Escape device of bentonite improving shield tunneling machine and construction method thereof

A construction method and technology of shield machine, which are used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of increased binding force of the cutter head, complicated geological conditions, and the inability of the cutter head to rotate, so as to reduce the binding force and reduce the binding force of the cutter head. Good economic benefits and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention. Apparently, the described embodiments are only illustrative partial implementations of the present invention, and are not intended to limit the scope of the present invention. , any equivalent changes and modifications made by those skilled in the art without departing from the concepts and principles of the present invention shall fall within the protection scope of the present invention.

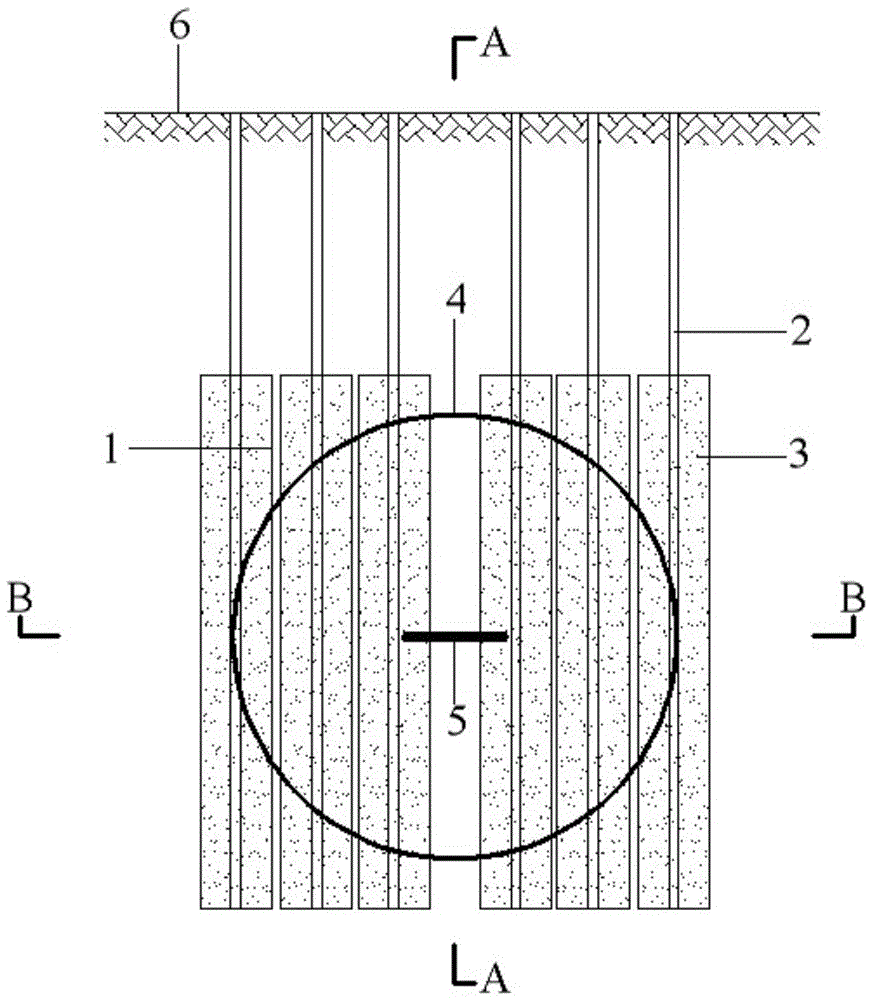

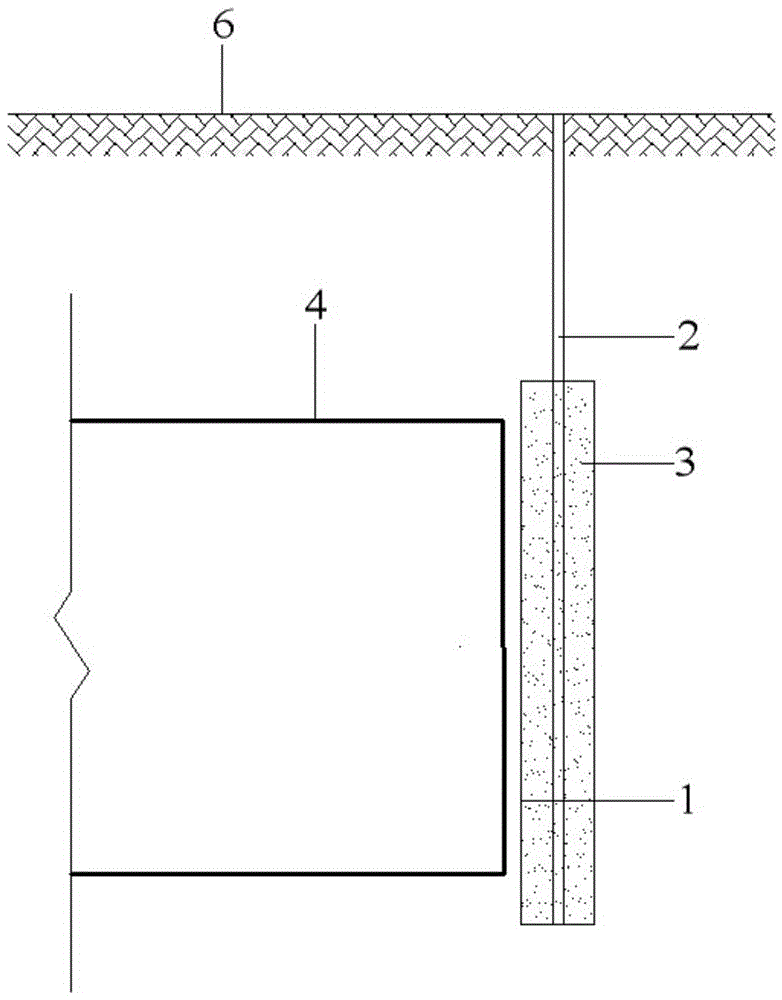

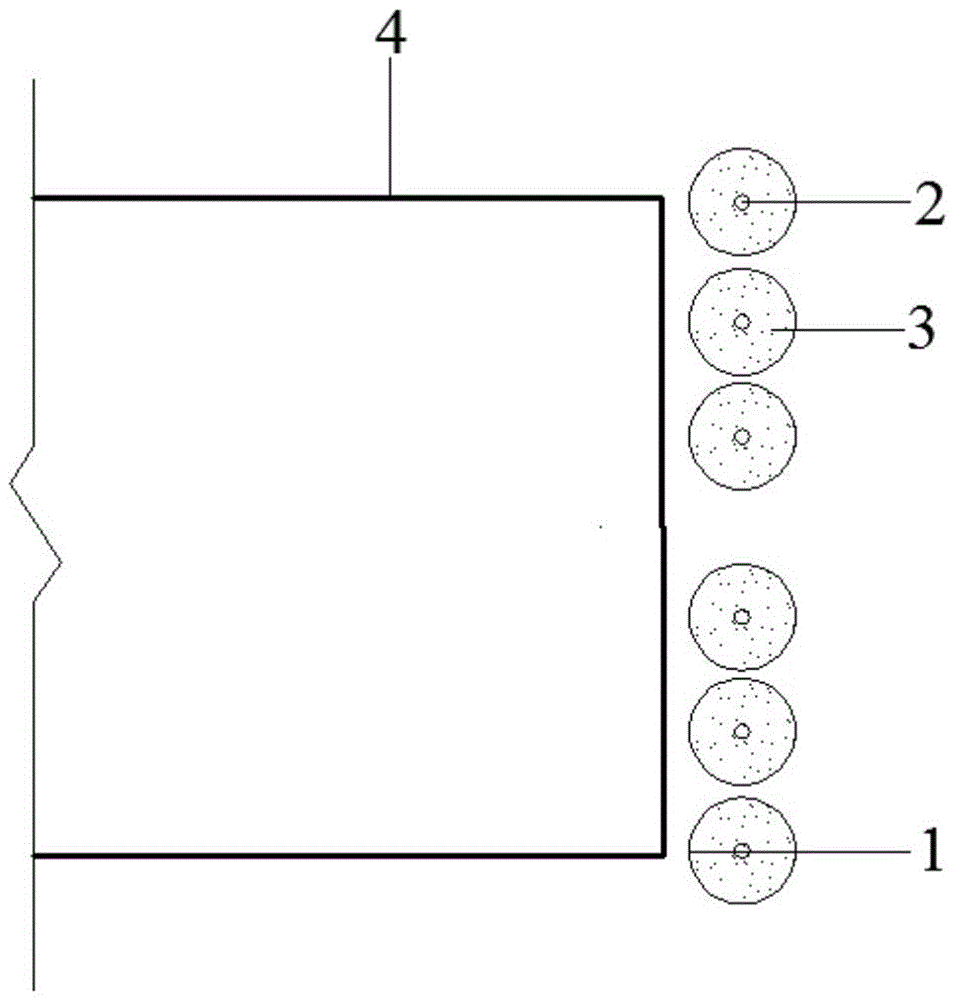

[0031] refer to Figure 1-3 As shown in the figure, a bentonite-improved soil shield machine relief device of the present invention includes a plurality of rotary spray piles 1 located in front of the cutter head of the shield machine 4 and arranged left and right along the cross section of the cutter head.

[0032] Specifically, in the aforementioned bentonite-improved soil shield machine trapping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com