Annular tool and method for deformation straightening of highly permeable sand layer large-diameter shield tail shield

A technology with a large diameter and shield tail, which is applied in the testing of machine/structural components, measuring devices, shaft equipment, etc. It can solve problems such as the escape of the shield machine, the inability of the shield machine to continue to excavate, and the plastic deformation of the tail shield. The effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

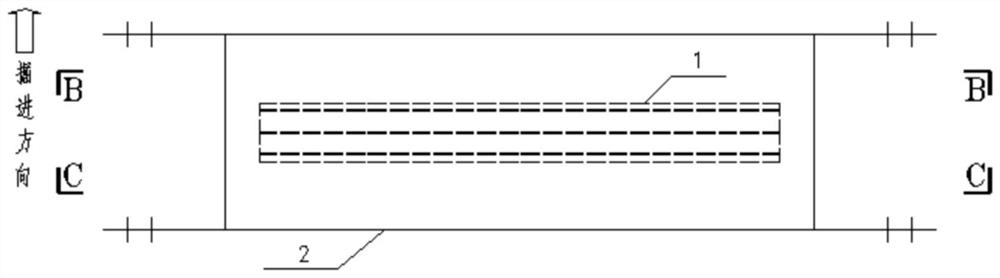

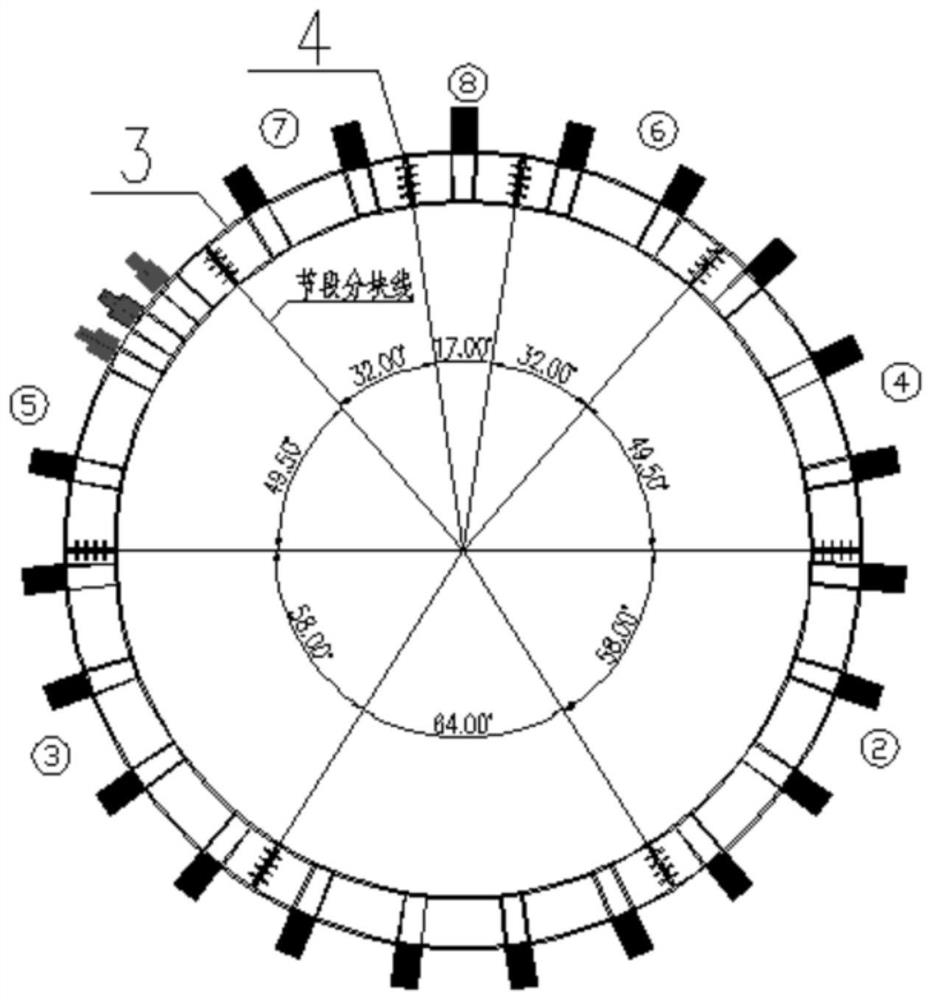

[0070] A circular tooling 1 for correcting the deformation of the tail shield of a large-diameter shield in a strong water-permeable sand layer, including:

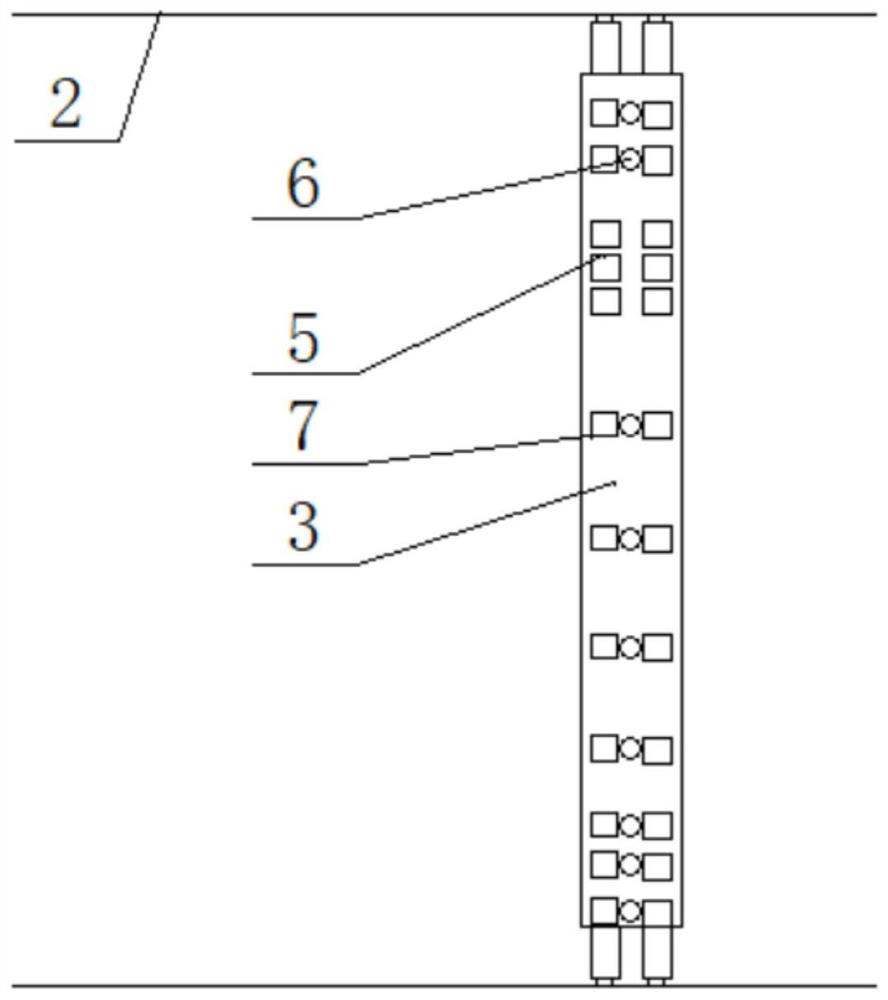

[0071] Reaction force support frame 3, which is a ring-shaped structure, the outer arc surface of the reaction force support frame 3 is provided with first pier 7 along the longitudinal and circumferential intervals, the first pier located in the longitudinal direction of reaction force support frame 3 7 is provided with a pre-tightening jack 6, and a number of correction jacks 5 are provided in the tail shield deformation area 16 corresponding to the outer arc surface of the reaction force support frame 3. There is no backing plate here, and the area of the cylinder of the jack is used as the pushing correction surface. If the effect is not good, consider increasing the top iron or curved steel plate to change the pushing correction area to increase the effect.

[0072] Backing plate 8, which fills the gap between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com