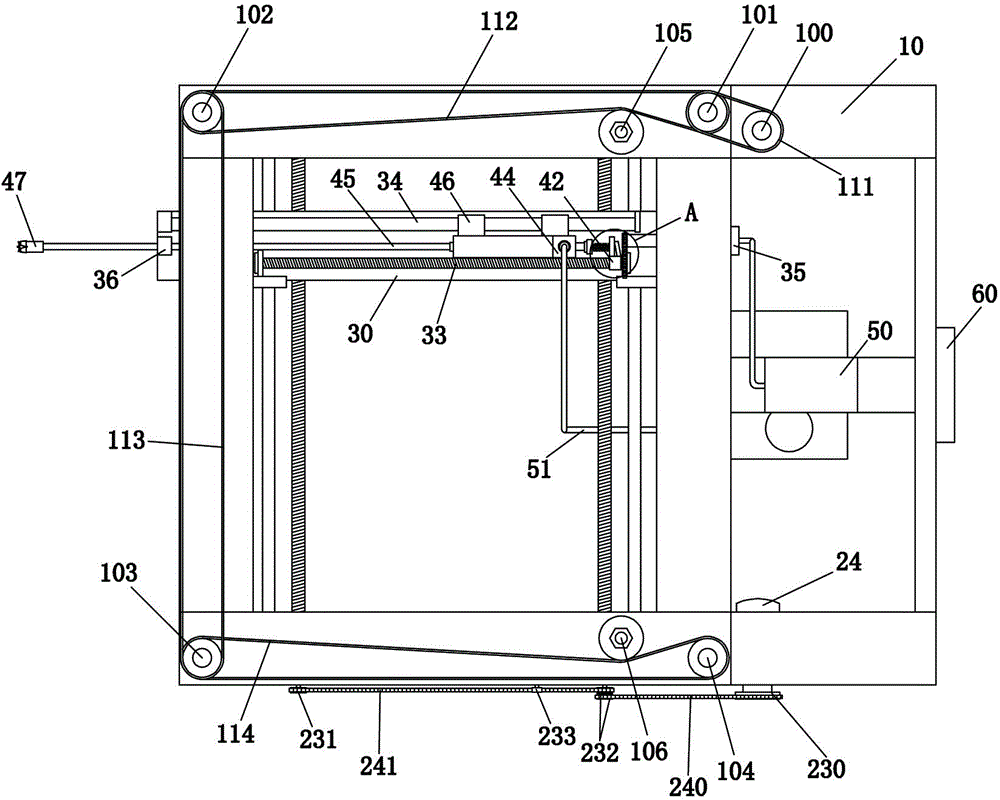

[0029] refer to figure 1 , figure 2 and image 3 , a granite cave mining equipment for facing, comprising an outer frame 10, each of the four corners of the outer frame 10 is provided with a vertical screw 11 arranged along the vertical direction in the length direction and a vertical screw parallel to the vertical screw. 11 vertical fixing bar 12. The outer frame 10 is provided with a movable frame 20 that can move up and down, and the four corners of the movable frame 20 are fixedly provided with vertical screw sleeves 21 that are matched with the vertical screw rods 11 one by one and are connected with the vertical fixed rods 12. The vertical movable cover 22 that fits. A first vertical screw gear 101 , a second vertical screw gear 102 , a third vertical screw gear 103 and a fourth vertical screw gear 104 are respectively connected to the tops of the four vertical screw rods 11 . The first motor 13 drives the first motor gear to rotate 100 , and the first motor gear 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com