Patents

Literature

36results about How to "Get out of trouble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

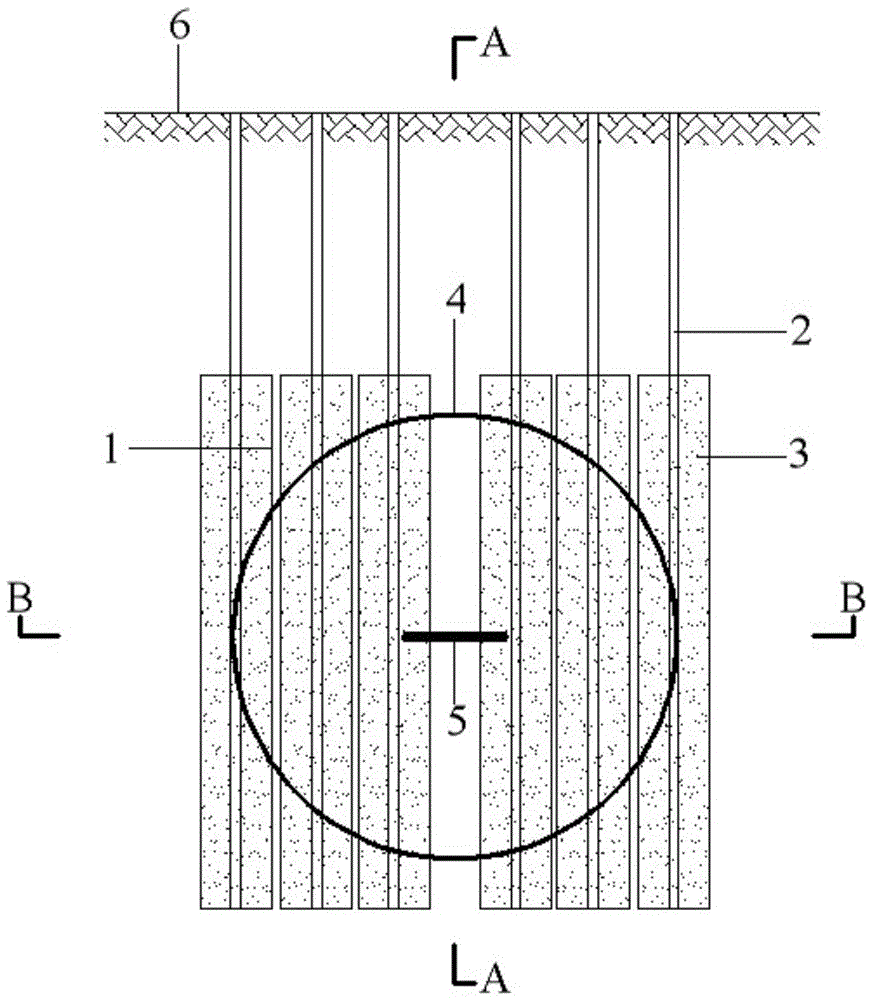

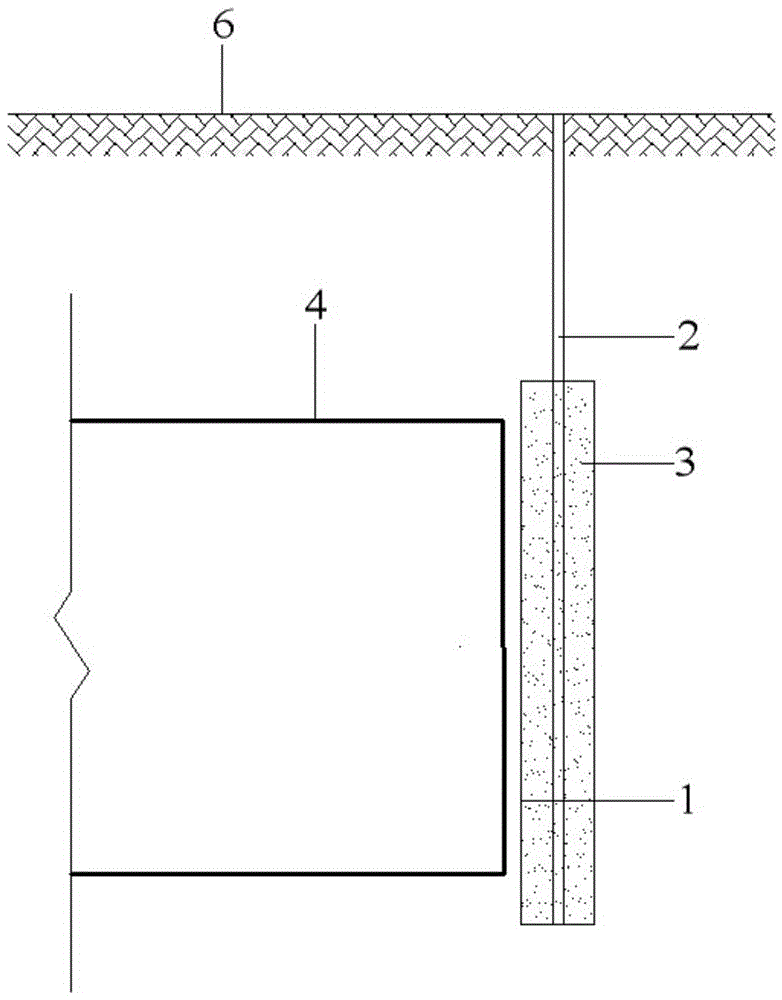

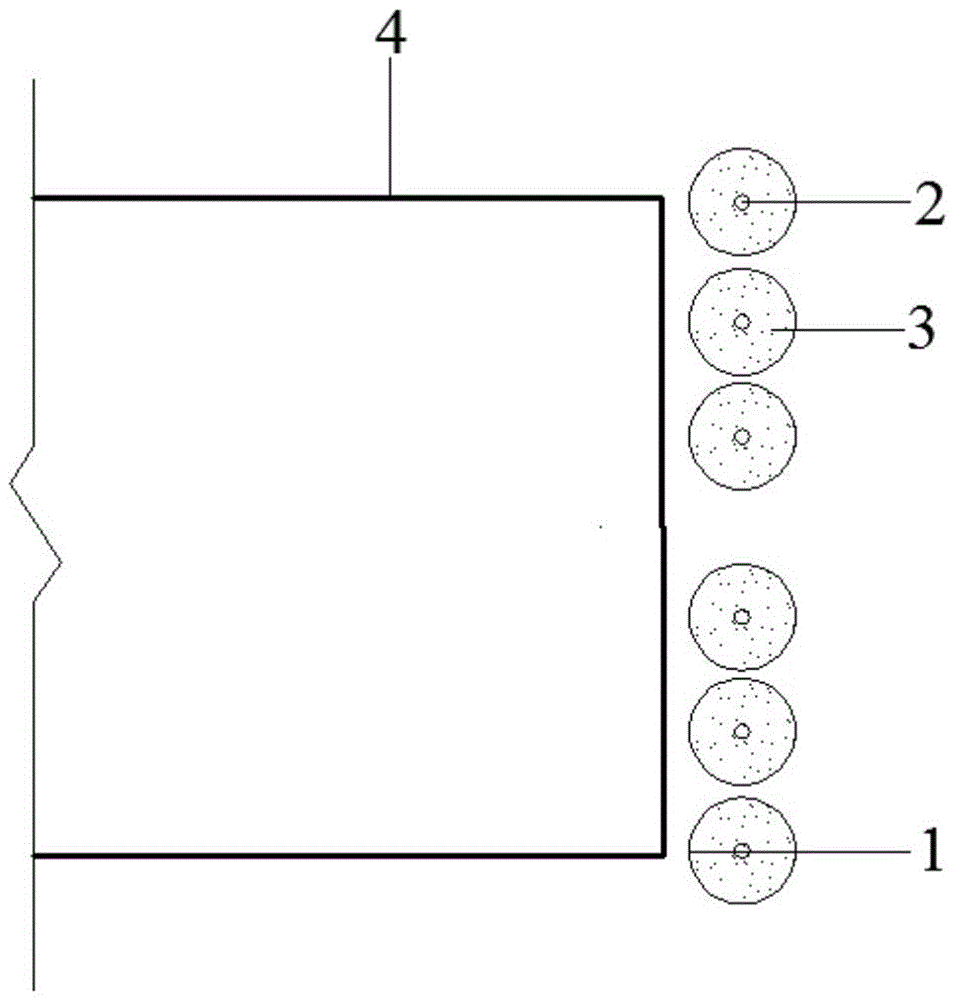

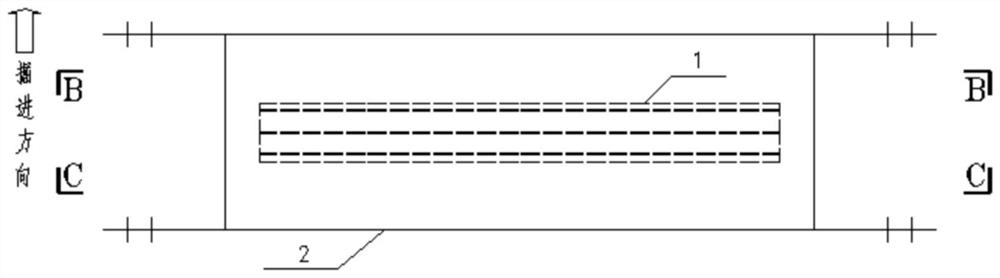

Escape device of bentonite improving shield tunneling machine and construction method thereof

The invention belongs to the technical field of shield tunnel construction, particularly relates to an escape device of a bentonite improving shield tunneling machine and a construction method. The escape device comprises an even number of jet grouting piles, wherein the jet grouting piles are three-pipe jet grouting piles, the pile forming diameter is 800-1000 mm, the specific number of the jet grouting piles is determined according to soil layer parameters and the cutterhead diameter of the shield tunneling machine, the jet grouting piles are located at the positions 400-500 mm away from the front of a cutterhead of the shield tunneling machine, jet grouting pile slurry is specially-prepared bentonite slurry, the mass ratio of bentonite to water to CMC to soda ash is 200 to 900 to 1 to 2, and the stratum which the structures of the jet grouting piles are applicable to is a dense sand layer. The construction method comprises the three steps: first step, the positions of the jet grouting piles are arranged; second step, the jet grouting pile slurry is prepared; third step, the bentonite slurry is rotary jet grouting for pile forming. The construction steps are simple, the escape problem of the shield tunneling machine in the dense sand layer can be effectively and quickly solved, a construction period is short, the construction cost is low, and good economic benefits are obtained.

Owner:CHINA RAILWAY TUNNEL

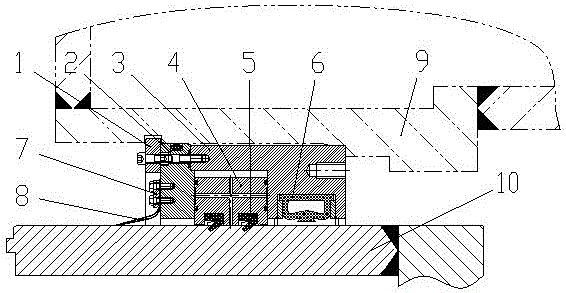

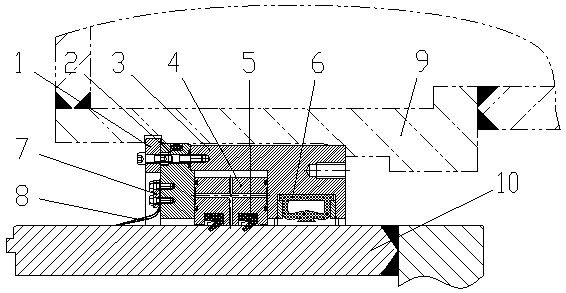

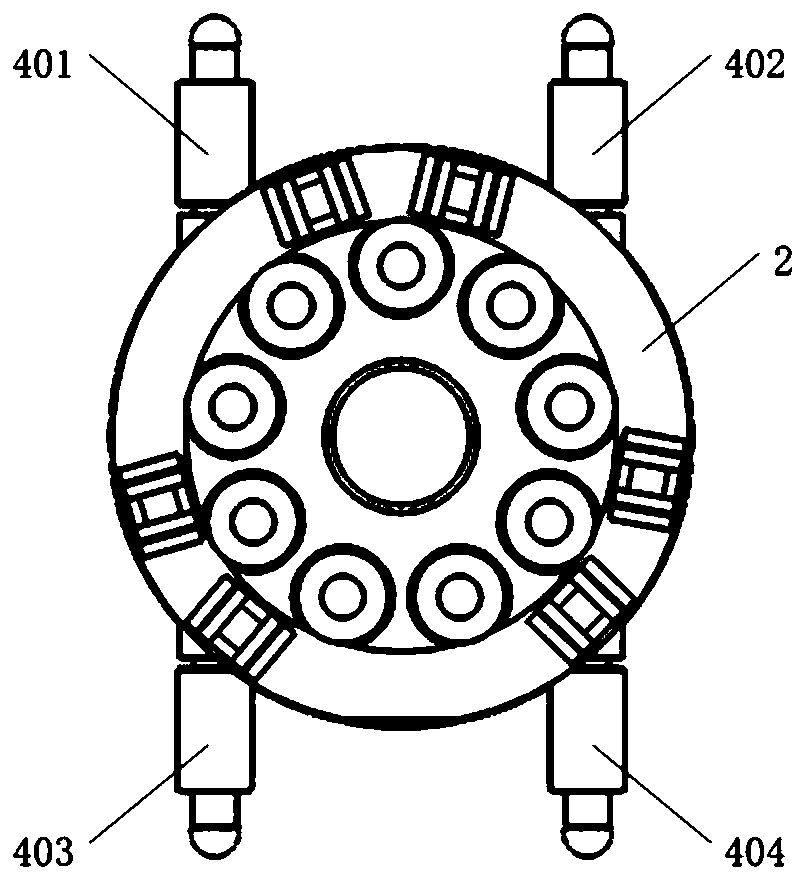

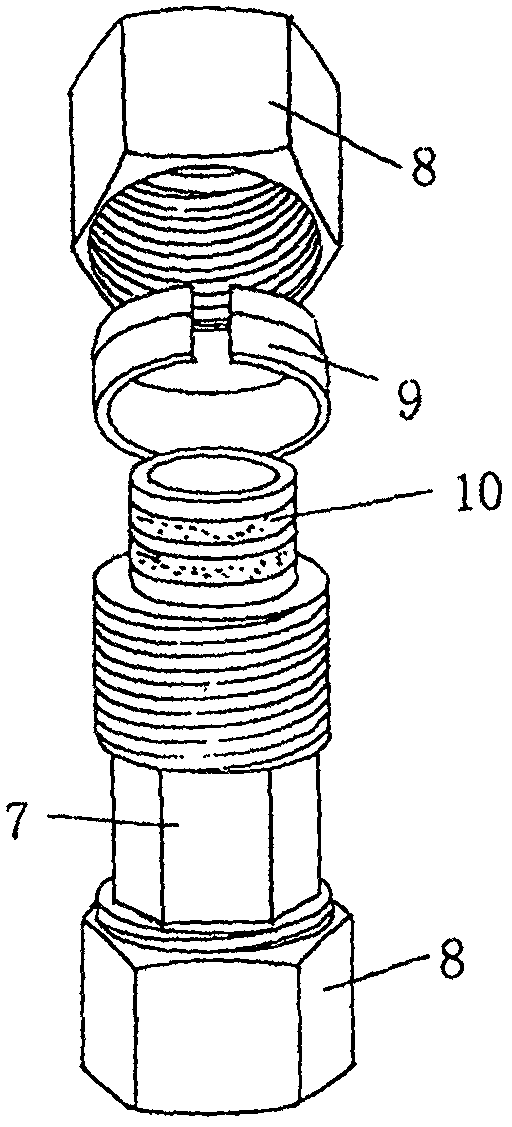

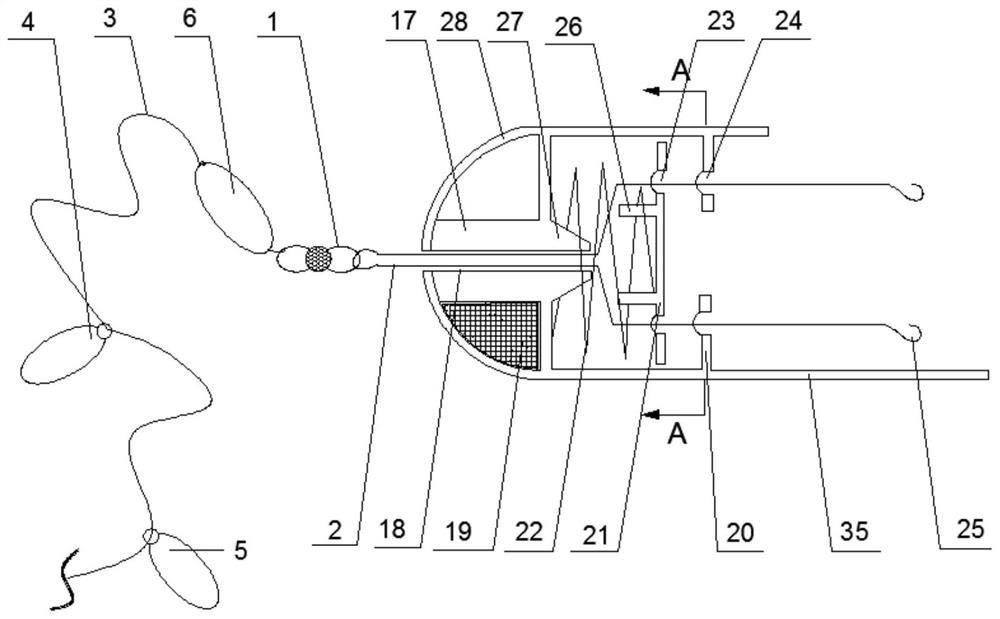

Telescopic main drive sealing device of larger-diameter shield machine

The invention discloses a telescopic main drive sealing device of a larger-diameter shield machine, wherein a sealing clamp ring is fixedly arranged at the lower part of a shield body, an air bag seal is arranged at the lower part of the sealing clamp ring, a sealing caulking ring is fixed on the sealing clamp ring, lip seals are nested at the lower part of the sealing caulking ring, the lip seals are closely contacted with a driving box, and the lip seals are positioned in front of the air bag seal; a sealing pressure ring is fixed at the front side of the sealing clamp ring, a snap ring is fixed at the upper part of the sealing pressure ring, the upper part of the snap ring is in clamp connection with the lower part of the shield body, a slag removal plate is fixed at the lower part of the sealing pressure ring by a pressing plate, and the lower part of the slag removal plate is arranged on the driving box. The upper part of the telescopic main drive sealing device is clamped at the lower part of the shield body, and the residue soil or mud in a soil chamber can be sealed in a main drive stretching process by means of enabling the lip seals or air bag seal to be connected with the driving box; furthermore, a cutter is more conveniently replaced under a condition of atmospheric pressure or belt pressure, so that a cutter head of the shield machine is bailed out in case of emergency, and the shield machine is further enabled to carry out shield construction smoothly.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

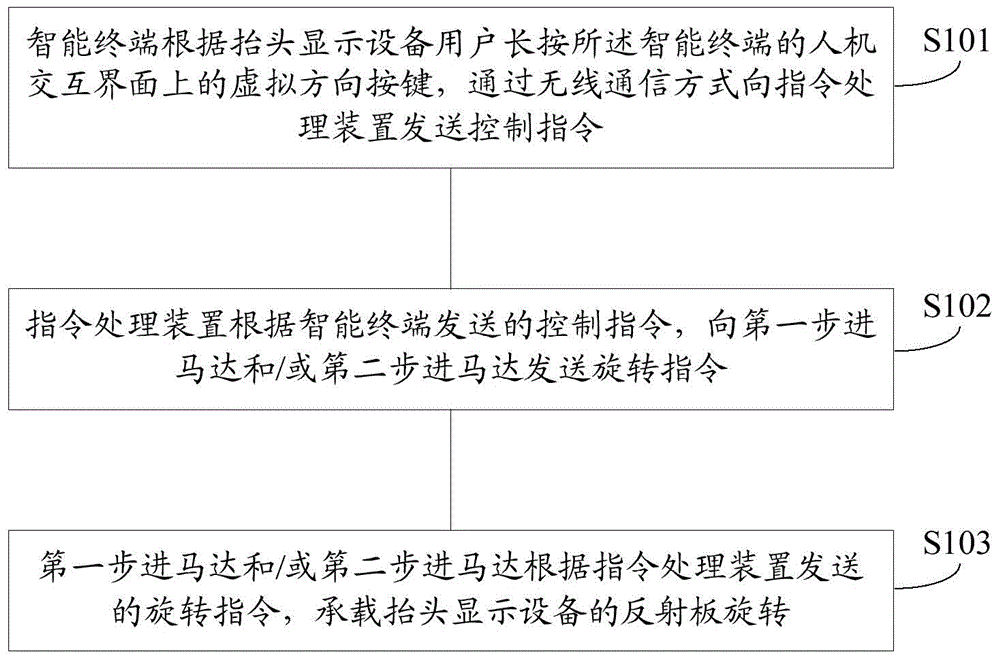

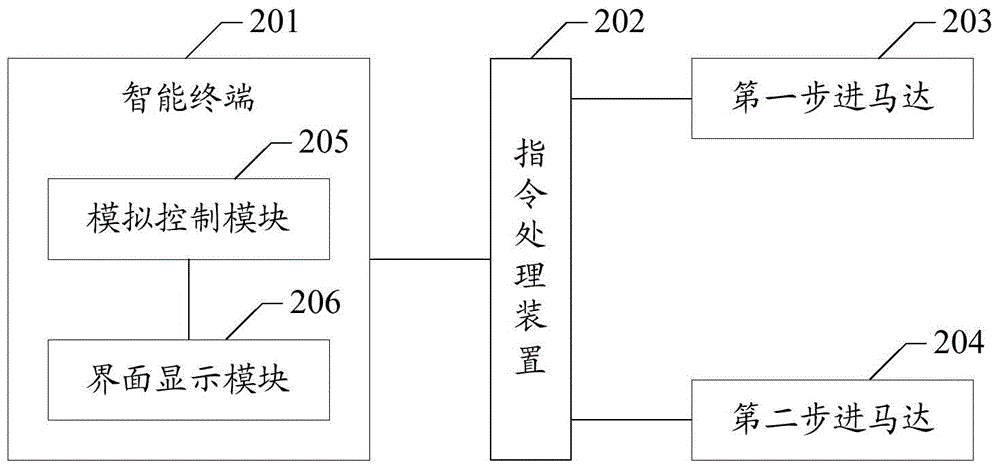

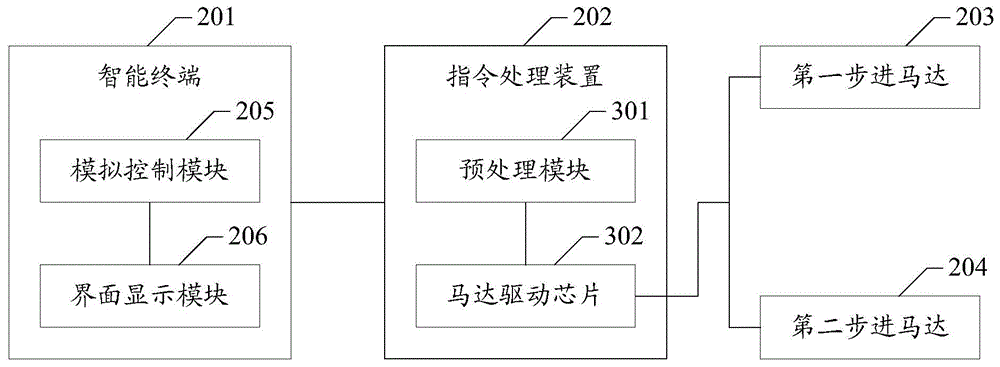

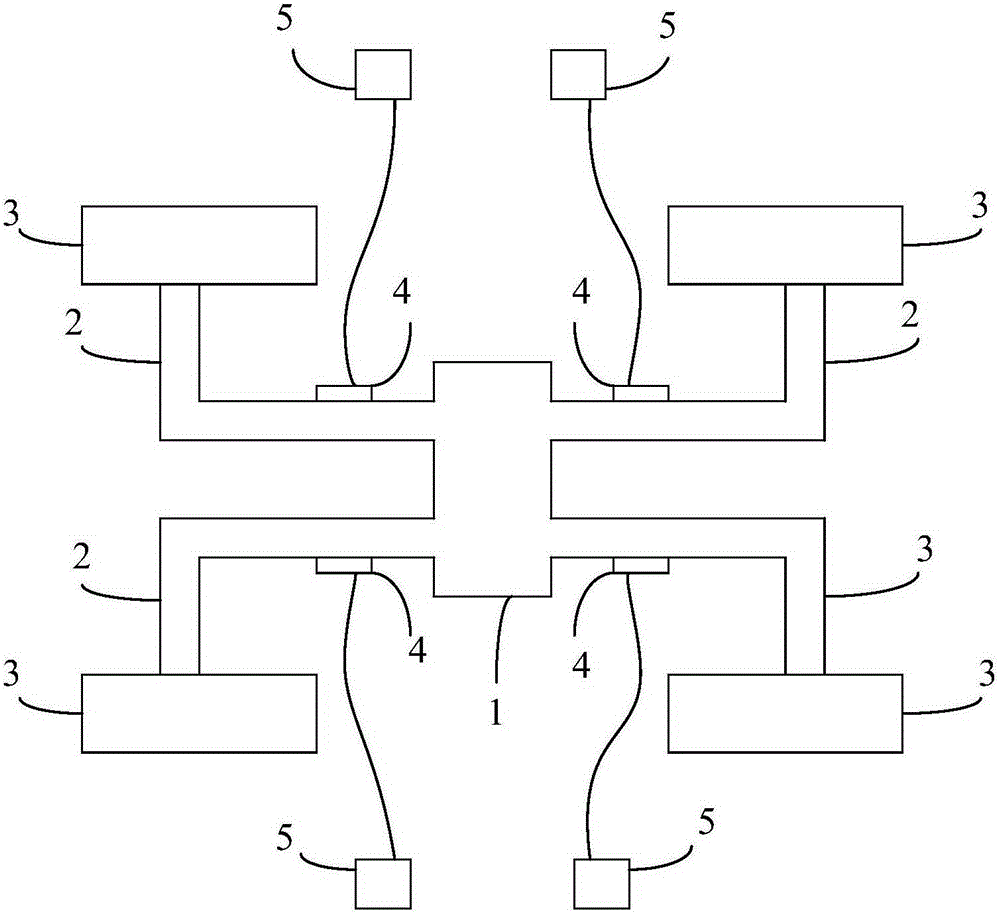

Method and system for regulating field angle of head-up display device

InactiveCN104598124AGet out of troubleLow costInput/output processes for data processingHead-up displayDisplay device

The invention discloses a method and system for regulating the field angle of a head-up display device. The field angle of the head-up display device can be conveniently regulated without manual operation. The method includes the steps that an intelligent terminal sends a control instruction to an instruction processing device in a wireless communication mode according to a virtual direction key, pressed by a user of the head-up display device for a long time, of a man-machine interaction interface of the intelligent terminal; the instruction processing device sends a rotation instruction to a first stepping motor and / or a second stepping motor according to the control instruction; a reflection plate of the head-up display device is borne to rotate through the first stepping motor and / or the second stepping motor according to the rotation instruction. On one hand, troubles caused by wiring are eliminated, and the cost for designing physical keys and a controller of the physical keys is reduced; on the other hand, as long as the user feels that the field angle is not good, the angle does not need to be manually regulated like the mode in the prior art, the angle only needs to be regulated in situ, the user can conveniently use the head-up display device, and the flexibly of the head-up display device is enhanced.

Owner:SHENZHEN DIANSHI INNOVATION TECH CO LTD

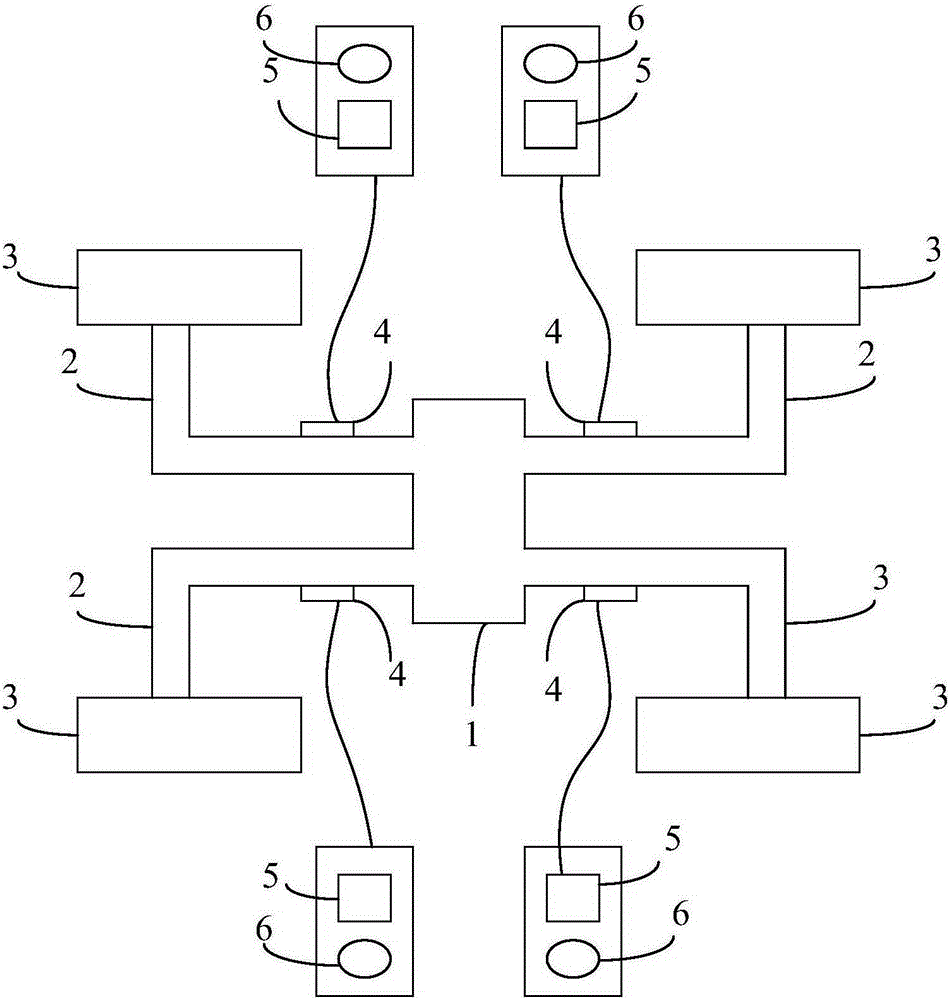

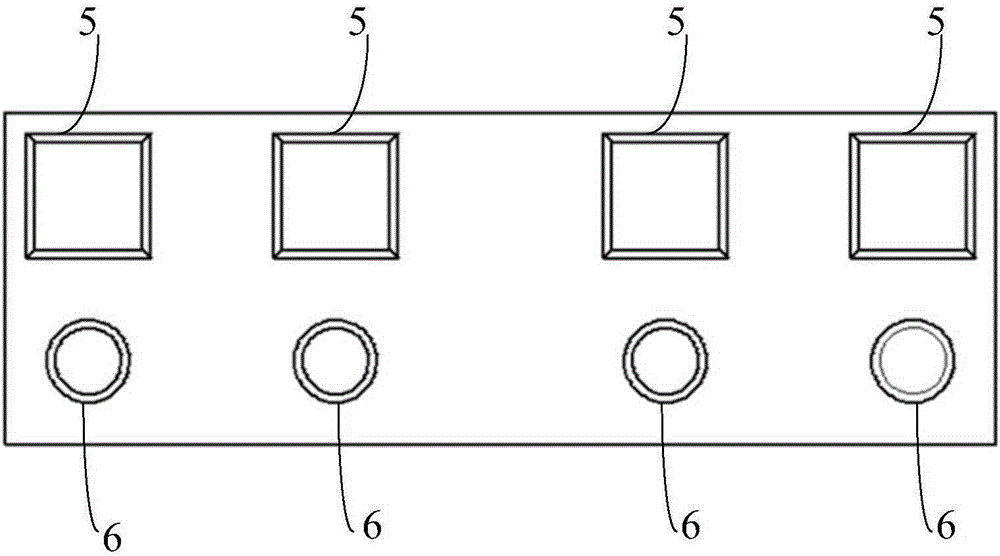

Vehicle trapping extricating system and vehicle

ActiveCN105235666AAvoid getting deeperReduce manufacturing costFluid braking transmissionOutput deviceVehicle brake

The invention provides a vehicle trapping extricating system and a vehicle. The vehicle trapping extricating system comprises a pressure outputting device, valves, and first control devices, wherein the pressure outputting device is connected with a vehicle brake pedal and is used for outputting pressure according to a brake of each braking-direction wheel of the brake pedal to enable the brake to work; the pressure outputting device is connected with the brake of each wheel of the vehicle by a braking pipeline; the valves are arranged on the braking pipelines; the first control devices are used for controlling the valves to be in a switching on or off state, and when at least one wheel is trapped, the first control devices control the valve on the braking pipeline corresponding to the trapped wheel to be switched on, and when the pedal is started, the trapped wheel obtains power; and the other first control devices are used for controlling the valves on the braking pipelines corresponding to the other wheels, except for the trapped wheel, to be switched off, the corresponding braking pipelines are cut off by the valves, and when the pedal is started, the other wheels, except for the trapped wheel, have no power. The vehicle trapping extricating system provided by the invention is good in trapping extricating effect and low in production cost.

Owner:BAIC GRP ORV CO LTD

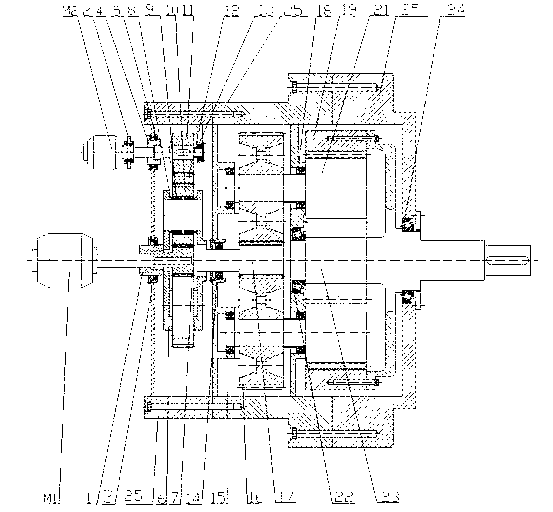

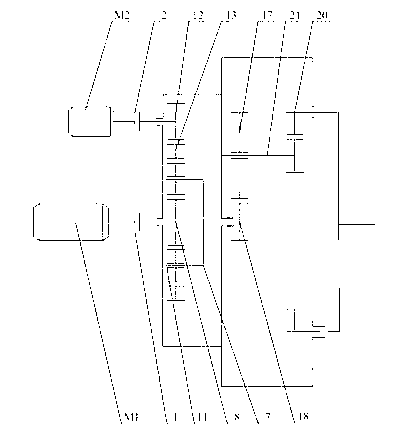

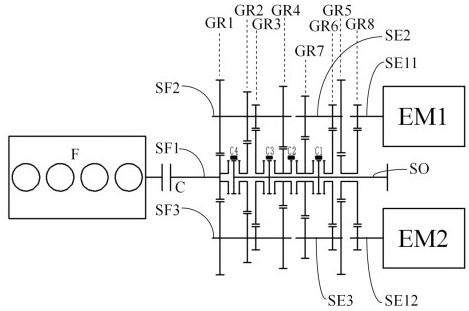

Dual-drive tunnel heading machine speed reducer

The invention discloses a dual-drive tunnel heading machine speed reducer. The speed reducer adopts a dual-input differential motion structure and an N-W type transmission output mechanism, the input motive power is converged through a differential motion mechanism and is output to a second-stage pinion through a connecting shaft, the pinion is externally engaged with three gearwheels in circumference distribution for realizing the power transmission and flow division, the gearwheels drive the rotation of a third-stage gear through a public shaft, the gears are internally engaged with a public inner tooth ring for realizing the convergence output, during the normal work, a large motor is used for driving, a small motor is used for braking, the large motor outputs at the rated power, when over-large soil and rock resistance moment or even collapse occurs, the large motor and the small motor are simultaneously used for driving, the difficulty escaping of a tunnel heading machine is realized, and in addition, the second and third states adopt the N-W type transmission mode. The dual-drive tunnel heading machine speed reducer has the advantages that the structure is simplified, the engagement point number is reduced, the uniform load performance is improved, the advantages of great reduction ratio, small size, light weight, simple structure and the like are also realized, and the low-speed large-torque output can be realized.

Owner:DALIAN UNIV OF TECH

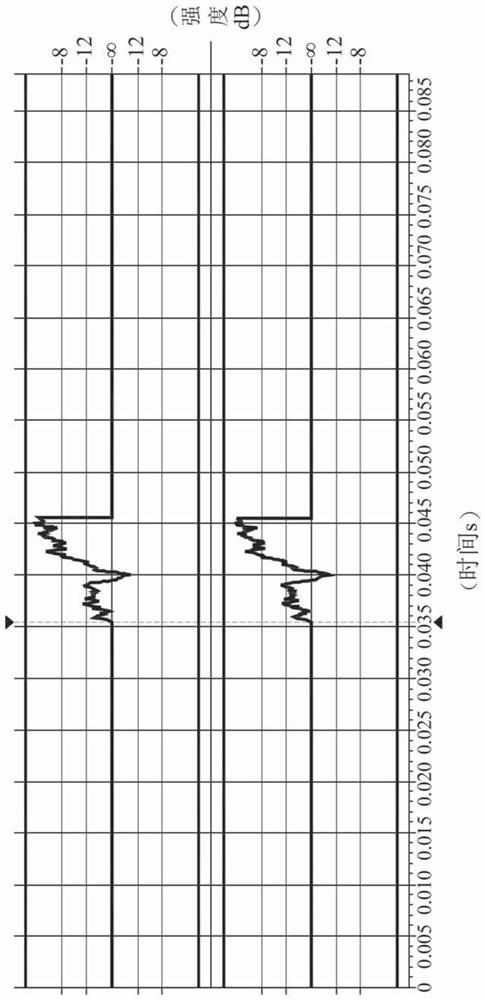

Boom detection method and device

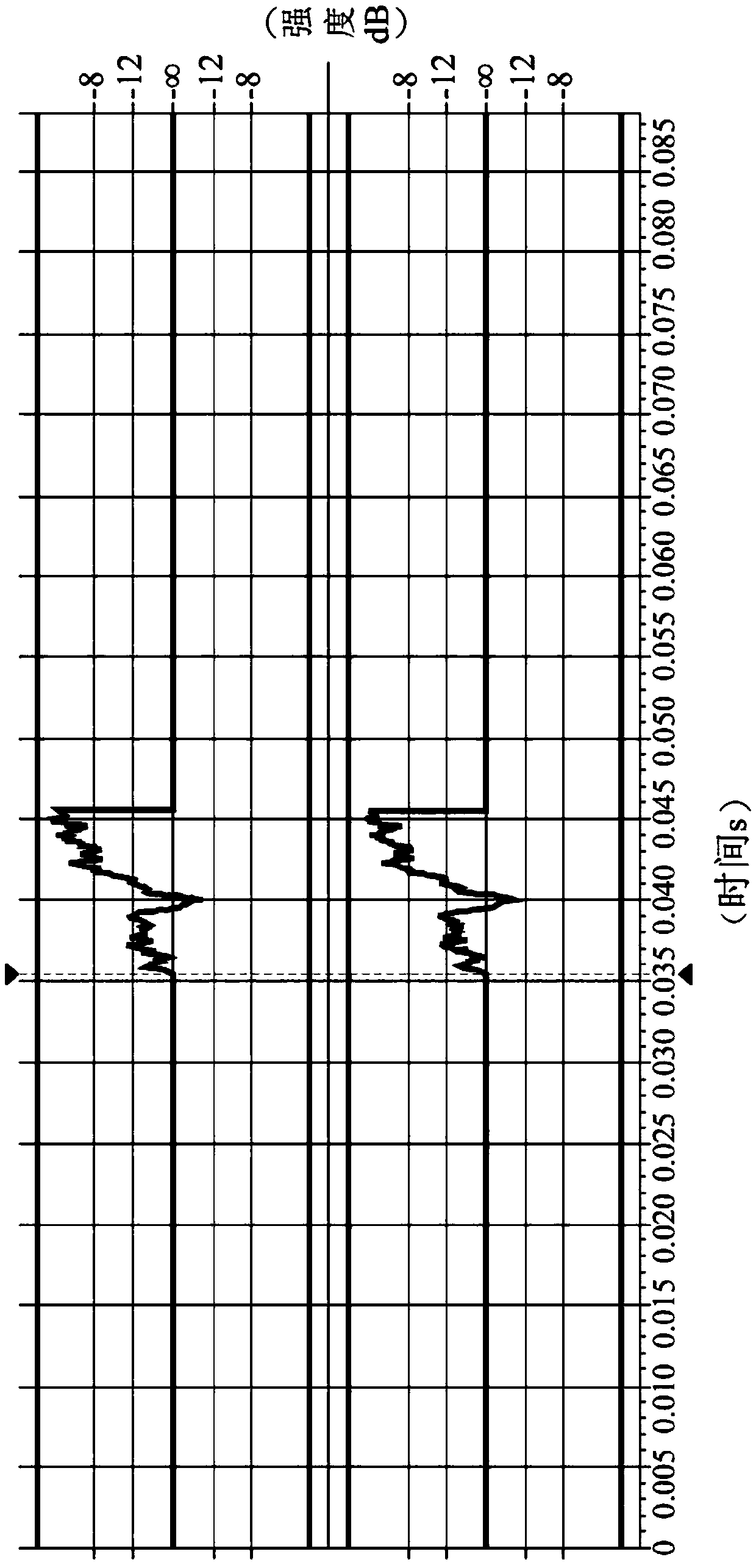

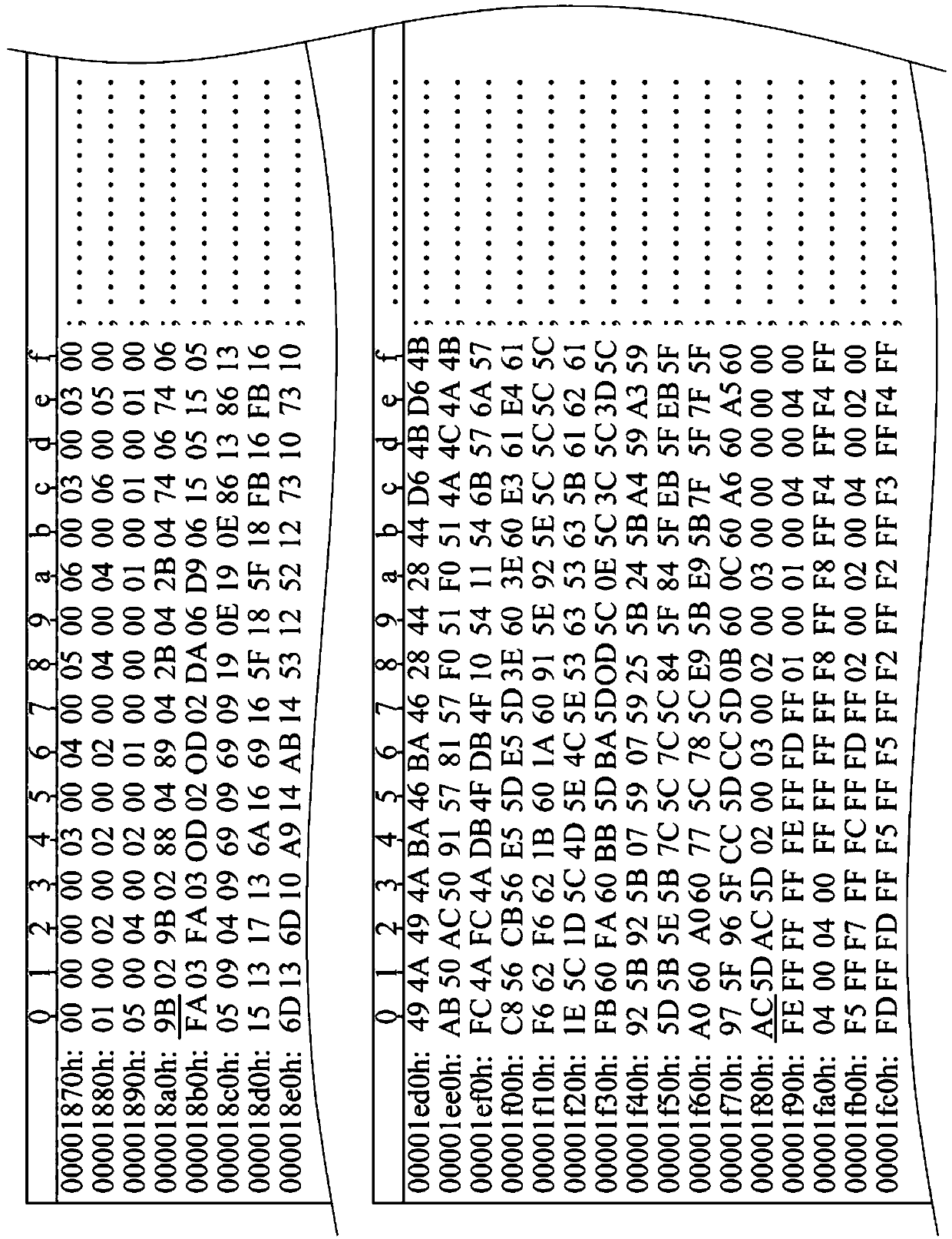

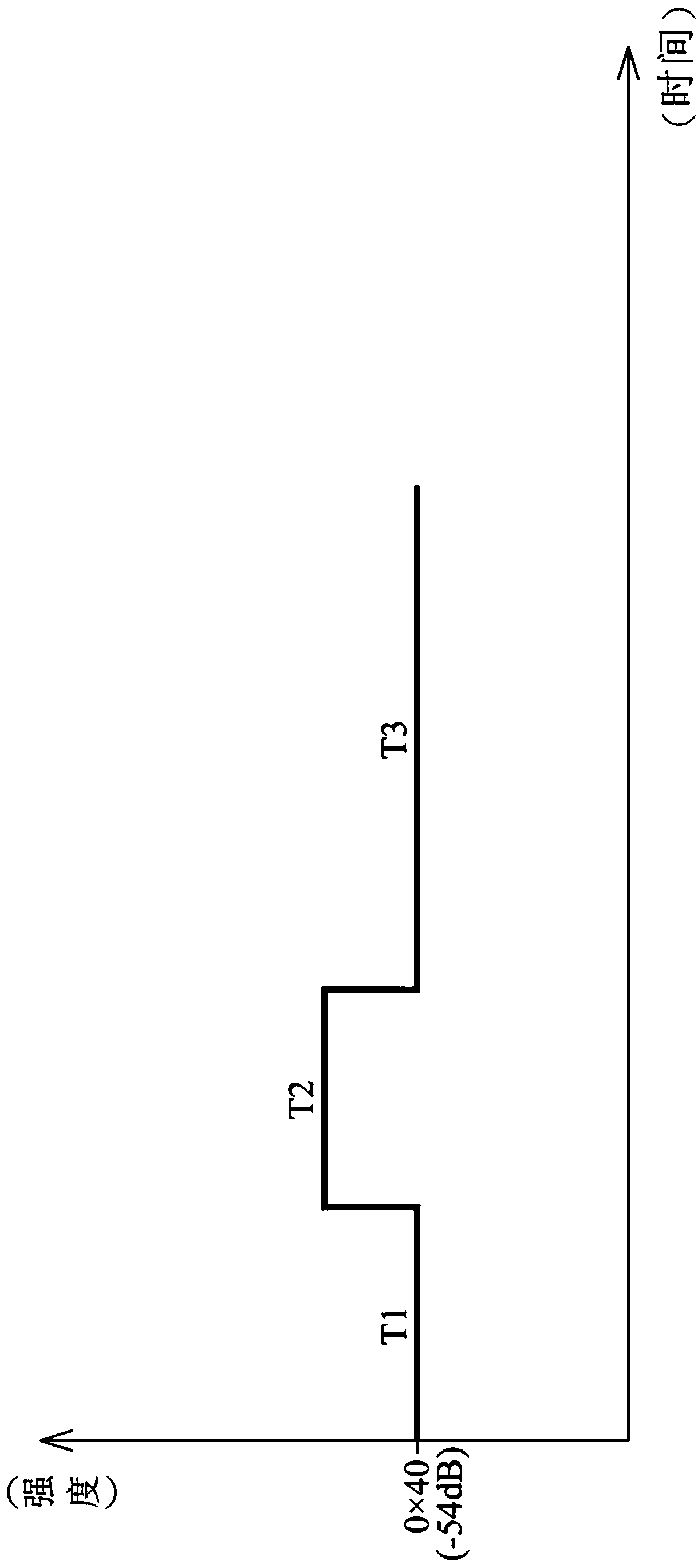

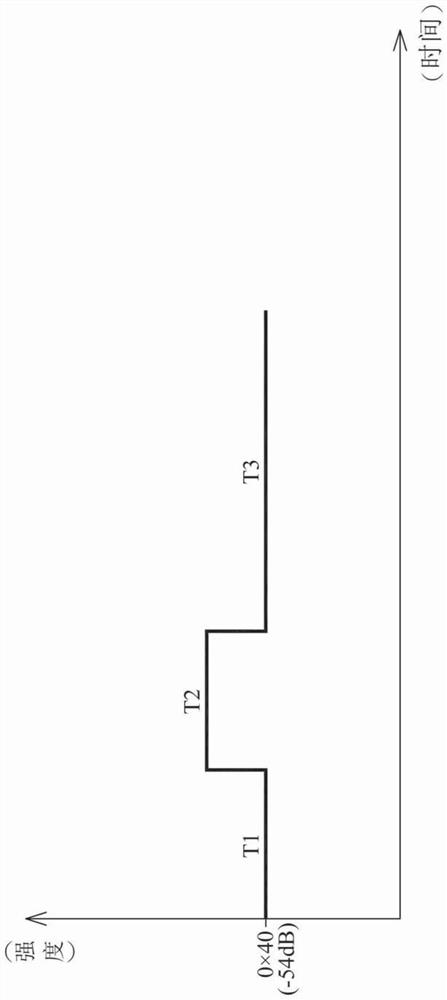

The invention provides a boom detection method, comprising: for a sound source signal, acquiring multiple audio boxes, formed in time sequence within a time domain; sampling each audio box; comparinga sample amplitude of each sampling result in each audio box to a preset sample amplitude; determining that each audio box belongs as a white noise part or a boom-like part according to the comparisonresults of each audio box; judging whether adjacent white noise parts, adjacent boom-like parts and adjacent white noise parts are present in time sequence in these audio boxes, thereby determining whether the sound source signal is boom, wherein when both one audio box and its adjacent at least one audio box are white noise parts, the corresponding audio boxes belongs as white noise parts, and when one audio box and its adjacent at least one audio box are boom-like parts, the corresponding audio boxes belong as adjacent boom-like parts.

Owner:UNIVERSAL GLOBAL TECH KUNSHAN

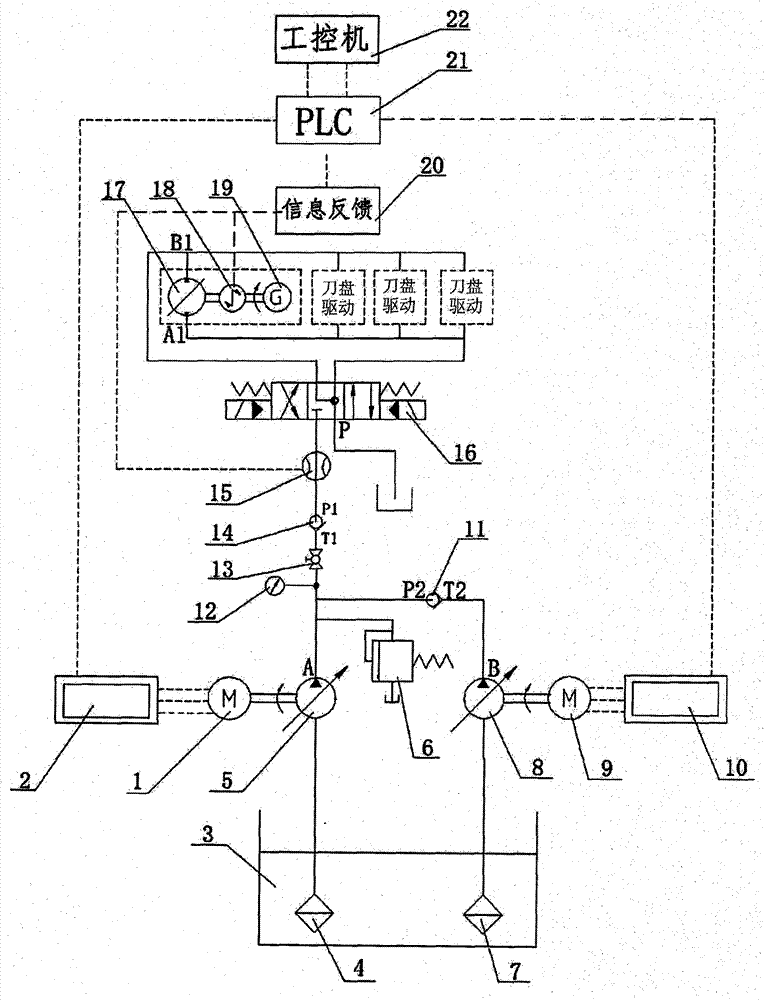

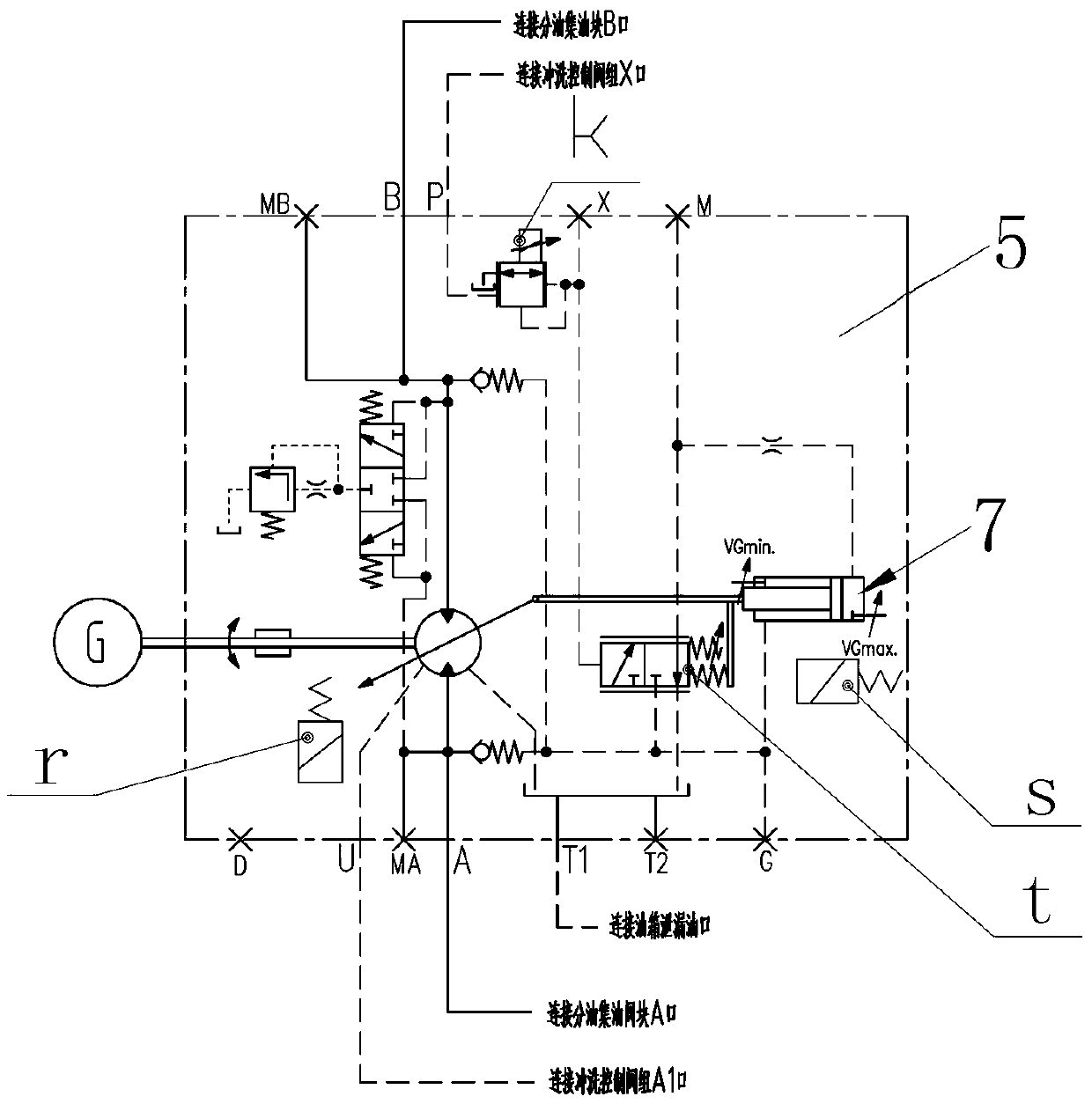

Tunnel boring machine (TBM) cutter head pressurizing freeing hydraulic control system

InactiveCN107327304AGet out of troubleIncreased load torqueTunnelsFrequency changerClosed loop feedback

The invention discloses a tunnel boring machine (TBM) cutter head pressurizing freeing hydraulic control system. The TBM cutter head pressurizing freeing hydraulic control system comprises a control assembly, a cutter head driving assembly, a main control oil circuit and a pressurizing control oil circuit. The control assembly comprises an industrial personal computer, a PLC control unit and an information feedback unit. The cutter head driving assembly comprises a hydraulic motor correspondingly connected with a TBM cutter head, a torque sensor and a reducer. The main control oil circuit comprises a main control frequency converter, a main control oil circuit motor and a main variable stroke pump, wherein the main control frequency converter, the main control oil circuit motor and the main variable stroke pump are connected in sequence. The pressurizing control oil circuit comprises a pressurizing frequency converter, a pressurizing oil circuit motor and a pressurizing variable stroke pump, wherein the pressurizing frequency converter, the pressurizing oil circuit motor and the pressurizing variable stroke pump are connected in sequence. According to the TBM cutter head pressurizing free hydraulic control system, system closed-loop feedback control is achieved, the working state of the cutter head fits in control of the main variable stroke pump and the pressurizing variable stroke pump and displacement of the hydraulic motor, when the cutter head is clamped or has a clamped trend, the pressurizing variable stroke pump is started quickly, the main variable stroke pump and the pressurizing variable stroke pump work simultaneously, the displacement of the motor is increased, and the cutter head is freed through instant high torque.

Owner:中铁南方投资集团有限公司 +1

Eyedrop capable of treating shortsightedness

InactiveCN104586883AGet out of troubleGet rid of troubleSenses disorderAluminium/calcium/magnesium active ingredientsEye/ear dropsSulfanilamide

The invention discloses an eyedrop capable of treating shortsightedness. The eyedrop comprises sulfanilamide powder, vitamin B6, bovine sulphate, ophiopogon root potassium chlorate and dipotassium glycyrrhizinate. The eyedrop serving as a common eyedrop has the functions of moistening eyes and relieving fatigue and also has excellent effect of treating shortsightedness, enabling the eyes to have the sight before shortsightedness and enabling people with shortsightedness to get rid of trouble and obsession of wearing glasses.

Owner:李艳琼

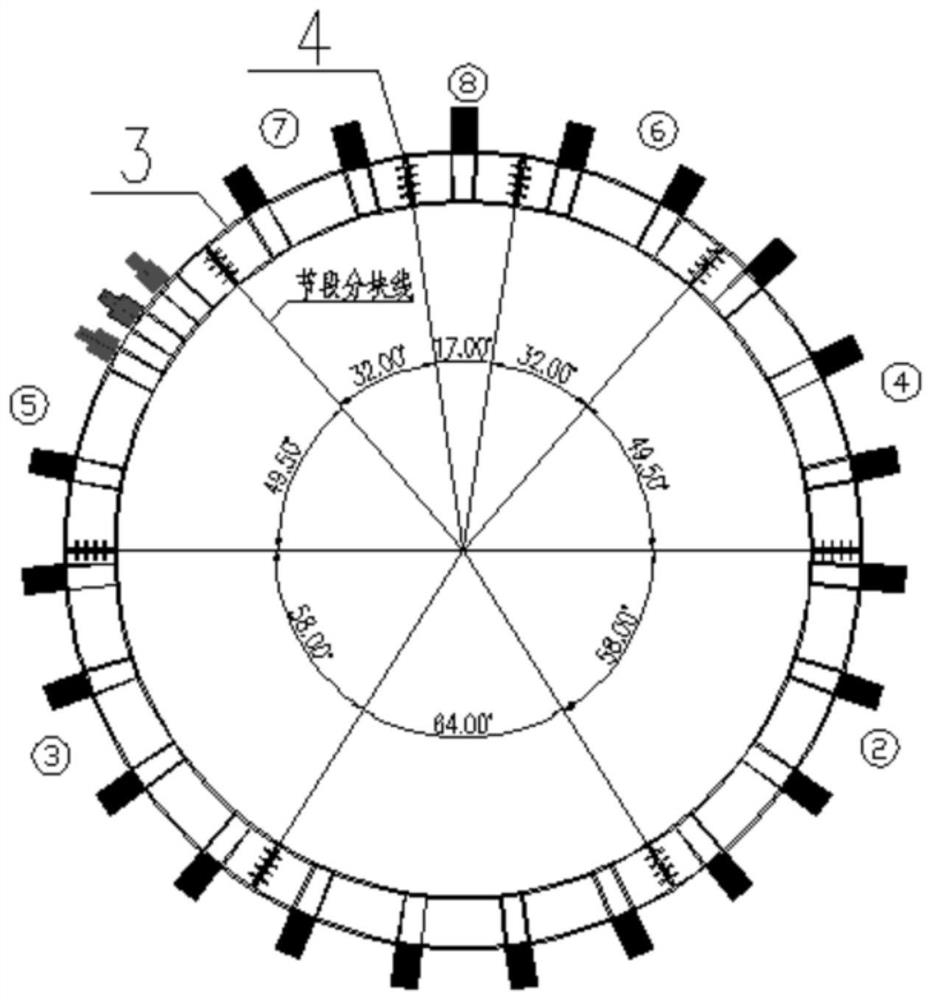

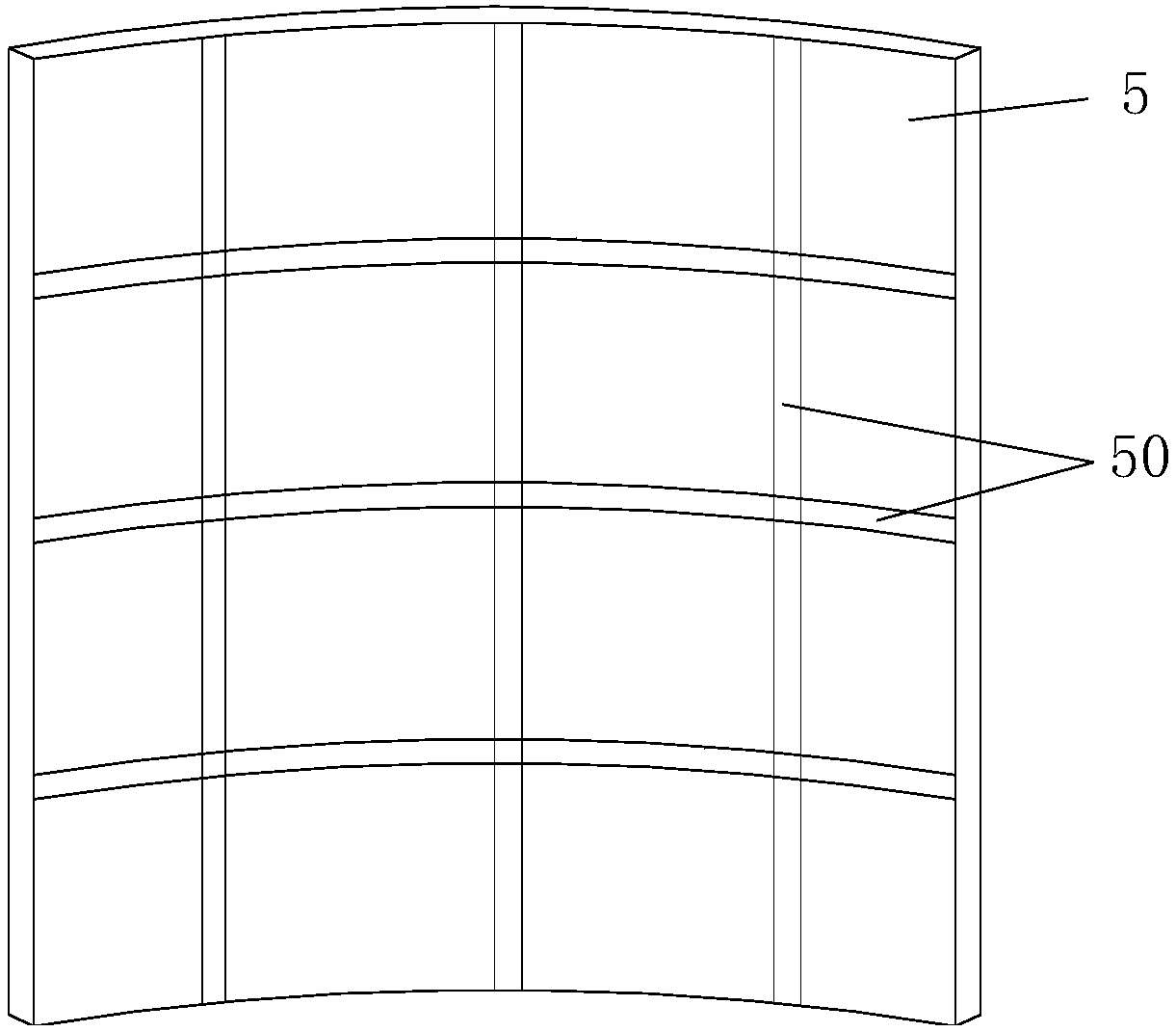

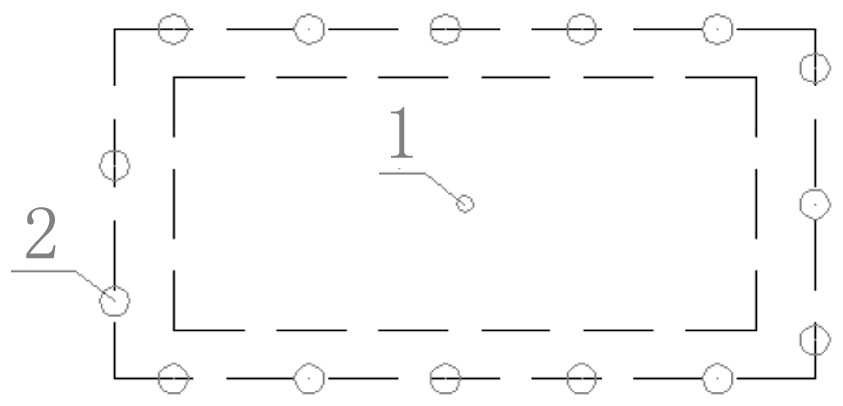

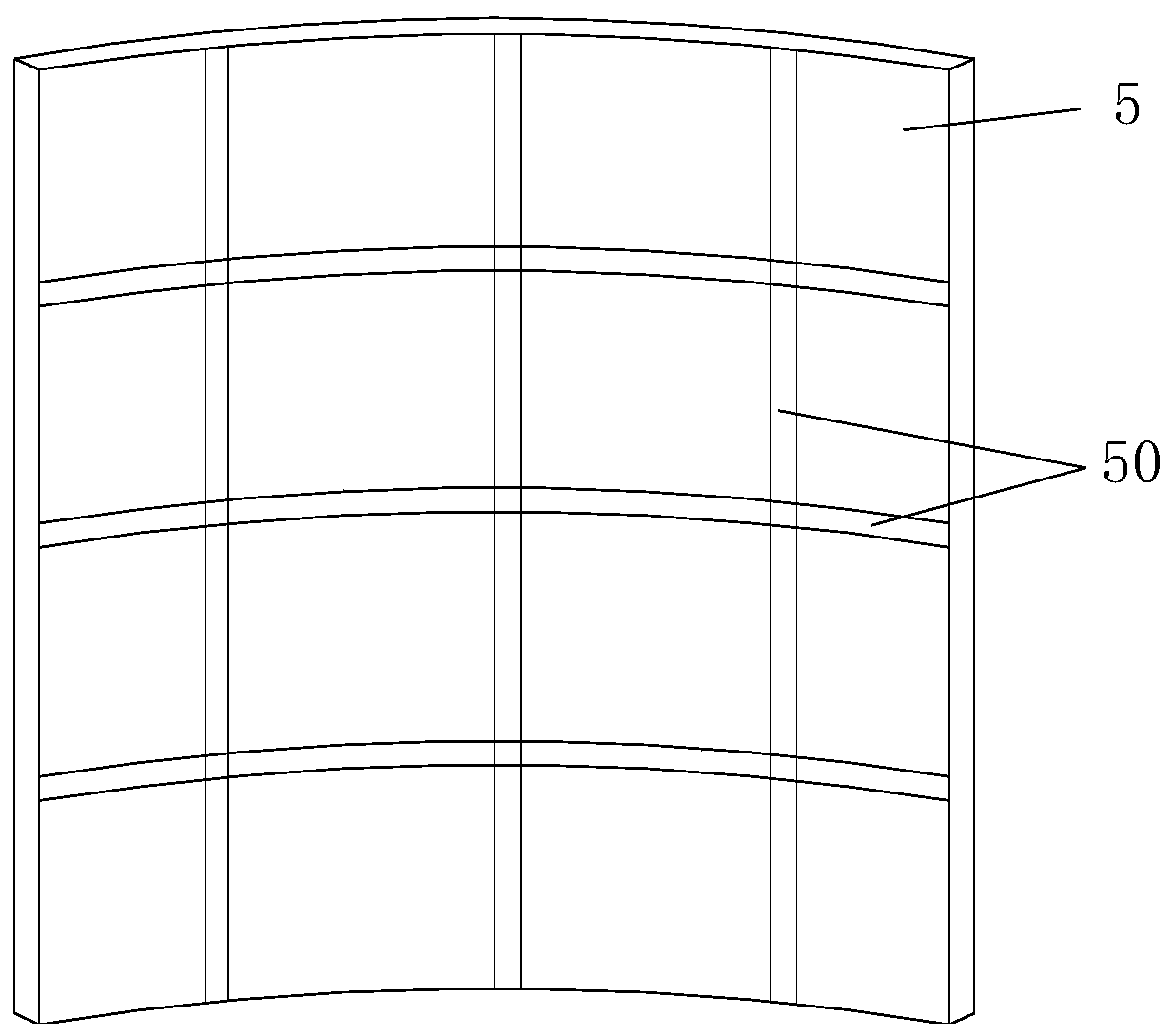

Annular tool and method for deformation straightening of highly permeable sand layer large-diameter shield tail shield

PendingCN111779492ARealize deformation correctionRealize full circleMachine part testingUnderground chambersButtressClassical mechanics

The invention discloses an annular tool and method for deformation straightening of a highly permeable sand layer large-diameter shield tail shield. The annular tool comprises a counterforce support frame, a base plate and a meniscus structure. The counterforce support frame is of an annular structure. The outer cambered surface of the counterforce support frame is provided with first buttresses at intervals in the longitudinal and circumferential directions. A pre-tightening jack is arranged between the first buttresses located in the longitudinal direction of the counterforce support frame.A plurality of straightening jacks are arranged in a tail shield deformation area corresponding to the outer cambered surface of the counterforce support frame. A gap between the first buttresses andthe tail shield is filled with the base plate. The meniscus structure is installed on the inner cambered surface, corresponding to the tail shield deformation area, of the counterforce support frame.Through the annular tool and method, the problems of tail shield deformation and tail shield rounding straightening of a shield tunneling machine are solved.

Owner:CCCC SECOND HARBOR ENG

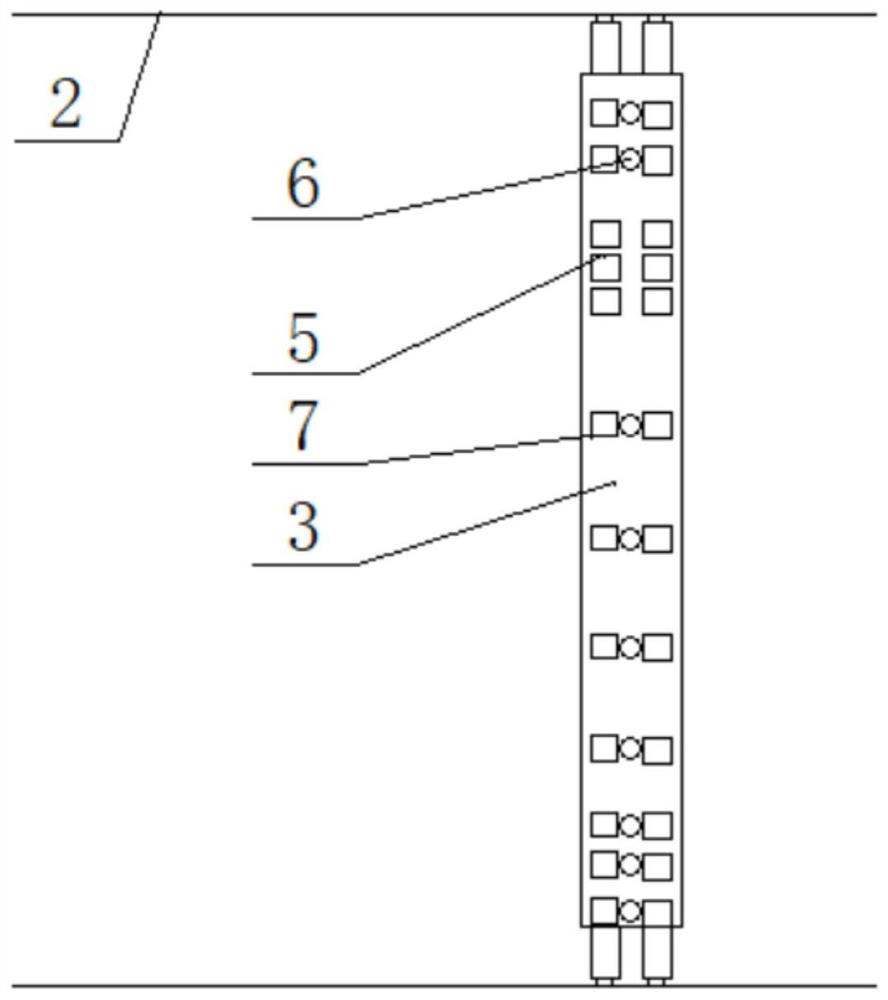

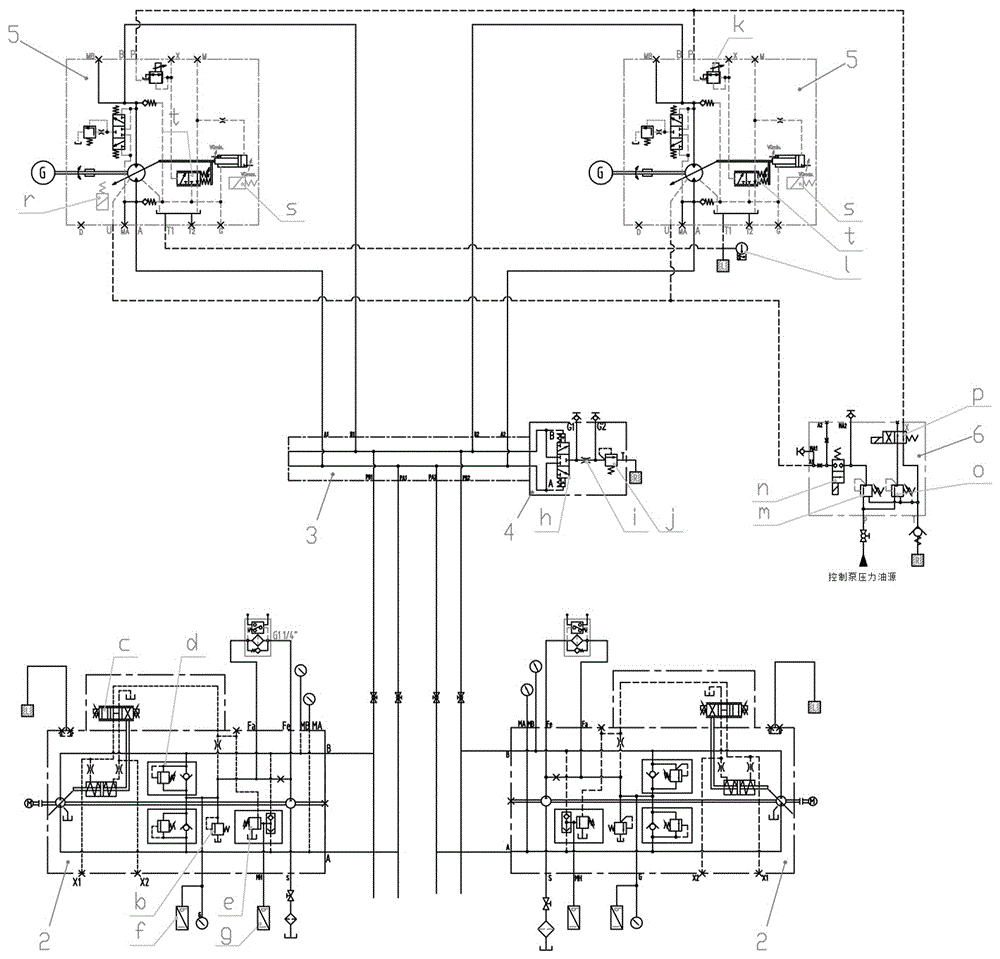

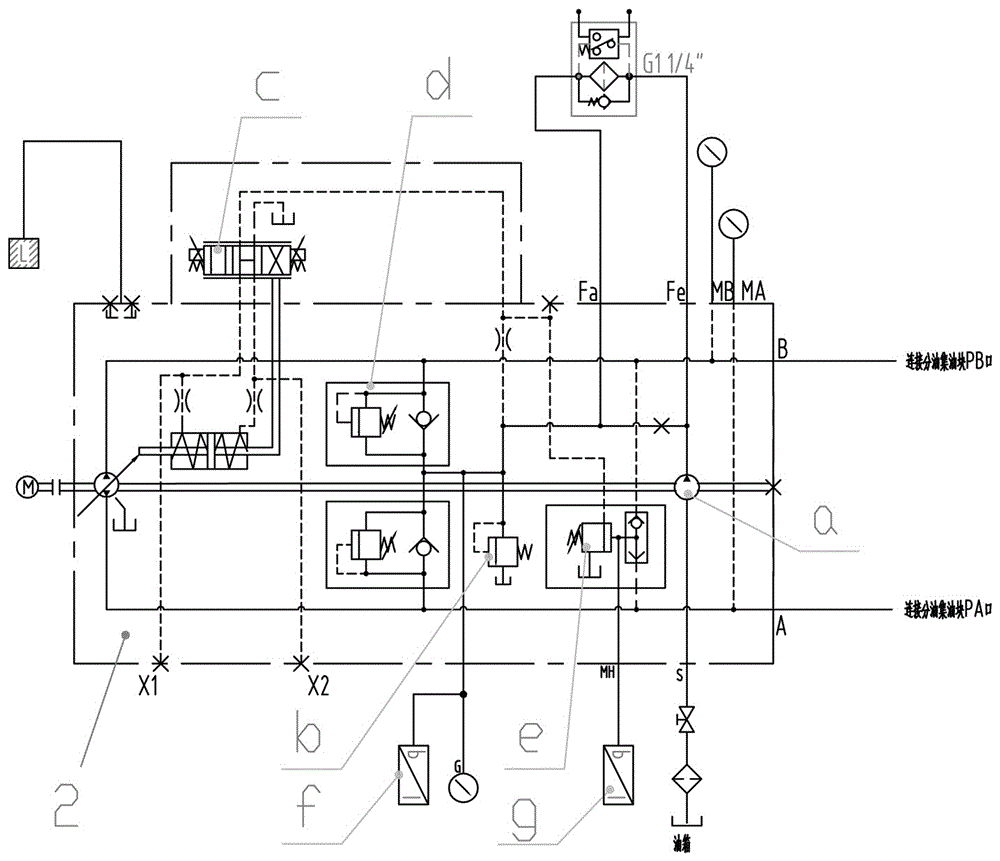

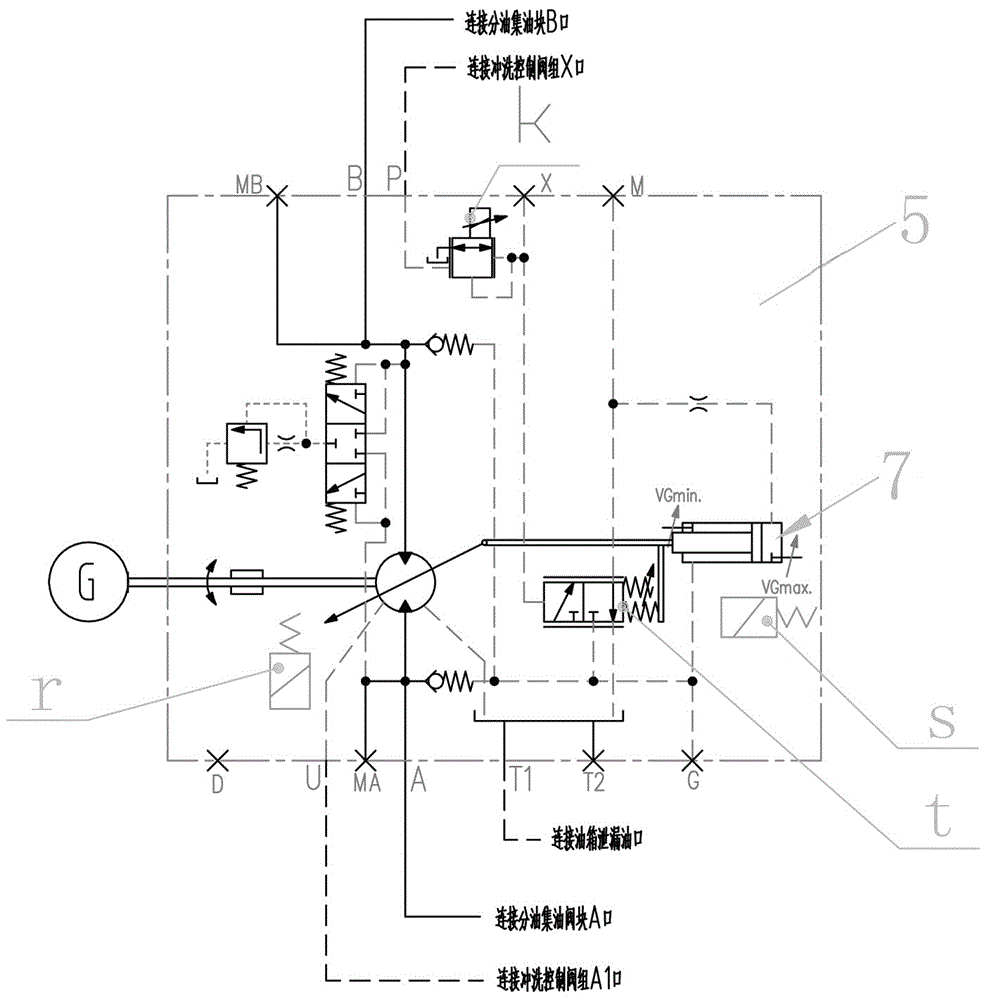

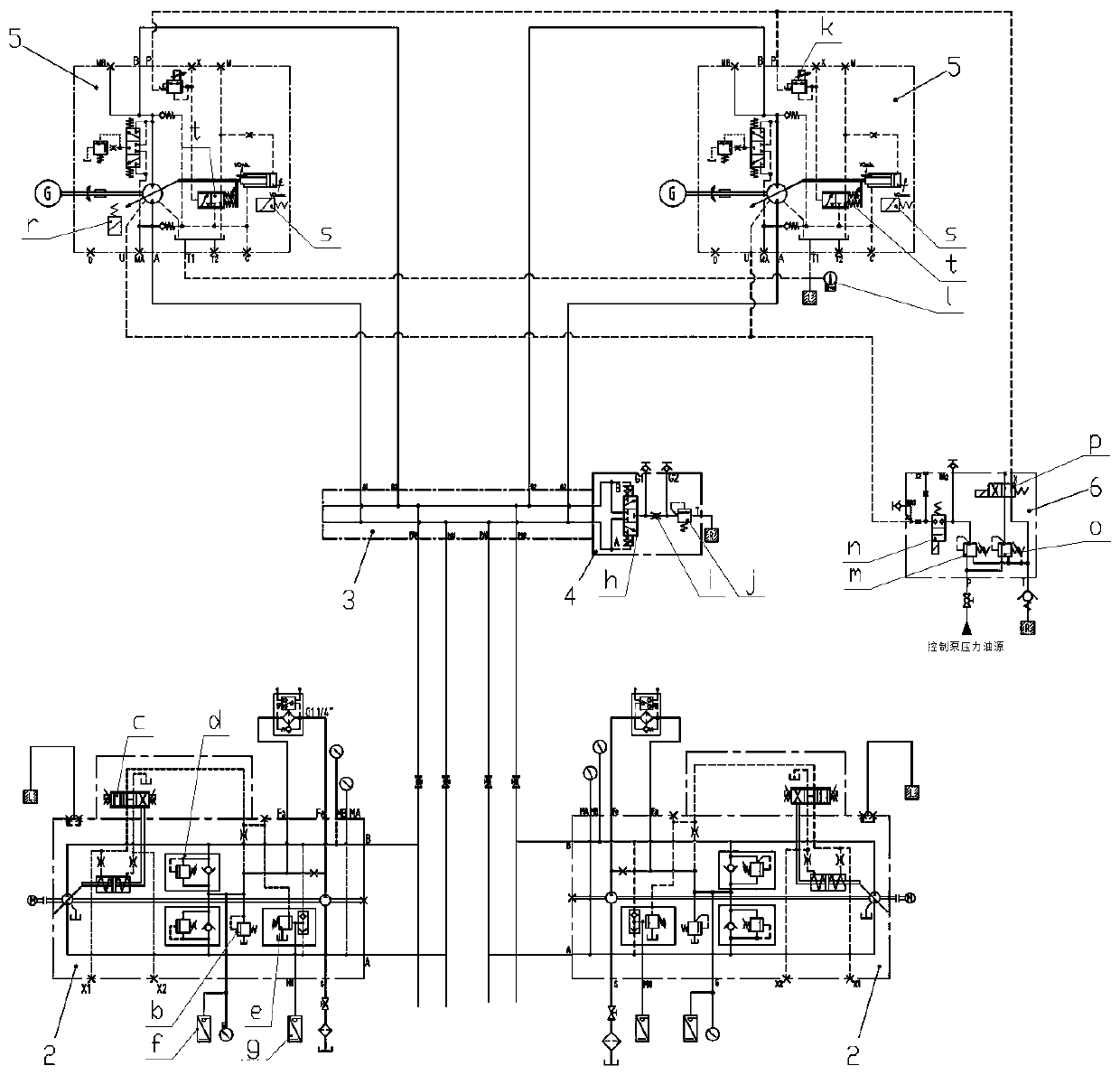

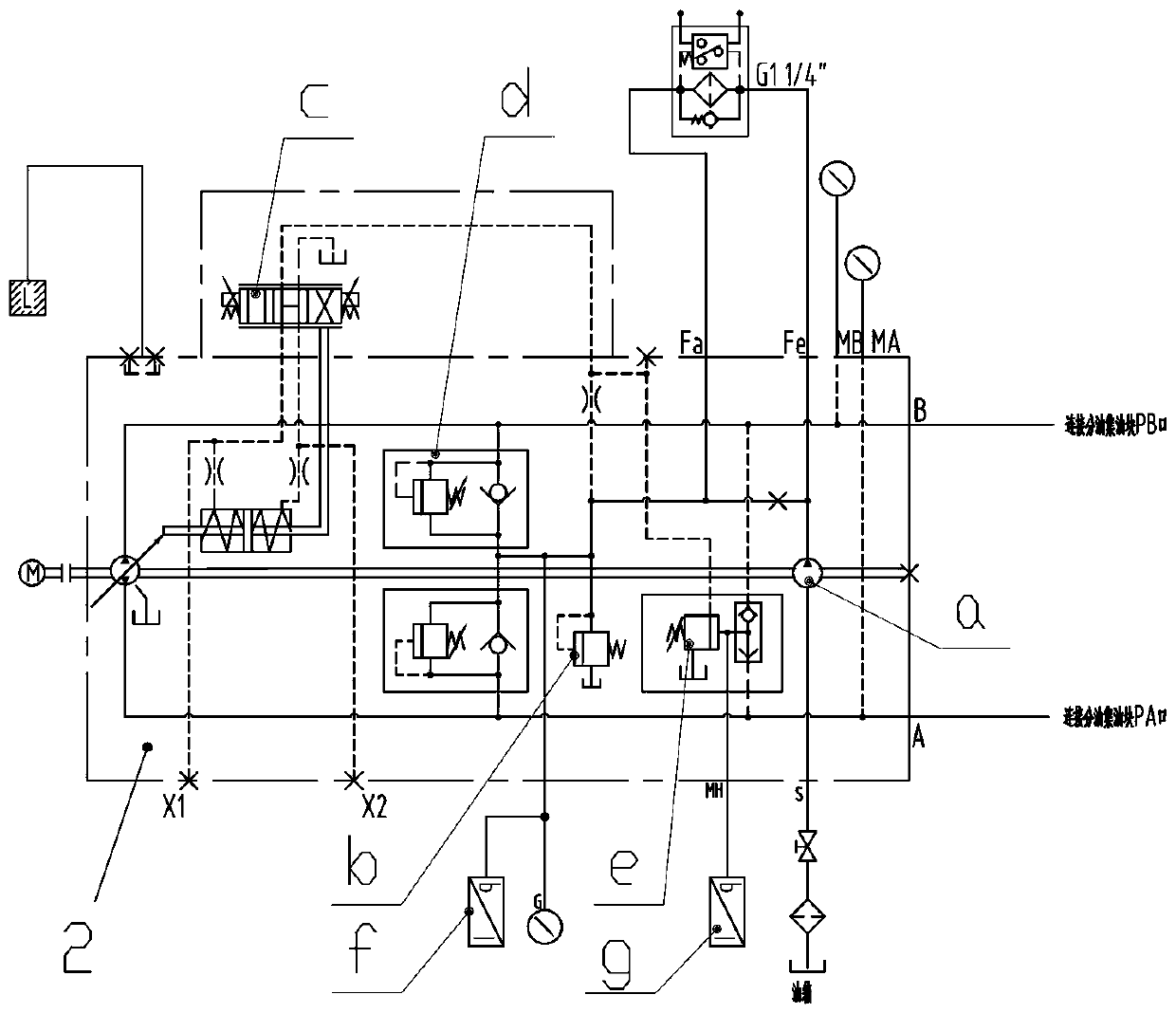

Stepless speed regulating hydraulic driving system of spiral conveyer for super-large diameter shield machine

ActiveCN106762889AGuaranteed stabilitySimple structureFluid-pressure actuator safetyServomotor componentsHydraulic motorHydraulic pump

The invention relates to a stepless speed regulating hydraulic driving system of a spiral conveyer for a super-large diameter shield machine. The stepless speed regulating hydraulic driving system comprises an oil case, a hydraulic pump set, a speed regulating hydraulic circuit, a reducer, a hydraulic motor set and a control unit. An oil separating and collecting valve module, a rinsing control valve module, a control pump and a sensor module are arranged in the speed regulating hydraulic circuit. The hydraulic pump set comprises a first hydraulic pump and a second hydraulic pump. The first hydraulic pump and the second hydraulic pump are both provided with displacement regulating mechanisms. The hydraulic motor set comprises a first hydraulic motor and a second hydraulic motor which operate simultaneously. The first hydraulic motor and the second hydraulic motor are both provided with output variable regulating mechanisms. The displacement regulating mechanisms and the output variable regulating mechanisms are in communicating connection with the control unit. The hydraulic driving system can meet the requirements for large torque and high rotation speed, has the functions of variable-speed regulating, overload protection and double-way rotating and is safe and reliable, and the stability of the operation performance of the spiral conveyer is guaranteed effectively.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

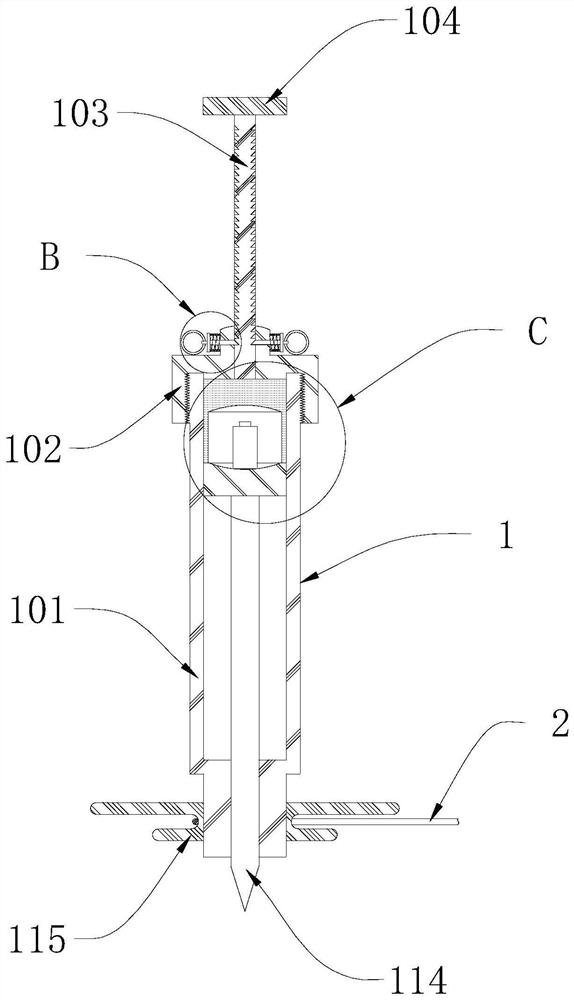

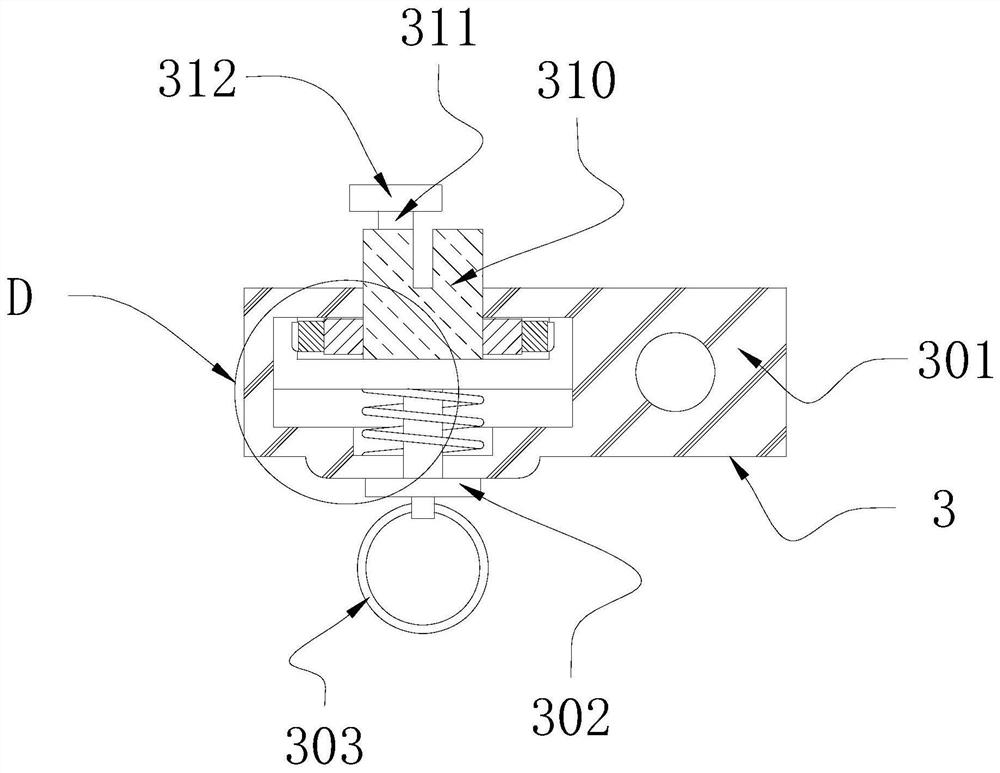

Automatic automobile get-out-of-trap device

The invention belongs to the technical field of automobiles, and particularly relates to an automatic automobile get-out-of-trap device which comprises a fixing device. The fixing device comprises a high-strength cylindrical shell, a high-strength threaded sealing cover, a square inner channel steel column, a first limiting plate, a high-strength sliding sealing head, a high-strength single-surface inclined clamping strip, a second limiting plate, a first pull ring, a cylindrical shell, an extension spring, a high-strength piston, explosive, a wireless ignition device, a ground inserting steel column and a limiting circular plate. The inner side of one end of the limiting circular plate is in contact connection with a steel wire rope, the outer side of one end of the steel wire rope is in contact connection with a locking device, and the locking device comprises a steel locking shell, a first limiting circular piece, a second pull ring, an alloy pull rod, an inner tooth limiting ring, a compression spring and a limiting sliding block. A winding device is arranged so that the device has the function of enabling the automobile to get out of a trap, can achieve automobile getting out of the trap without traction of other automobiles, and is simple, direct and effective.

Owner:东台市高科技术创业园有限公司

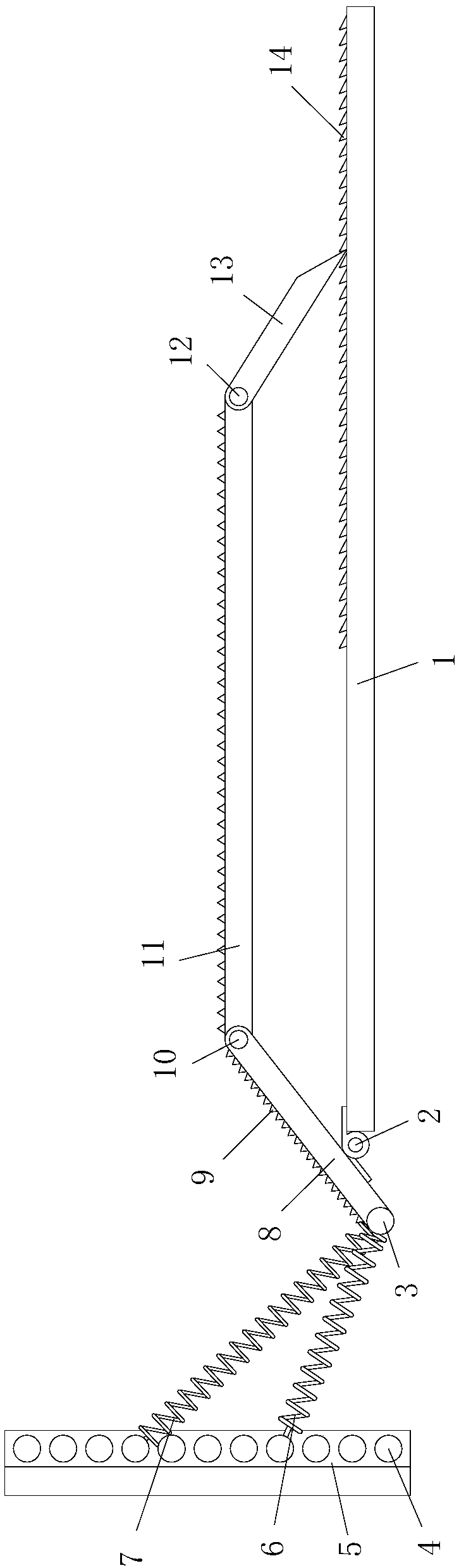

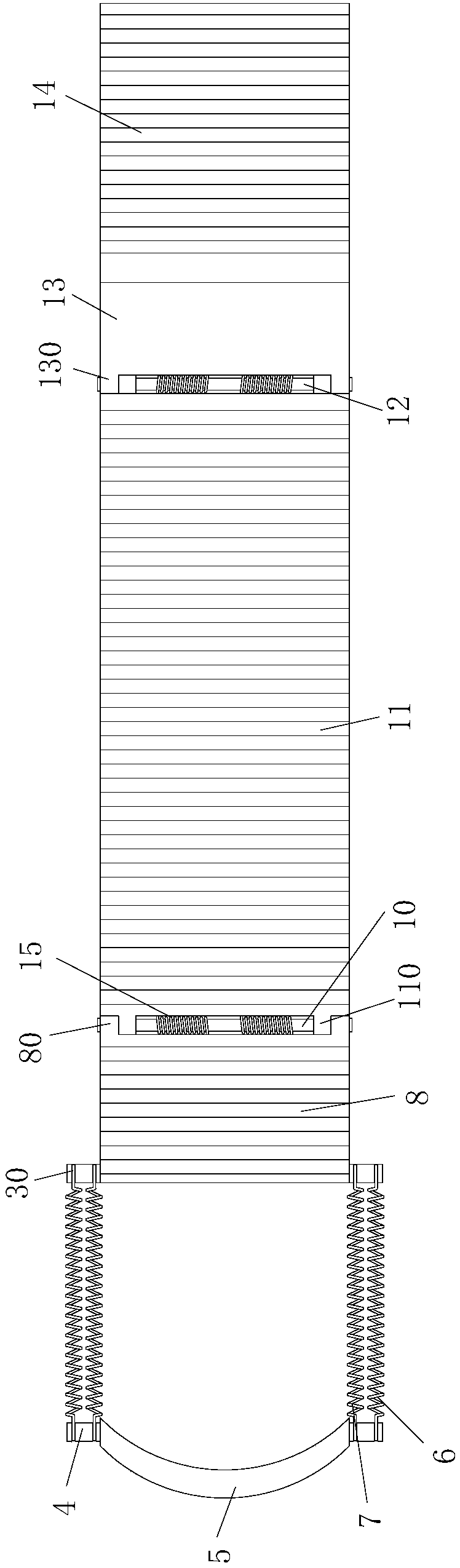

Automobile trapping lifting apparatus

InactiveCN107719334AEasy to useIncrease frictionVehicle manoeuvring devicesTorsion springHinge angle

The invention discloses an automobile trapping lifting apparatus which structurally comprises a bottom plate, a hinge, a hang rod, fixing rods, an arc-shaped plate, a first spring, a second spring, afront plate, convex strips, a first positioning pin, a support plate, a second positioning pin, a fixing plate, barrier strips and torsion springs. The bottom plate is arranged below the support plateand is parallel to the support plate, four lugs are arranged on two sides of the support plate, the center line of the support plate is used as the symmetric axis of the lugs, through holes are formed in the lugs, connecting blocks are arranged at two ends of a side of the front plate, via holes are formed in the connecting blocks, and concentric circles are formed by the through holes of the lugs and the via holes of the connecting blocks. The automobile trapping lifting apparatus has the advantages that the fixing plate clamped at the barrier strips can be repositioned, accordingly, the inclination of the front plate can be adjusted, and the automobile trapping lifting apparatus can be flexibly used; wheels can be pushed towards the front plate by the arc-shaped plate under the effectsof elastic force of first springs and second springs, accordingly, frictional force of the front plate and the wheels can be increased, the wheels can be quickly released from dilemmas when rotating,and good trapping lifting effects can be realized.

Owner:浙江智尊保科技股份有限公司

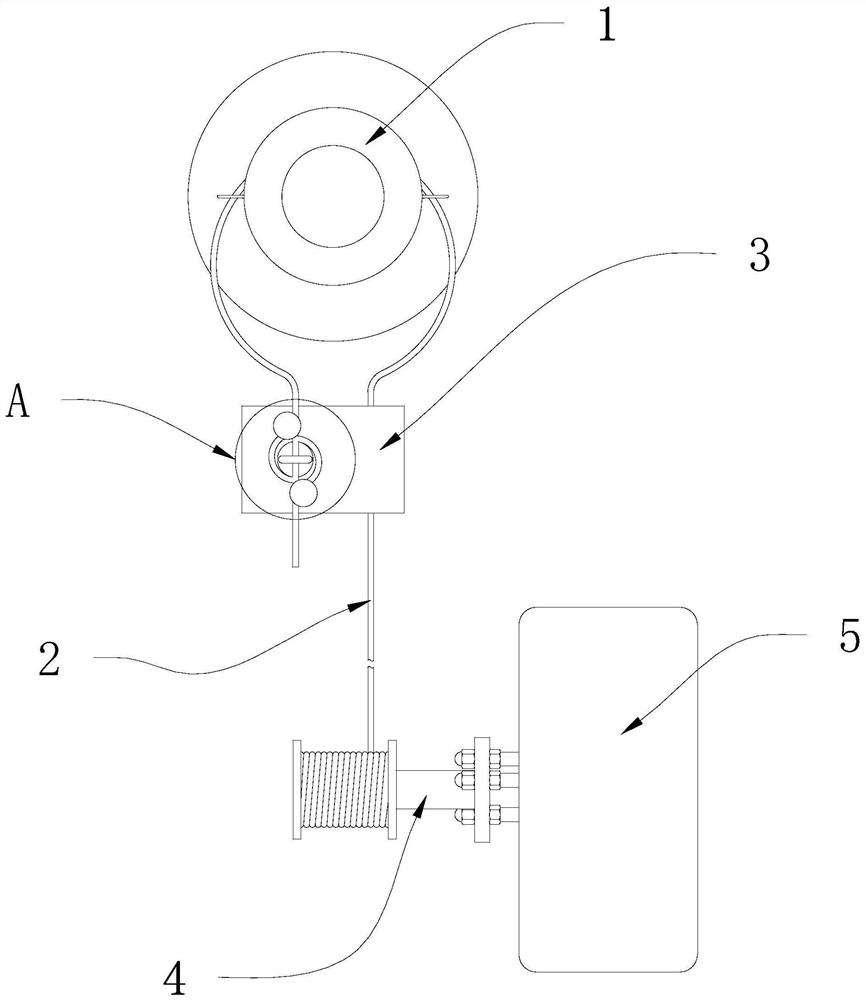

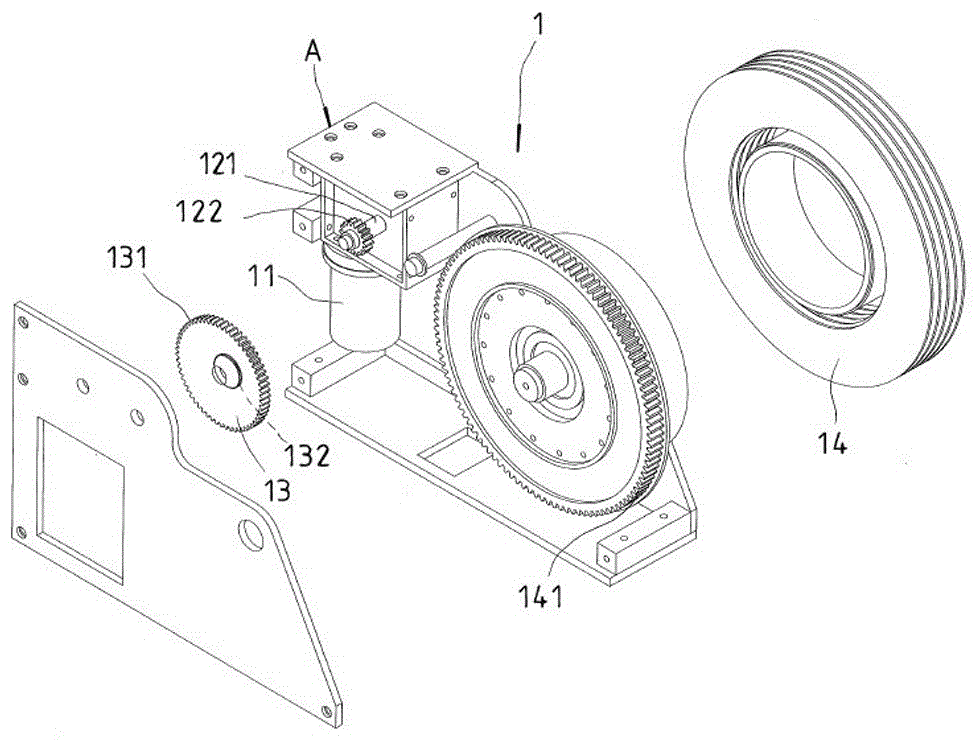

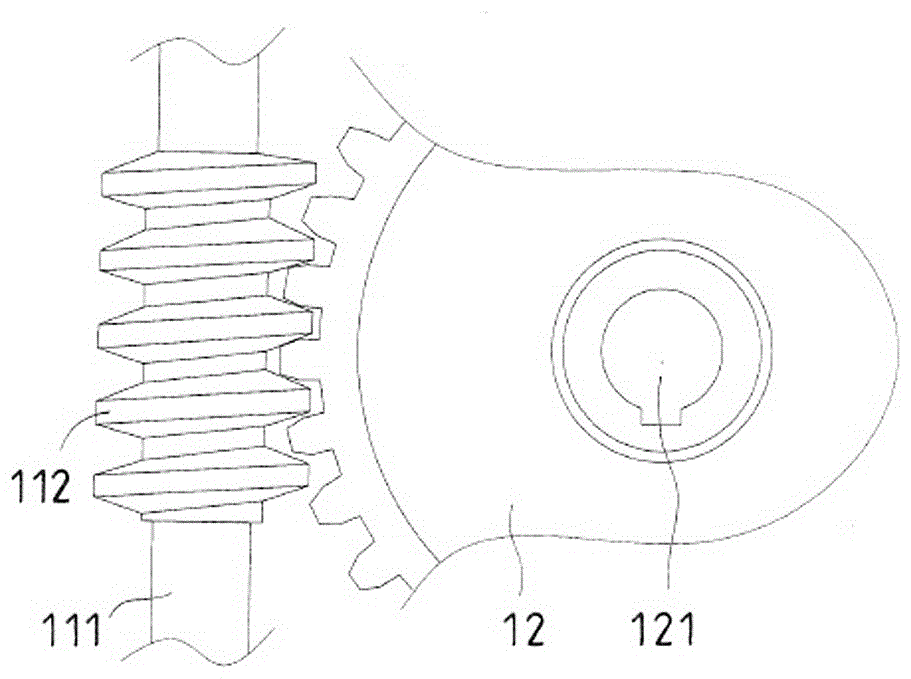

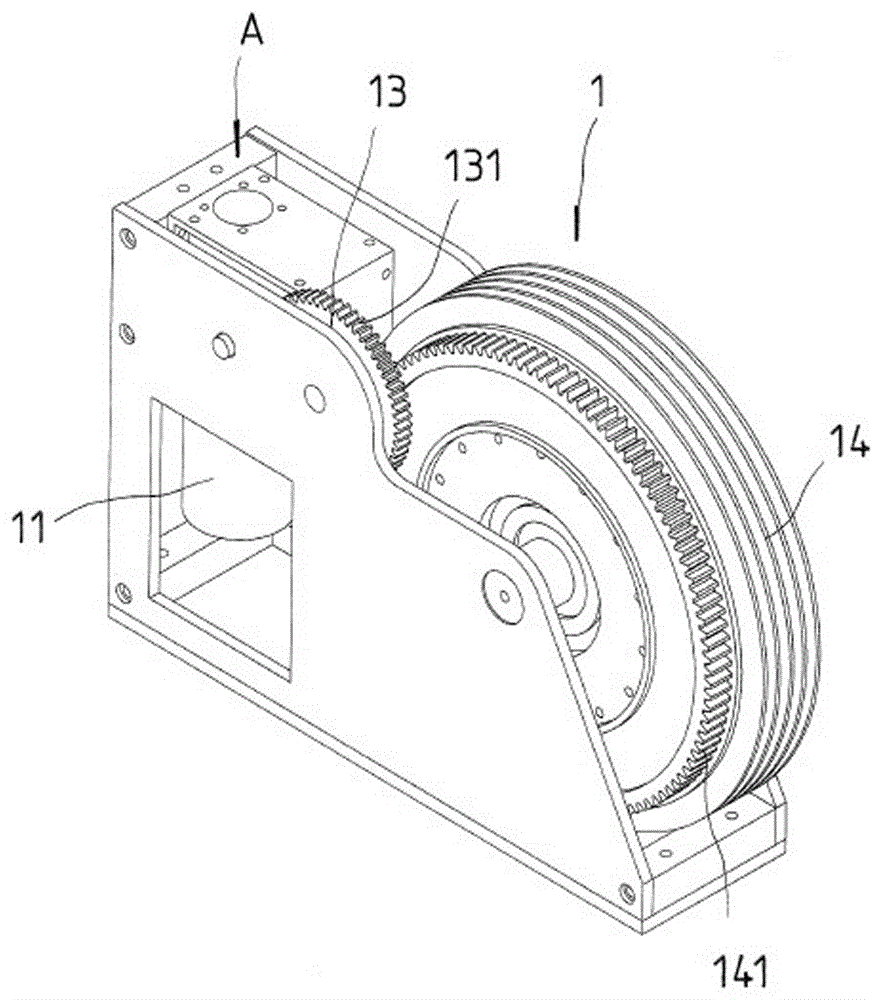

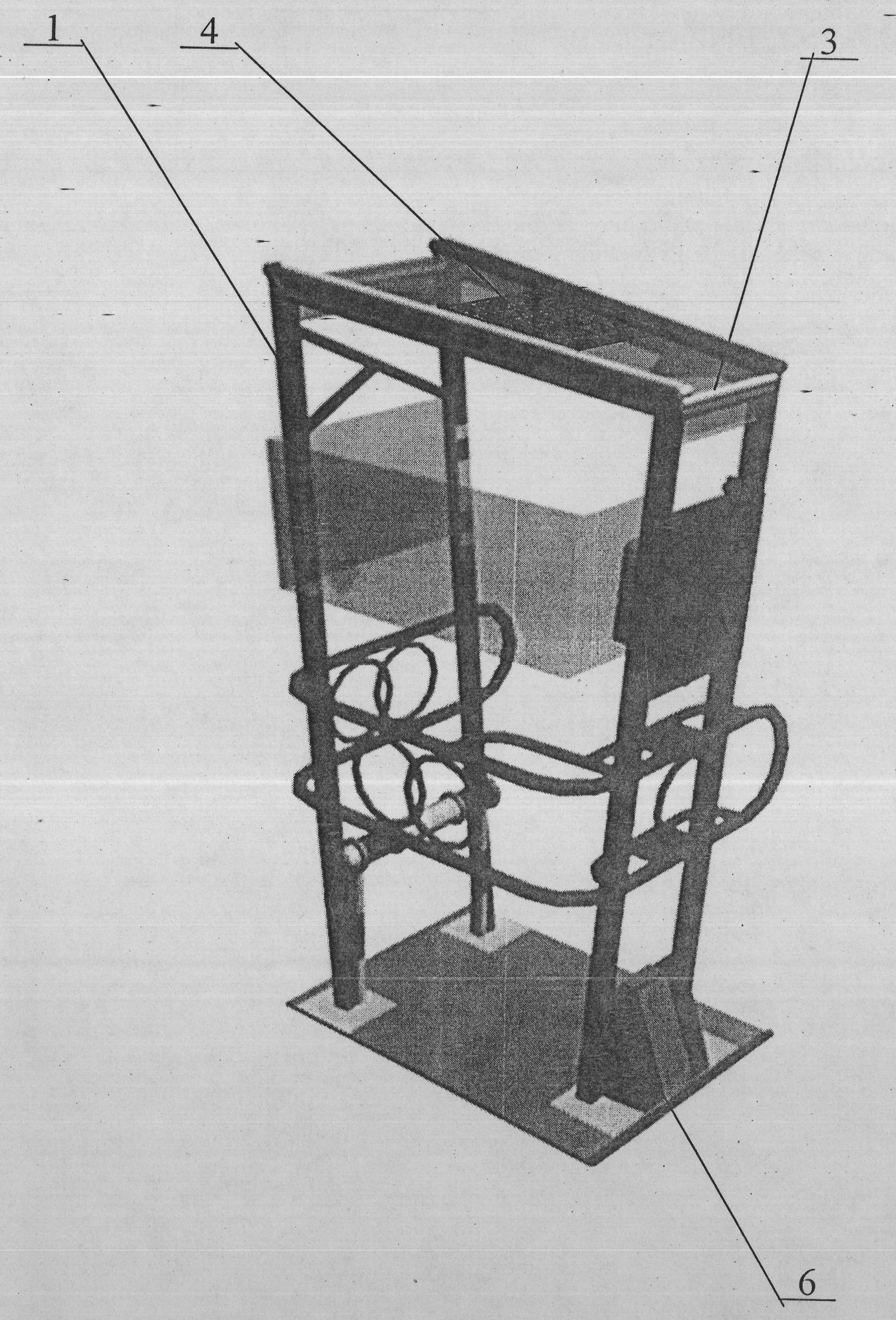

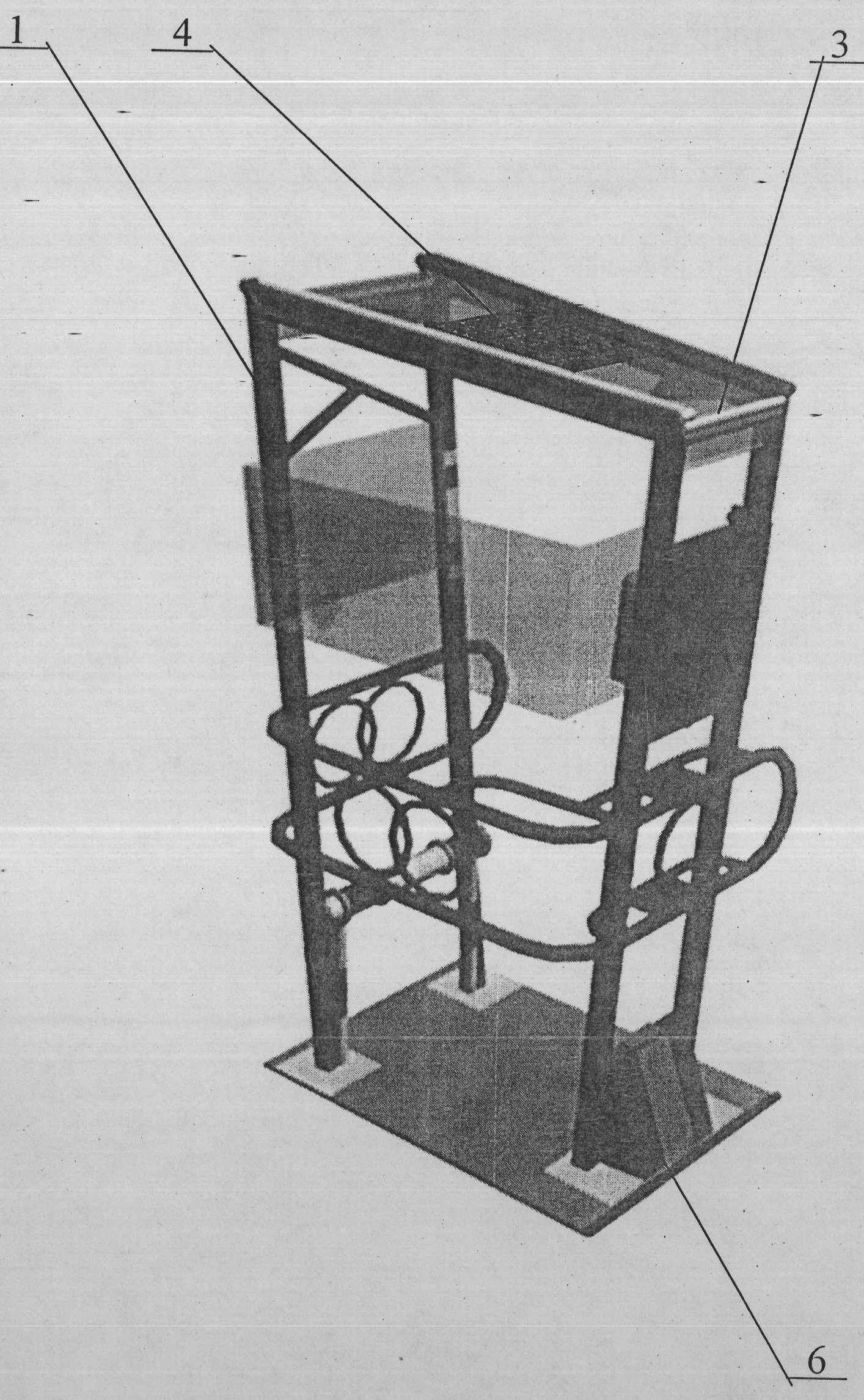

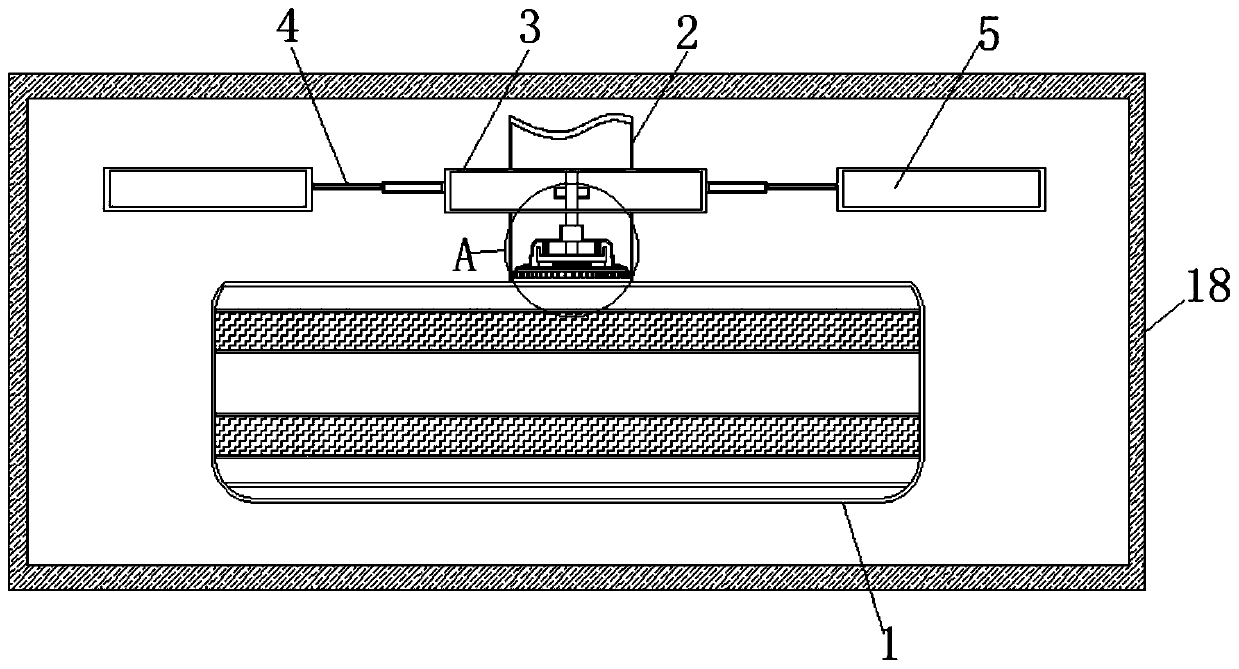

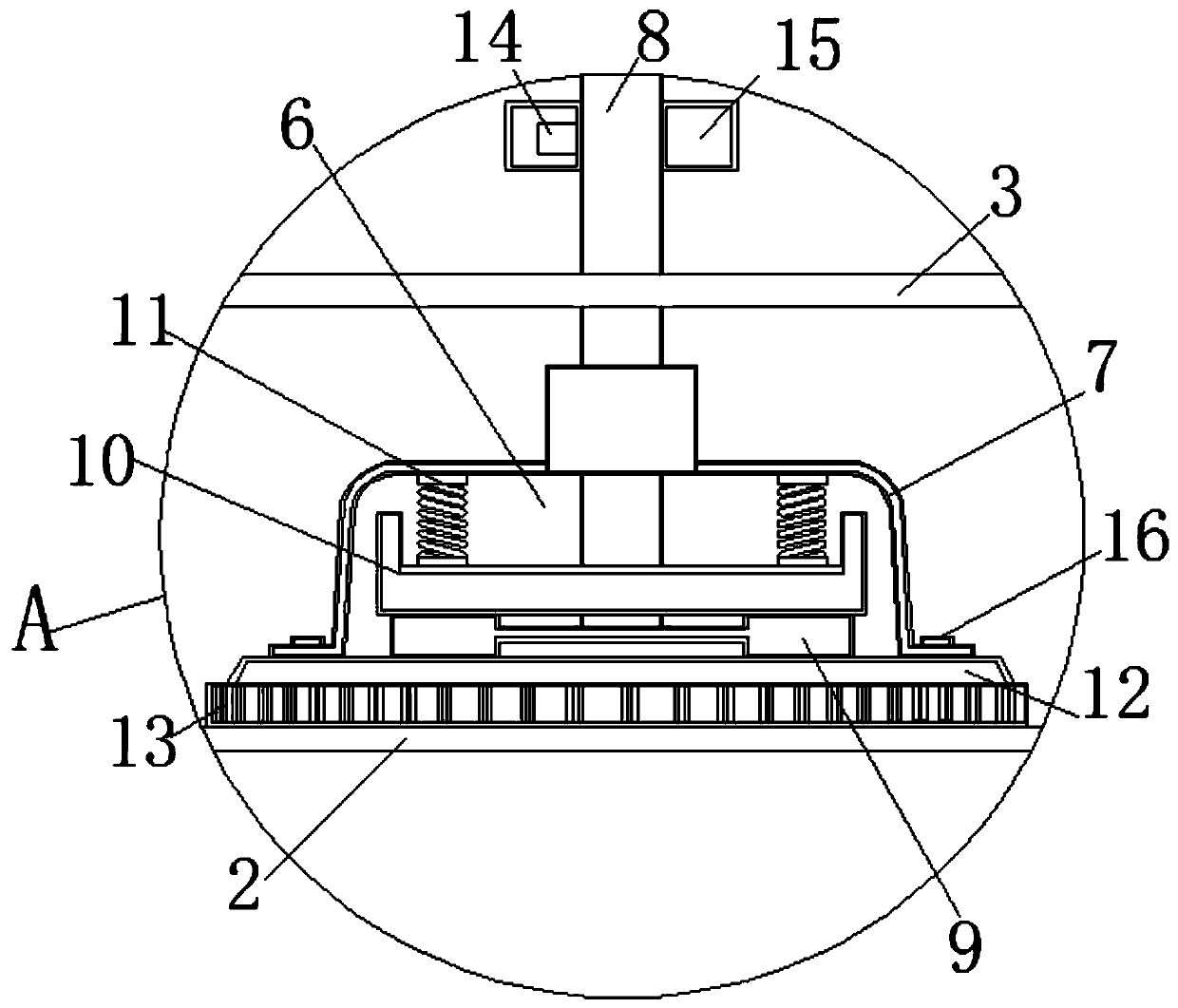

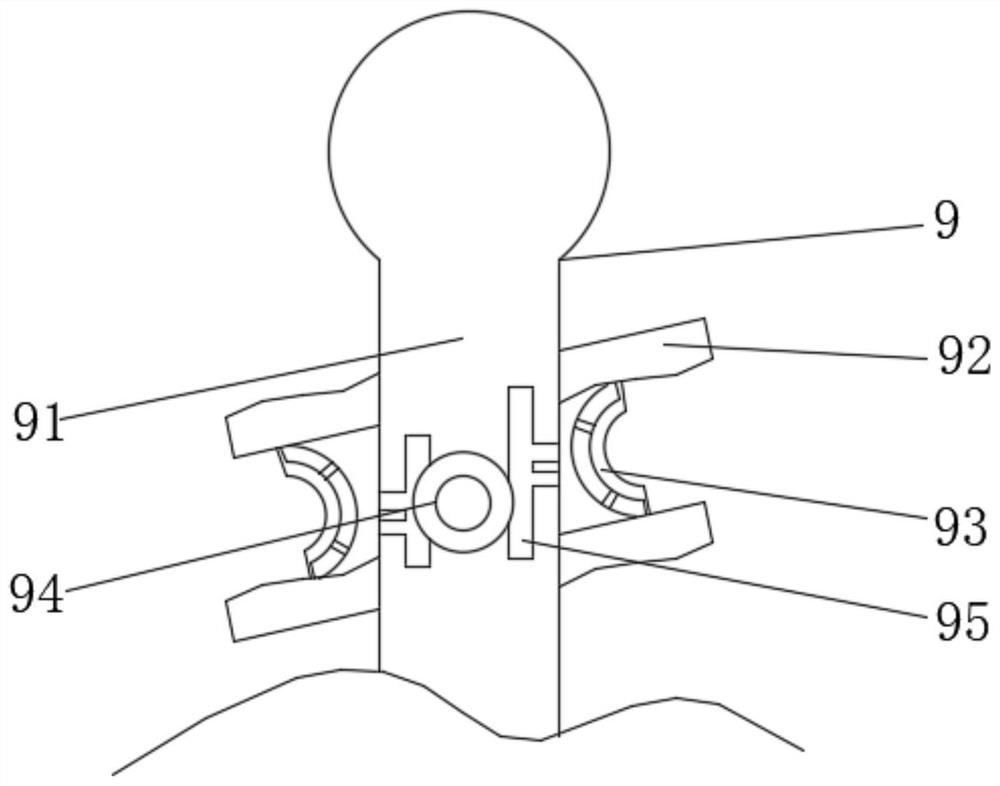

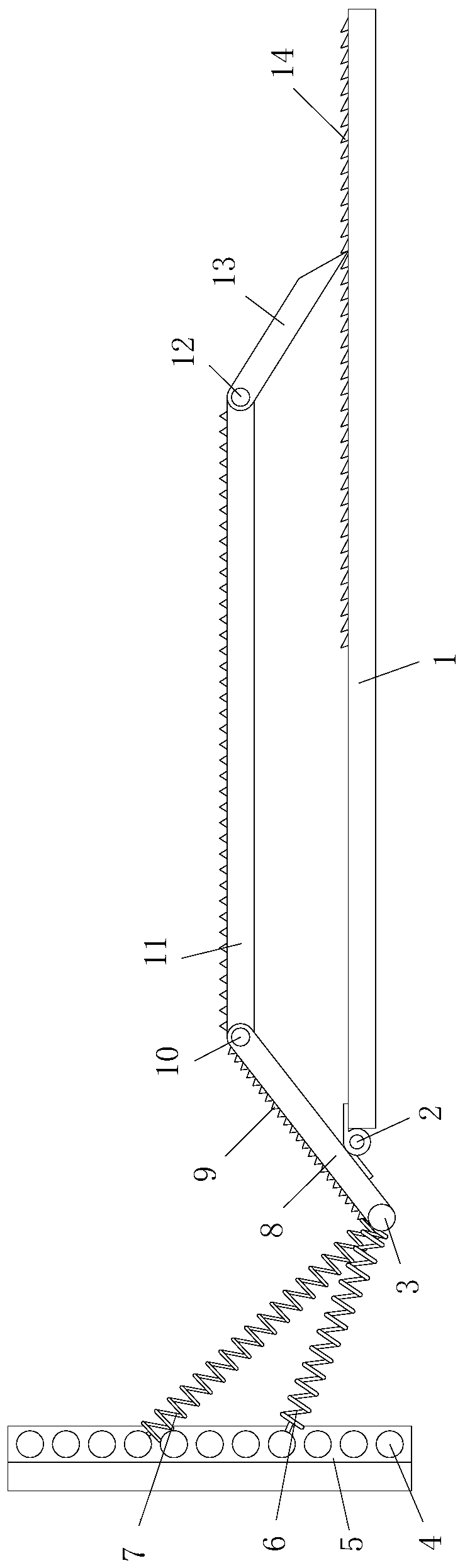

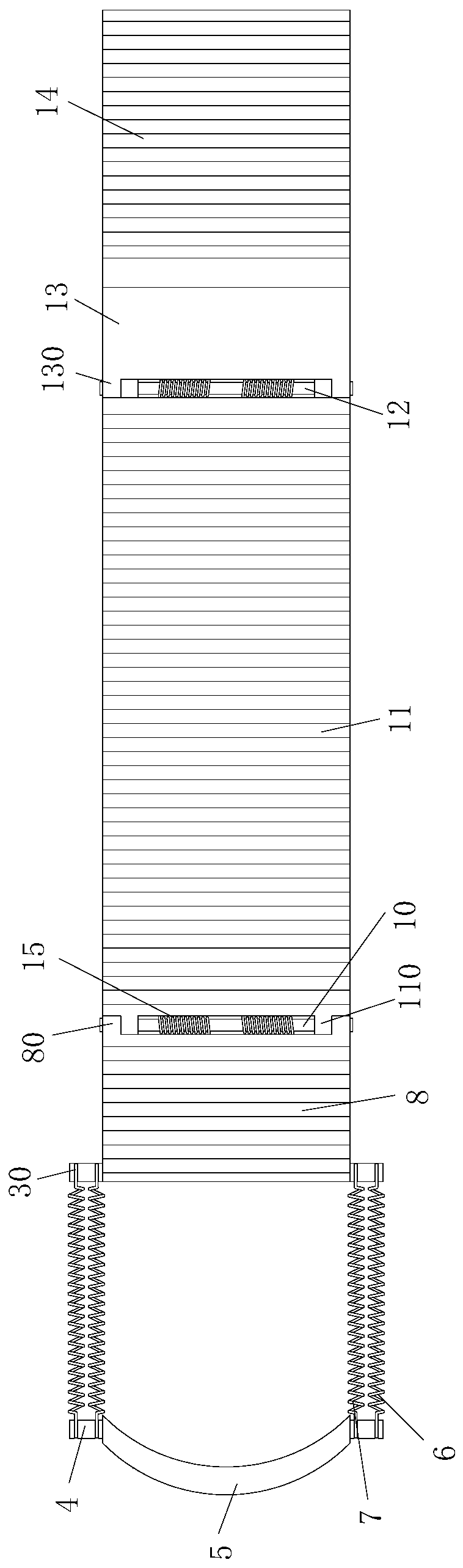

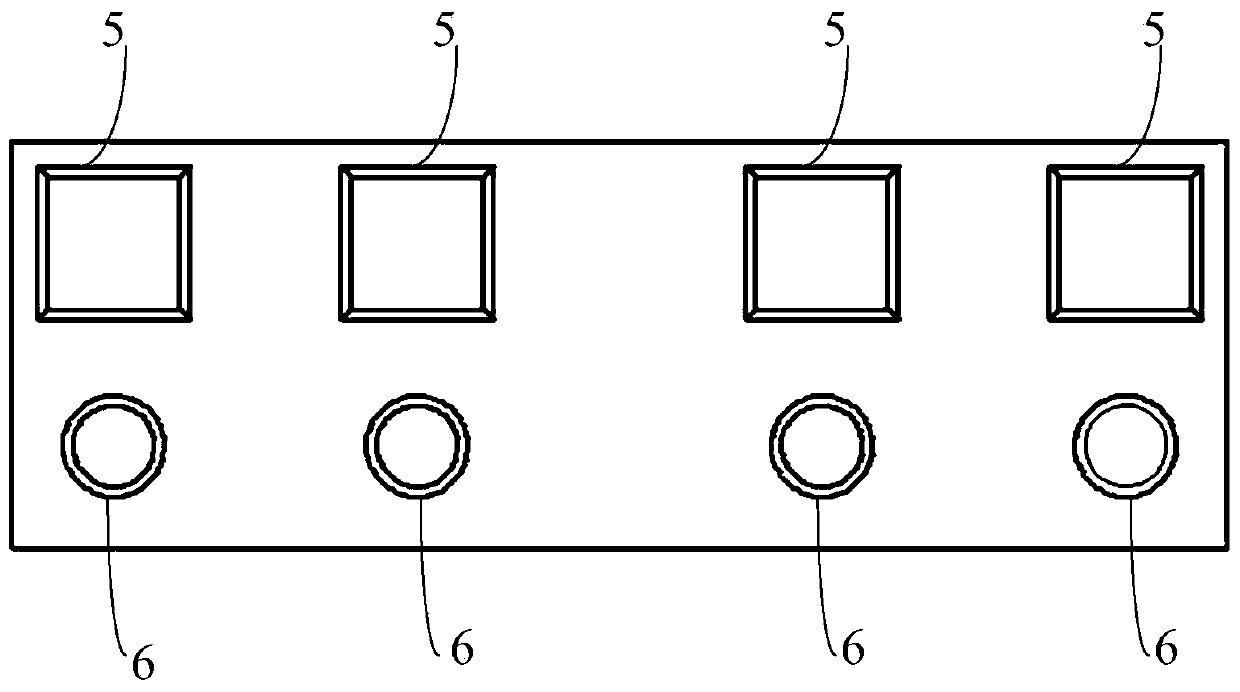

Elevator automatic rescue device

Disclosed is an automatic rescue apparatus for an elevator. The apparatus comprises a base (A), a motor (11), an input shaft (111), a linkage gear (122), a worm gear (12), a worm screw (121), a reduction gear set (13), a bobbin line disk (14), and a steel cable (2). The motor (11) is connected to the input shaft (111). The input shaft (111) is provided with a thread segment (112). The input shaft (111) is meshed with the worm gear (12) by means of the thread segment (112). The worm gear (12) is connected to the worm screw (121). An outer end of the worm screw (121) is provided with the linkage gear (122). The linkage gear (122) is meshed with a bull gear (131) of the reduction gear set (13). One end of the bobbin line disk (14) is provided with a gear (141). The gear (141) is meshed with a pinion gear (132) of the reduction gear set (13). The steel cable (2) is wound on the bobbin line disk (14). The apparatus has a scientific and proper design, is convenient and practical, and can enable an elevator car to be stably lowered to the position of an elevator door of a nearest floor when a power failure or fault occurs, thereby allowing a person taking the elevator to successfully escape.

Owner:XIAMEN A L B T MACHINE EQUIP

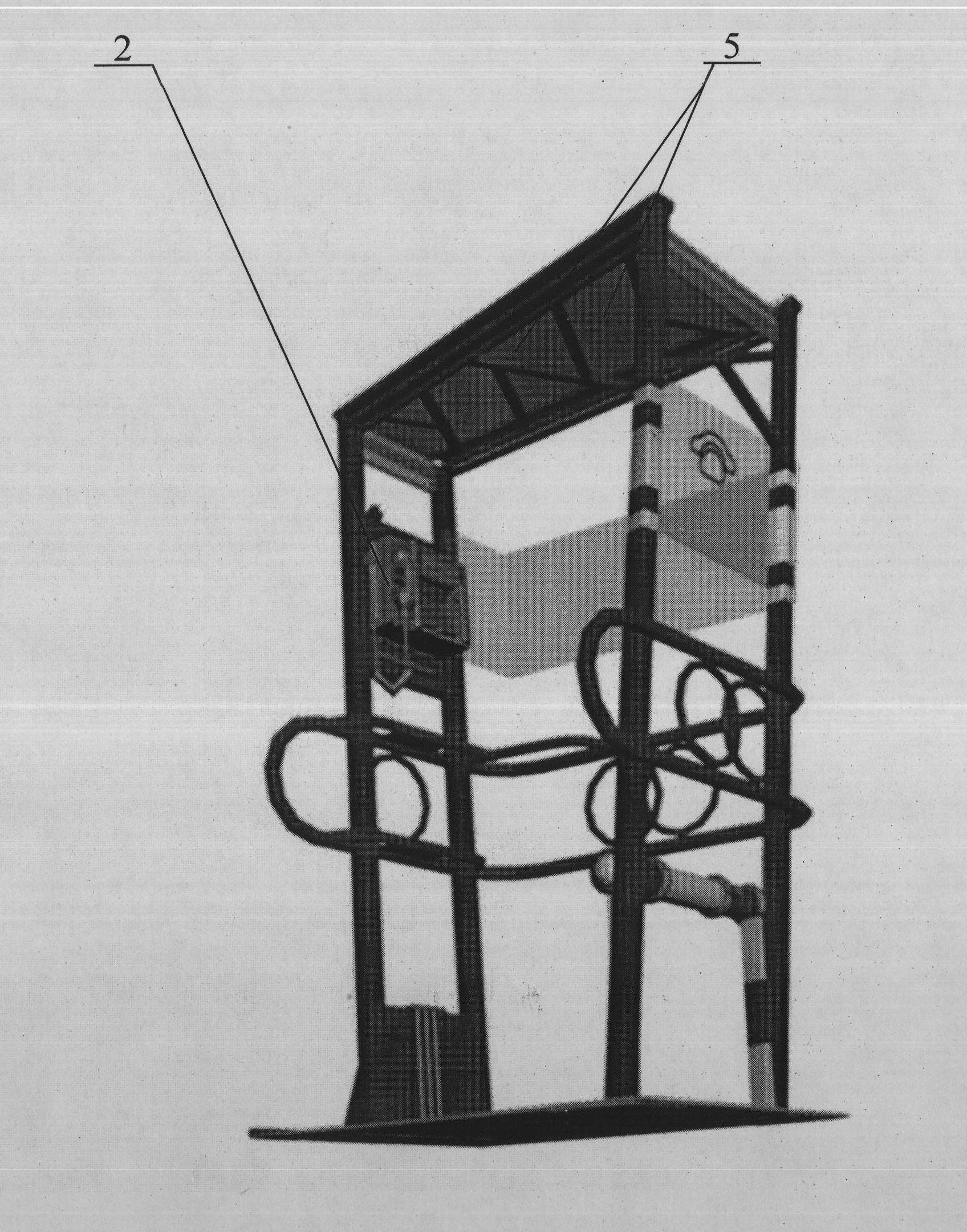

Solar wireless communication telephone booth

InactiveCN102140853AOptimize layoutGet out of troubleEnergy efficient ICTRoof covering using slabs/sheetsTelephone boxLandmark

The invention relates to a telephone booth, which is powered by solar energy to provide a wireless telephone for communication and provide light rays for illumination, is a safe and environment-friendly effective measure for reducing materials, saving energy and reducing emission for public communication, relates to the fields of wireless communication, the public communication, green energy, municipal administration, urban landscape and the like, and is manufactured by modifying a landmark telephone booth.

Owner:高文标

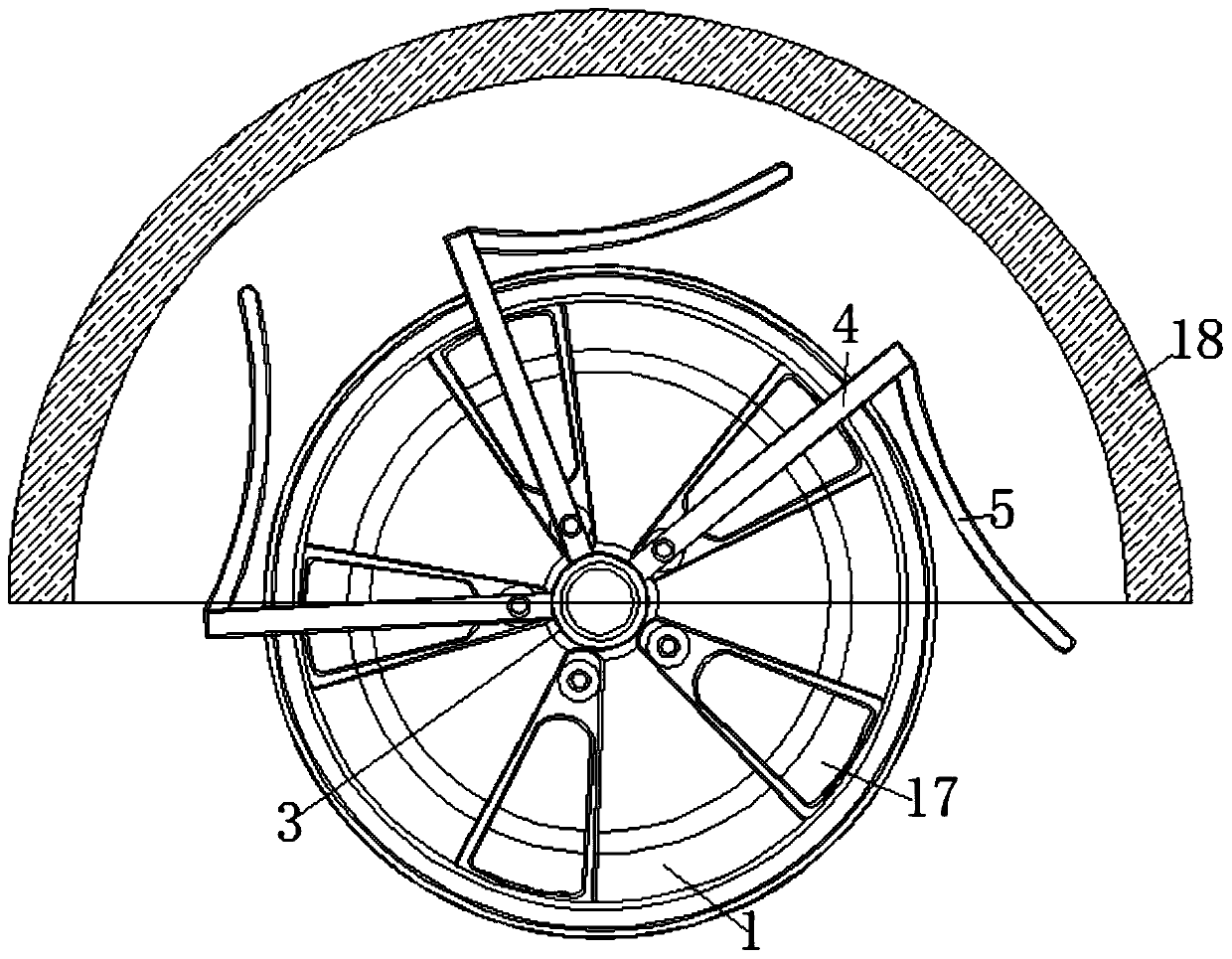

Convenient self-rescue escape device without disassembling automobile tire when automobile tire sinks into pit

InactiveCN111186257ALarge range of motionGet out of troubleAuxillary traction increasing equipmentDrive shaftControl theory

The invention relates to the technical field of vehicle escape, and discloses a convenient self-rescue escape device without disassembling an automobile tire when the automobile tire sinks into a pit.The convenient self-rescue escape device comprises a tire, and a rotating shaft is movably connected to the center of the tire. The surface of the rotating shaft is sleeved with a sleeve. The side surface of the sleeve is fixedly connected with connecting rods. The ends, away from the sleeve, of the connecting rods are fixedly connected with swing plates. An isolator is arranged in the rotating shaft and is positioned between the tire and the sleeve in a sleeving manner. The upper surface of a bracket is sleeved with a driven shaft which sequentially penetrates through the isolator and the sleeve. A friction plate is arranged on the lower portion of a driven disc. When an automobile sinks into a pit, the connecting rods are manually pulled outwards to extrude the driven disc to be in contact with the friction plate, and a limiting block is in contact with a limiting groove to be locked, so that the originally fixed swing plates coaxially rotate along with the rotating shaft, namely the tire, under the combined action of the three swing plates, the movement range of the tire is enlarged, and the tire is supported. The structure can be always arranged on a vehicle after being mounted once.

Owner:欧伟聪

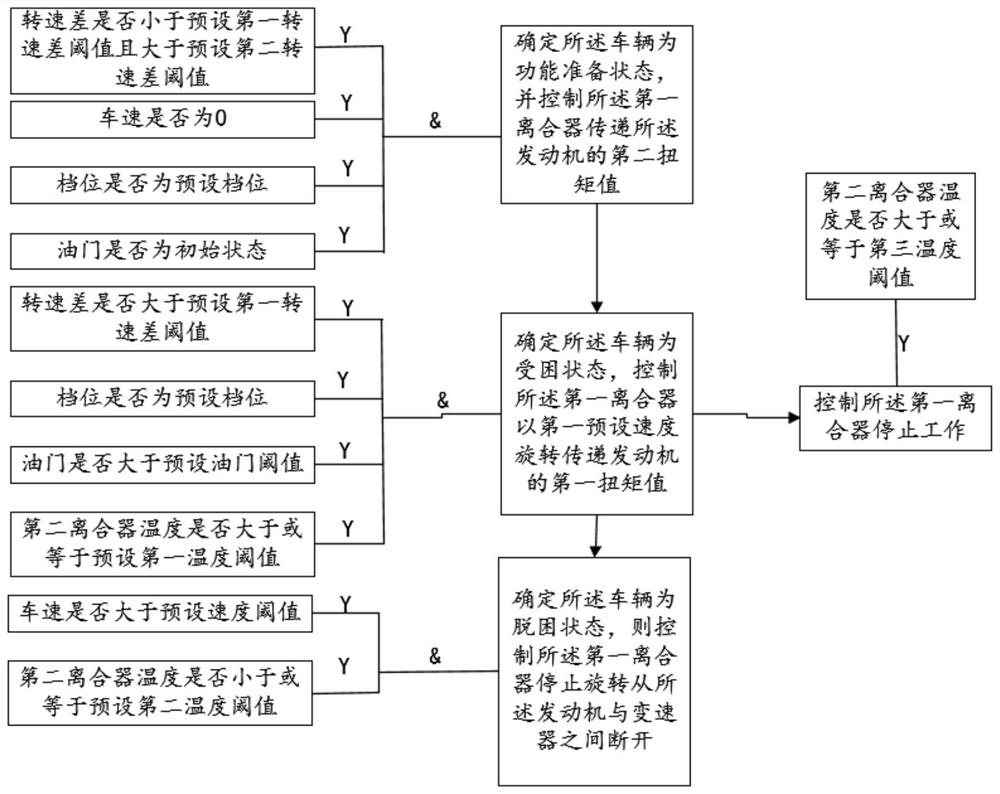

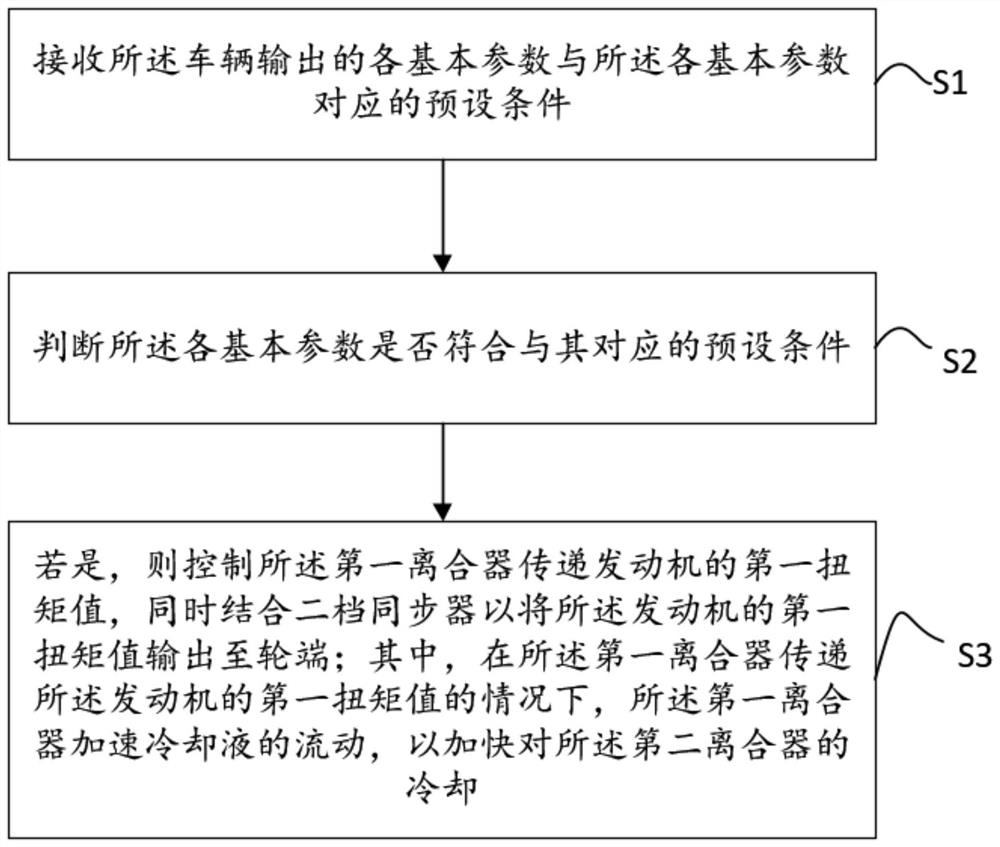

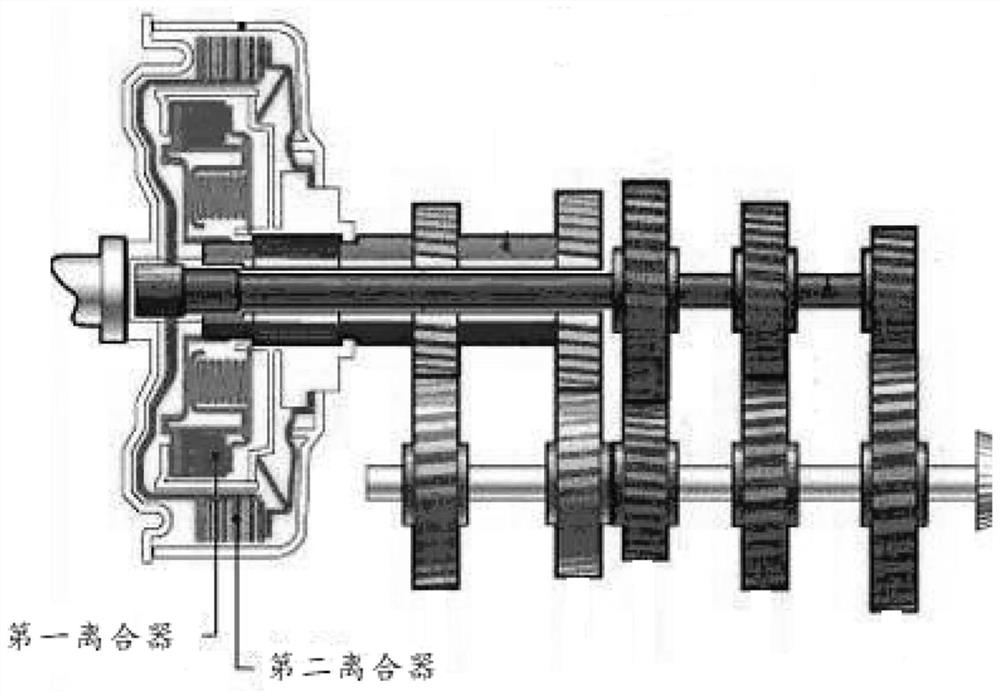

Double-clutch vehicle escape method, device and system and vehicle

PendingCN114321215AHelpAvoid high temperature ablationGearing controlFriction clutchesControl theoryClutch

The embodiment of the invention provides a double-clutch vehicle escape method, device and system and a vehicle, and belongs to the technical field of automobiles. The method is applied to a vehicle, and the vehicle comprises a first clutch and a second clutch. The method comprises the steps that basic parameters output by the vehicle and preset conditions corresponding to the basic parameters are received; judging whether the basic parameters conform to corresponding preset conditions or not; if yes, the first clutch is controlled to transmit a first torque value of an engine, and meanwhile, a second-gear synchronizer is combined to output the first torque value of the engine to a wheel end; and under the condition that the first clutch transmits the first torque value of the engine, the first clutch accelerates flowing of cooling liquid so as to accelerate cooling of the second clutch. By means of the double-clutch vehicle escape method, the second clutch can be cooled on the premise that the vehicle is helped to escape.

Owner:GREAT WALL MOTOR CO LTD

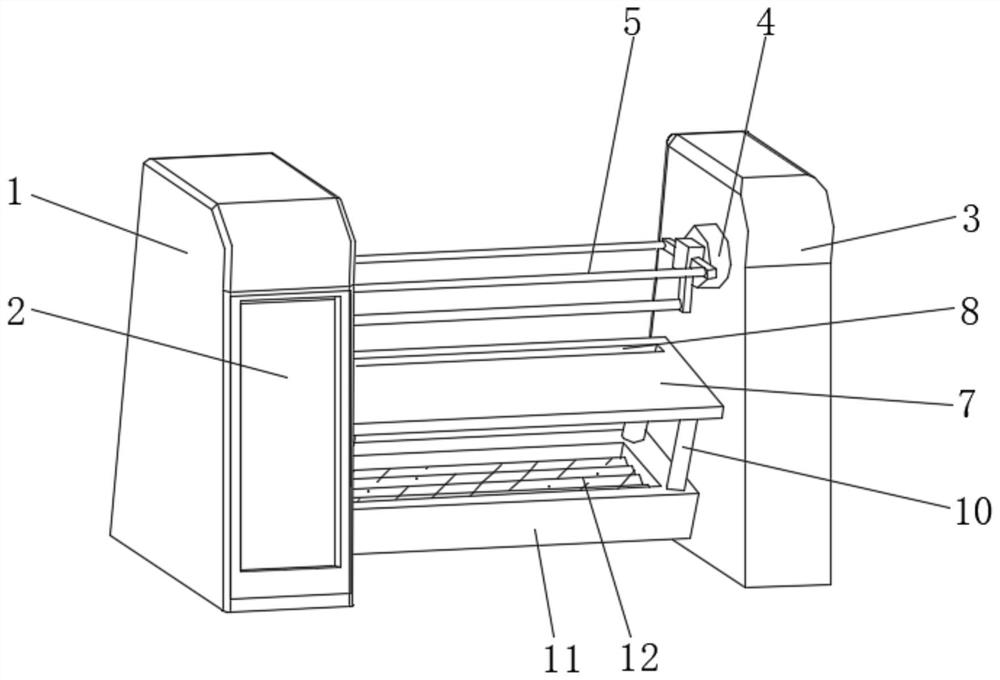

Intelligent textile equipment

InactiveCN112877949AReduce knottingChanged the problem that it is impossible to judge whether combing needs to be done according to the state of the lineTextile treatment rollersLiquid/gas/vapor yarns/filaments treatmentOperation safetySmart manufacturing

The invention discloses intelligent textile equipment, and relates to the technical field of intelligent manufacturing equipment. The intelligent textile equipment comprises a workbench and a connecting table; an operation display screen is fixedly mounted right in front of the workbench; a fixing seat is fixedly connected to the left side of the outer surface of the connecting table; a rotating bearing is rotatably connected to the outer surface of the fixing seat; and first winding shafts are uniformly and fixedly connected to the outer surface of the rotating bearing. Through cooperative use of a fixing mechanism, a carding mechanism and a flushing mechanism, the textile threads are actively carded and flushed during cyclic operation of winding, flushing and carding of the textile threads through a first winding shaft and a second winding shaft, manual flushing and thread arranging work is replaced, and the problem that the machine cannot judge whether carding is needed or not according to the state of the threads is solved, the workload of workers is reduced, the phenomenon that the spinning threads are knotted is reduced, and the operation safety of the machine is improved.

Owner:李羊

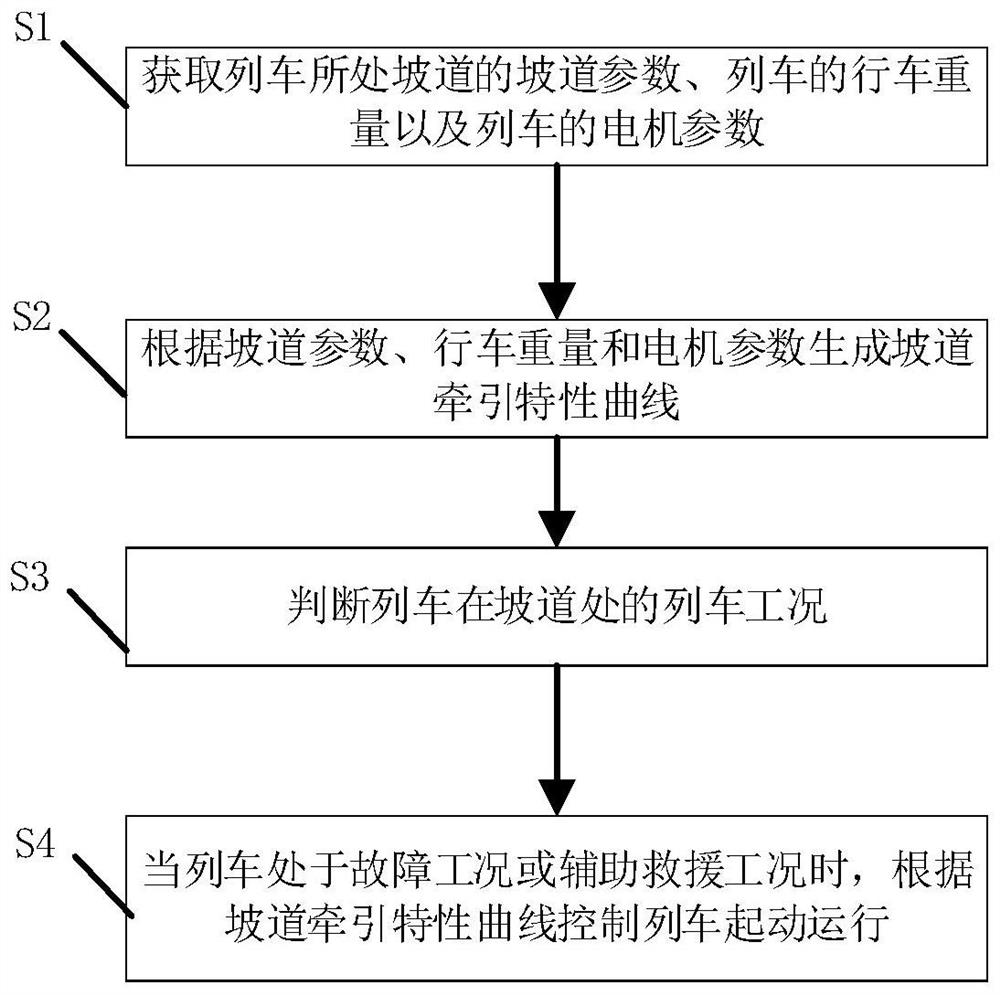

Control method and device for suspension type rail train and storage medium

The invention provides a control method and device for a suspension type rail train and a storage medium. The control method for the suspension type rail train comprises the steps that ramp parameters of a ramp where the train is located, the running weight of the train and motor parameters of the train are obtained; generating a ramp traction characteristic curve according to the ramp parameters, the driving weight and the motor parameters; the train working condition of the train at the ramp is judged; and when the train is in the fault working condition or the auxiliary rescue working condition, the train is controlled to start and operate according to the ramp traction characteristic curve. The method has the beneficial effect that the suspended rail train can be smoothly started at the ramp conveniently.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

Retractable Main Drive Sealing Device for Large Diameter TBM

The invention discloses a telescopic main drive sealing device of a larger-diameter shield machine, wherein a sealing clamp ring is fixedly arranged at the lower part of a shield body, an air bag seal is arranged at the lower part of the sealing clamp ring, a sealing caulking ring is fixed on the sealing clamp ring, lip seals are nested at the lower part of the sealing caulking ring, the lip seals are closely contacted with a driving box, and the lip seals are positioned in front of the air bag seal; a sealing pressure ring is fixed at the front side of the sealing clamp ring, a snap ring is fixed at the upper part of the sealing pressure ring, the upper part of the snap ring is in clamp connection with the lower part of the shield body, a slag removal plate is fixed at the lower part of the sealing pressure ring by a pressing plate, and the lower part of the slag removal plate is arranged on the driving box. The upper part of the telescopic main drive sealing device is clamped at the lower part of the shield body, and the residue soil or mud in a soil chamber can be sealed in a main drive stretching process by means of enabling the lip seals or air bag seal to be connected with the driving box; furthermore, a cutter is more conveniently replaced under a condition of atmospheric pressure or belt pressure, so that a cutter head of the shield machine is bailed out in case of emergency, and the shield machine is further enabled to carry out shield construction smoothly.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

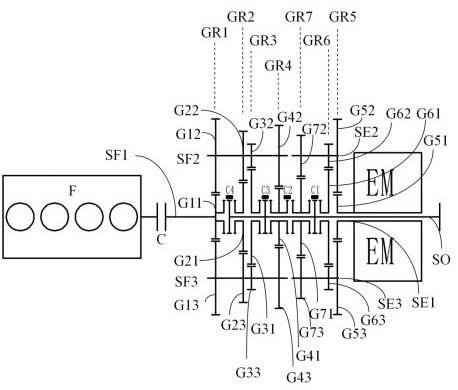

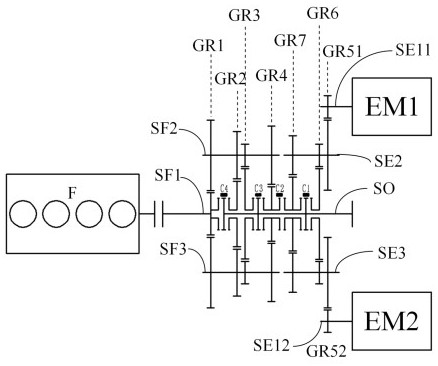

Hybrid power system

PendingCN114801689AGet out of troubleAchieve runnabilityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric machineryControl theory

According to the hybrid power system, the hybrid power system in which an engine is combined with a single motor or the engine is combined with multiple motors is adopted, the engine working mode of as many as 9 gears can be achieved, the high-gear high vehicle speed can be achieved, the low-gear large-load requirement can be met, meanwhile, the speed ratio stage difference is small, and the engine can continuously work in a high-efficiency area. Under the condition that the electric quantity of the vehicle is low or zero, the vehicle can still run out of the trap and run in heavy load; a more efficient parking power generation function can be achieved, that is, the engine is stabilized in the optimal efficient area during parking, the motor is driven to generate power through a proper transmission ratio, and meanwhile the motor can be just stabilized in the optimal efficient area.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

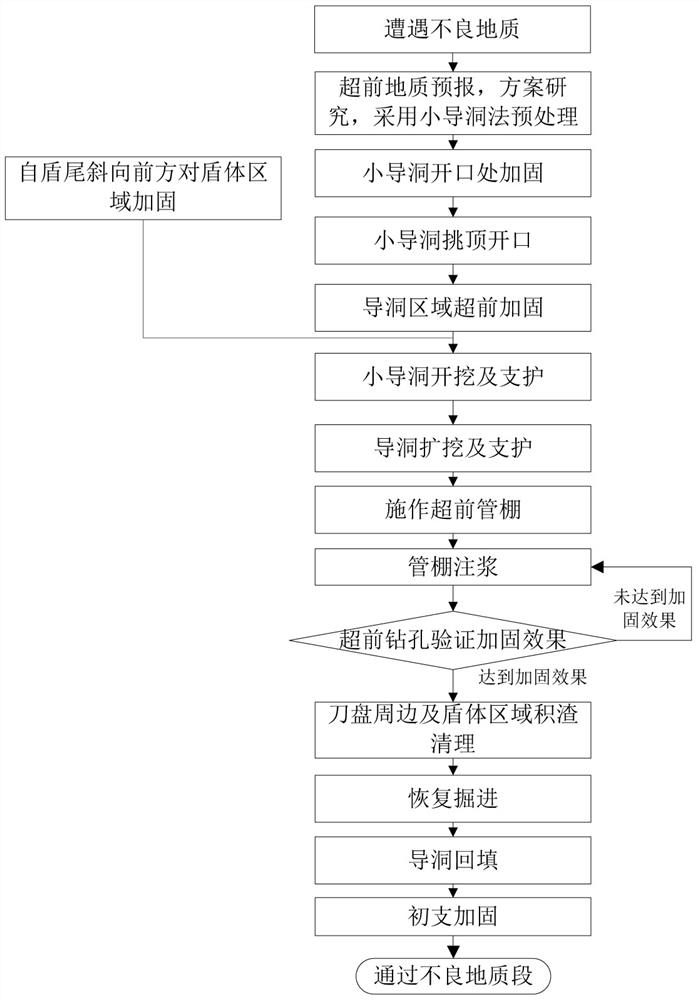

Methods of getting stuck and improving geology in tbm construction tunnel

ActiveCN111997639BGet out of troubleLow rotational resistanceUnderground chambersTunnel liningEnvironmental energySocial benefits

The invention discloses a method for getting rid of stuck machines and reinforcing and improving geological conditions in bad geological sections of TBM construction tunnels, aiming to solve the technical problems in the prior art that poor geological conditions cause difficult excavation and easy stuck machines in open TBM construction. The invention carries out small guide tunnel construction from above the TBM shield, performs long-distance horizontal reinforcement on the unfavorable geology in front of the tunnel face, and cleans up slag accumulation around the cutter head and shield body. The method of the present invention can effectively reduce the risk of getting stuck and get out of trouble, and can realize the horizontal advance reinforcement of the surrounding rock in front of the TBM. At the same time, the shield is released using the construction space of the pipe shed, so that the TBM gets out of trouble after the machine gets stuck; the treatment period is short, and the cost input is low. Construction safety; and broaden the application prospect of TBM construction method, make TBM still can continue to construct after adopting the related method of the present invention under the unfavorable geological tunnel environment, have promoted the further development of tunnel cause, have obtained good social benefit; The construction techniques and methods are all conventional methods, and the machines, tools and materials are used rationally, which saves resource input; at the same time, the poor geological pre-reinforcement using the small pilot tunnel method has less construction waste materials, and the environmental and energy-saving benefits are remarkable.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Stepless speed regulation hydraulic drive system of screw conveyor for super large diameter shield tunneling machine

ActiveCN106762889BGuaranteed stabilitySimple structureFluid-pressure actuator safetyServomotor componentsHydraulic pumpFuel tank

The invention relates to a stepless speed-regulating hydraulic drive system for a screw conveyor for super-large-diameter shield tunneling, which includes a fuel tank, a hydraulic pump group, a speed-regulating hydraulic circuit, a reducer, a hydraulic motor group, and a control unit. There are oil separation and oil collection valve modules, flushing control valve modules, control pumps, and sensor modules. The hydraulic pump group includes hydraulic pump 1 and hydraulic pump 2. Both hydraulic pump 1 and hydraulic pump 2 are equipped with displacement adjustment mechanisms , the hydraulic motor group includes hydraulic motor 1 and hydraulic motor 2 that operate synchronously, and hydraulic motor 1 and hydraulic motor 2 are both provided with an output variable adjustment mechanism, and the displacement adjustment mechanism and output variable adjustment mechanism are all communicated with the control unit . The present invention can satisfy the hydraulic drive system with high torque and high rotational speed, realize the functions of variable speed adjustment, overload protection, and bidirectional rotation, is safe and reliable, and effectively guarantees the stability of the operation performance of the screw conveyor.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

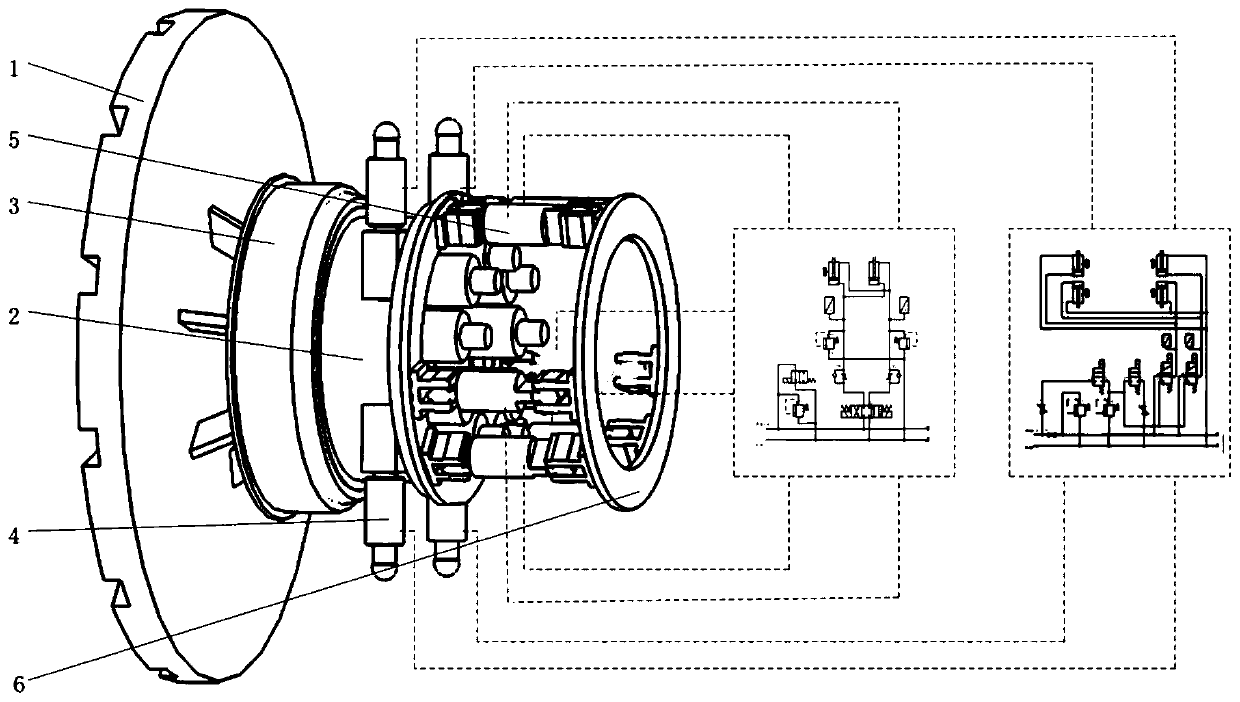

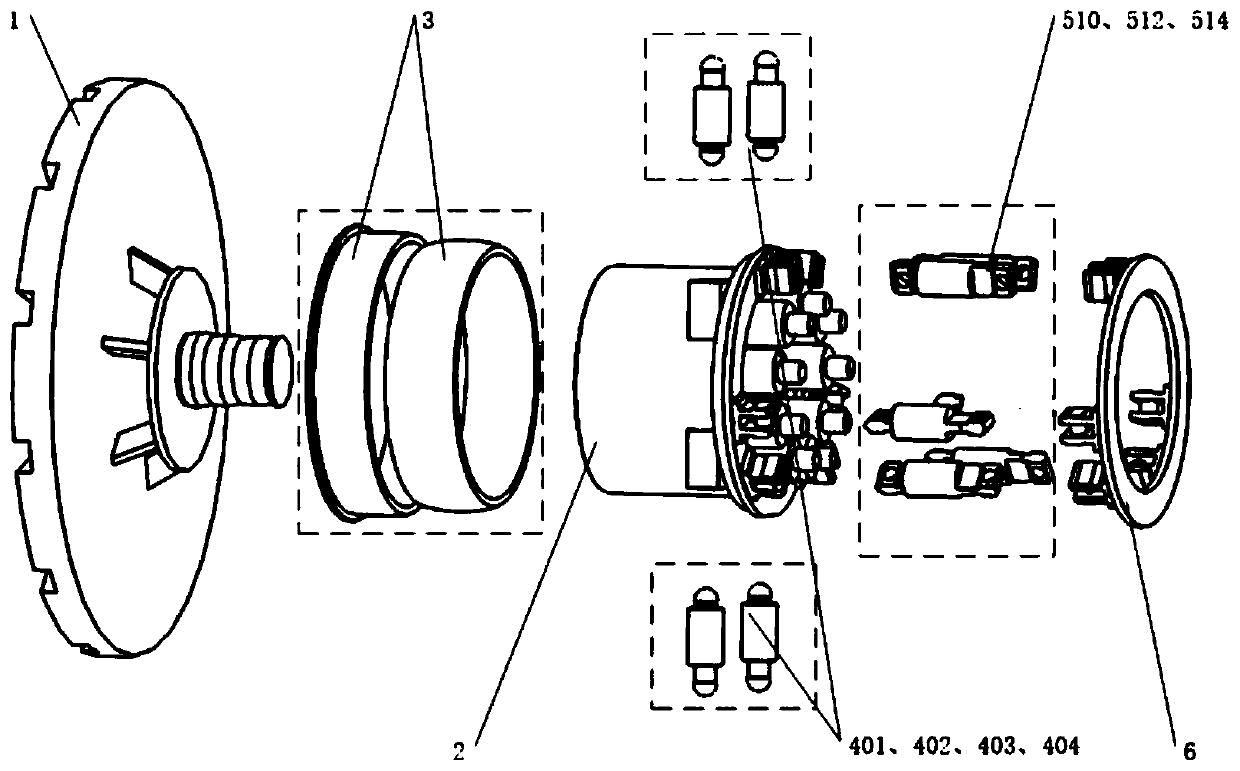

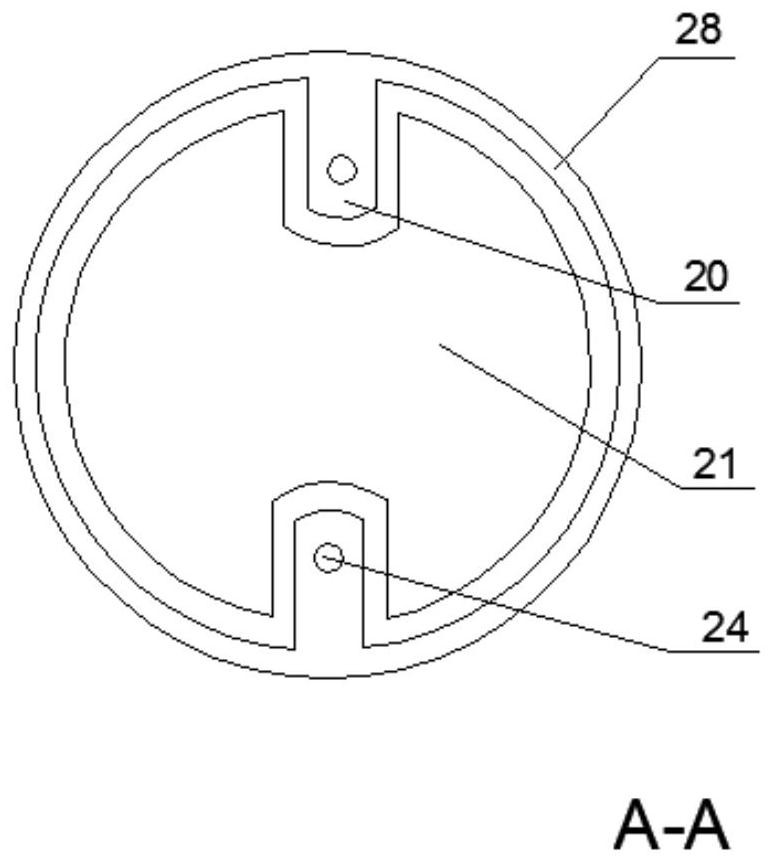

An active shield machine telescopic swing system

ActiveCN110284891BImprove motion stabilityImprove adaptabilityTunnelsBall bearingClassical mechanics

The invention relates to an active shield tunneling machine telescopic oscillating system, which comprisesa cutterhead, a cutterhead driving module, a ball bearing, an anti-kink system, a telescopic oscillating subsystem, and acapstan. The tail end of the cutterhead is connected to the inside of the cutterhead driving module; the cutterhead driving module is of a movable structure; the inner ring of the ball bearing is fixed to the cutterhead driving module, and the outer ring is fixedly connected with a shield body; one ends of four torque oil cylinders in the anti-kink system are fixed toa corner of the cutterhead driving module, the other endsare fixed to the shield body, an internal hydraulic control component is placed at the rear of the shield body and connected with the torque oil cylinders through hydraulic pipelines; the telescopic oscillating subsystem comprises six telescopic oscillating oil cylinders which are fixed between the cutterhead driving module and the capstan, and the capstan is fixedly connected with the shield body. The active shield tunneling machine telescopic oscillating system is used for cutterhead tool change and shield body escape, and efficiency and safety of shield constructioncan be effectively improved.

Owner:ZHEJIANG UNIV

car trap

InactiveCN107719334BImprove card setting effectHigh hardnessVehicle manoeuvring devicesTrappingEngineering

The invention discloses an automobile trapping lifting apparatus which structurally comprises a bottom plate, a hinge, a hang rod, fixing rods, an arc-shaped plate, a first spring, a second spring, afront plate, convex strips, a first positioning pin, a support plate, a second positioning pin, a fixing plate, barrier strips and torsion springs. The bottom plate is arranged below the support plateand is parallel to the support plate, four lugs are arranged on two sides of the support plate, the center line of the support plate is used as the symmetric axis of the lugs, through holes are formed in the lugs, connecting blocks are arranged at two ends of a side of the front plate, via holes are formed in the connecting blocks, and concentric circles are formed by the through holes of the lugs and the via holes of the connecting blocks. The automobile trapping lifting apparatus has the advantages that the fixing plate clamped at the barrier strips can be repositioned, accordingly, the inclination of the front plate can be adjusted, and the automobile trapping lifting apparatus can be flexibly used; wheels can be pushed towards the front plate by the arc-shaped plate under the effectsof elastic force of first springs and second springs, accordingly, frictional force of the front plate and the wheels can be increased, the wheels can be quickly released from dilemmas when rotating,and good trapping lifting effects can be realized.

Owner:浙江智尊保科技股份有限公司

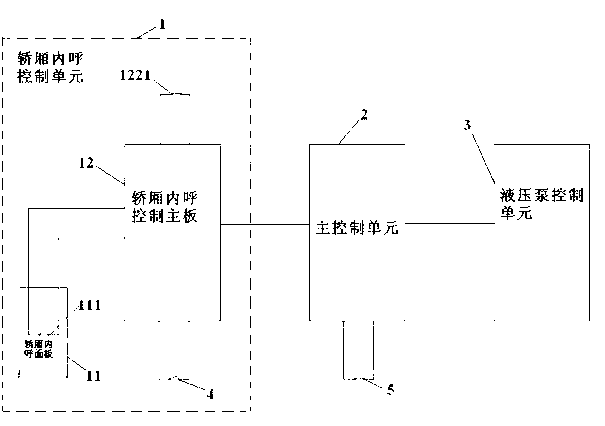

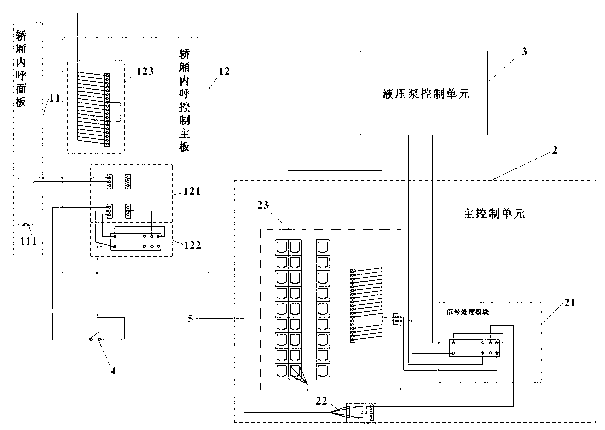

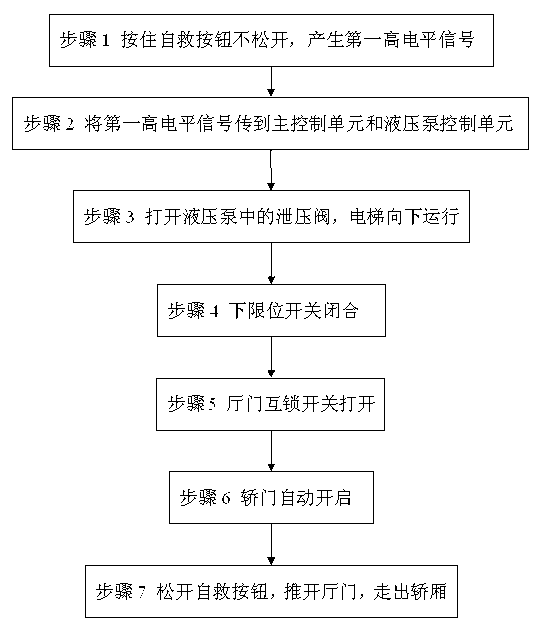

Self-rescue system and method for hydraulic elevator

The invention provides a self-rescue system for a hydraulic elevator. The self-rescue system comprises a car call control unit, a main control unit, a hydraulic pump control unit and a direct-current (DC) power supply for supplying electricity to the self-rescue system for the hydraulic elevator, wherein, the car call control unit is connected with the main control unit through a cable; the car call control unit comprises a car call panel and a car call control main board; the car call panel is equipped with a self-rescue switch, and the self-rescue switch is connected with the car call control main board through a circuit; and the main control unit is connected with the hydraulic pump control unit through a circuit. The self-rescue system and method for the hydraulic elevator have the beneficial effects that passengers can get out of a car so as to achieve the self-rescue purpose by taking simple and easy measures, and the rescue cost is lowered.

Owner:蒂升家用电梯(上海)有限公司

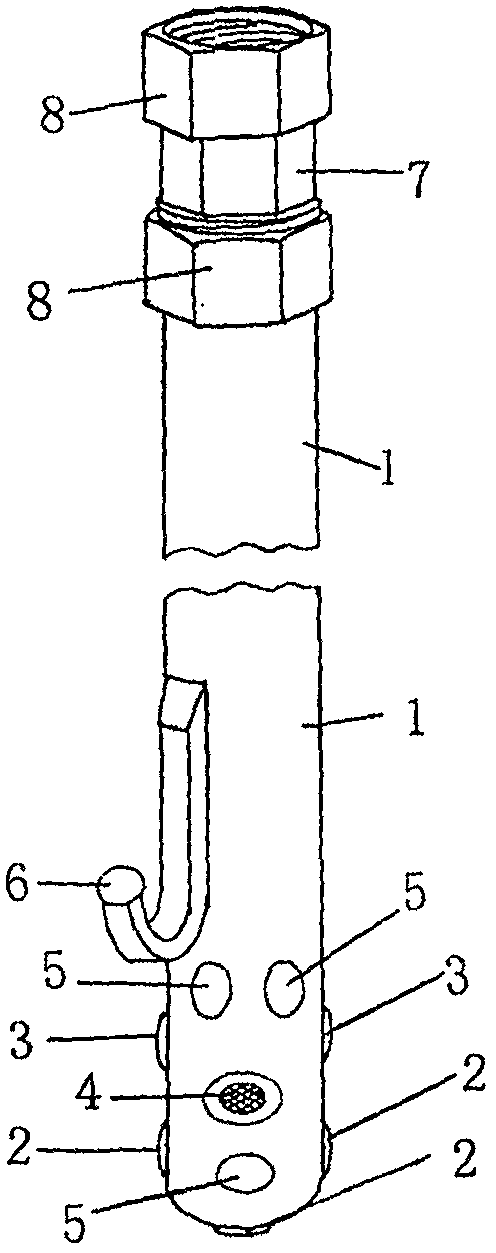

Pipe body device for deep well detection and rescue

PendingCN110917523AGet out of troubleCan't solveBreathing protectionMechanical engineeringClassical mechanics

The invention provides a pipe body device for deep well detection and rescue. The device can be connected with a lengthened pipe body, a camera for omni-directional adjustment and use is arranged at abottom end, and a plurality of LED pipe lamps and a plurality of air holes are arranged. The bottom end of the pipe body is also provided with a talkback device and a hook convenient for rescue. Thedevice integrates multiple settings such as camera shooting, illumination, talkback, the air holes and the hook, and can be directly inserted into a deep well to seek trapped people and master an internal current situation during usage so that rescue personnel can better rescue the trapped people in complex environments such as a deep well, deep water, collapsed buildings and the like.

Owner:鞠开宇

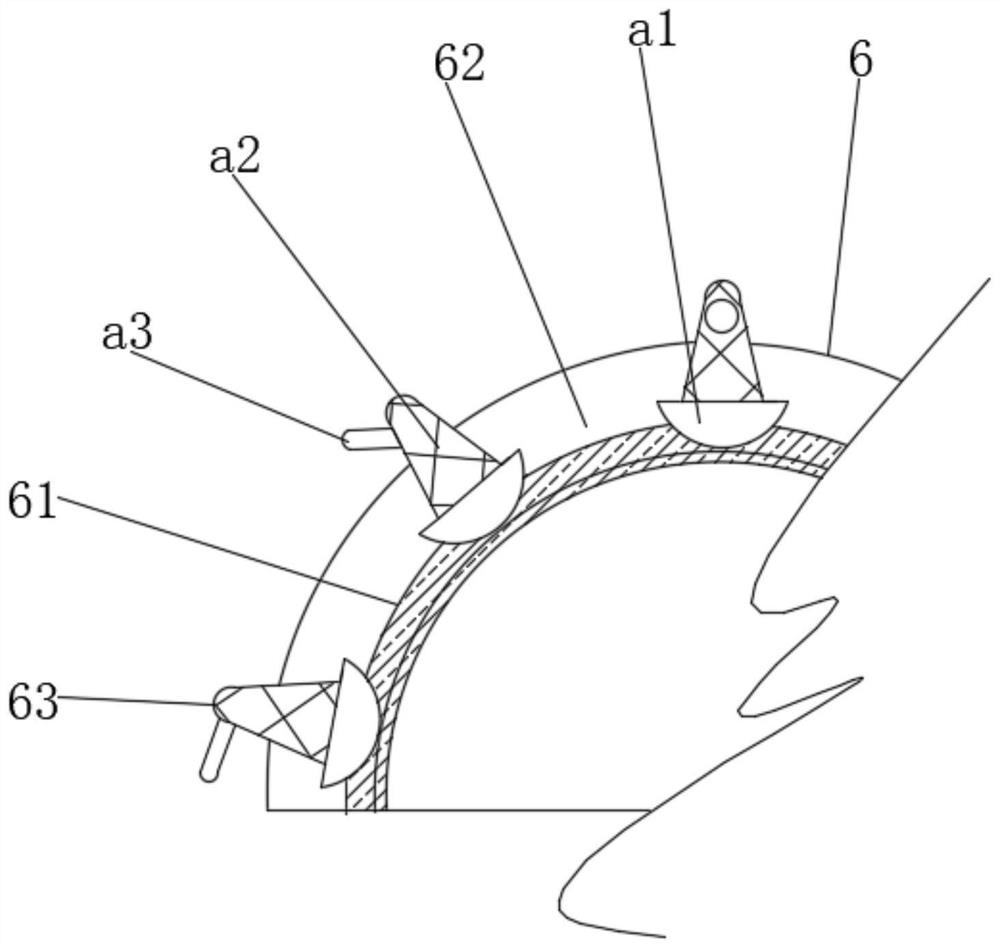

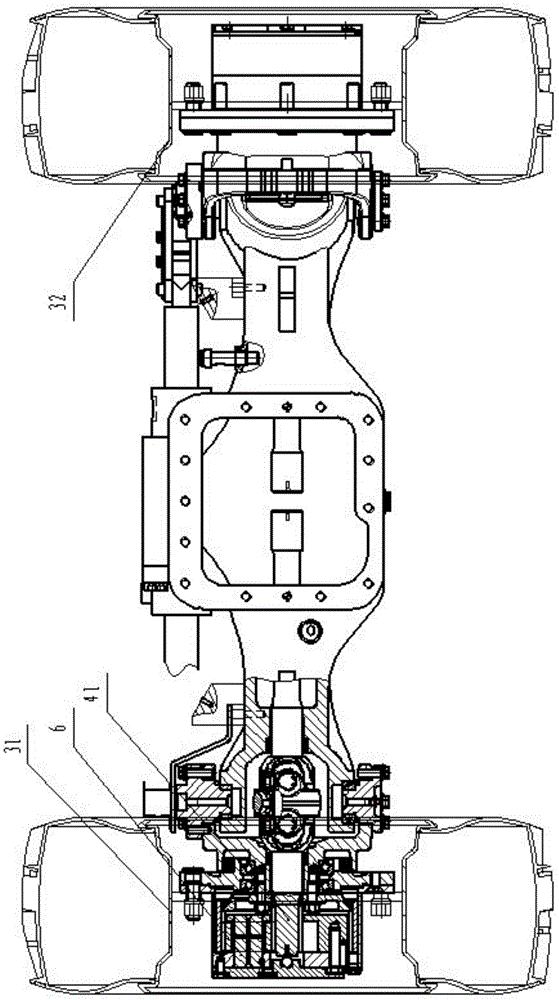

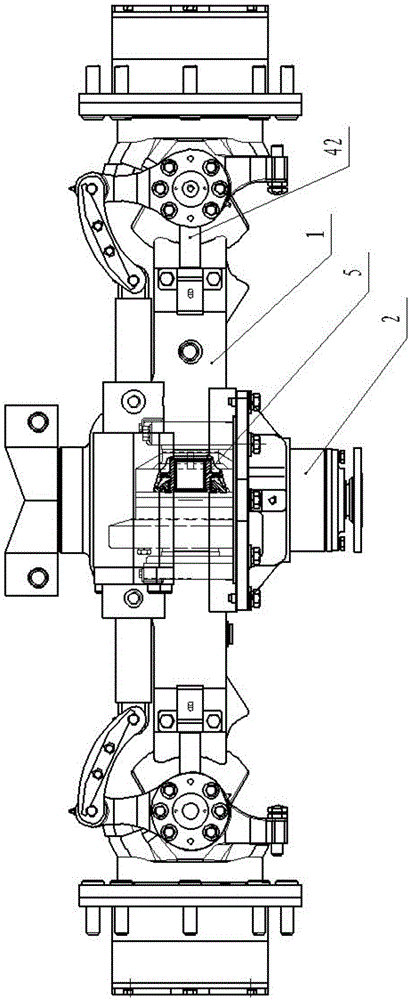

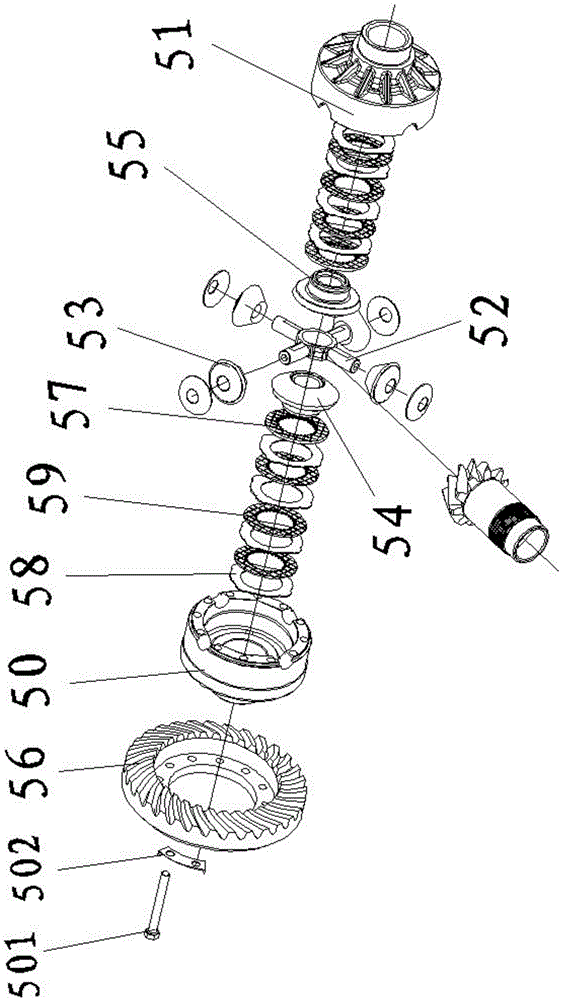

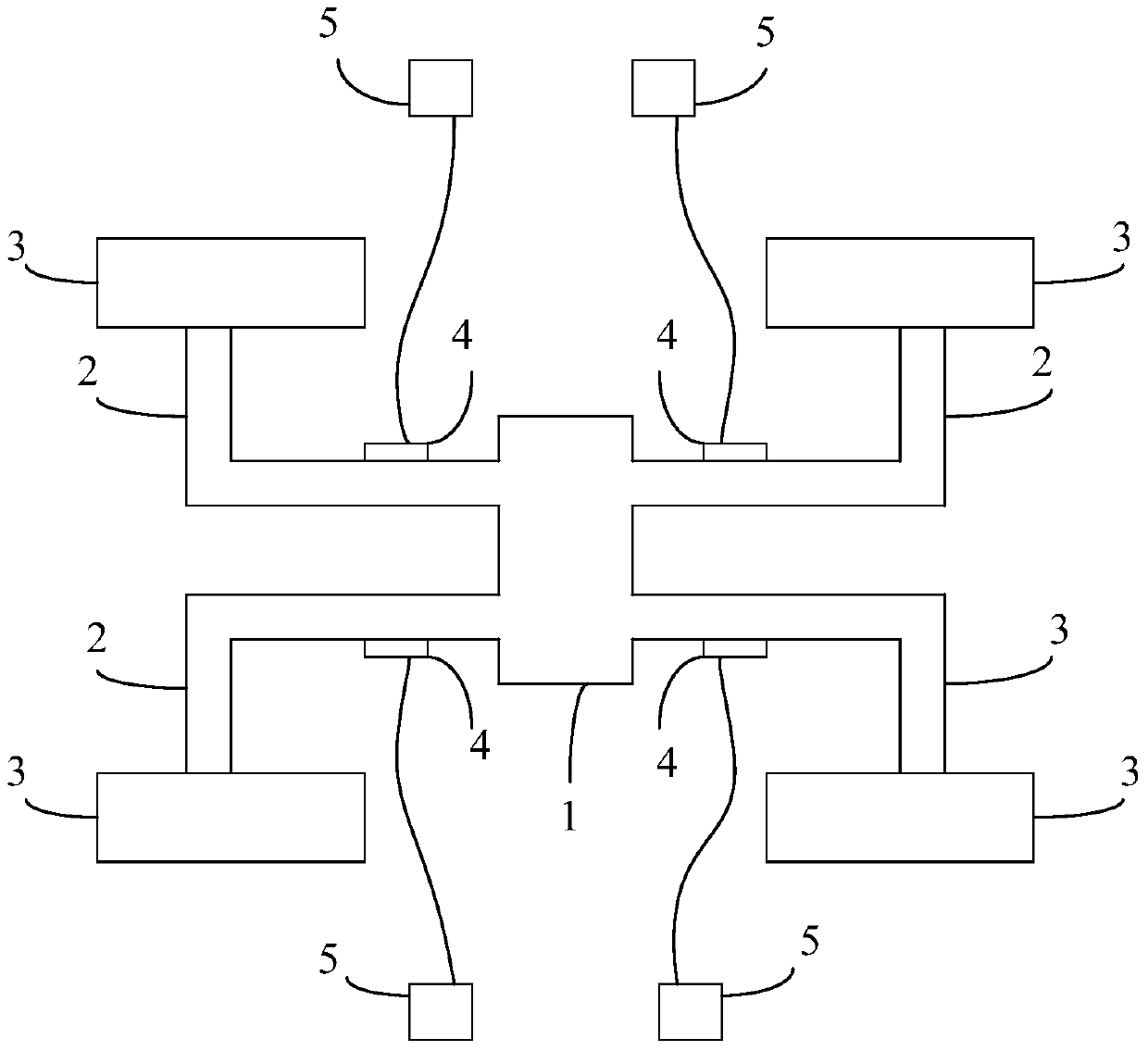

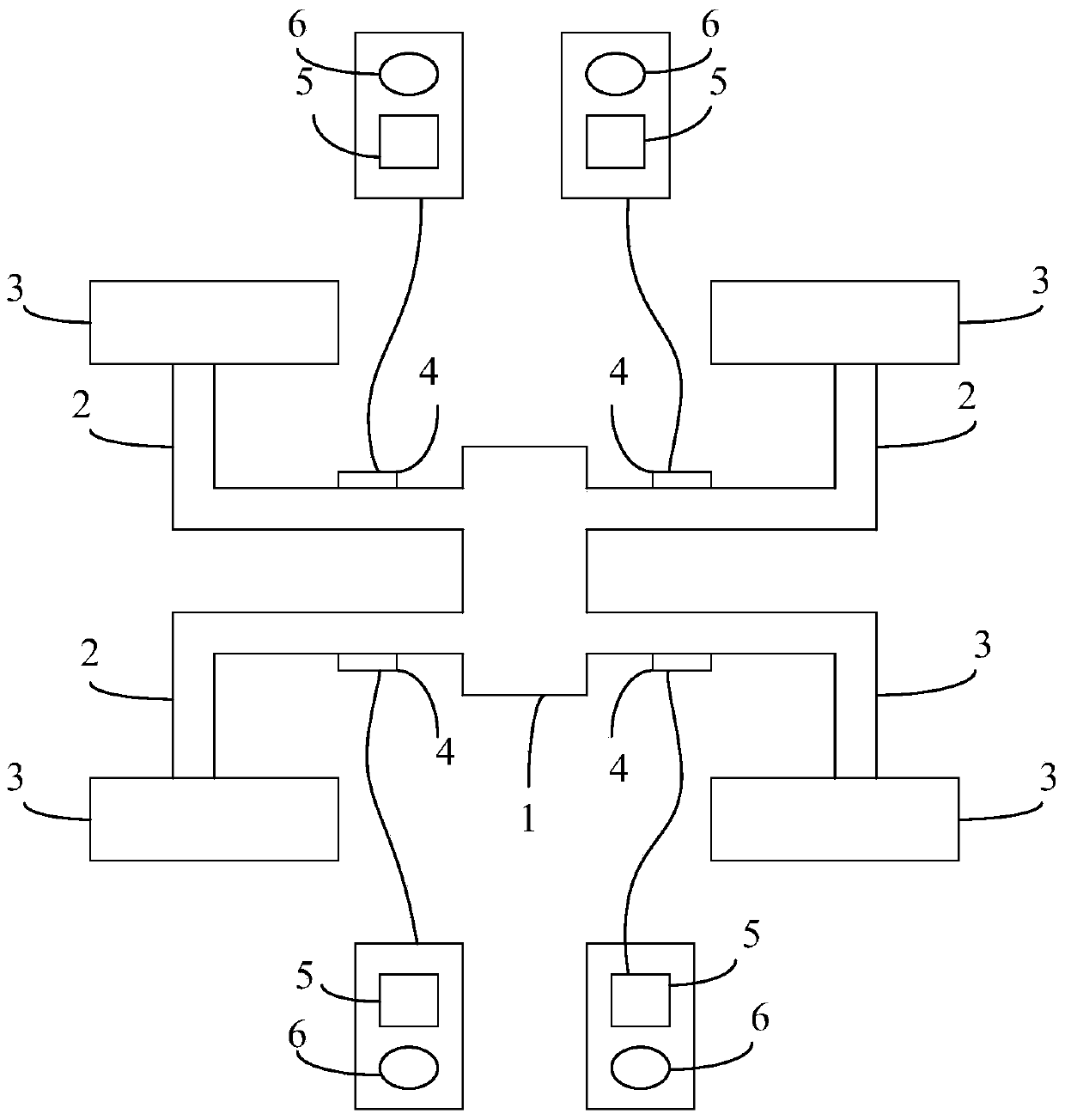

Rear steering drive axle assembly of forklift

The invention relates to a rear steering drive axle mechanism and discloses a rear steering drive axle assembly of a forklift, comprising an axle body assembly (1). The axle body assembly (1) is fitted with a main reducer (2), two sides of the axle body assembly (1) are provided respectively with left and right axle shaft assemblies (41 and 42) connected with left and right hubs (31 and 32), a differential lock (5) is fitted inside the main reducer (1), and the differential lock (5) is connected with the left and right axle shaft assemblies (41 and 42) through splines; both ends of the left and right axle shaft assemblies (41 and 42) are connected with wheel reduction mechanisms (6) through splines. Four drive performance of the forklift is implemented through the rear steering axle that is provided with drive, off-road performance, driving capacity and gradeability of the forklift are improved, and work efficiency is finally improved; the differential lock with a slide limiting function is disposed in the main reducer, the axle shaft of the side wheel that slides is locked to achieve freeing when the tires of the forklift get trapped in sandy land and mire.

Owner:ZHEJIANG MAXIMAL FORKELEVATOR

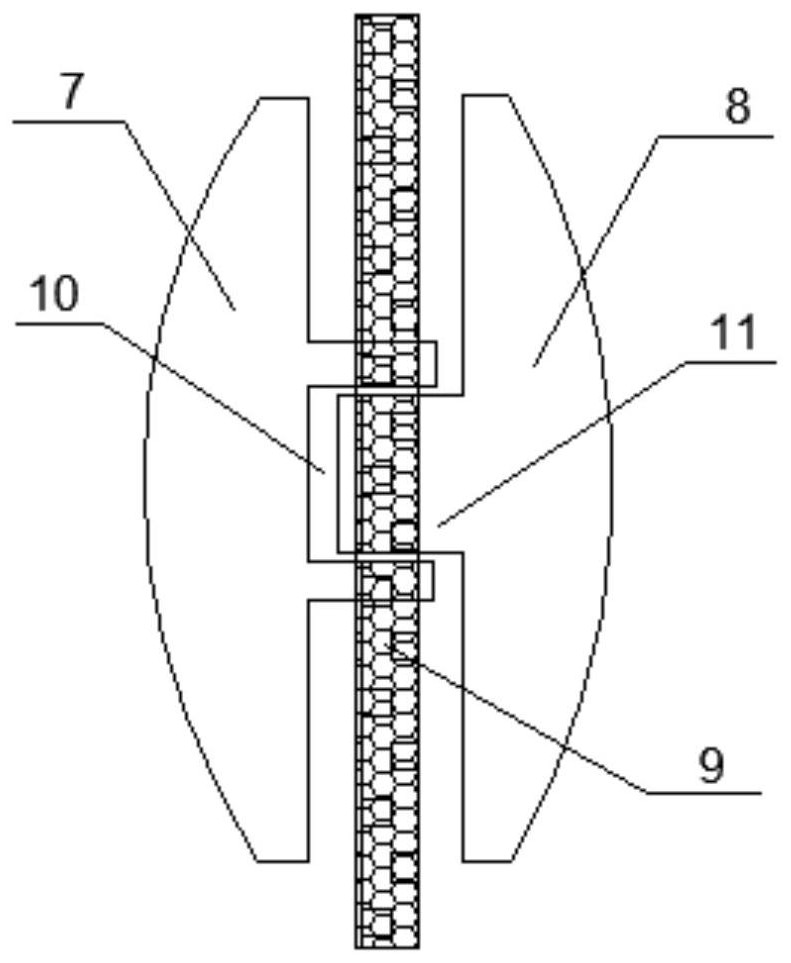

Anti-hanging bottom fishing tackle

ActiveCN106172280BAvoid incomeRelieve stressFish-hooksOther angling devicesZoologyMechanical engineering

Owner:贾贤杰

Popping sound detection method and device

Owner:UNIVERSAL GLOBAL TECH KUNSHAN

A vehicle escape system and vehicle

ActiveCN105235666BAvoid getting deeperReduce manufacturing costFluid braking transmissionOutput deviceVehicle brake

Owner:BAIC GRP ORV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com