Patents

Literature

51results about How to "Small binding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of antibacterial mould-proof plywood for decoration

ActiveCN107351197AInhibit residual mold activityGood flexibilityRadiation/waves wood treatmentNon-macromolecular adhesive additivesCelluloseHuman health

The invention mainly relates to the technical field of machining of artificial boards, and discloses a preparation method of antibacterial mould-proof plywood for decoration. The preparation method comprises drying, dipping, freezing, gluing, hot pressing and arrangement; the method is simple, safe and nontoxic; the obtained plywood for decoration reaches the mould inhibition rate of 76.3%, and contains no poisonous chemical reagent; the human health is guaranteed in the preparation and use process of the plywood; a veneer is firstly dried at low temperature, so that the water content is lower than the water content of a conventional veneer, the activity of the mould remained in the veneer is inhibited, the moulding is inhibited, the absorption of treatment solution in later treatment process is promoted, and the production efficiency is improved; and the dried veneer is put in sodium selenite solution for ultrasonic dipping, so that the sodium selenite solution is fully infiltrated in the veneer to inhibit growth of infectious microbes, the binding force of lignin to cellulose is reduced, the softness of the veneer is improved, breakage is prevented, and the machining performance and the use performance of the plywood are improved.

Owner:徐州市嘉翔木业有限公司

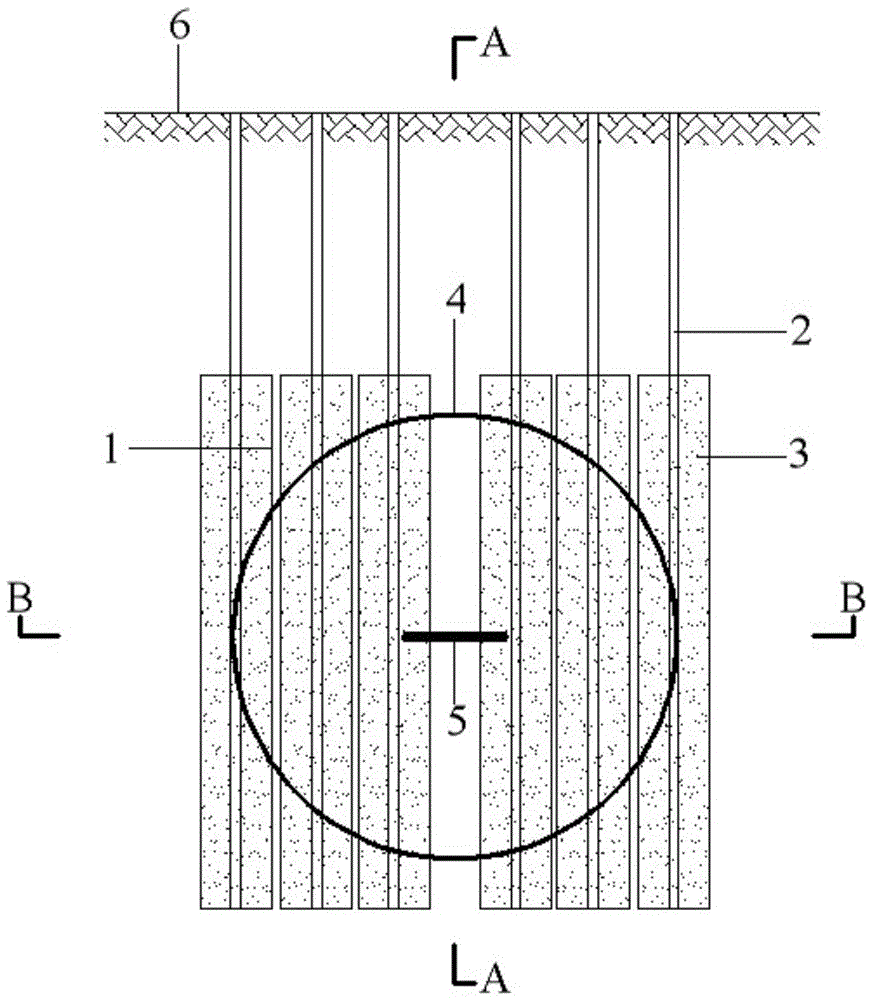

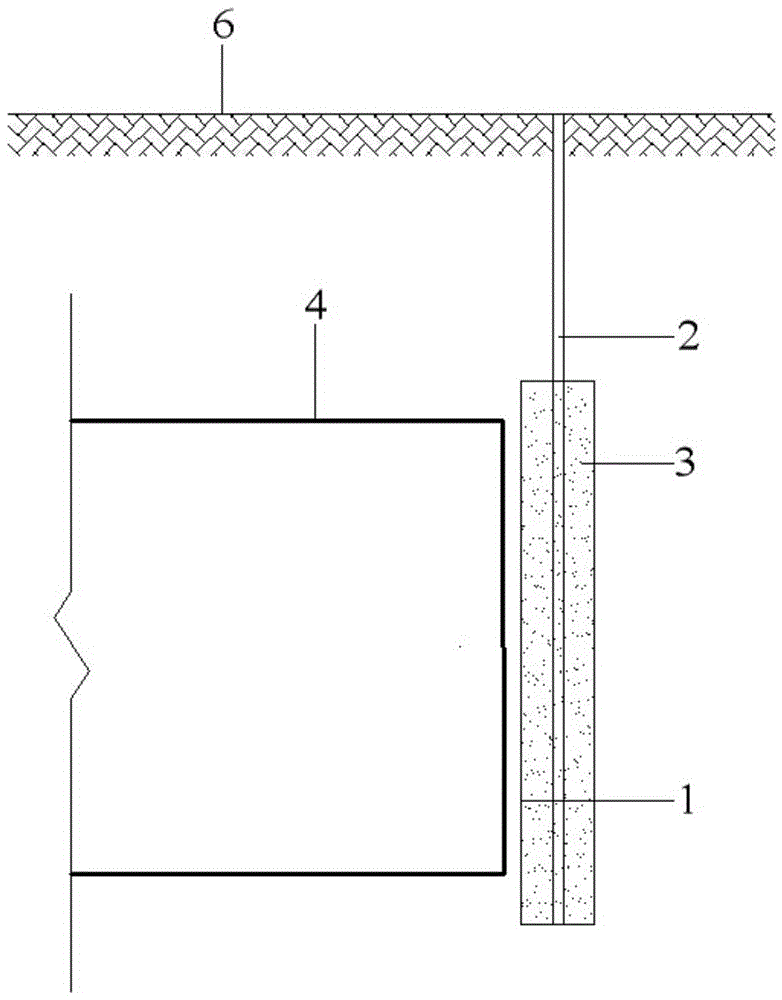

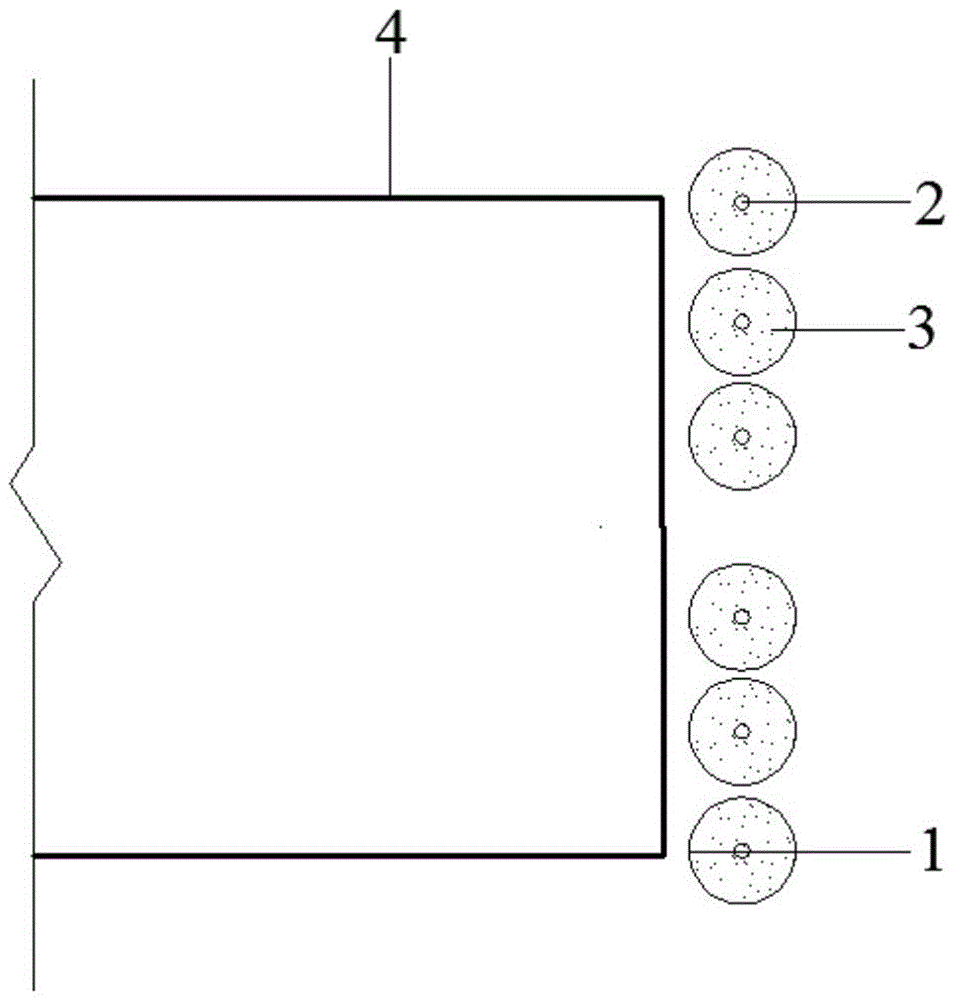

Escape device of bentonite improving shield tunneling machine and construction method thereof

The invention belongs to the technical field of shield tunnel construction, particularly relates to an escape device of a bentonite improving shield tunneling machine and a construction method. The escape device comprises an even number of jet grouting piles, wherein the jet grouting piles are three-pipe jet grouting piles, the pile forming diameter is 800-1000 mm, the specific number of the jet grouting piles is determined according to soil layer parameters and the cutterhead diameter of the shield tunneling machine, the jet grouting piles are located at the positions 400-500 mm away from the front of a cutterhead of the shield tunneling machine, jet grouting pile slurry is specially-prepared bentonite slurry, the mass ratio of bentonite to water to CMC to soda ash is 200 to 900 to 1 to 2, and the stratum which the structures of the jet grouting piles are applicable to is a dense sand layer. The construction method comprises the three steps: first step, the positions of the jet grouting piles are arranged; second step, the jet grouting pile slurry is prepared; third step, the bentonite slurry is rotary jet grouting for pile forming. The construction steps are simple, the escape problem of the shield tunneling machine in the dense sand layer can be effectively and quickly solved, a construction period is short, the construction cost is low, and good economic benefits are obtained.

Owner:CHINA RAILWAY TUNNEL

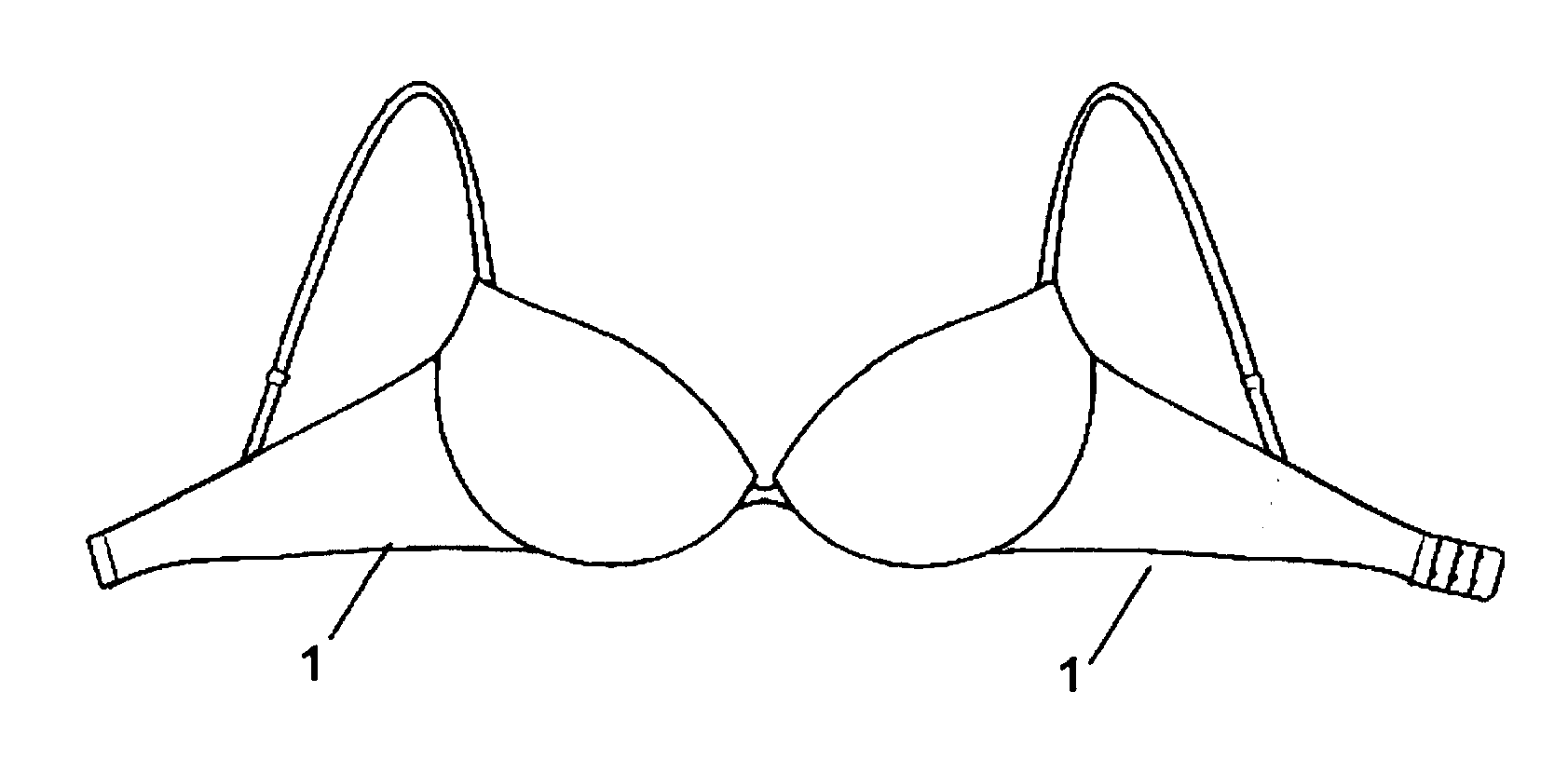

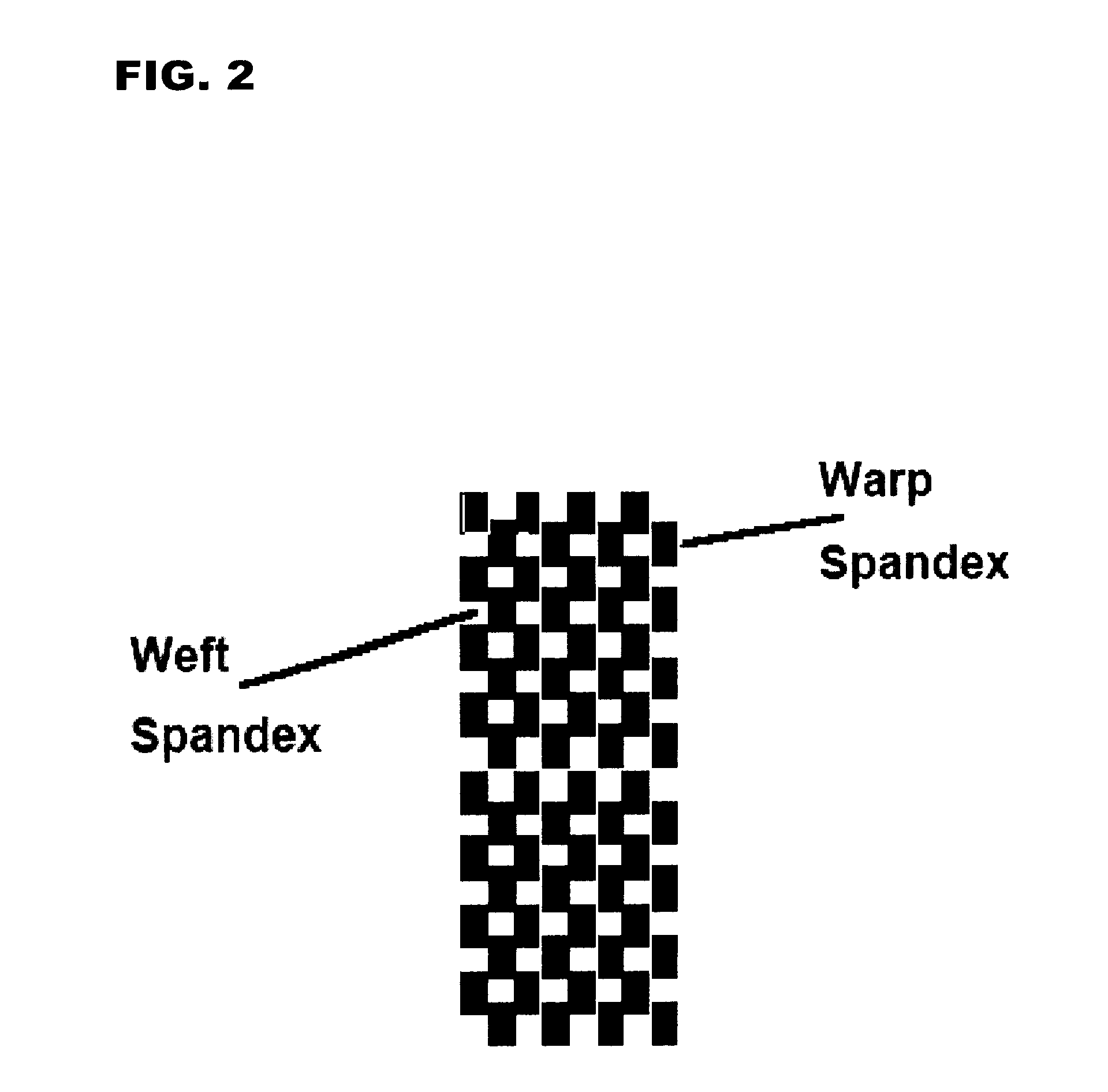

Novel Fabric Made of All Elastomeric Fiber and Its Applications

The present invention relates to a knitted fabric which adopts a novel weaving principle of changing knitting material structure to realize functions and effects which can not be achieved by ordinary fabric. The knitted fabric comprises the main component of novel woven 100 percent spandex fabric made of 100 percent spandex filament. Presently, elastic rubber pieces, rubber bands, etc., are applied to the underwear at the market for enhancing the elasticity and supporting effect. The common features is that they all have a poor elastic resilience, unstable structure, and prone to distortion and raveling. The present novel knitted fabric changes the principle of crocheting of the ordinary material of the traditional knitted fabric, adopting 100 percent spandex filament as the main material to change the elastic resilience, force, and structure stability of the traditional knitted fabric. The mutual double pulling effect of the knitted fabric in the spandex filament after crocheting is to remedy the defaults of the fabric of which the structure is deformed and the elastic resilience and the force are weakened after the fabric is elongated. Compared with the original fabric, the elastic recovery and the elastic force of the fabric are greatly increased and improved.The weaving process and the features of the novel 100 percent spandex fabric are as follows:(1) Warp yarn and weft yarn which are made of 100% spandex filament material are mutually crocheted.(2) The back weft of the spandex filament is required to pass through a filament packaging frame and a weft yarn accelerating conveyer device is provided.(3) Curling is required to be avoided. The specification of the spandex filament of which the warp yarn used required to be considered, so is the specification and constituents of the back weft made of the spandex filament.The preset novel 100% spandex fabric can completely replace the elastic woven band and rubber piece in the prior underwear to play a role of enhancing the elasticity and strength. It can also completely replace the prior common elastic woven band and rubber piece, providing good hand feel, flatness, smoothness, close fit, sound elastic resilience, comfort wear, etc. It can be widely applied to garment industry, particularly to the underwear, such as brassiere, swimwear, briefs, etc.A strap having a memory function, comprising yarns of substantially 100% spandex. The rubber band and ordinary strap applicable in the present market provide a poor elastic resilience, which would easily deform. The said strap having a memory function weaved with warp yarn made of 100% spandex and weft yarn made of 100% spandex, whose structure could be not only plain weave, but also twill or tracery. The fabric has the “memory” function by which it returns to substantially its original shape after being stretched many times it original size. It can provide excellent hand feel, good flatness, smoothness, close fit, sound elasticity, and comfortable wear when used to replace the existing ordinary elastic rubber bands. It can be widely applied in the garment industry, especially in the field of underwear such as brassiere, swimwear, briefs, lingerie, etc.The present patent for utility model discloses a laminable elastic fabric whose main components are 100% spandex elastic woven band and warp knitted shell fabric or weft knitted cloth, and the elastic fabric is formed through laminating processing. The laminated fabric currently used on the market does not have good elastic resilience and is thus easily deformed and is relatively thick. The new laminated elastic fabric of the present patent is relatively light and thin, and the elastic woven band is formed by interweaving 100% spandex warp threads and 100% spandex weft threads, and the elastic fabric is formed by laminating it to the inner side of the shell fabric. The fabric has a recovery of nearly 100% after many times of use. The fabric laminated with said woven band has the characteristics of excellent hand feel, good levelness, softness and smoothness, close fit, good elasticity, comfortable wear, etc. Meanwhile, the processing is simple, and mechanical automation and mass production can be realized, which complies with the efficiency of market economy.

Owner:BEST PACIFIC TEXTILE

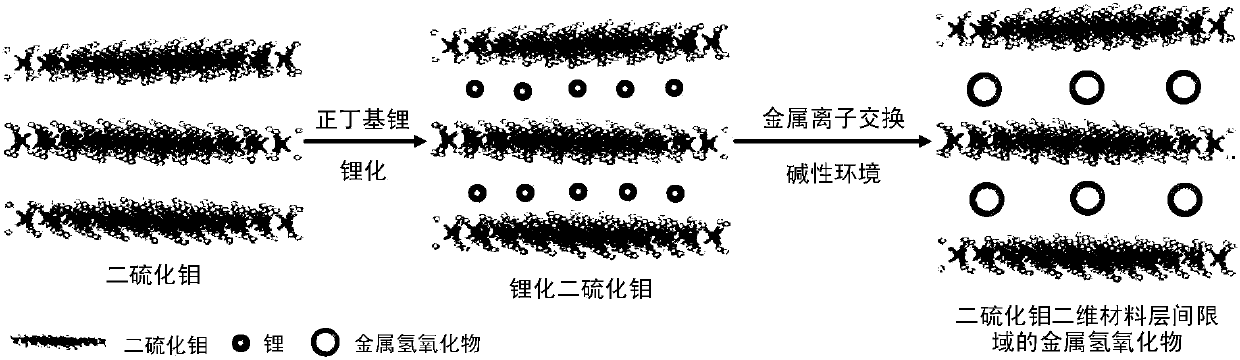

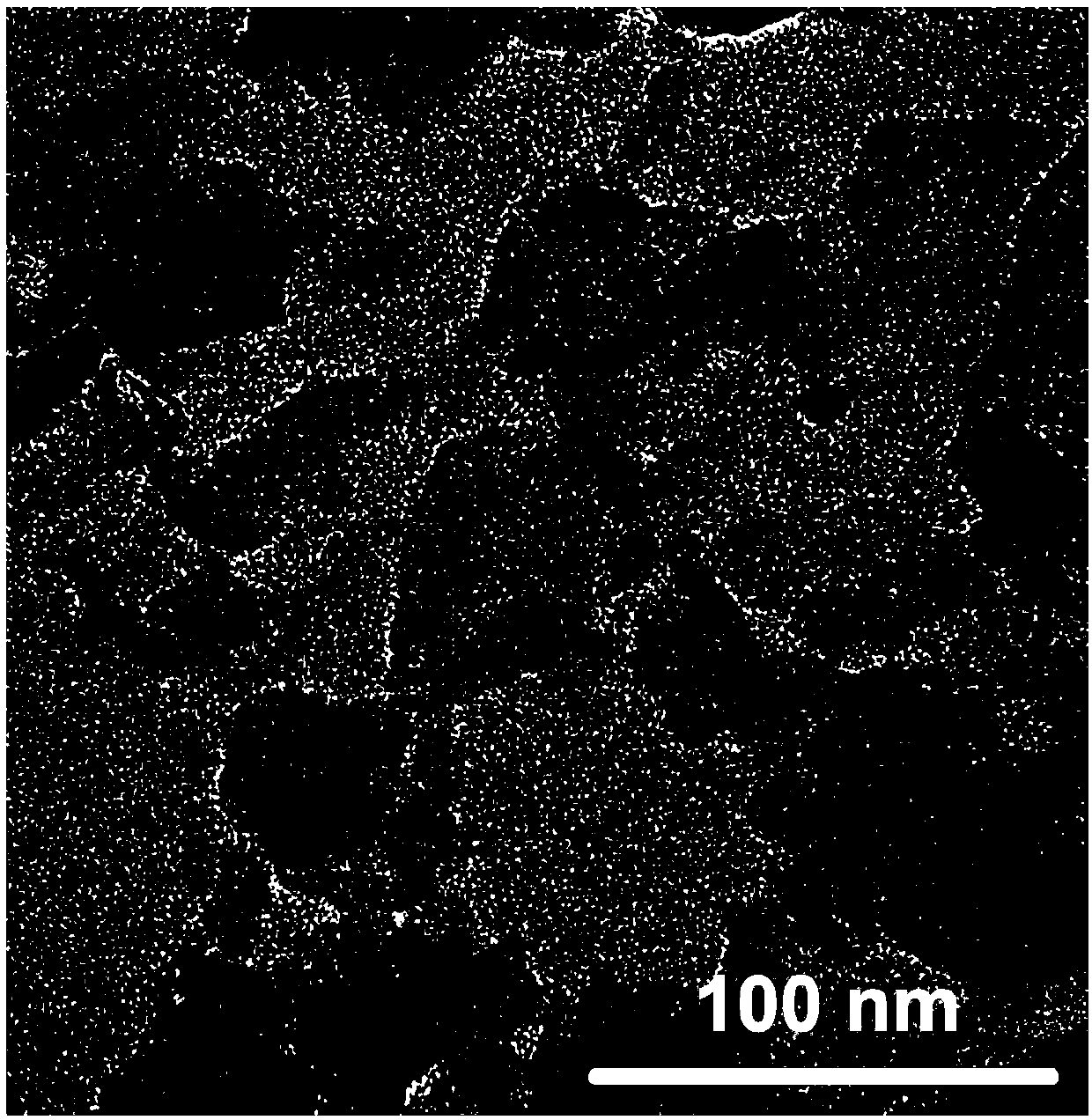

Layered two-dimensional material interlayer-confined metal or metal compound composite material as well as preparation method and application thereof

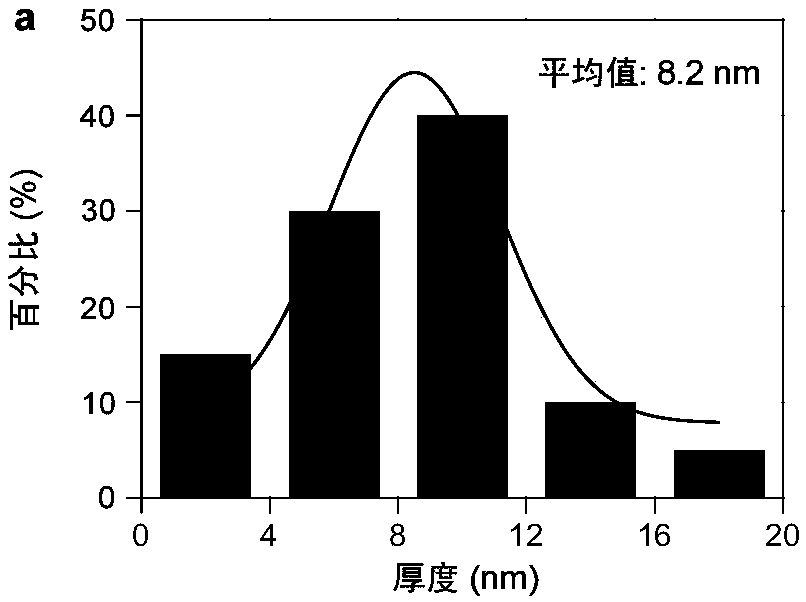

ActiveCN108579769AAvoid shedding and clumpingGood catalytic activityMaterial nanotechnologyCatalyst activation/preparationSolventMolybdenum disulfide

The invention discloses a layered two-dimensional material interlayer-confined metal or metal compound composite material as well as a preparation method and application thereof. The composite material comprises a layered two-dimensional material and a metal or metal compound confined among layers of the layered two-dimensional material. The method comprises the following steps: 1) performing lithiation treatment on the layered two-dimensional material to obtain a lithiated layered two-dimensional material; and 2) mixing the dried lithiated layered two-dimensional material, a metal salt and asolvent, performing sealing in a reaction kettle, and performing a hydrothermal reaction to obtain the layered two-dimensional material interlayer-confined metal or metal compound composite material.The preparation method disclosed by the invention can realize controllable preparation of a series of two-dimensional material interlayer-confined metal and metal compound composite materials; and theprepared composite material, especially a two-dimensional molybdenum disulfide interlayer-confined metal hydroxide composite material has the advantages of high electrocatalytic activity and good stability when being used as a hydrogen evolution catalyst, and has application prospects in the field of production of hydrogen by electrolysis of water.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

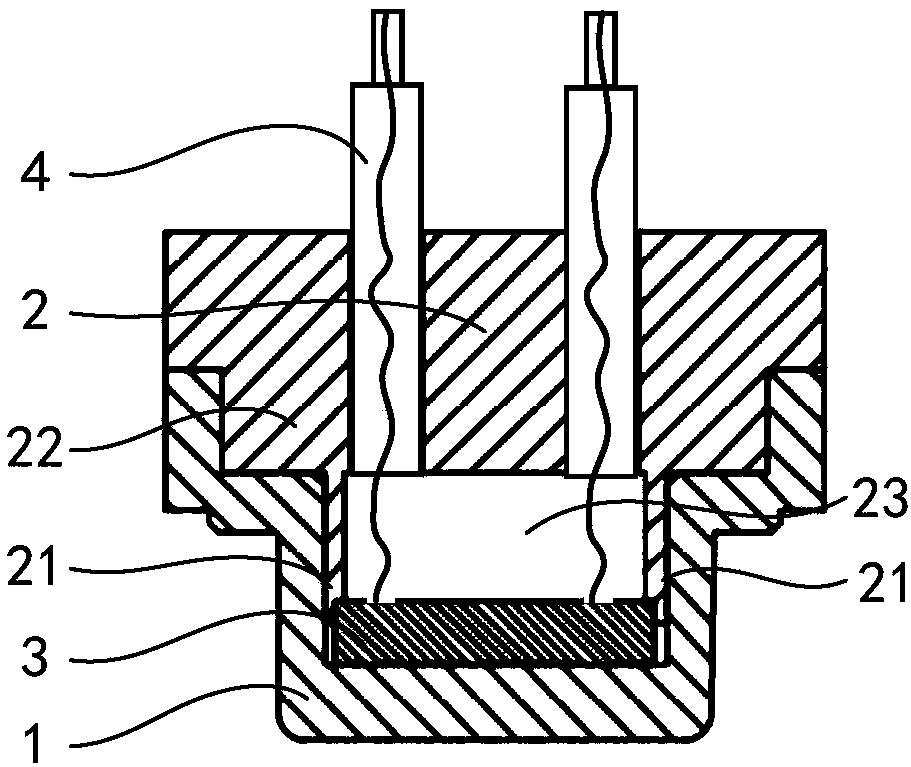

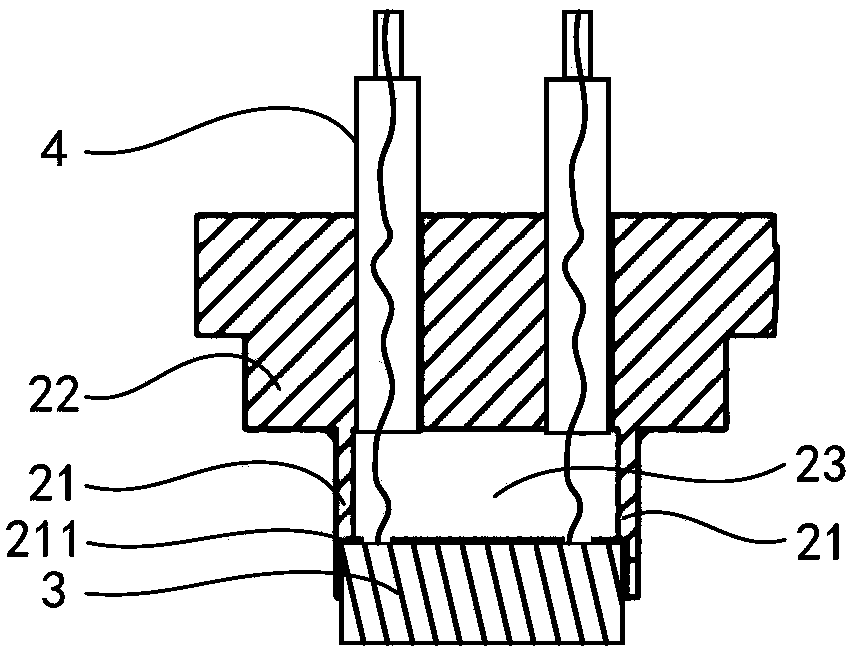

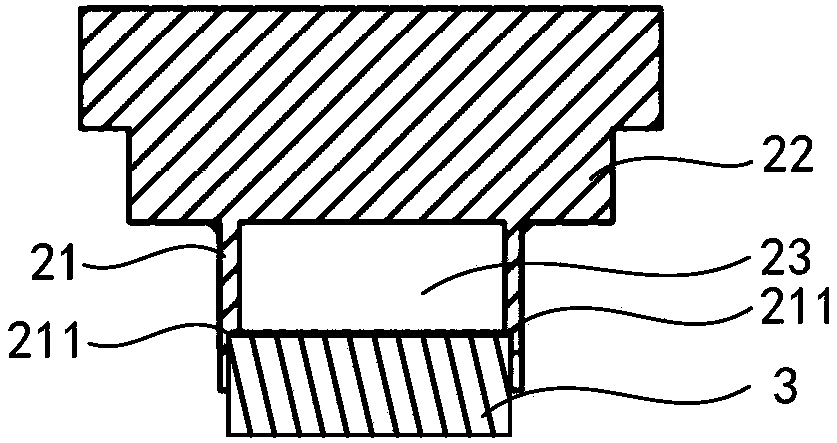

Ultrasonic sensor

PendingCN108435521AAvoid vibrationSmall binding forceMechanical vibrations separationUltrasonic sensorEngineering

The invention discloses an ultrasonic sensor. The ultrasonic sensor comprises a shell, a fixing assembly and a piezoelectric ceramic piece, wherein one end of the shell is open, a cavity is formed inthe shell, and the piezoelectric ceramic piece is arranged on the bottom of the cavity; the fixing assembly comprises a fixing piece and a supporting piece, the fixing piece is connected to the opening end of the shell in a sealing mode, one end of the supporting piece is connected to the surface of the end, facing the piezoelectric ceramic piece, of the fixing piece, and the other end of the supporting piece abuts against the piezoelectric ceramic piece; and a groove is formed in the supporting piece, and the groove is located between the fixing piece and the piezoelectric ceramic piece. According to the ultrasonic sensor, the process is effectively simplified; and free vibration of the piezoelectric ceramic piece is realized, so that the sensitivity is improved.

Owner:ZHAOQING AUDIOWELL SENSOR TECH CO LTD

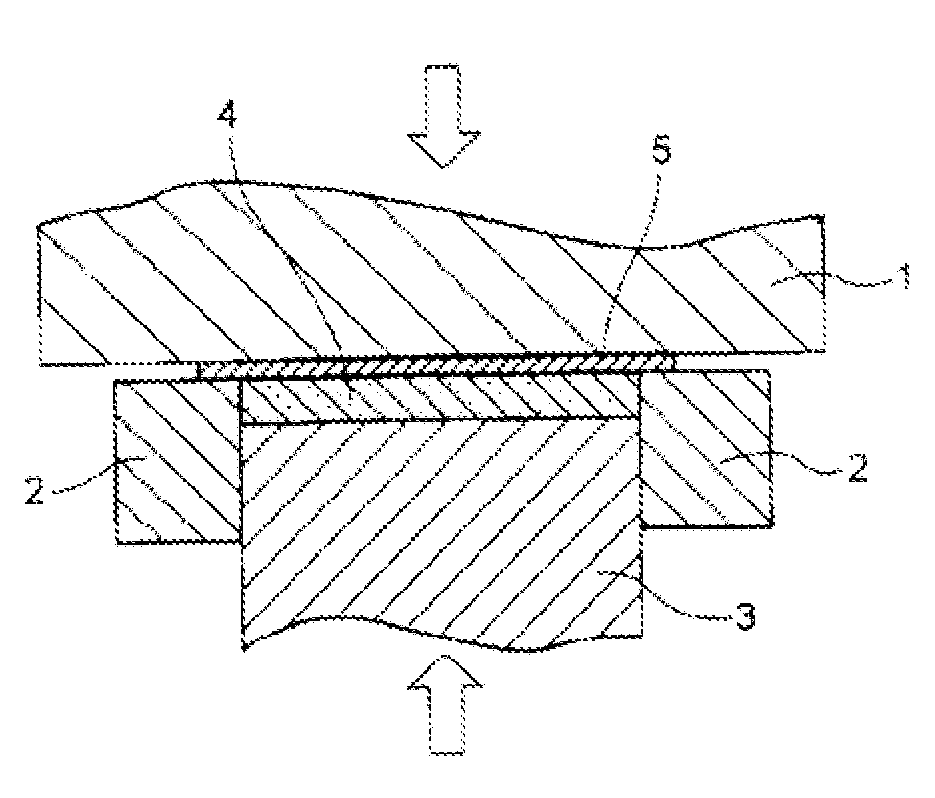

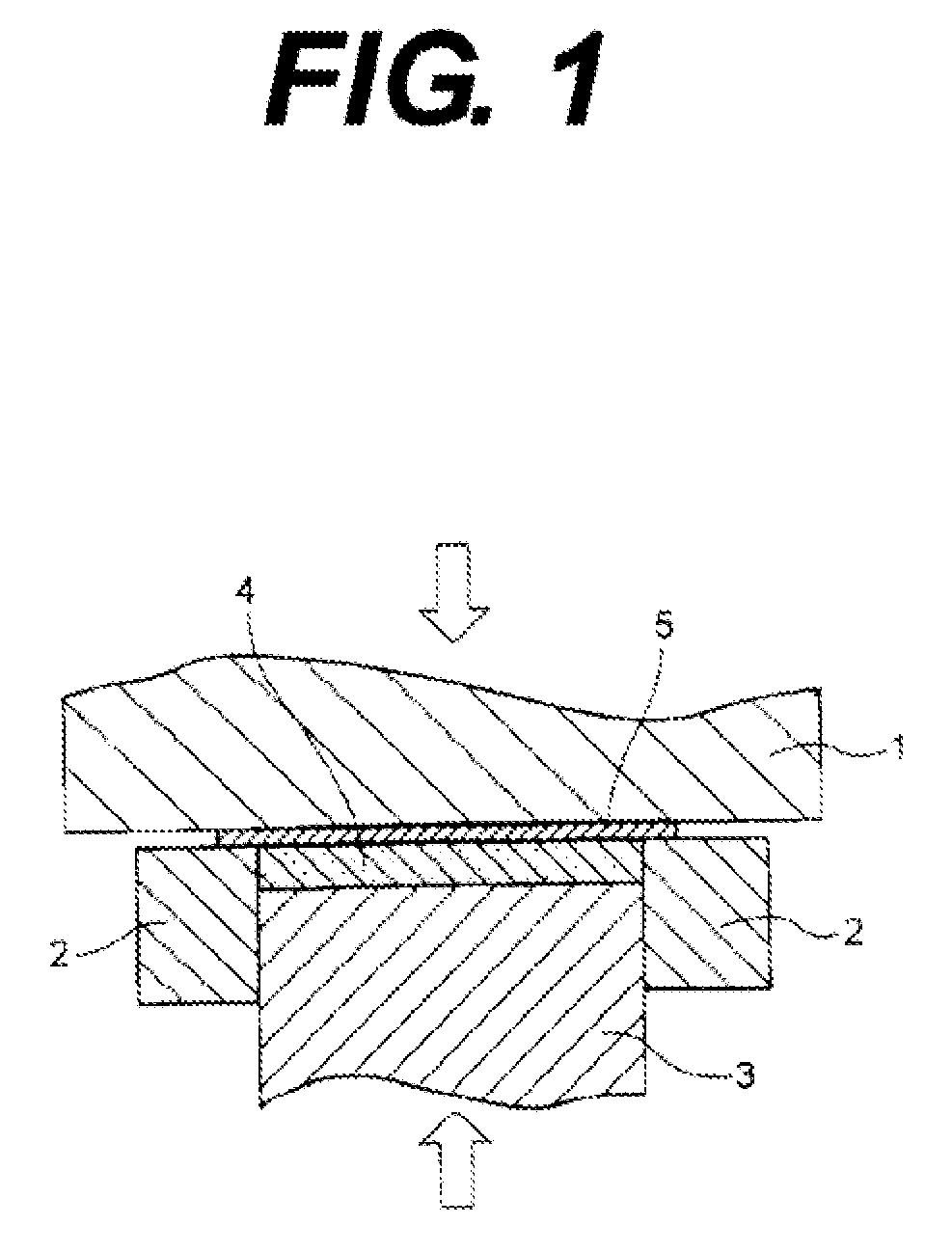

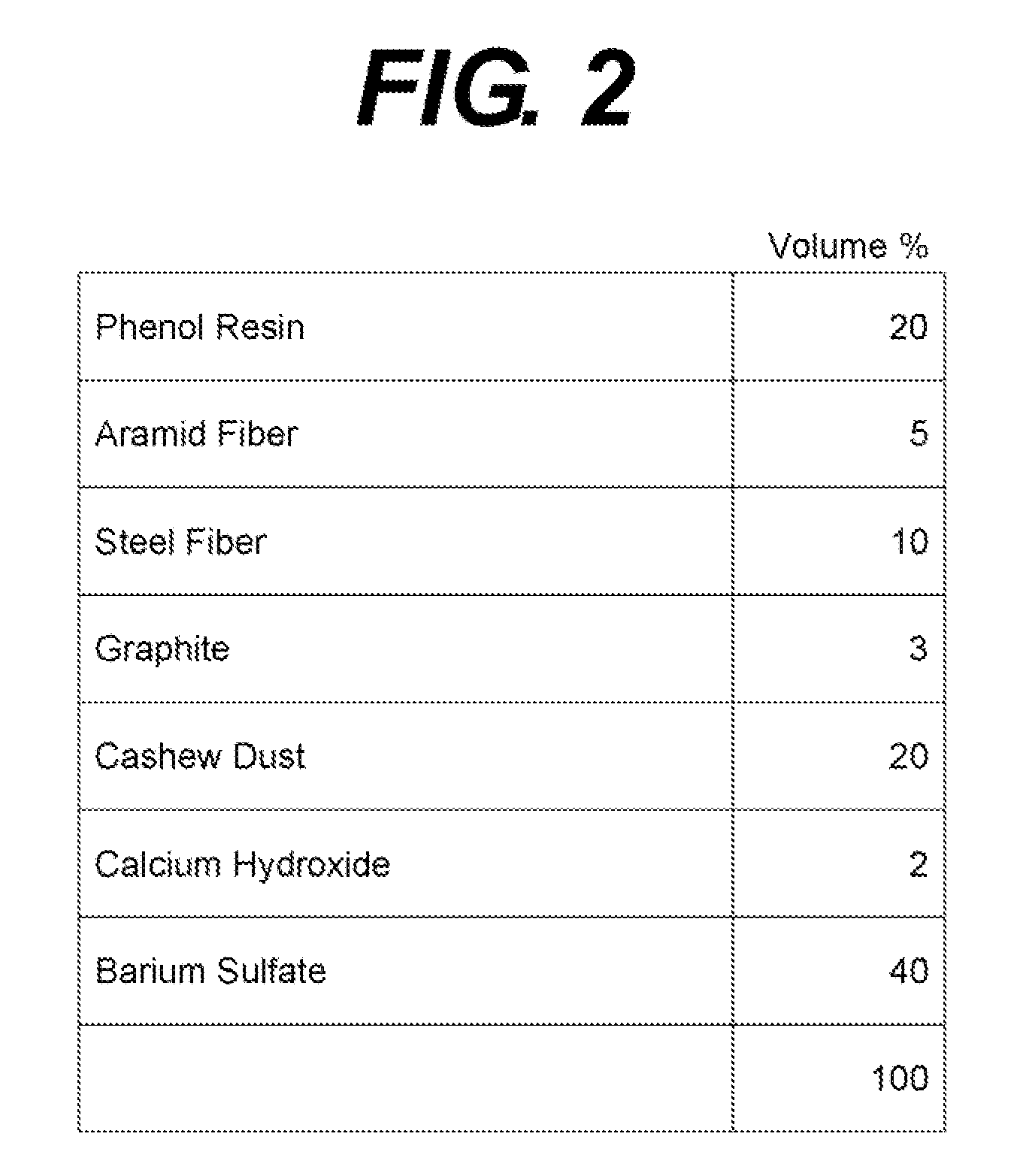

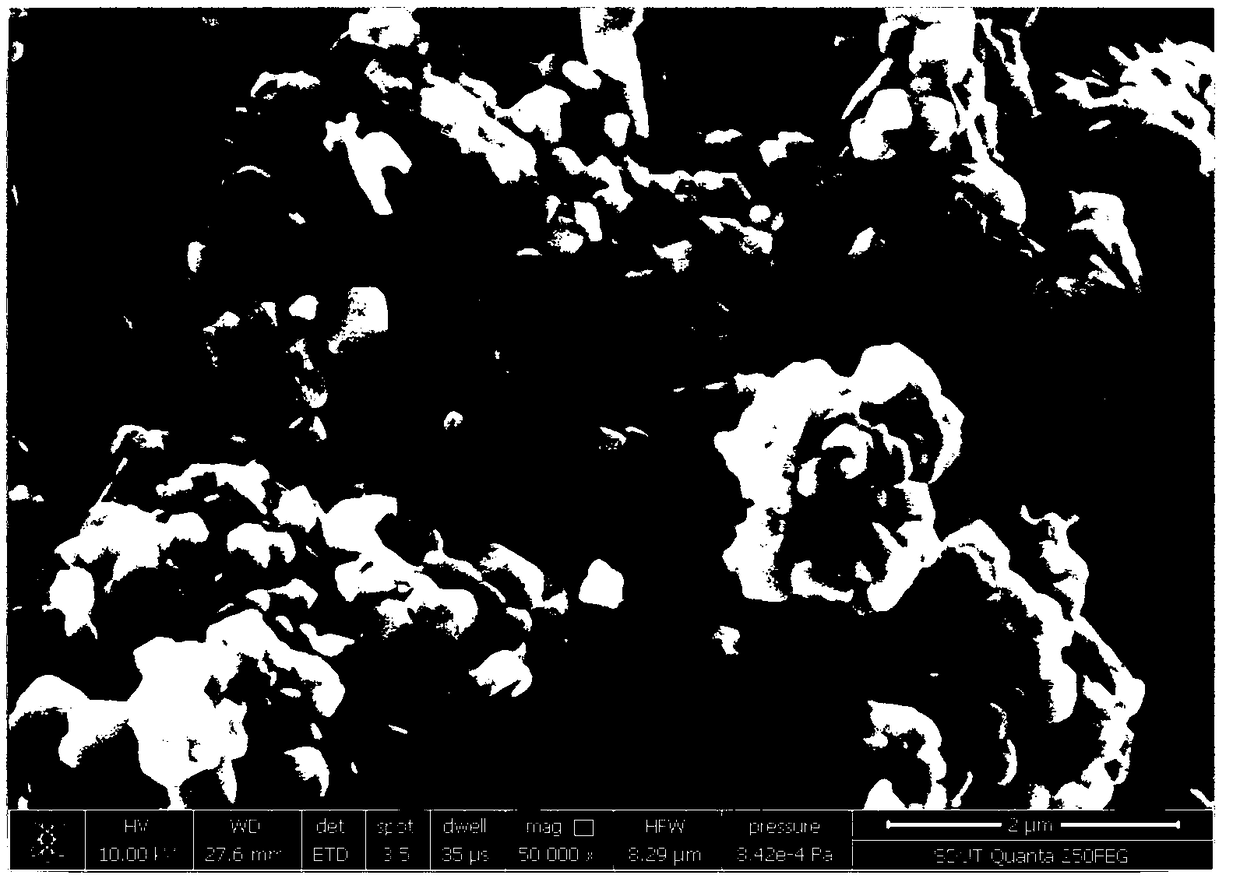

Manufacturing Method For Friction Material Products

InactiveUS20070052126A1Molding step can be reducedMaintain qualityWood working apparatusFlat articlesComposite material

Owner:NISSHINBO IND INC

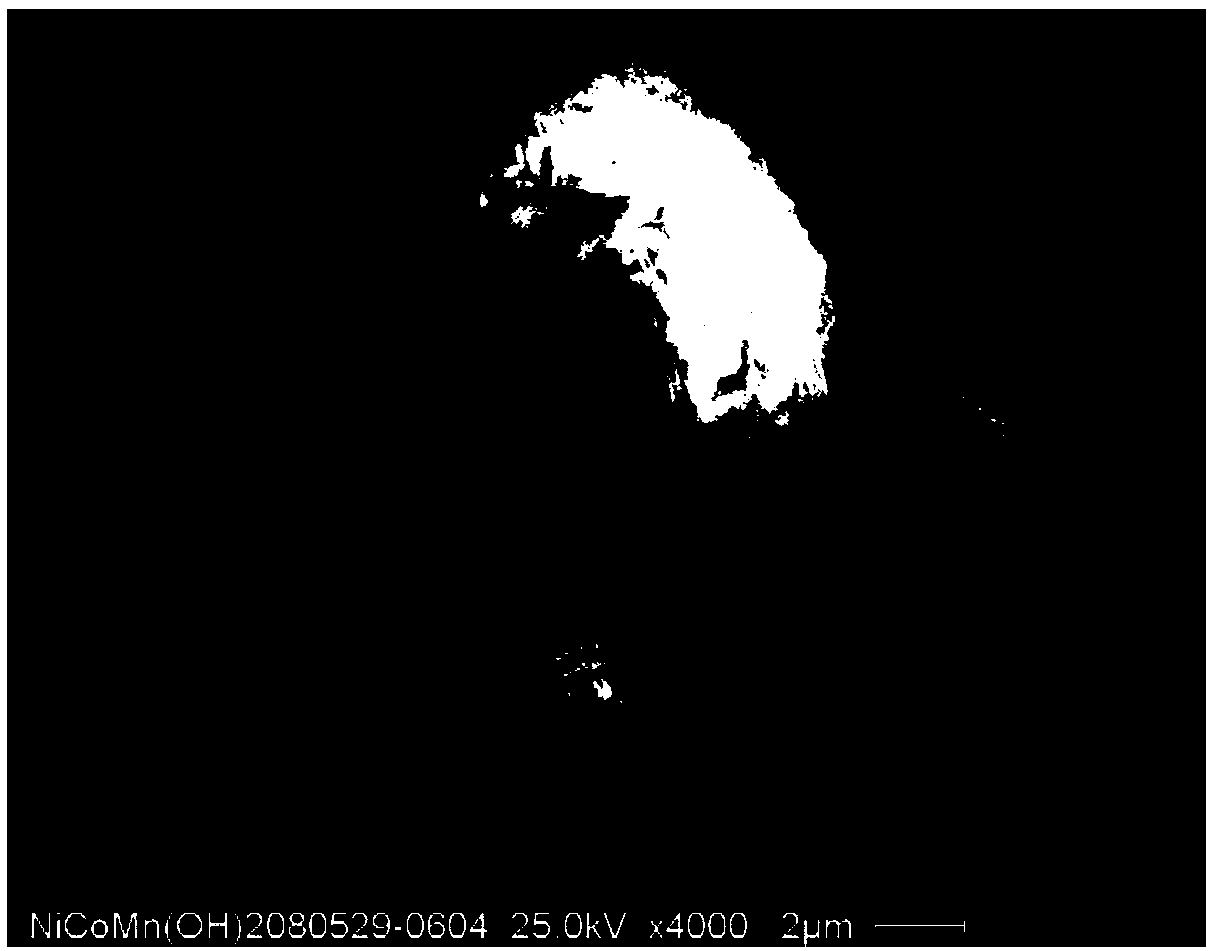

Method for preparing lithium aluminate modified ternary anode material based on spent lithium-ion battery cathode materials

ActiveCN108878837AGuaranteed uniformityAchieving cryogenic recoveryCell electrodesWaste accumulators reclaimingLithium aluminateCobalt

The invention belongs to the technical field of ternary material precursor preparation, and particularly to a method for preparing lithium aluminate modified ternary anode materials based on spent lithium-ion battery cathode materials. The method comprises the steps that anode materials are separated from spent lithium-ion batteries; the anode materials are leached in a caustic solution and filtered; lithium carbonate is obtained by adding carbonate to filtrate; a filter cake is leached with sulfuric acid and leaching liquid is obtained; an adjustment solution is obtained by adjusting the molar ratios of nickel, cobalt and manganese in a leaching solution; the adjustment solution, an ammonia water solution and a caustic solution are flow into a reaction still together, and the ternary material precursor is prepared by coprecipitation; then the ternary material precursor is mixed with lithium carbonate for roasting, and ternary anode materials are obtained; and the lithium aluminate modified ternary anode materials are prepared by adding sec-butyl alcohol, lithium methoxide and the ternary anode materials in a mixture of ethyl acetoacetate, ethanol and water for reaction and roasting. The ternary anode materials have good structure stability, good electrochemical performance, lower production cost and high product quality, and realize the directional circulation of nickel-cobalt-manganese lithium resources.

Owner:SHANDONG UNIV OF TECH

Method for directly preparing ternary positive electrode material modified by lithium zinc oxide by utilizing positive electrode material of waste lithium battery

ActiveCN108878836AGuaranteed uniformityAchieving cryogenic recoveryCell electrodesWaste accumulators reclaimingLithium oxideManganese

The invention belongs to the technical field of ternary material precursor preparation, in particular to a method for directly preparing a ternary positive electrode material modified by lithium zincoxide by utilizing a positive electrode material of a waste lithium battery. The method comprises the steps of separating out the positive electrode material from the waste lithium ion battery; performing leaching with a caustic alkali solution, and filtering; adding carbonate into the filtrate to obtain lithium carbonate; leaching a filter cake by using sulfuric acid, so that a leaching solutionis obtained; adjusting the molar ratio of nickel, cobalt and manganese in the leaching solution; performing parallel flow on the leaching solution, an ammonia water solution and the caustic alkali solution into a reaction kettle, and carrying out co-precipitation to prepare a ternary material precursor; performing mixing and roasting on the ternary material precursor with lithium carbonate, so asto obtain a ternary positive electrode material; and enabling zinc acetate, ethylene glycol methyl ether, amine and methanol lithium to be mixed, and adding the ternary positive electrode material toobtain gel, and performing roasting on the gel to obtain the lithium zinc oxide modified ternary positive electrode material. The lithium zinc oxide modified ternary positive electrode material is high in structural stability and high in electrochemical performance, the production cost is lowered, the product quality is high, and directional circulation of the nickel-cobalt-manganese-lithium resources is realized.

Owner:SHANDONG UNIV OF TECH

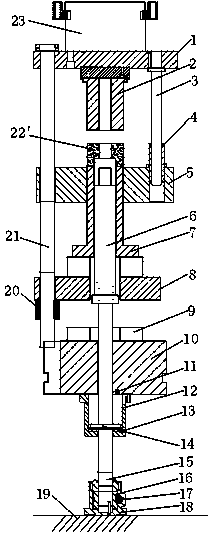

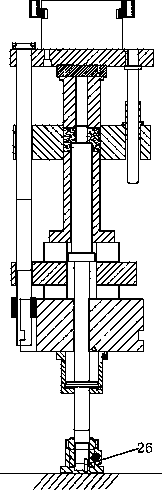

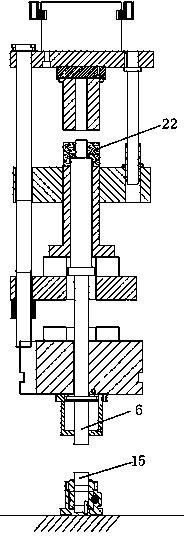

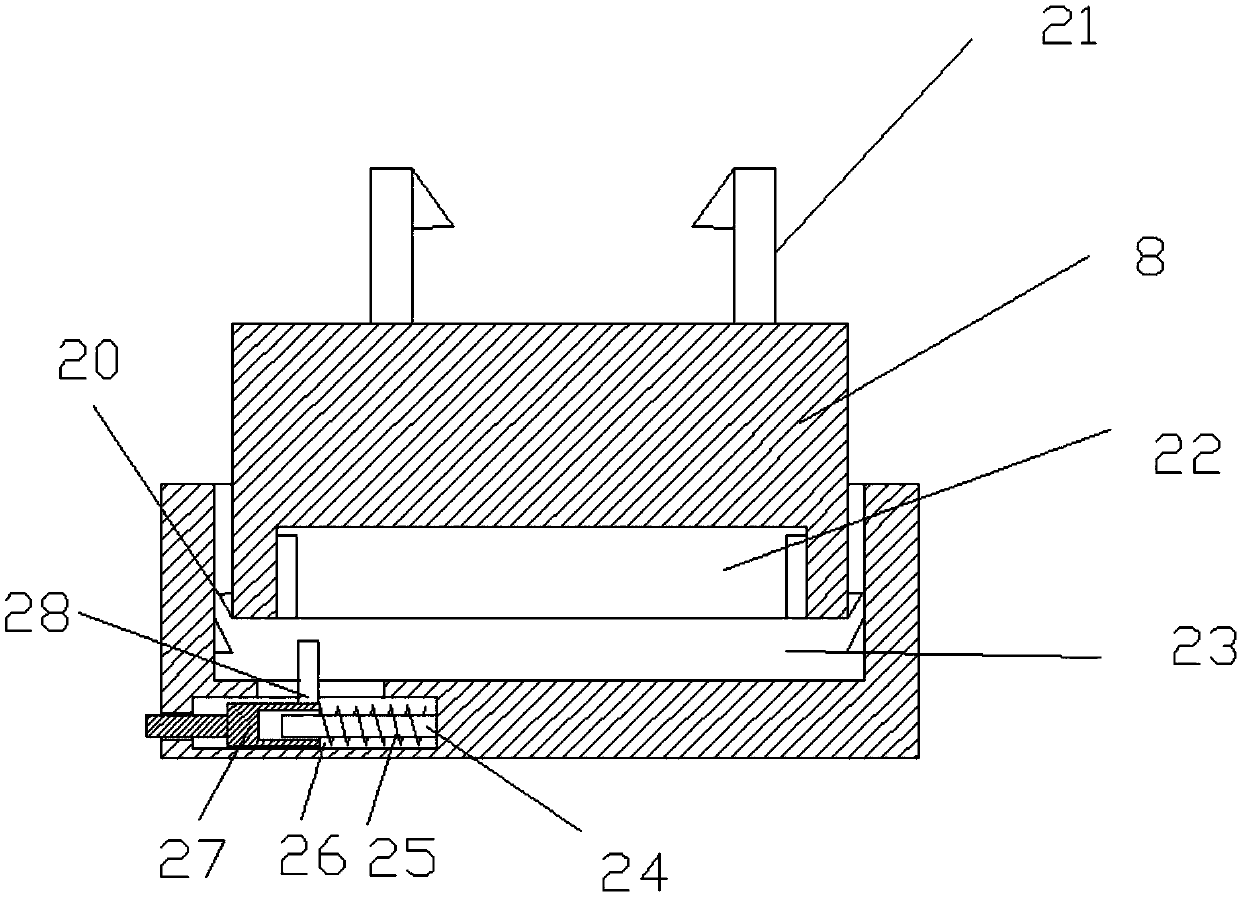

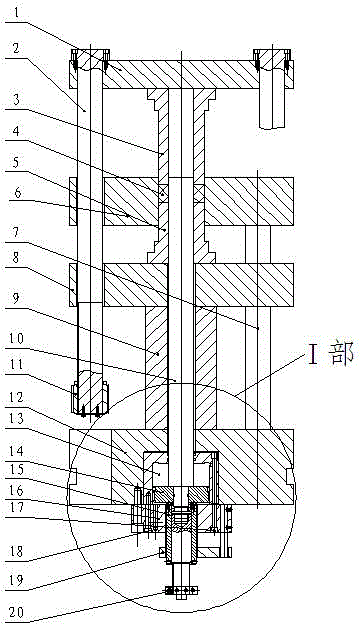

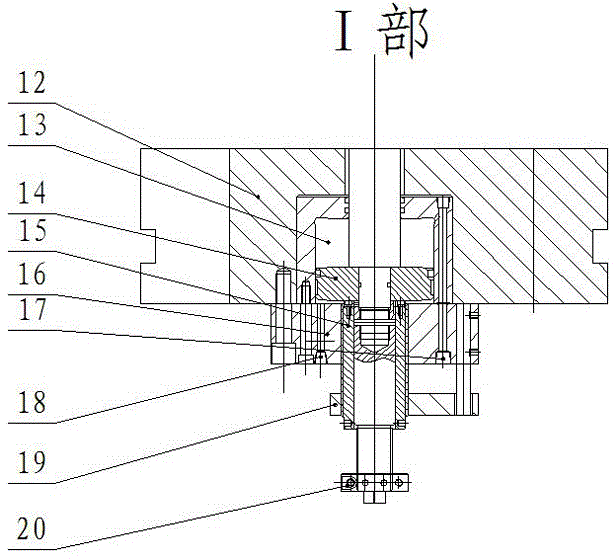

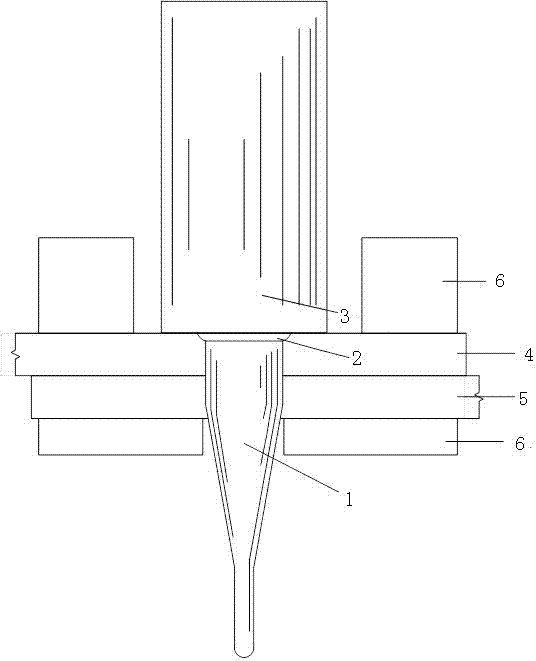

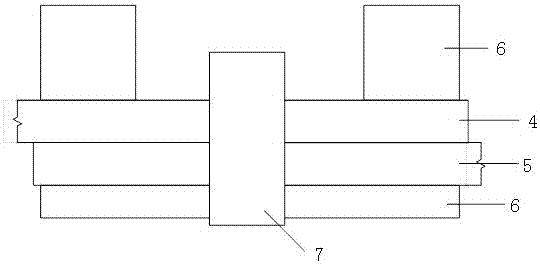

Mandril adjusting device for shaping die set of powder sintering part

A mandril adjusting device for the shaping die set of a powder sintering part is characterized in that an upper punching plate, a female die plate, and a lower punching plate are connected into a whole by a guide post and a die stripping rod, and is matched with a die set fixing plate fixed with a cylinder; the die set fixing plate is fixed at the side wall of a rack; the mandril is mounted on a mandril piston and penetrates through the cylinder, the die set fixing plate, the lower punching plate and a lower punch to be connected onto the female die plate; the top end of the mandril is step-cylindrical while the tail end corresponds to and is matched with a check block fixed in a lifting mechanism in an adjusting seat on the rack, or the tail end of the mandril is provided with a telescopic rod to correspond to and be matched with a positioning block on the rack. The adjusting function of the mandril on a shaping machine is increased, the stroke is adjustable, vertical moving for multiple times can be realized, and the original demolding for one time is changed to be demolding for two times, thus greatly reducing the restraining force on the mandril during demolding, avoiding damages such as wearing, tearing and breaking of the mandril and prolonging the service life of the mandril; and the mandril adjusting device for the shaping die set of the powder sintering part can shape products with different inner hole shapes, and the use range of the shaping machine is expanded.

Owner:严俏敏

Sodium-zinc PVC stabilizer and method for preparing same

The invention discloses a sodium-zinc PVC stabilizer and a method for preparing the same, and belongs to the technical field of PVC thermal stabilizer preparation. The method for preparing the same comprises the following steps: adding iso-octoic acid, antioxidant, defoaming agent, zinc oxide and filtration aid in proportion, stirring the mixture for 10 to 20 minutes, heating the mixture to 110 to 130 DEG C, adding iso-octoic acid in the same weight as the extracted distilled water after vacuumizing, stirring again to obtain zinc intermediate; adding iso-octoic acid, coal oil, sodium hydroxide, dibutyl maleate and filtration aid in proportion, stirring the mixture for 10 to 20 minutes, heating the mixture to 110 to 130 DEG C, adding coal oil in the same weight as the extracted distilled water after vacuumizing, stirring again to obtain sodium intermediate; and combining the obtained zinc intermediate and sodium intermediate, adding phosphorous acid ester and acrylic resin, heating the mixture to 100 to 110 DEG C, then stirring the mixture for 10 to 20 minutes, and cooling to obtain Na / Zn stabilizer. The method has the advantages of simple process, safe technique and capability of producing Na / Zn stabilizer on a large scale.

Owner:江苏嘉仁禾科技有限公司

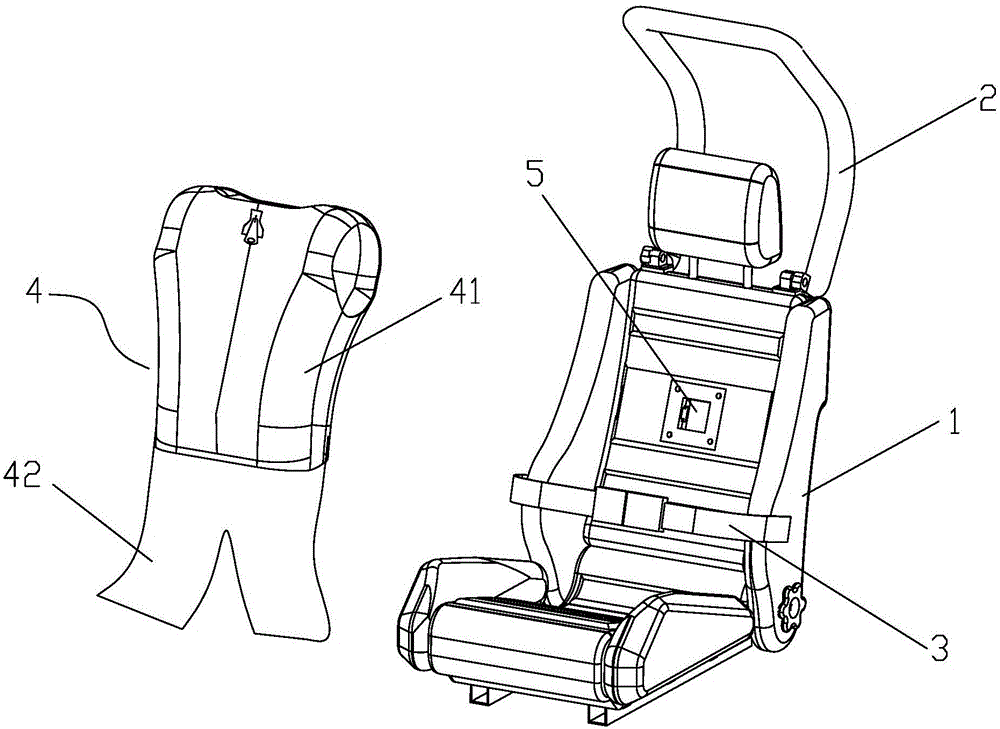

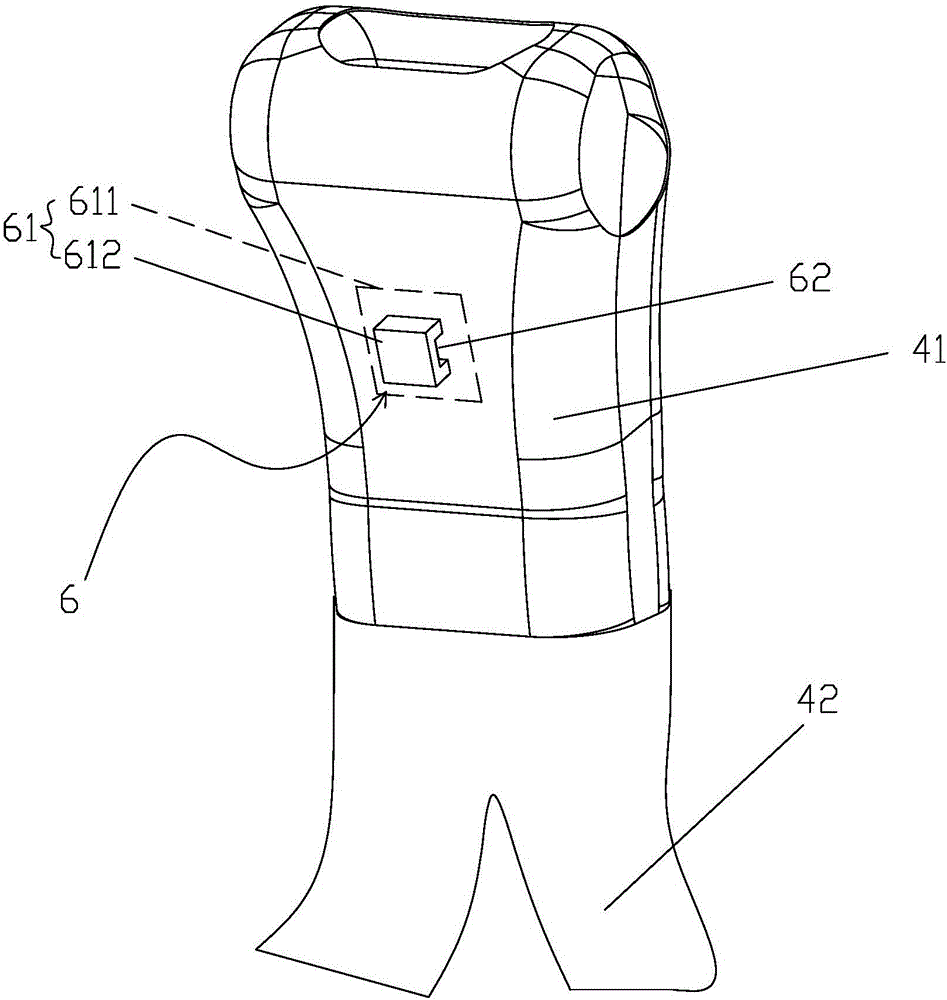

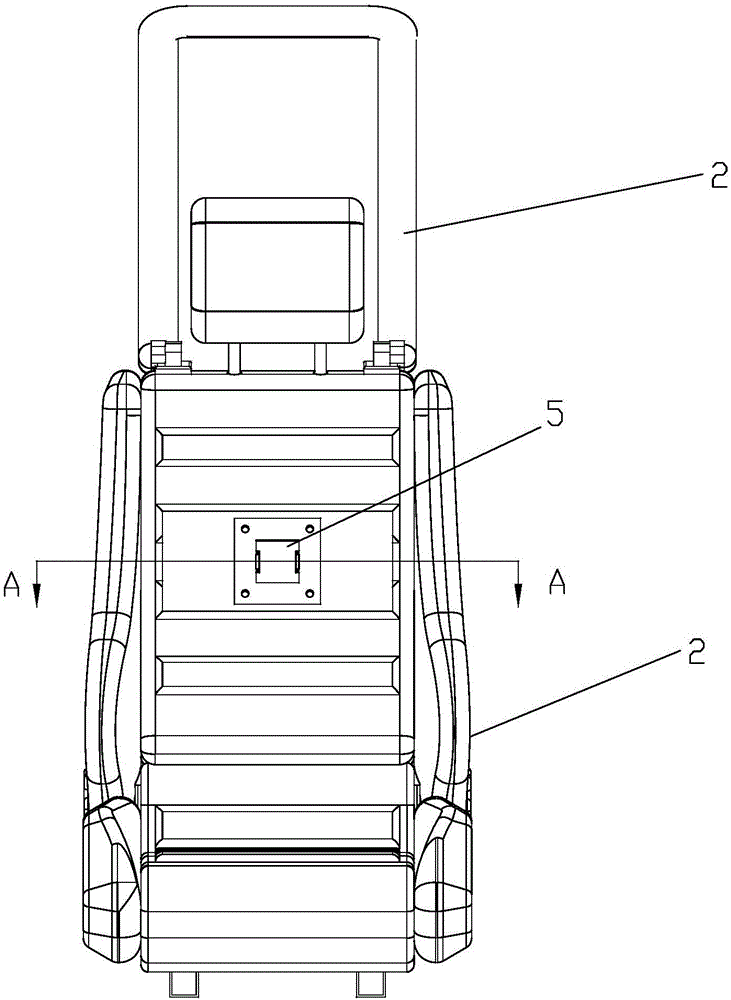

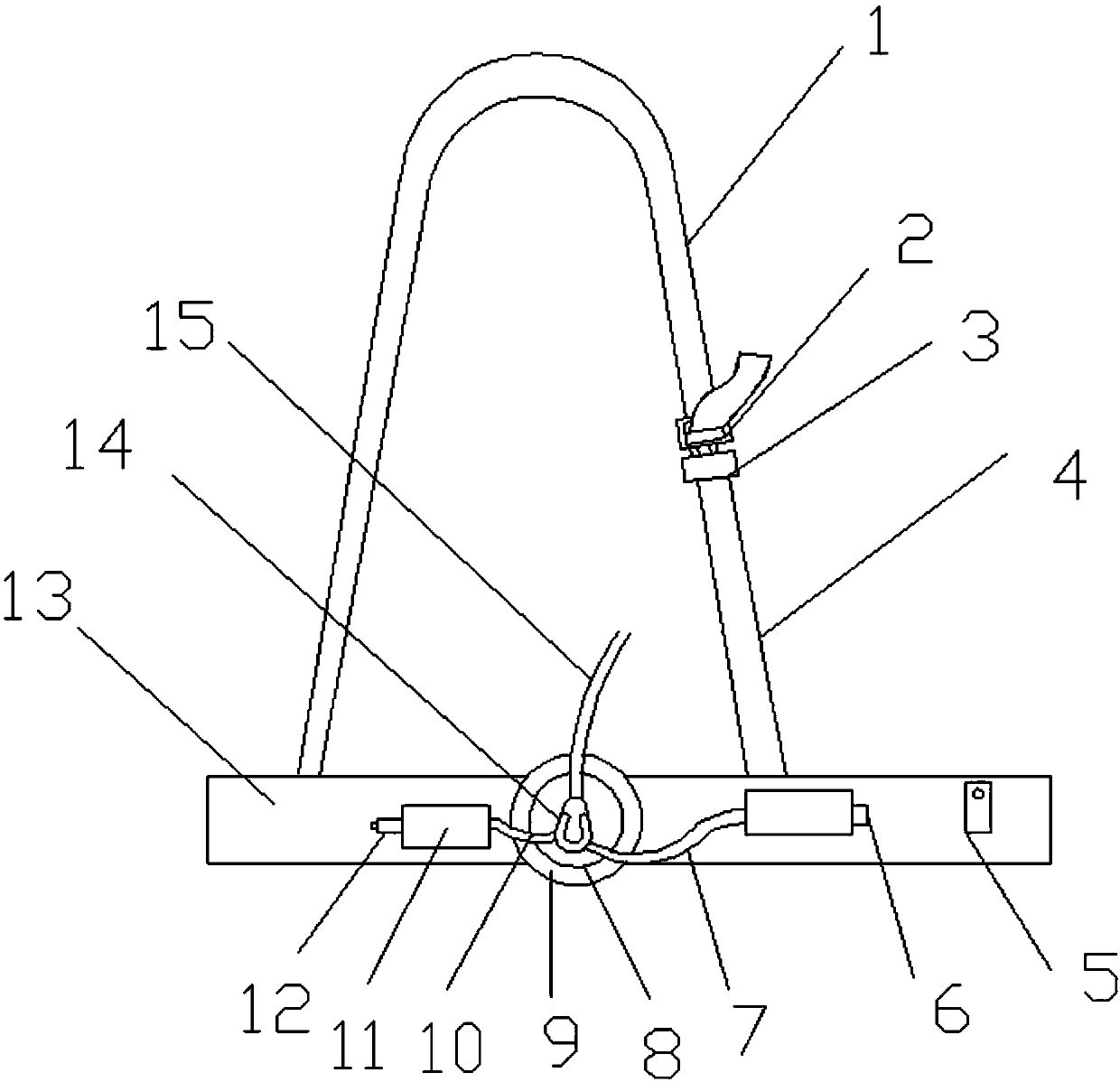

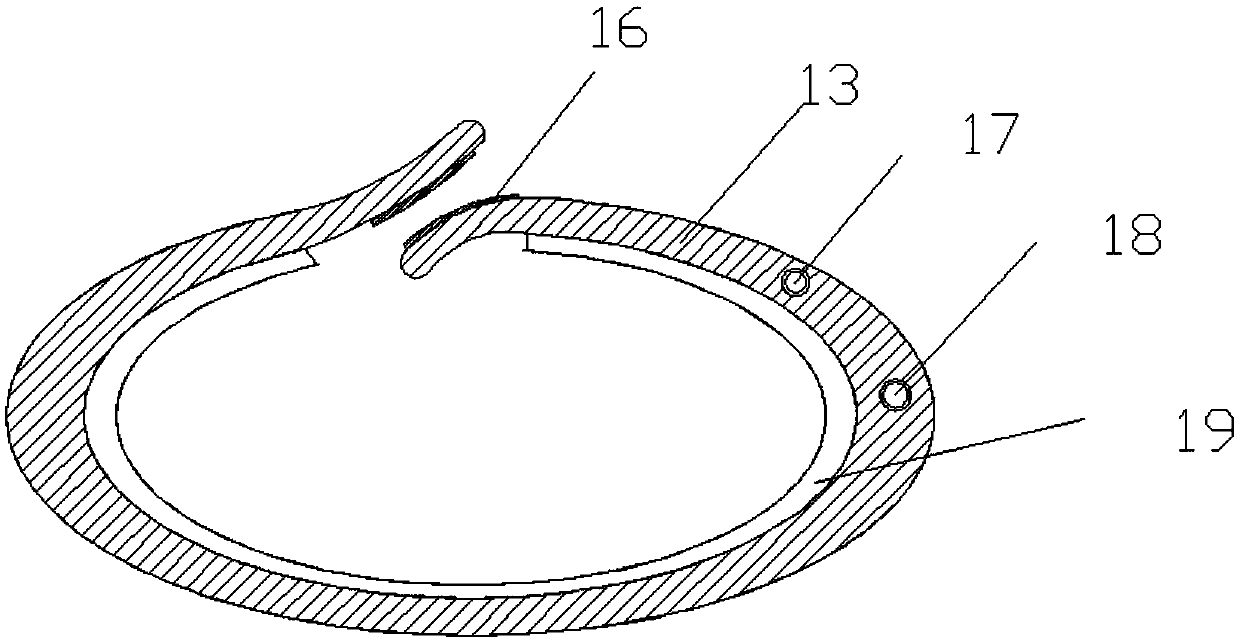

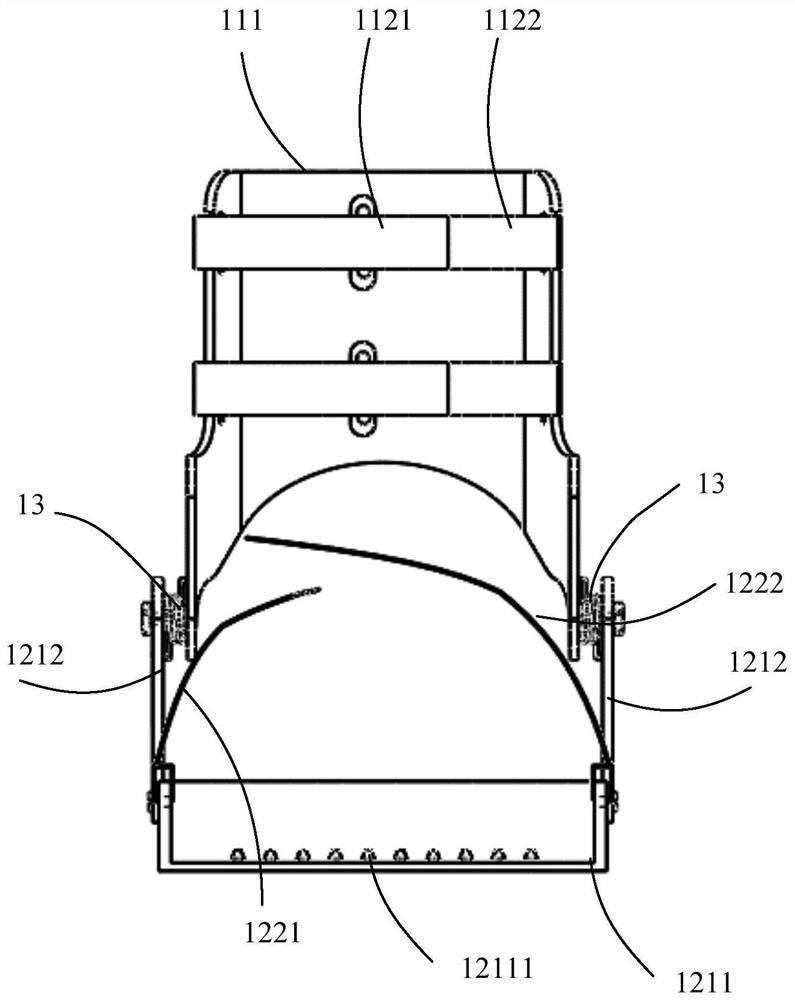

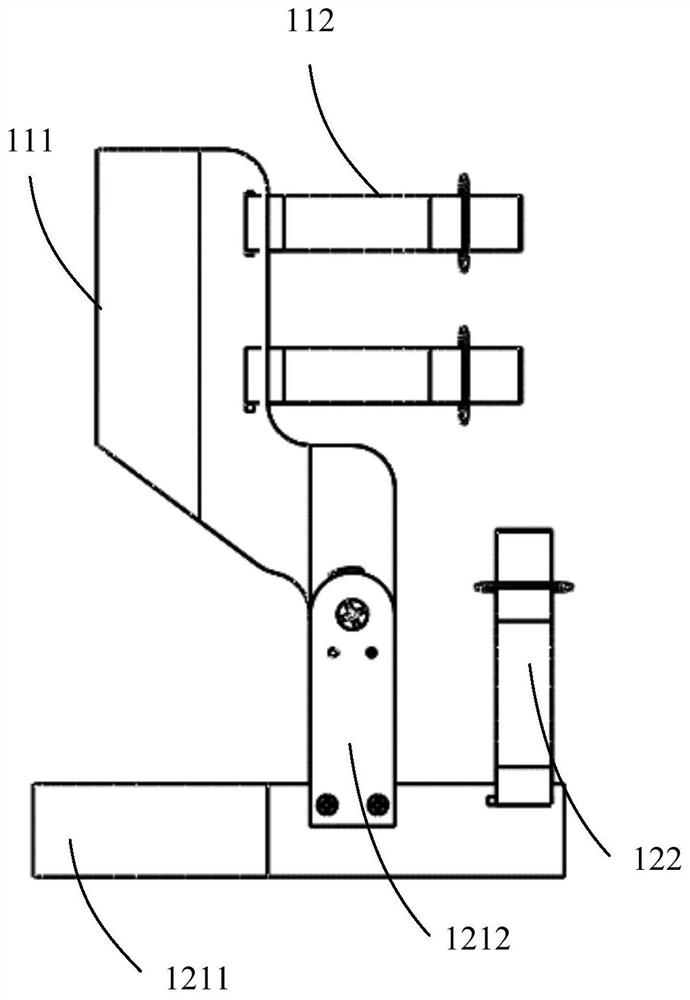

Constraining assembly of recreation facility

ActiveCN106693372AAvoid strangulationSmall binding forceRussian swingsGreat wheelsHuman bodyRecreation

The invention discloses a constraining assembly of a recreation facility. The constraining assembly of the recreation facility comprises a seat (1) for sitting and safe clothes (4), wherein a safe pressing lever (2) which can rotate relative to the seat (1) to protect a human body (10) and a safe belt ( 3) which can constrain the human body (10) are arranged on the seat (1); the human body (10) can wear the safe clothes (4); the safe clothes (4) can be connected with the seat (1); a clamping structure (5) is arranged on a backrest of the seat (1); and a clamp connection structure (6) which can be in clamped connection with the clamping structure (5) is arranged on the back of the safe clothes (4). The constraining assembly of the recreation facility is simple in structure and good in safety.

Owner:甘兵鹏

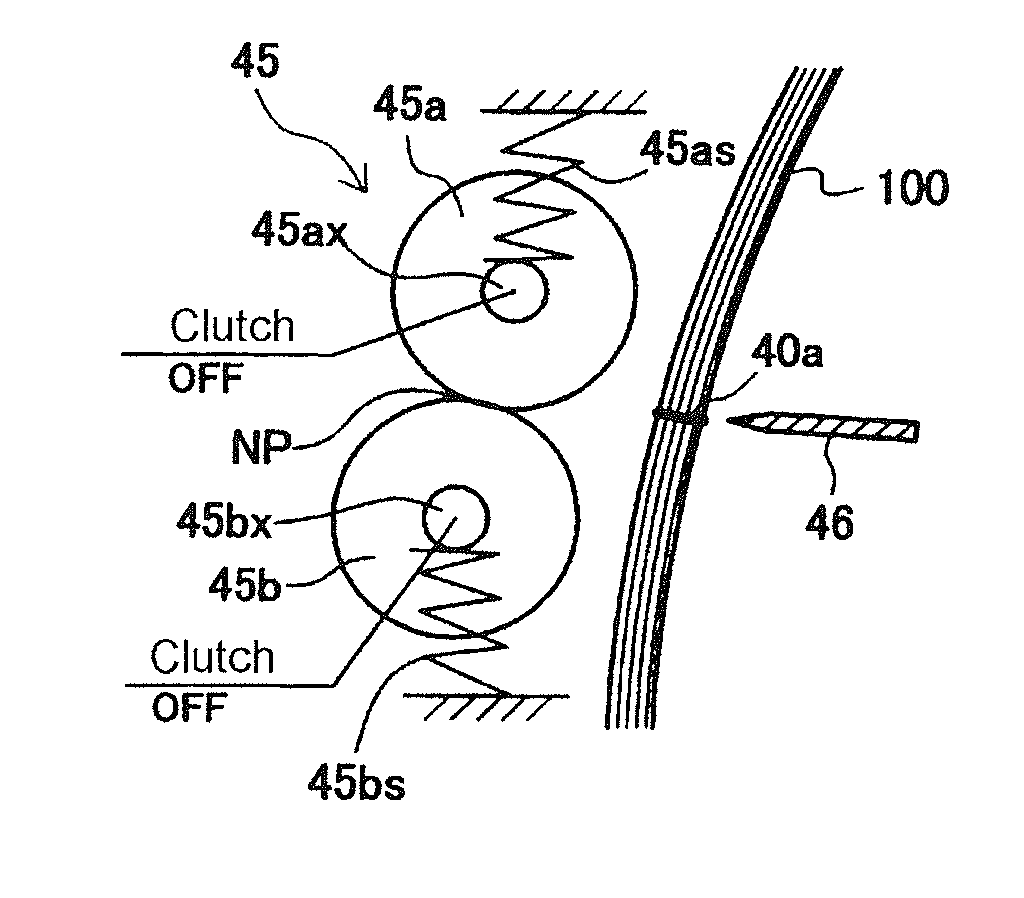

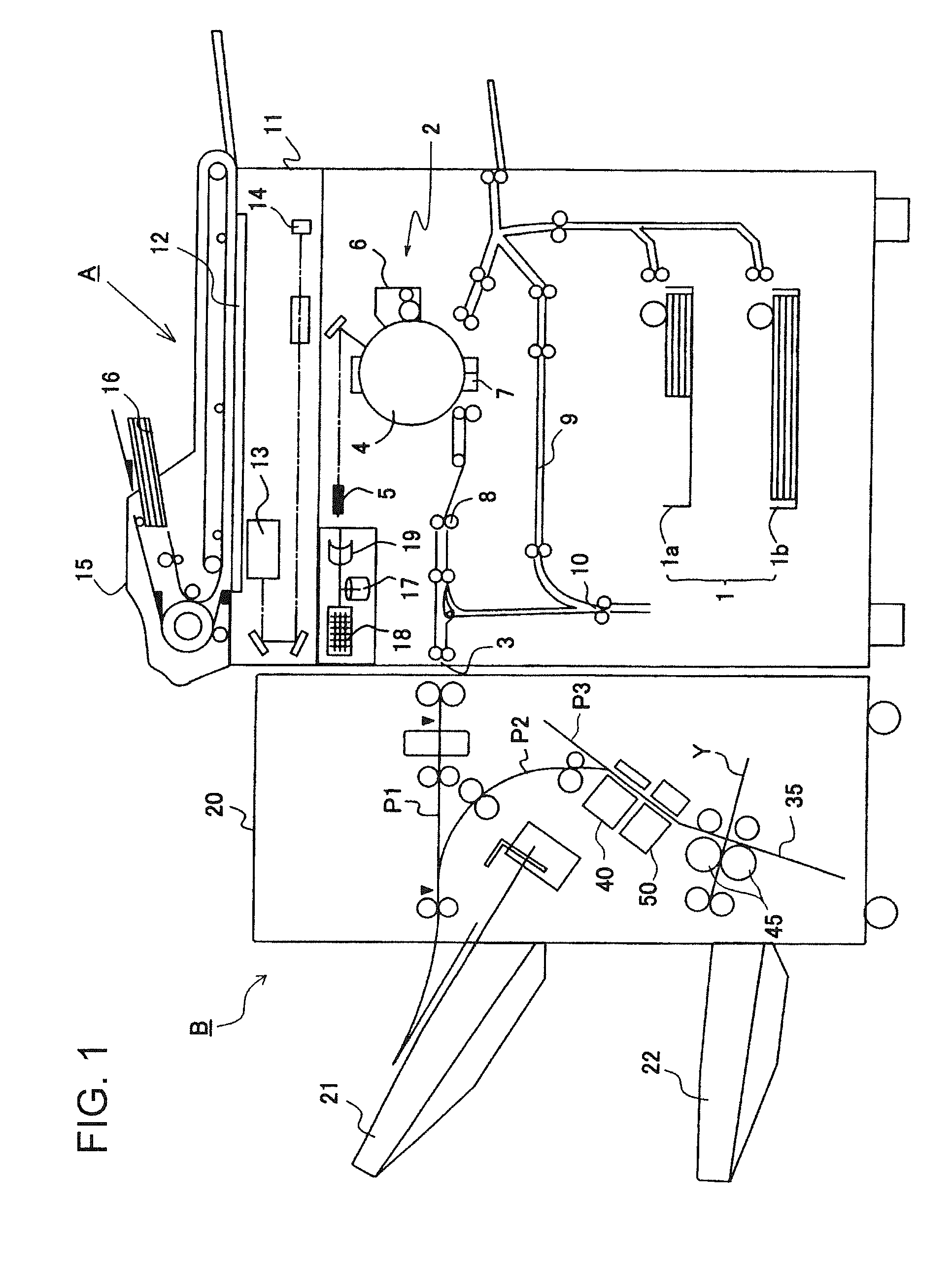

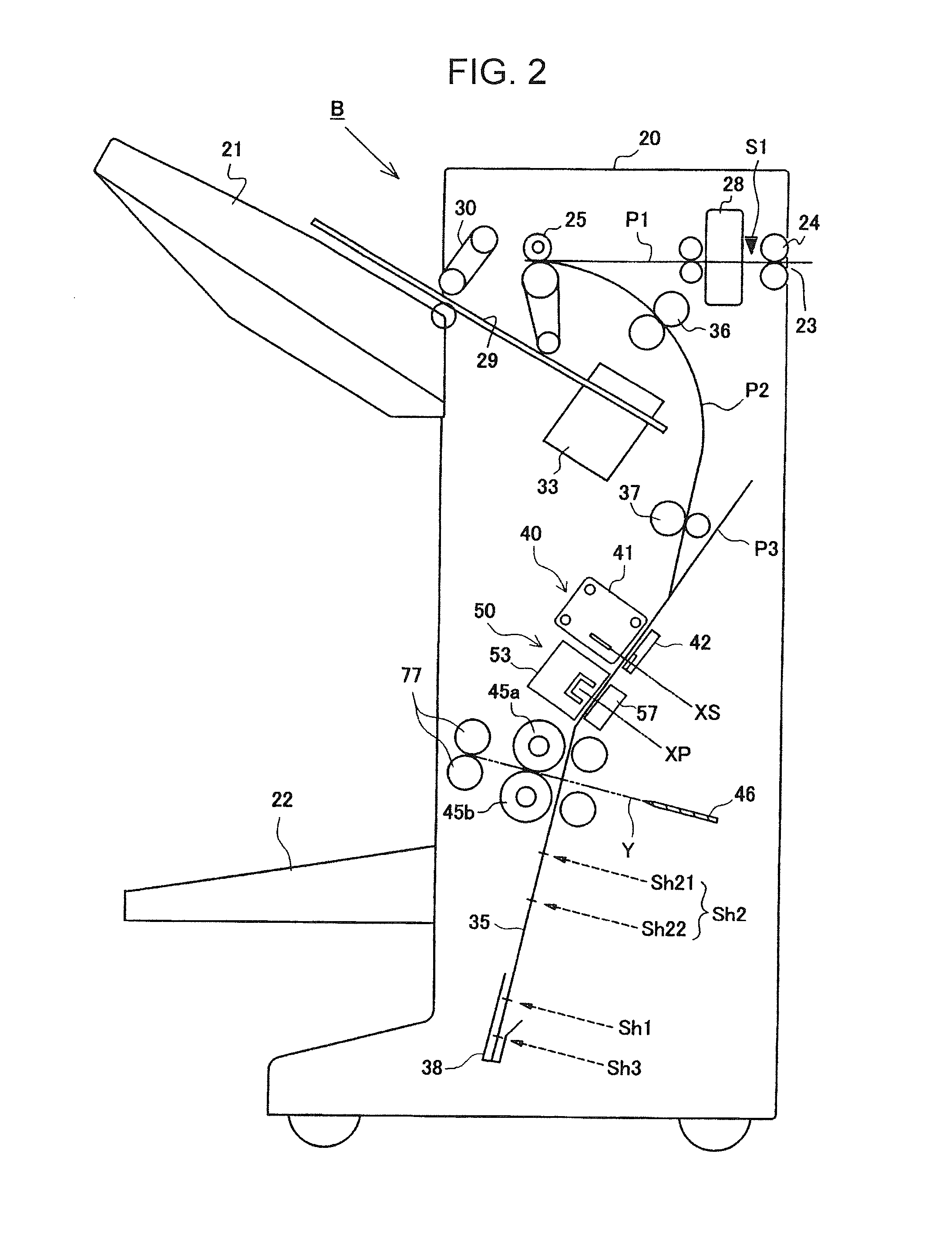

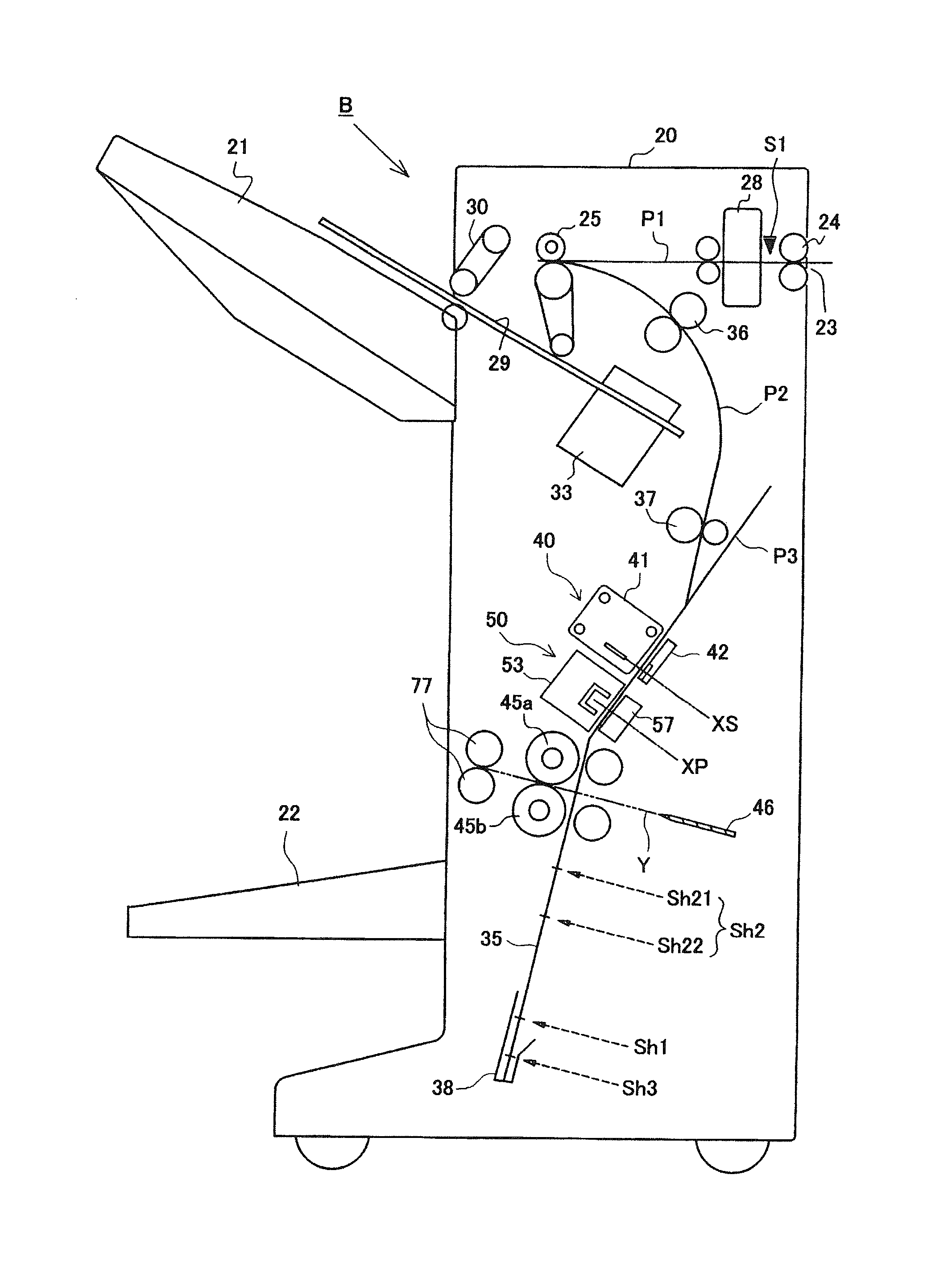

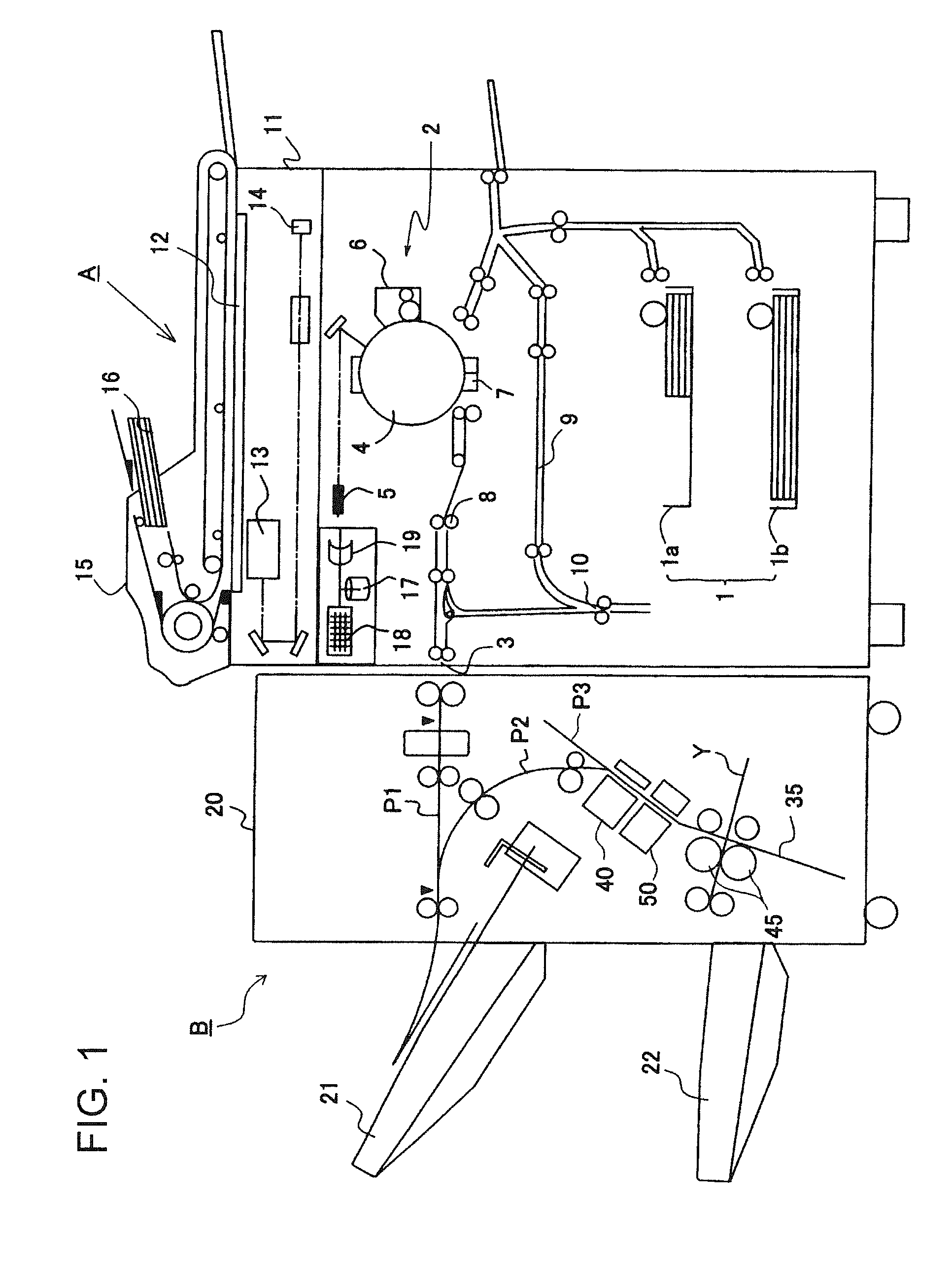

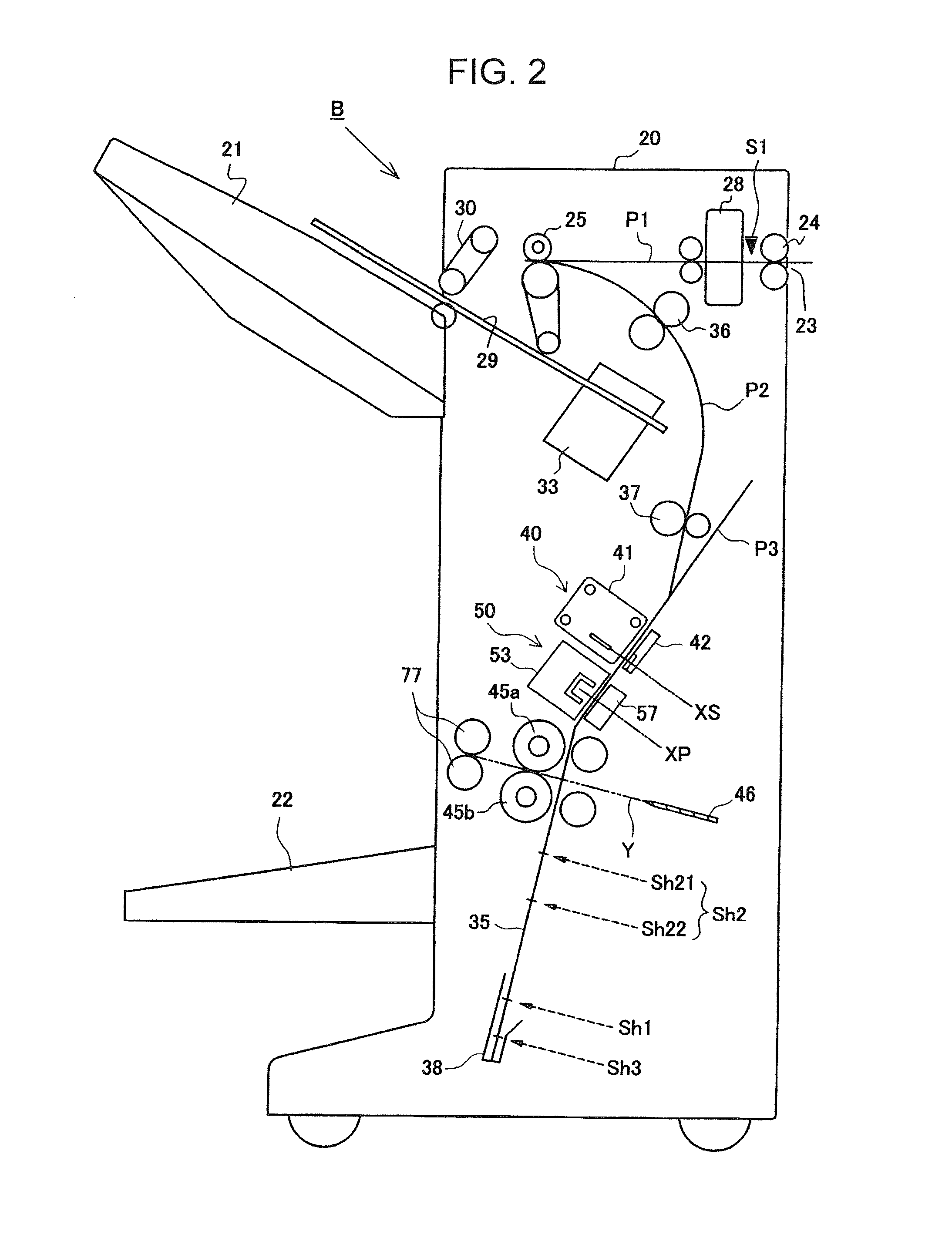

Sheet processing device and image forming device provided with the sheet processing device

ActiveUS20150117983A1Small sizeSmall binding forceMechanical working/deformationBook making processesEngineeringPaper sheet

To provide a sheet processing device that performs saddle stitching processing that binds a bundle of stacked paper sheets at a position around a center thereof and then folds in half the paper sheet bundle at the binding portion, the device being capable of selectively performing both saddle stitching using a metallic staple and saddle stitching not using the metallic staple for environmental protection and capable of reducing a size.A sheet processing device includes a stacker section that temporarily stacks conveyed paper sheets in a substantially vertical attitude, a stopper that regulates the paper sheets stacked in the stacker section, a first binding section that is provided in the stacker and saddle-stitches, with a metallic staple, a paper sheet bundle at a binding position around a center of the paper sheet bundle in a sheet conveying direction, a second binding section that saddle-stitches, without using the metallic staple, the paper sheet bundle at the binding position around the center of the paper sheet bundle in the sheet conveying direction, and a folding section that folds in half the paper sheet bundle. An interval between the second binding section and folding section is set smaller than an interval between the first binding section and folding section.

Owner:NISCA KK

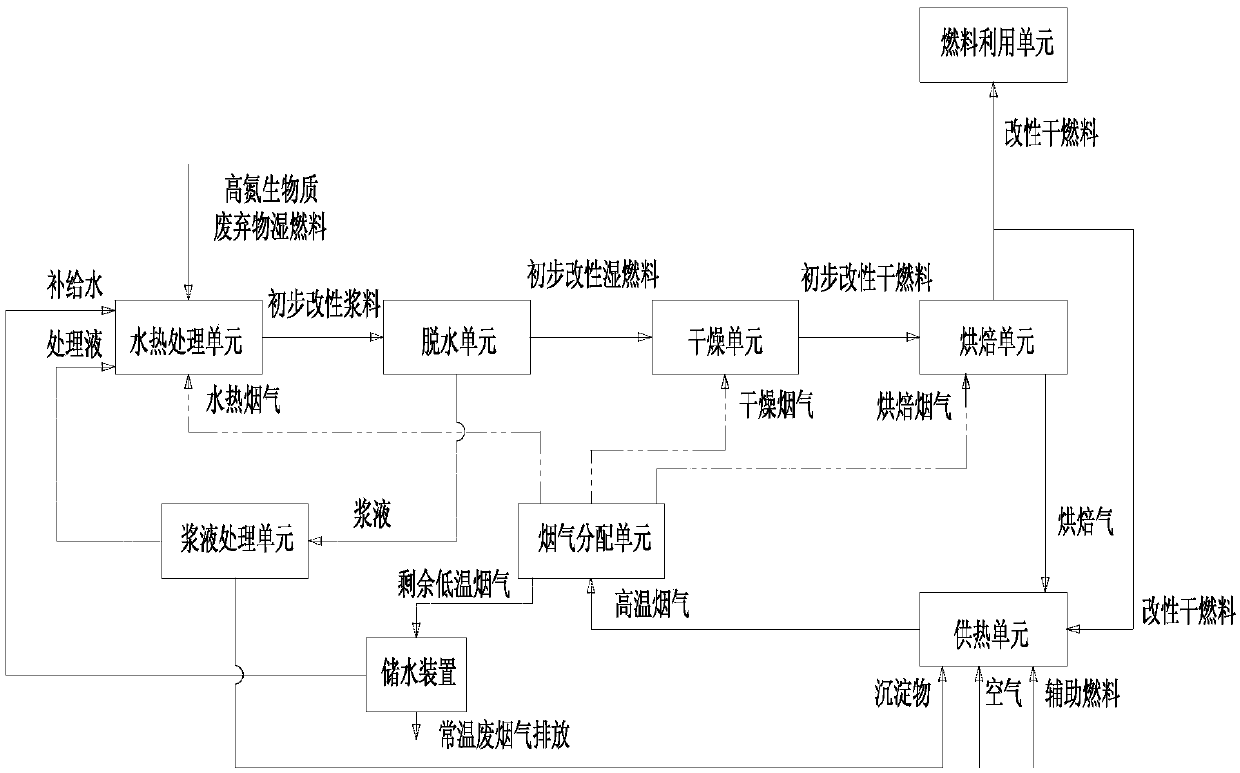

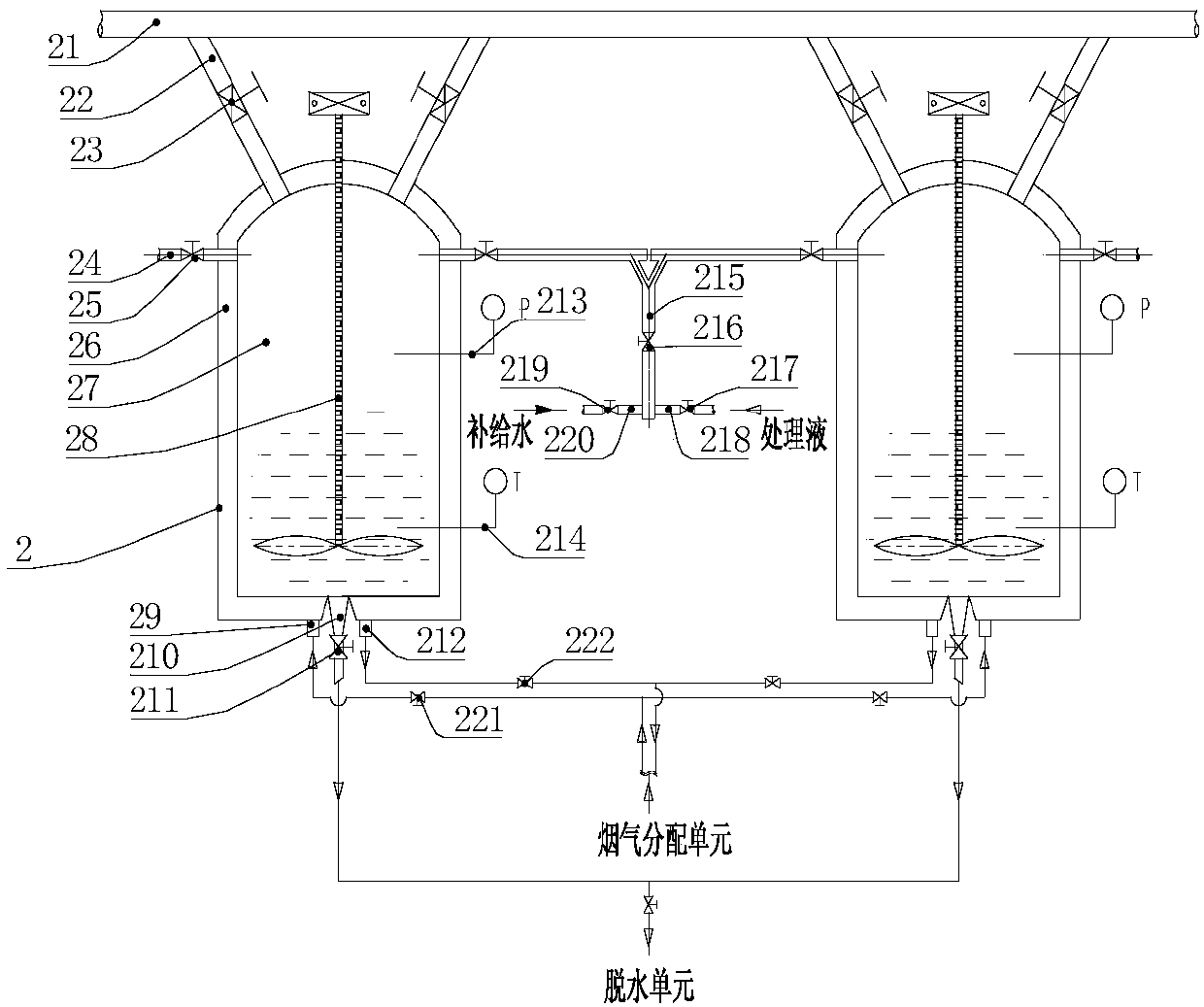

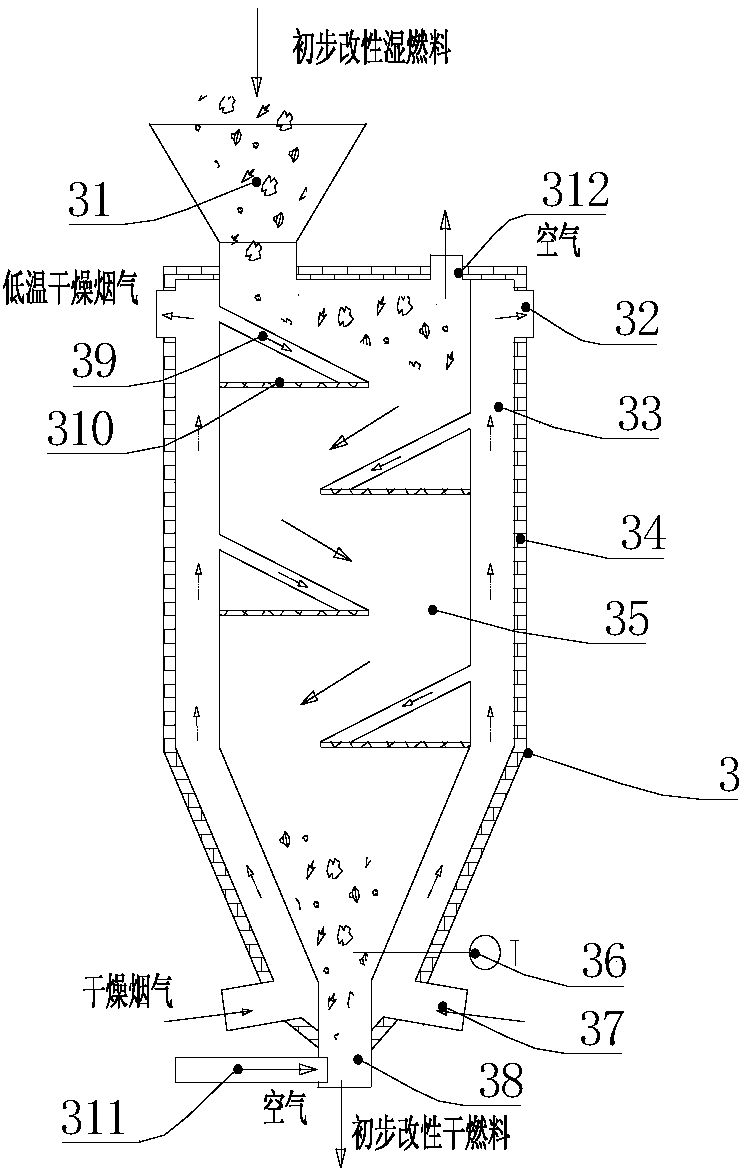

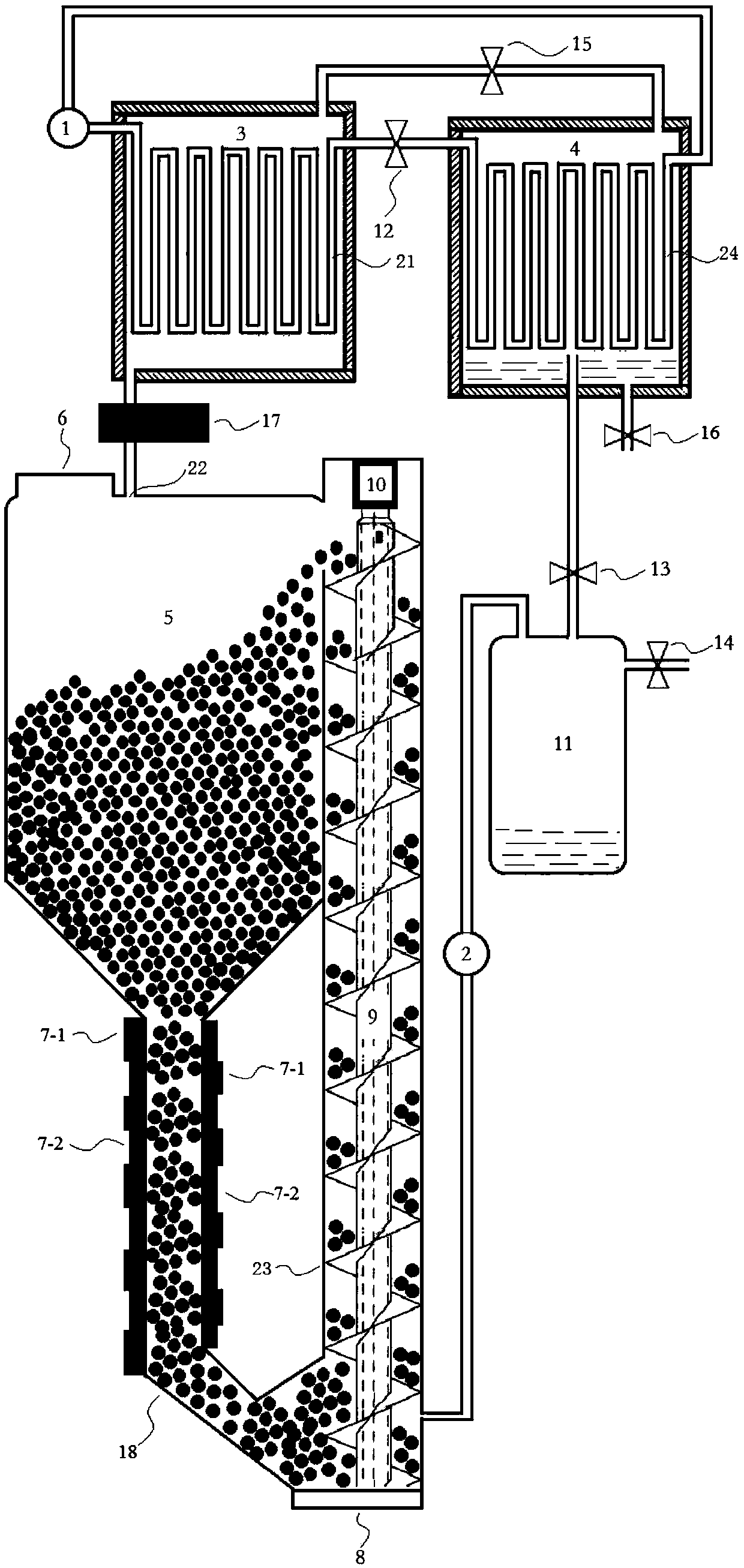

Upgrading and denitriding modification method by using high-nitrogen biomass wastes as fuel

The invention provides an upgrading and denitriding modification method by using high-nitrogen biomass wastes as fuel. In the upgrading and denitriding modification method, a hydrothermal treatment unit, a dewatering unit, a drying unit and a baking unit which are used for modifying the high-nitrogen biomass wastes in sequence, and a heat supply unit for supplying energy, a flue gas distribution unit, and a slurry treatment unit and a water storage device which are used for balancing a material are involved. By a reasonable coupling pretreatment process, effective upgrading (dewatering and increase of the energy density) and denitriding of the high-nitrogen biomass wastes are realized under basically self-heat-supplying and pollution-free conditions. The dry-basis heat value of the modified fuel is increased by 12 to 34 percent, the fuel denitriding rate is 55 to 75 percent, and the water content is 5 percent or below; efficient and clean thermochemical utilization of the rear end canbe realized; the method is simple in coupling process, high in operability, pollution-free, and extremely low in energy consumption and energy loss, and is a pretreatment method capable of effectivelyincreasing the reutilization value of the high-nitrogen biomass wastes.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

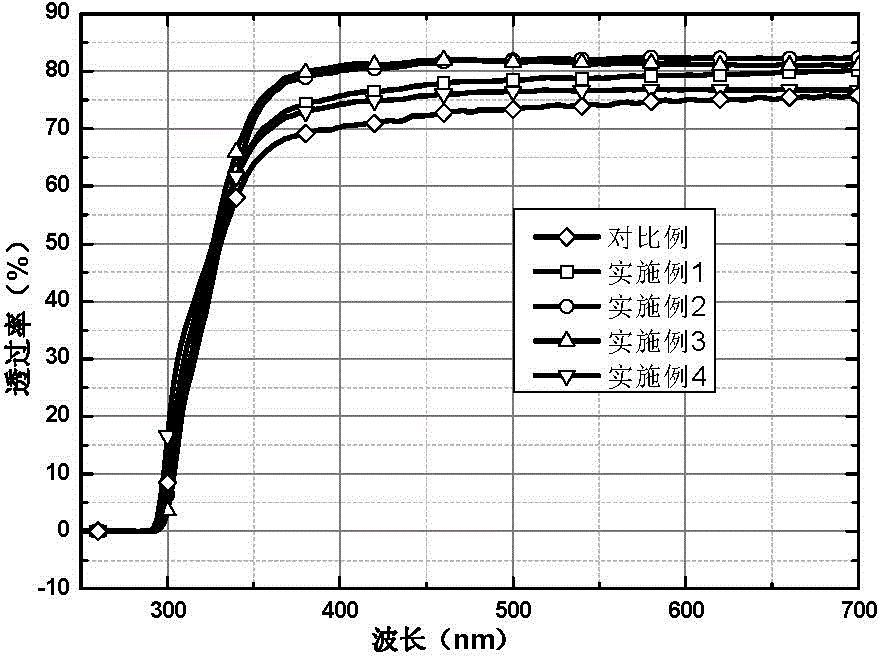

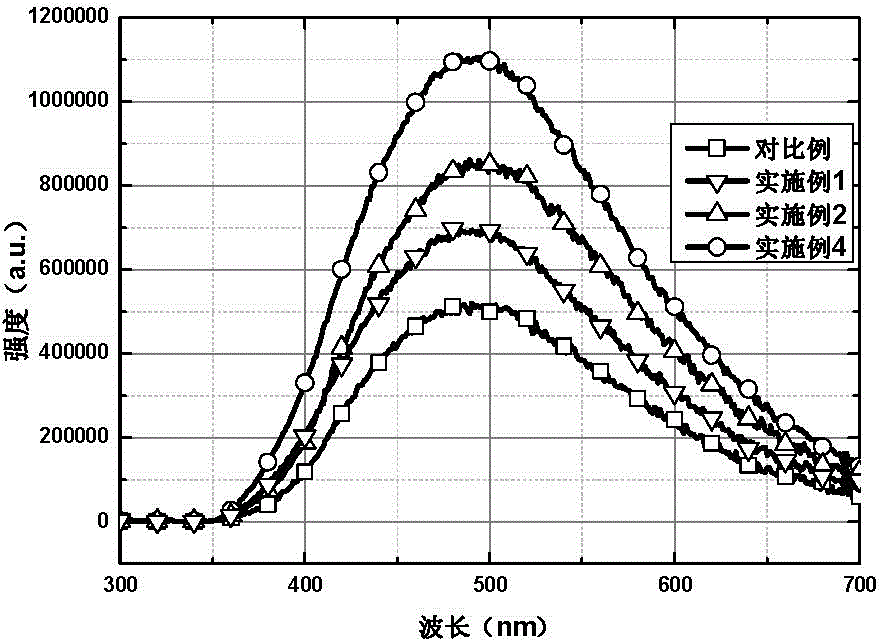

Anion-cation co-doped bismuth silicate scintillation crystal and preparation method thereof

InactiveCN104562205ALow viscosityPromote absorptionPolycrystalline material growthFrom frozen solutionsSilicon oxygenScintillation crystals

The invention relates to an anion-cation co-doped bismuth silicate scintillation crystal and a preparation method thereof. The bismuth silicate scintillation crystal is doped with F<-> and Ba<2+>. According to the doped ions F<-> and Ba<2+>, local charge imbalance inside the crystal is compensated to a certain degree; and moreover, bridging oxygen between silica tetrahedrons can be broken by F, the bridging oxygen is replaced to enter the BSO melt, and the binding force between silicon-oxygen aggregation layers can be reduced, so that the viscosity of the BSO melt is reduced, and the macroscopic defects are reduced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

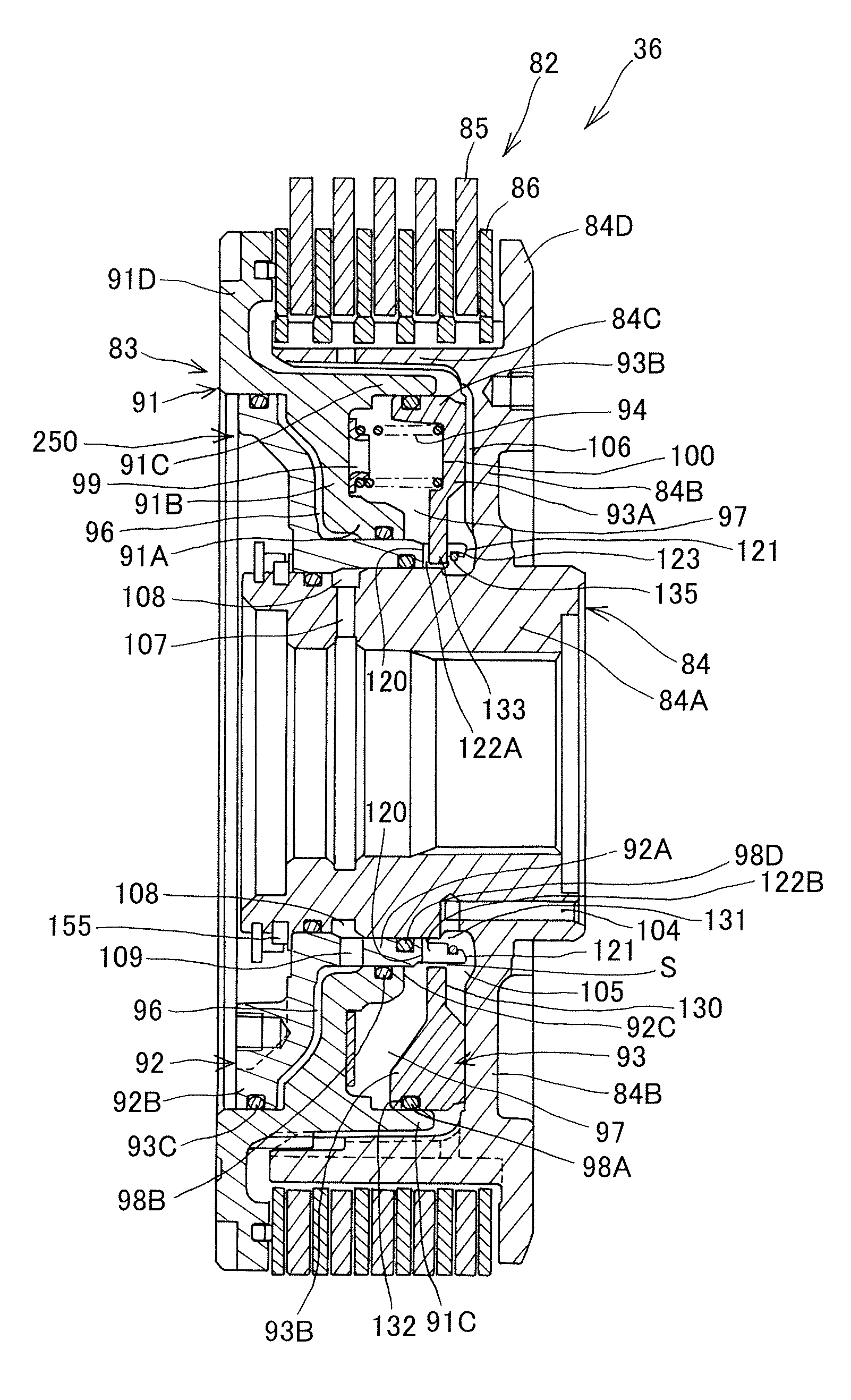

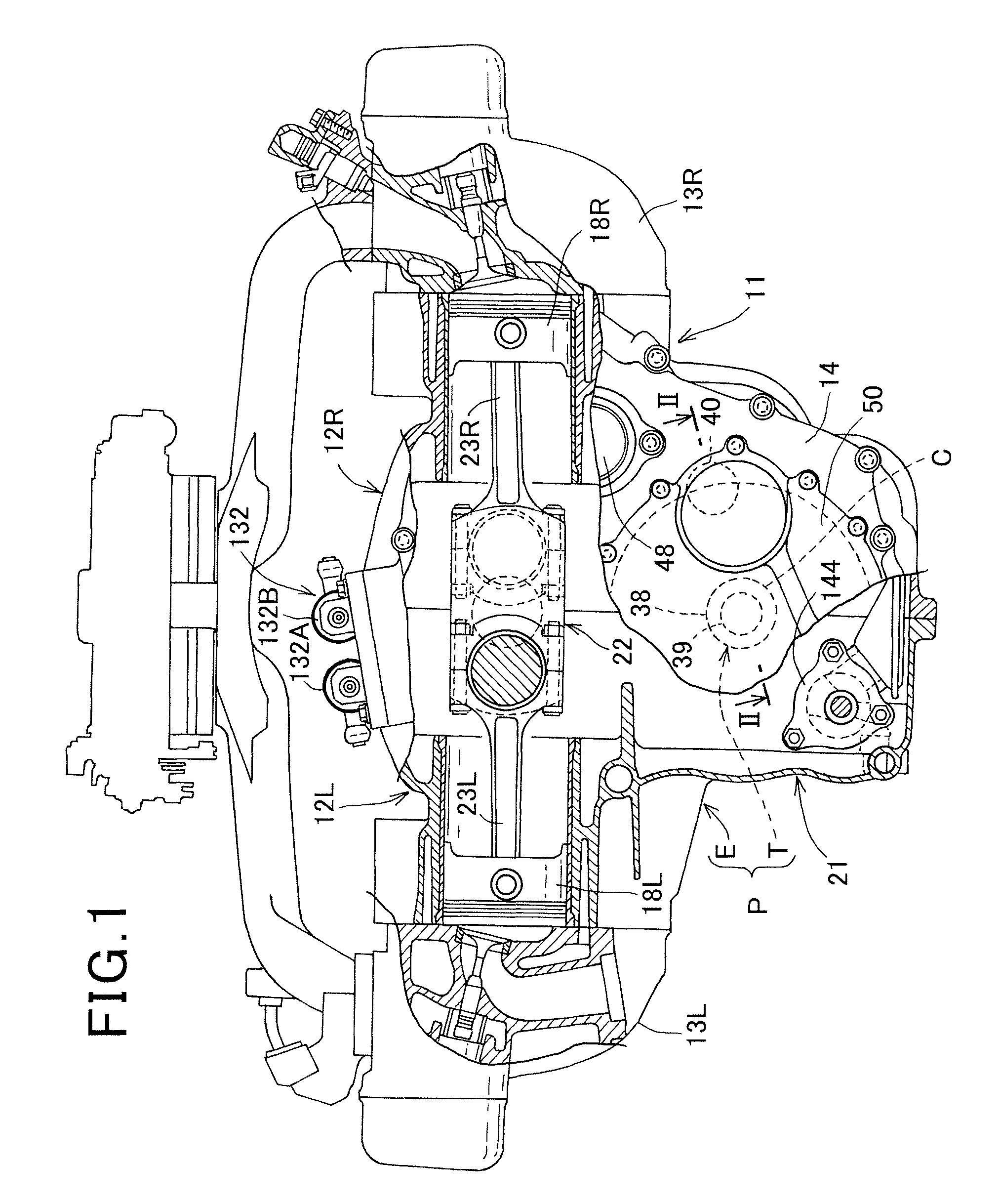

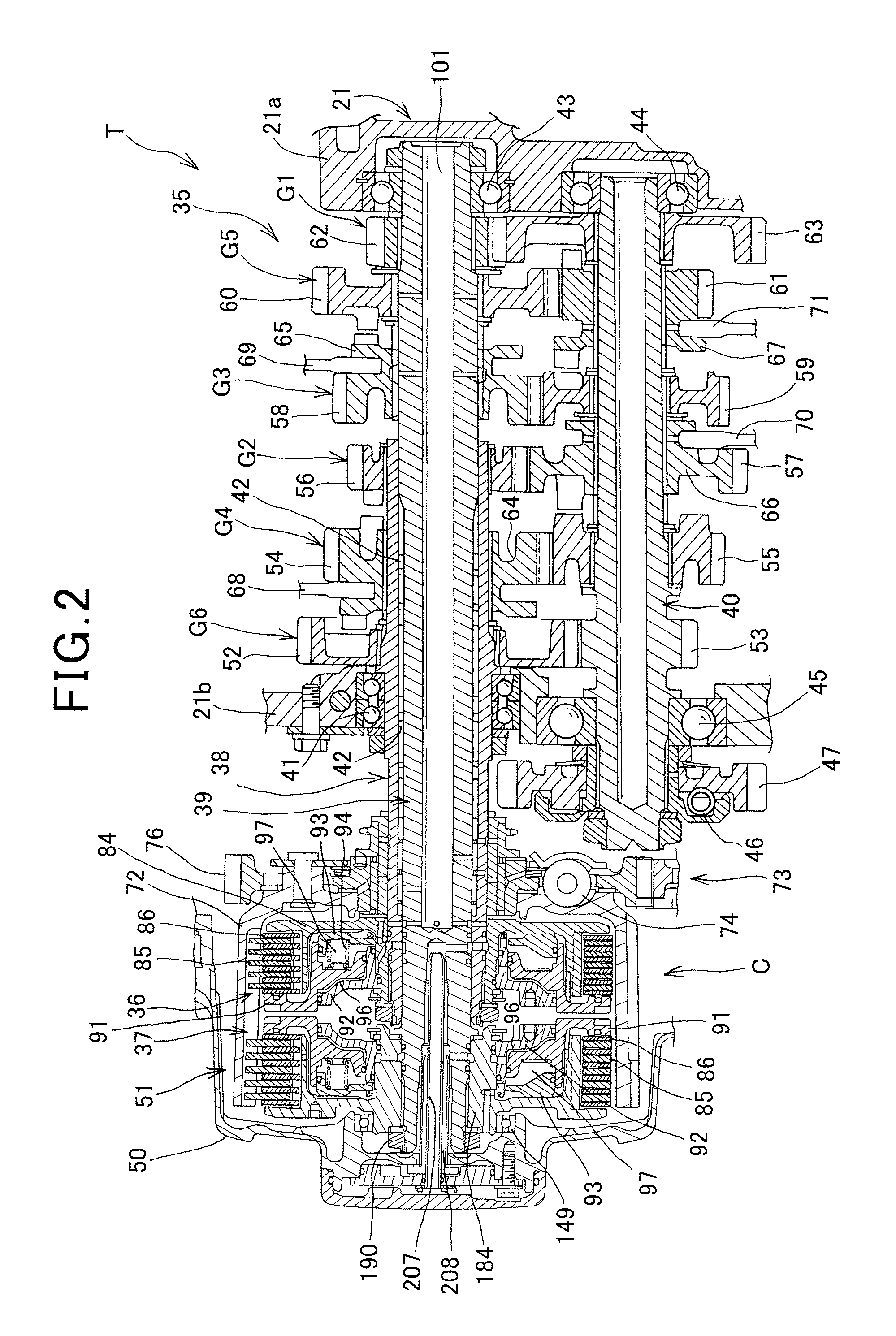

Hydraulic clutch device

ActiveUS8640843B2Small locking forceImprove assembly workabilityFluid actuated clutchesFriction clutchesPiston GuideClutch

In a first hydraulic clutch device 36 provided with a first clutch inner 84, a pressure bearing plate portion 84D disposed on the first clutch inner 84 opposing driving and driven friction plates 85 and 86, a clutch piston 91 that is consecutively disposed to a pressurizing plate portion 91D and moves to the side to pressurize the driving and driven friction plates 85 and 86 in accordance with an increase in a hydraulic pressure in a control hydraulic chamber 96, a piston guide 92 that forms a control hydraulic chamber 96 between itself and the clutch piston 91, and a canceller plate 93 that forms a hydraulic canceller chamber 97 on the side opposite to the control hydraulic pressure chamber 96, a projection portion 133 of the canceller plate 93 and a notch portion 122 disposed in the piston guide 92 and engaged with the projection portion 133 are engaged with each other and assembled, and a clip 135 that is engaged with an engagement groove 123 of the notch portion 122 and regulates axial movement of the canceller plate 93 is disposed.

Owner:HONDA MOTOR CO LTD +1

Biliary drainage tube fixing device for post-orthotopic liver transplantation

InactiveCN109589487ASmall binding forceRelieve painMedical devicesCatheterEngineeringOrthotopic liver transplantation

The invention relates to the technical field of medical apparatus and instruments, and particularly discloses a biliary drainage tube fixing device for post-orthotopic liver transplantation. The biliary drainage tube fixing device for post-orthotopic liver transplantation comprises a cross belt, wherein the cross belt is fixedly connected with a left pull belt and a right pull belt; two fixing buckles, a fixing seat and a buckling portion are fixedly arranged on the outer surface of the cross belt; the cross belt has an inflatable air bag structure; an air inlet is formed in the upper surfaceof the cross belt; a rotating groove is formed in the fixing seat; a rotating seat is placed in the rotating groove; the fixing seat and the rotating seat are connected through a clamping device; a groove is formed in the bottom of the rotating seat; tooth grains are arranged on the inner side wall of the groove; a buckle is fixedly arranged on the upper surface of the rotating seat; a sliding groove is formed in the bottom of the fixing seat; a sliding block is placed in the sliding groove; the right end of the sliding groove is elastically connected with the right side surface of the slidinggroove through a spring; and a vertical clamping block is fixed on the upper surface of the sliding block. The biliary drainage tube fixing device for post-orthotopic liver transplantation has the advantages of convenience in mounting, simplicity in structure, convenience in operation, safety and reliability, adjustable angle of a flow distributing body, and capability of greatly relieving pain of a patient.

Owner:王新

Powder product finishing machine mold base core rod regulating device and finishing process thereof

The invention relates to a powder product finishing machine mold base core rod regulating device and a finishing process thereof. The powder product finishing machine mold base core rod regulating device is characterized in that a mold stripping regulating bar fixedly connected to an upper punching fixed plate is arranged on the upper punching fixed plate and passes through a female mold plate and a lower punching fixed plate which are sequentially arranged at the lower end of the upper punching fixed plate; a lower fixed seat is arranged at the lower part of the lower punching fixed plate; cavities into which a core rod penetrates are formed in the female mold plate, the lower punching fixed plate and the lower fixed seat; the lower end of the core rod passes through a core rod air cylinder arranged in the lower fixed seat and is connected to a core rod piston; the lower surface of the core rod piston leans against a regulating threaded rod which can move up and down; and a regulating block which can move up and down along the mold stripping regulating bar is arranged at a place of the mold stripping regulating bar, which is located at the lower part of the lower punching fixed plate. The powder product finishing machine mold base core rod regulating device has the beneficial effects that the operating stroke of the core rod can be adjusted; and when a product is stripped from a mold, the core rod is stripped from a female mold along with the product, then the product expands after an exogenic action does not exist, and the binding force of the core rod is reduced; and the core rod is stripped from the inner hole of the product under the action of the core rod air cylinder force, thus, the core rod is less likely to be damaged and the service life of the core rod is prolonged.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Sheet processing device and image forming device provided with the sheet processing device

ActiveUS9352604B2Small binding forceFirmly bonded stateMechanical working/deformationBook making processesImage formationEngineering

Owner:NISCA KK

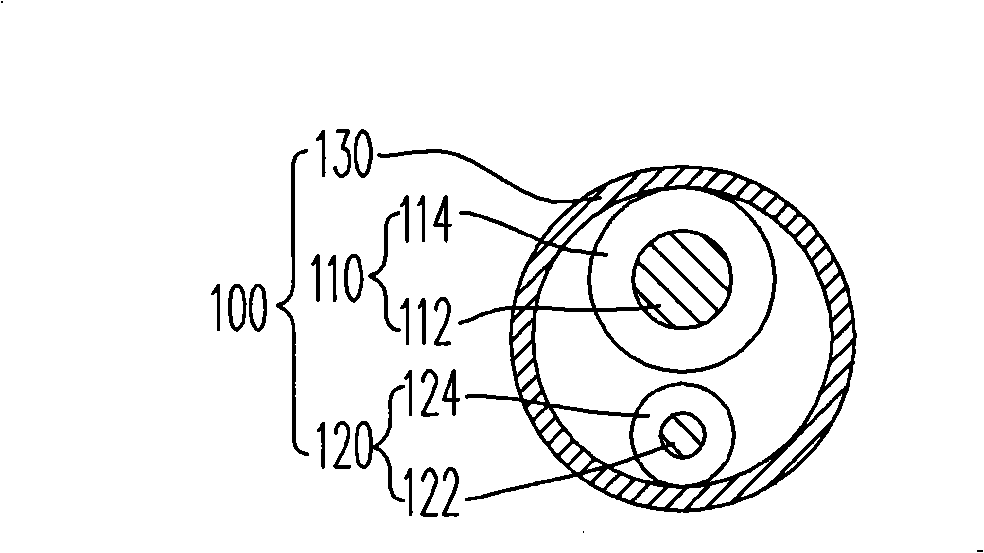

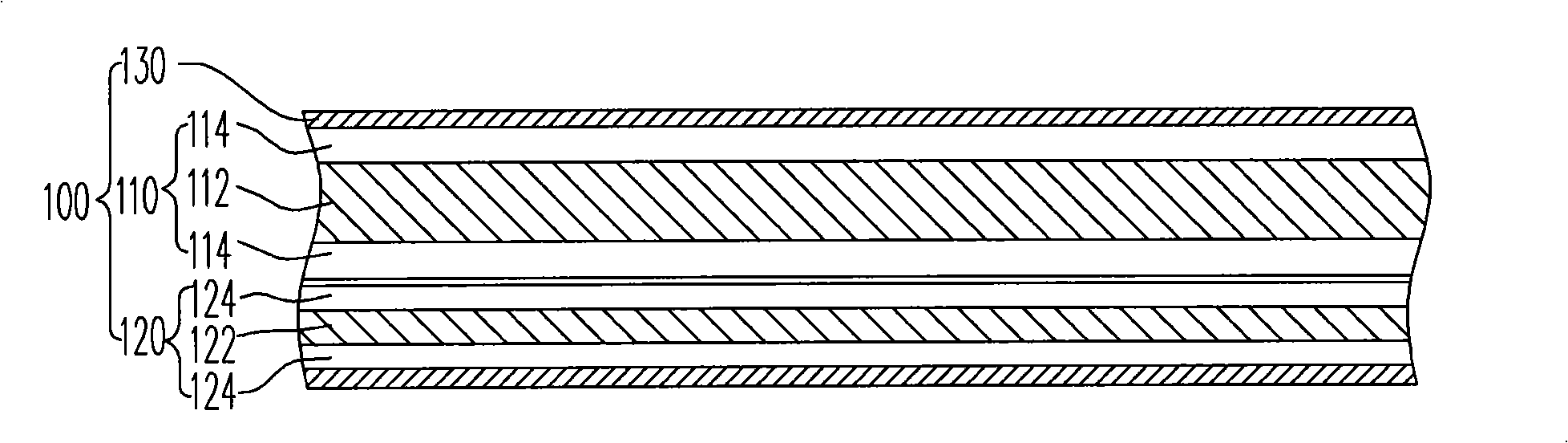

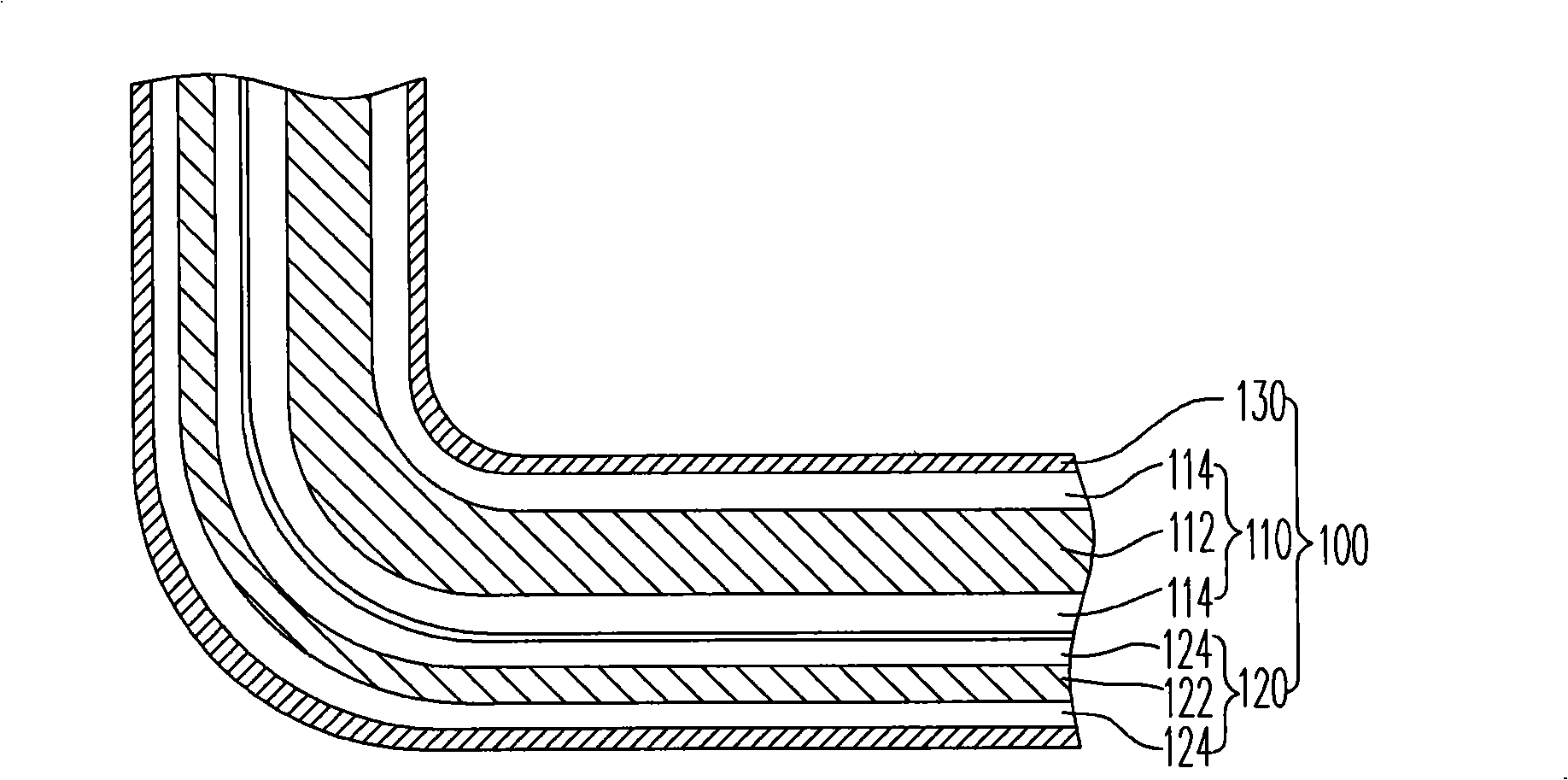

Wire structure and backlight module group applying same

InactiveCN101312081AAvoid disconnected situationsImprove reliabilityInsulated cablesNon-linear opticsLow voltageEngineering

The invention discloses a conductor structure, comprising a high-voltage conductor, a low-voltage conductor and a heat-shrinkable tubing. The heat-shrinkable tubing is coated around the peripheries of the high-voltage conductor and the low-voltage conductor, and the surface of the tubing is provided with a plurality of broken holes for partially exposing the high-voltage conductor and the low-voltage conductor. A contact area among the heat-shrinkable tubing, the high-voltage conductor and the high-voltage conductor can be reduced by aid of the designed broken holes on the heat-shrinkable tubing, and thereby the problem that the conductor structure in the prior art is easy to result in breaking when the conductor structure is pulled can be avoided.

Owner:CHUNGHWA PICTURE TUBES LTD

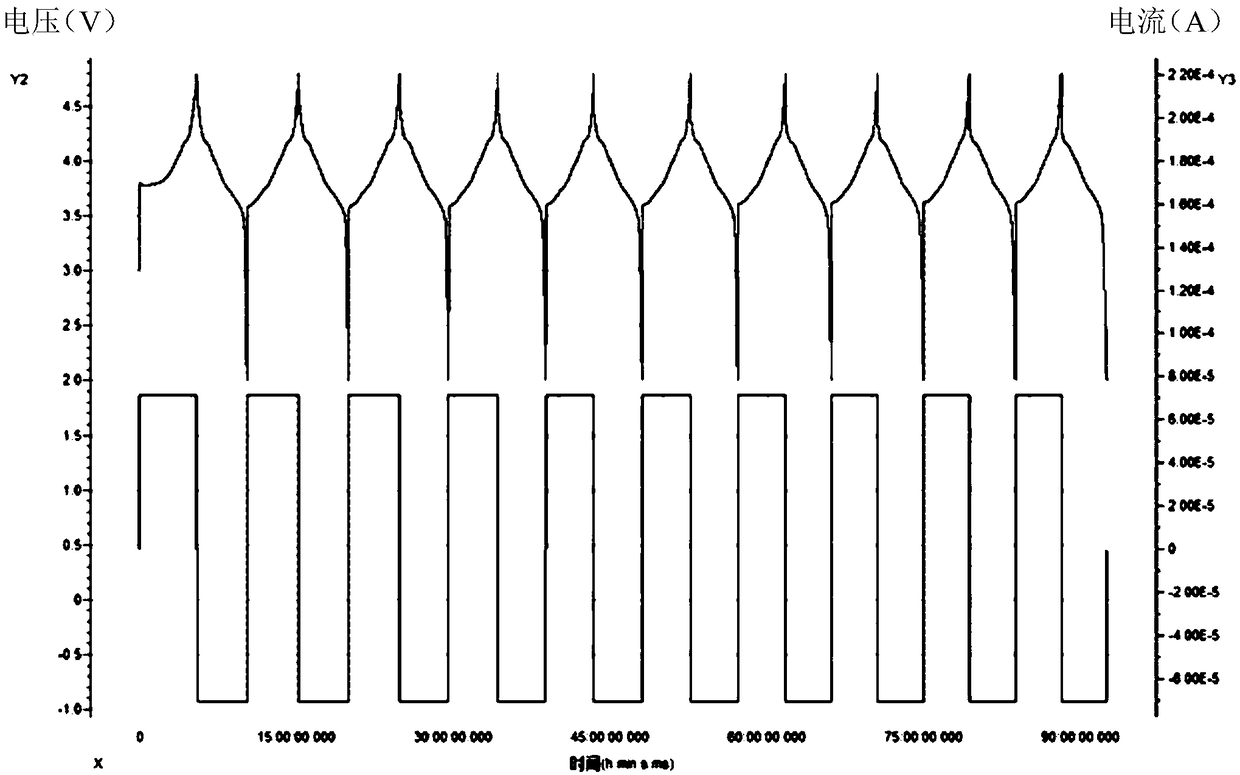

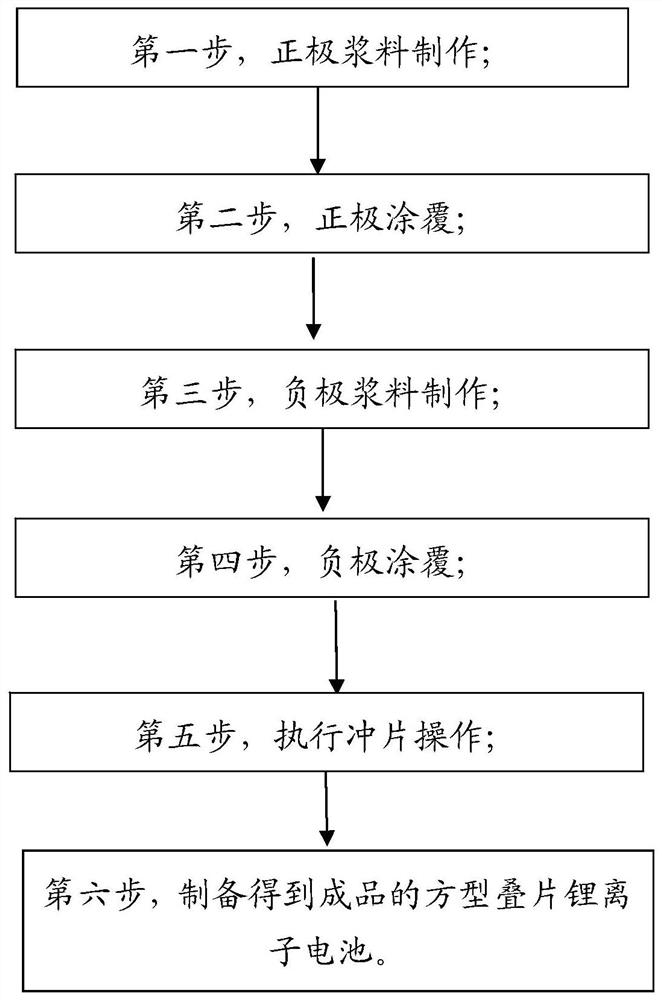

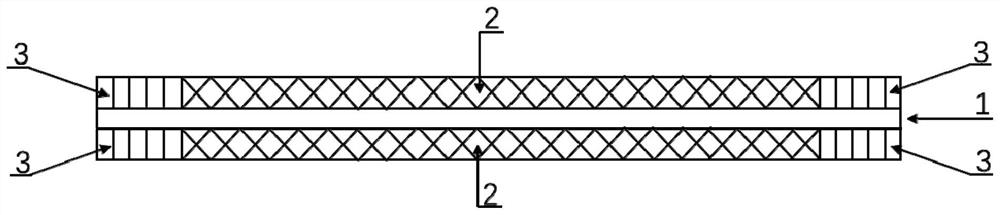

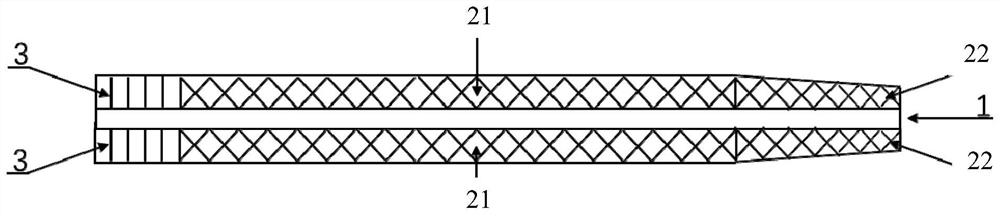

Preparation method and application of square laminated lithium ion battery capable of improving stress

PendingCN114464895AEasy to prepareRelieve stress concentrationFinal product manufactureElectrode collector coatingAdhesiveEngineering

The invention discloses a preparation method of a square laminated lithium ion battery capable of improving stress. The preparation method comprises the following steps: 1, preparing positive electrode slurry; 2, coating a positive electrode; step 3, manufacturing negative electrode slurry; 4, coating a negative electrode; step 5, performing sheet punching operation to obtain a cut positive electrode sheet and a cut negative electrode sheet C1; and 6, sequentially carrying out existing processes of lamination, tab welding, shell entering, drying, liquid injection, exhausting, formation, aging and capacity grading on the cut positive plate obtained in the step 5 and the cut negative plate C1 to obtain the finished square laminated lithium ion battery. The method is scientific in design, the coating process of the positive plate is improved, and the two sides of the positive plate are scientifically coated with the ceramic adhesive and the positive slurry according to a preset mode, so that the binding force of the bottom corner of the battery shell to a battery pole group assembled in the battery shell can be effectively reduced, and the stress concentration problem of the square laminated lithium ion battery is relieved; and the cycle performance of the square laminated lithium ion battery is improved.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

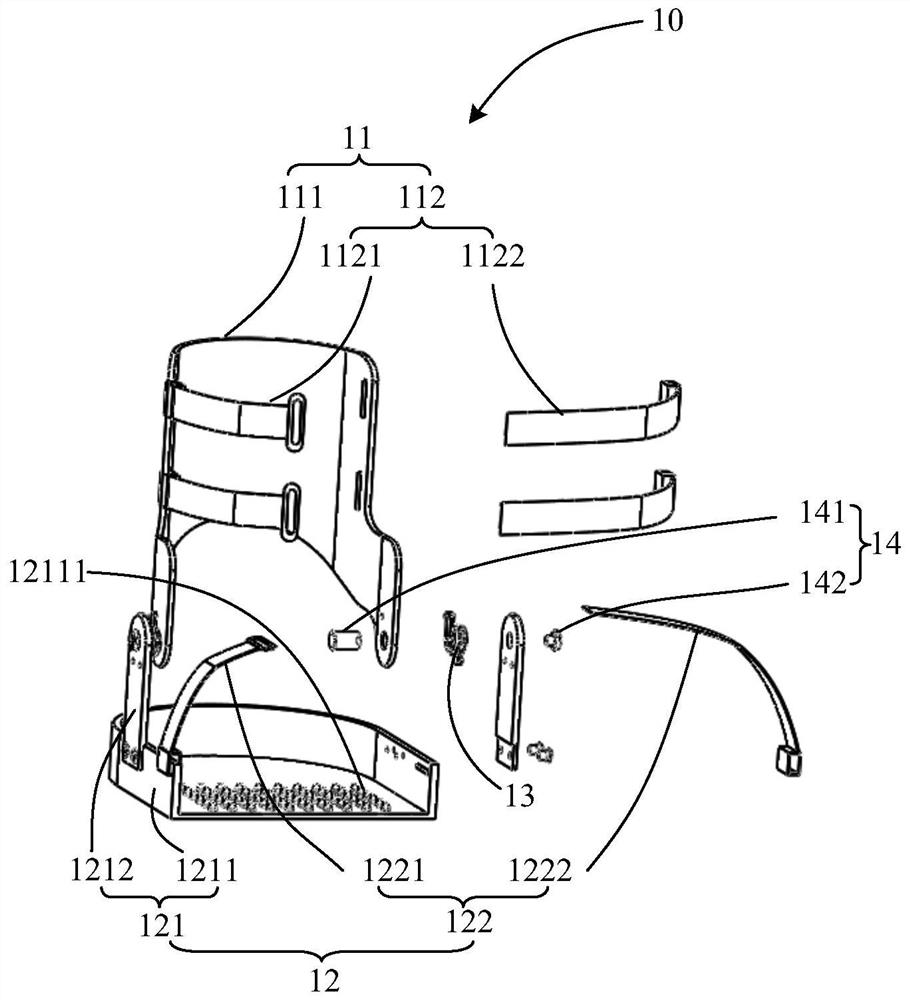

Ankle joint assisting exoskeleton device and assisting shoes

InactiveCN111604886ASmall binding forceReduce the impact of forceProgramme-controlled manipulatorFootwearEngineeringPhysical therapy

The invention relates to an ankle joint assisting exoskeleton device and assisting shoes. The device comprises a leg assembly, a foot assembly and an elastic part, wherein the leg assembly comprises aleg frame, the leg frame is used for being wound around a leg of a user, the foot assembly is rotationally connected with the leg frame and used for being worn on a foot of the user, and the elasticpart is arranged at the joint of the leg frame and the foot assembly and used for generating elastic deformation or restoring to the natural state when an included angle between the leg frame and thefoot assembly changes within a preset angle range so as to store or release energy. The ankle joint assisting exoskeleton device can store negative work in the walking process of the user and feed thenegative work back to the user when positive work needs to be done so as to provide walking assistance for the user, and the influence on leg muscle power generation of the user can be greatly reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

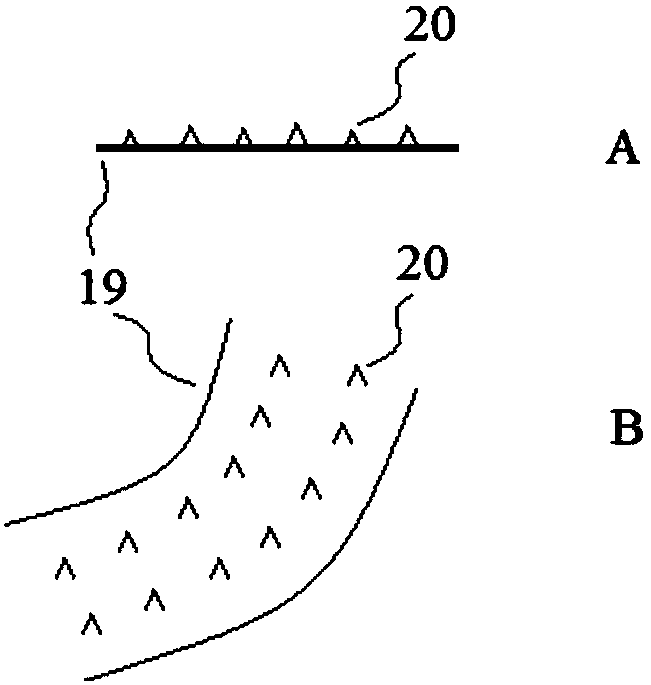

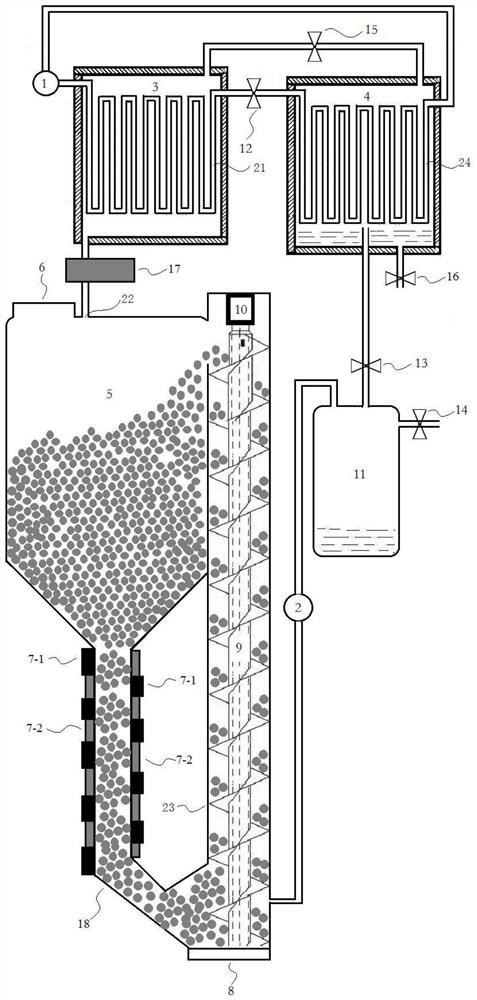

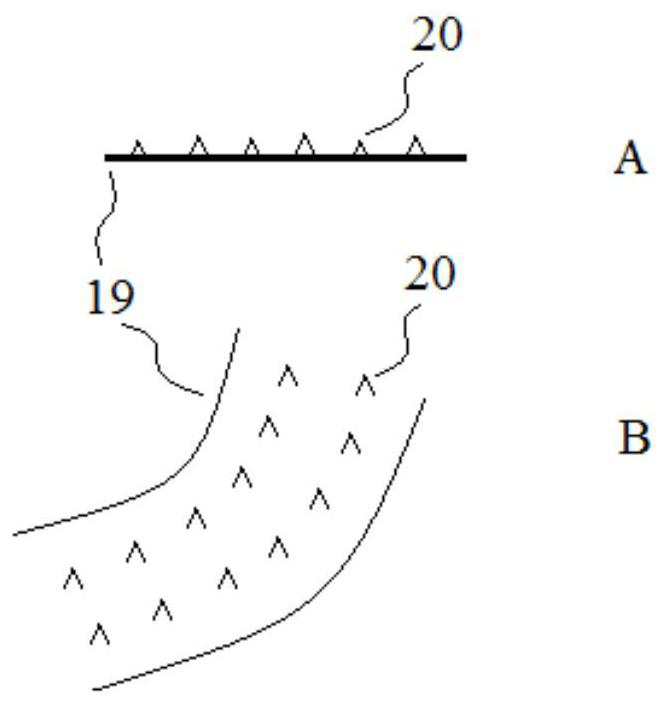

Idesia polycarpa seed drying device

ActiveCN107822175AChange the state of hydrogen bondsSmall binding forceFood treatmentEvaporationPropeller

The present invention discloses an idesia polycarpa seed drying device. The idesia polycarpa seed drying device comprises a baking tank. A material feeding inlet is opened on a top part of the bakingtank, a bottom part of the baking tank communicates with a top end of a tunnel, microwave emitters and strong magnets are arranged on the tunnel, a hot air inlet is arranged at the top part of the baking tank, a bottom part of the tunnel communicates with a bottom end of a longitudinal lifting channel, a material discharge port is arranged at the bottom end of the longitudinal lifting channel, anda screw propeller is arranged in the longitudinal lifting channel and in a shaft connection with a drive motor. A microwave magnetic field technology is combined with a vacuum technology, and compared with other structures, the drying device can promote a quick evaporation of internal moisture of materials and greatly shortens drying time.

Owner:湖北旭舟林农科技有限公司

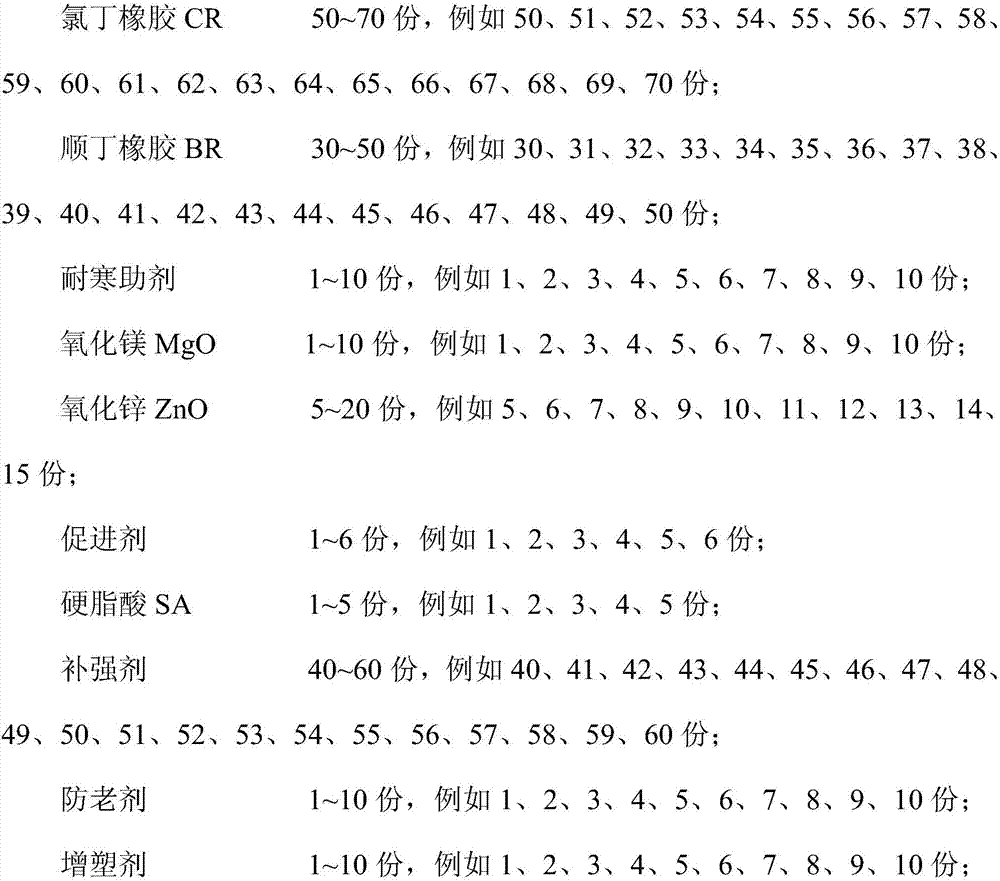

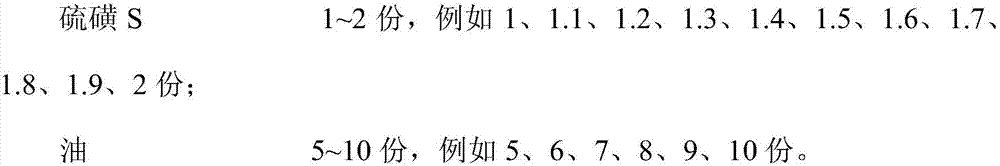

Cold-resistant drive belt primer and preparation method thereof

The invention discloses a cold-resistant drive belt primer and a preparation method thereof. The cold-resistant drive belt primer is made from the materials in parts by weight: 50-70 parts of chloroprene rubber (CR), 30-50 parts of butadiene rubber (BR), 1-10 parts of cold-resistant additive, 1-10 parts of magnesium oxide (MgO), 0.5-15 parts of zinc oxide (ZnO), 1-6 parts of accelerant, 1-5 parts of stearic acid (SA), 40-60 parts of reinforcing agent, 1-10 parts of anti-aging agent, 1-10 parts of plasticizer, 1-2 parts of sulphur (S) and 5-10 parts of oil. According to the cold-resistant drive belt primer, the cold-resistant additive, the vulcanizing agent, the accelerant, the stearic acid, the reinforcing agent, the anti-aging agent and the plasticizer act synergistically to jointly improve the low temperature crystallization-resistant property of the drive belt at the temperature of -10 DEG C under the premise of keeping physical properties of the drive belt such as break strength, tear strength, hardness and elongation at break.

Owner:锐牛股份有限公司

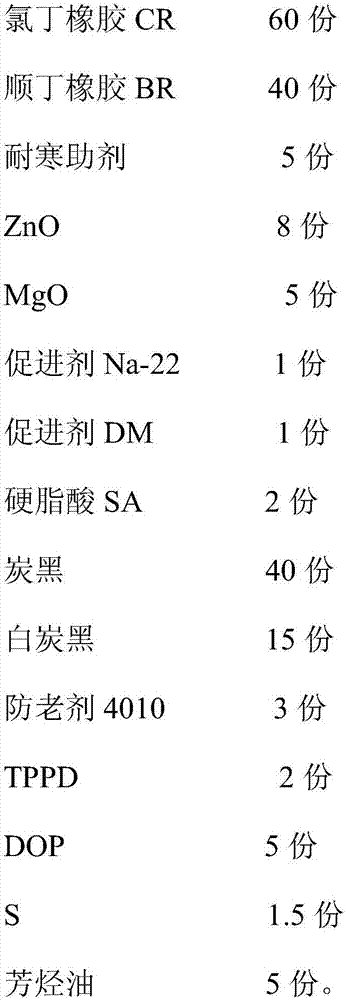

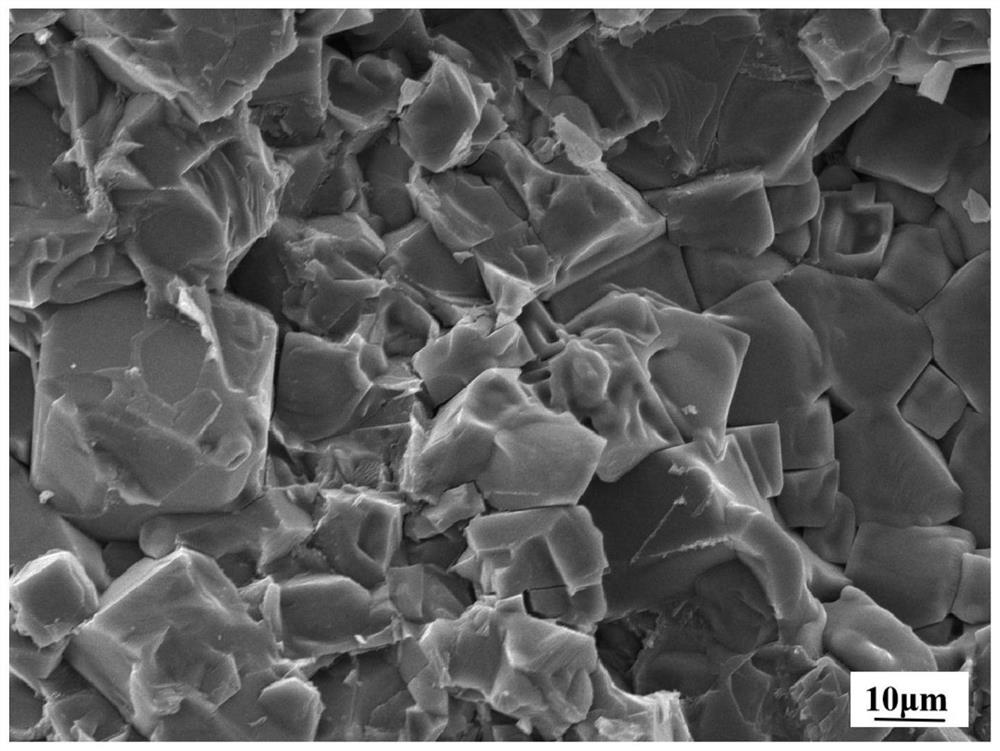

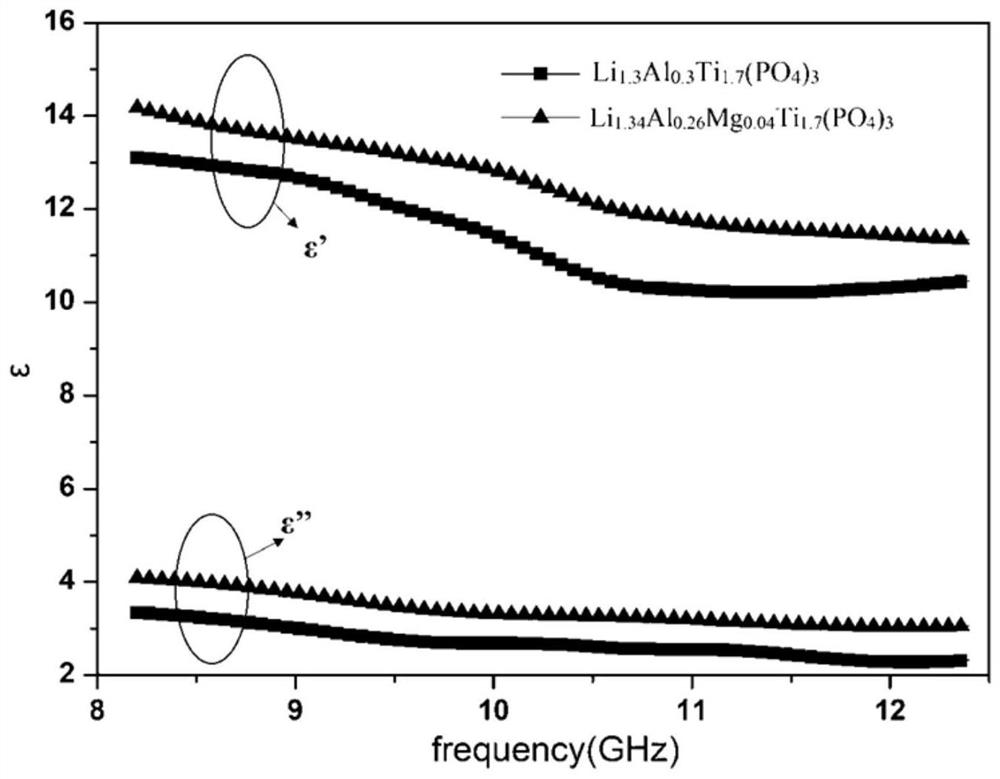

Lithium aluminum magnesium titanium phosphate LAMTP single-phase ceramic wave-absorbing material, preparation method and application thereof

ActiveCN111848151ASmall binding forceIncrease the number ofMagnetic/electric field screeningInterfacial reactionTitanium phosphate

The invention discloses a lithium aluminum magnesium titanium phosphate LAMTP single-phase ceramic wave-absorbing material, a preparation method and application thereof. The preparation method comprises the following steps of: taking Li2CO3, NH4H2PO4, TiO2, Al2O3 and MgO as raw materials in a mass ratio of 1.1(0.65+0.5x):3:1.7:0.15-0.5x:x, wherein x is 0.01-0.1; mixing the raw materials, then performing presintering at a temperature of 880DEG C-920DEG C, and then conducting plasma discharge sintering at a temperature of 980DEG C-1020DEG C. According to the invention, a composite material is not required to be adopted, and the lithium aluminum magnesium titanium phosphate LAMTP single-phase ceramic wave-absorbing material with remarkable wave-absorbing performance is directly prepared, so that the problems of oxidation and interface reaction of the composite material during long-term use are avoided.

Owner:XIAN AERONAUTICAL UNIV

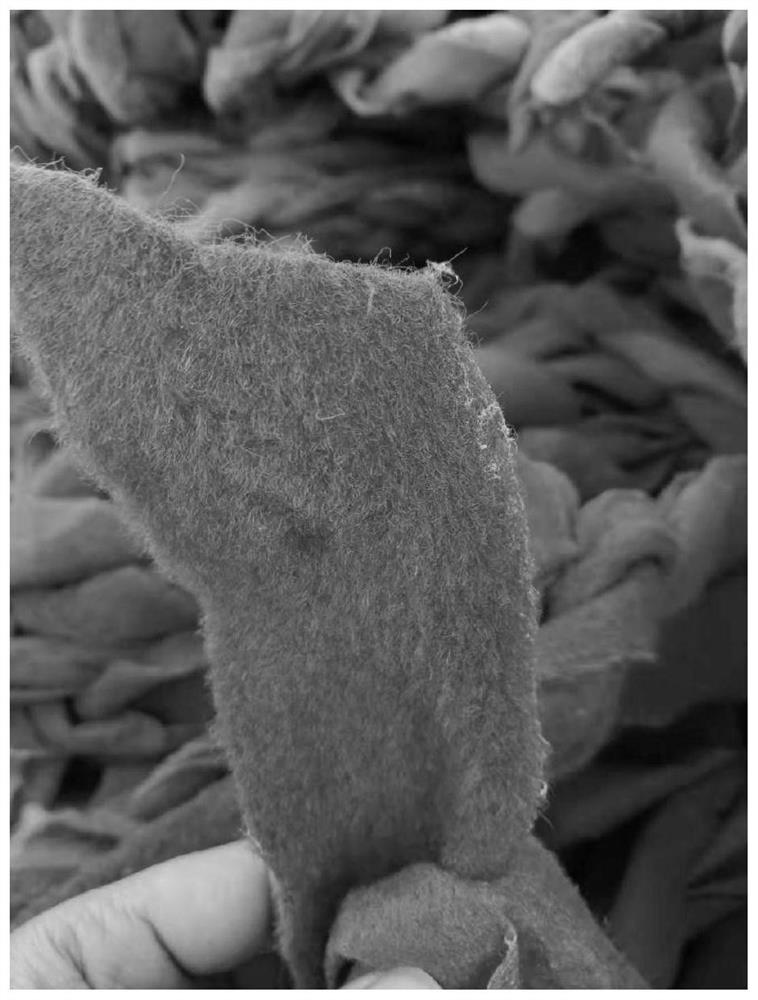

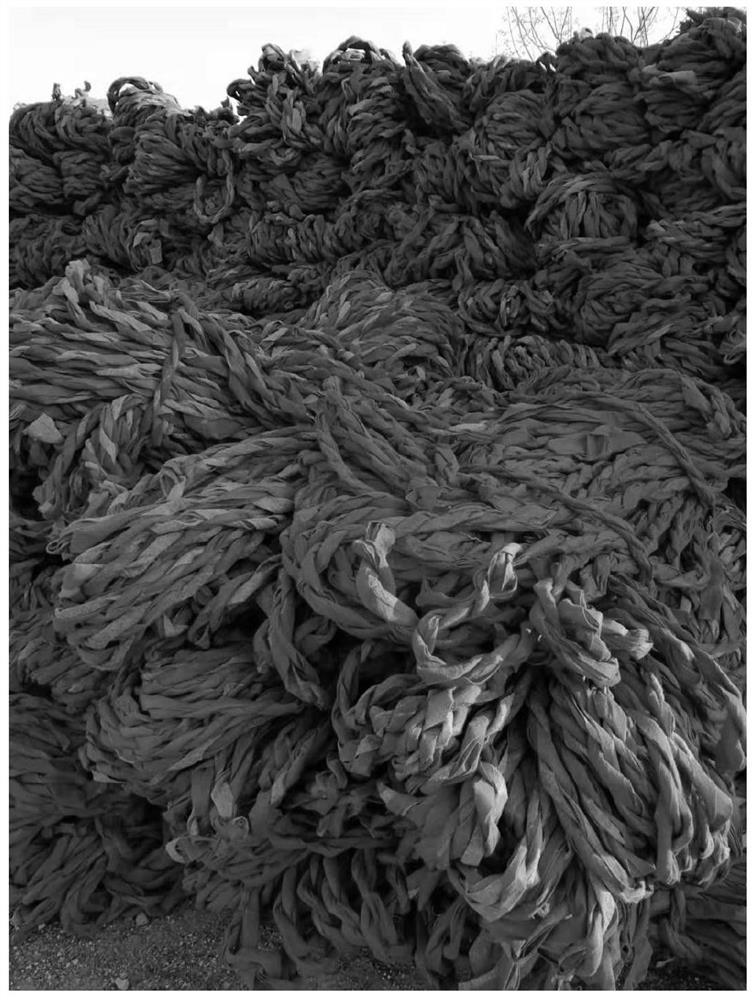

A cultured seedling rope and seedling clamping method for preventing kelp from falling off

ActiveCN111406639BReduce risk of sheddingSoft materialCultivating equipmentsSeaweed cultivationSeedlingNutrient

The invention discloses a cultured seedling rope for preventing kelp from falling off. The seedling rope is prepared by the following method: first weaving two carpet corner wastes counterclockwise into one rope; then weaving three ropes clockwise to obtain a rope with a diameter of 3cm breeding seedling rope. The present invention also provides a method for clamping seedlings with a cultured seedling rope to prevent kelp from falling off: loosen the seedling rope from one end of the cultured seedling rope against the weaving direction of the seedling rope, so that gaps leak out between the three strands of the seedling rope and fake the seaweed seedlings. Insert a kelp seedling into the gap along the direction of the vertical seedling rope, so that the false root of the kelp seedling does not leak out of the seedling rope, and restore the state before the three-strand rope is unscrewed; clamp 4 kelp seedlings at an interval of 3-5cm as a group , and continue clamping seedlings at an interval of 25-30cm between each group until the entire seedling rope is clamped by the kelp. The method of the invention can reduce the risk of kelp falling off, increase the flow of water, ensure sufficient supply of nutrient salts, improve the light effect, and facilitate the growth of kelp.

Owner:DALIAN HAIBAO FISHERY

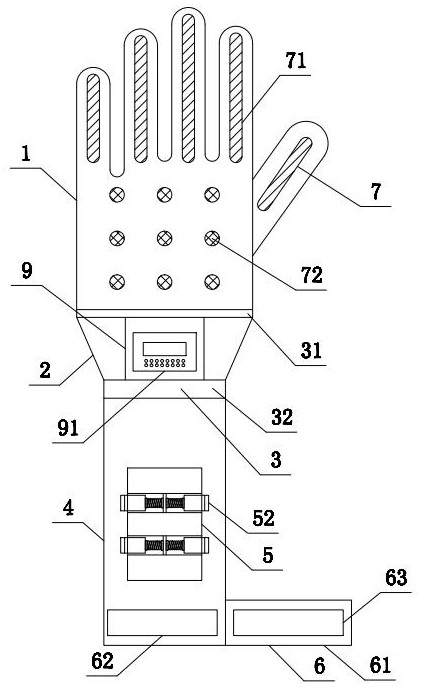

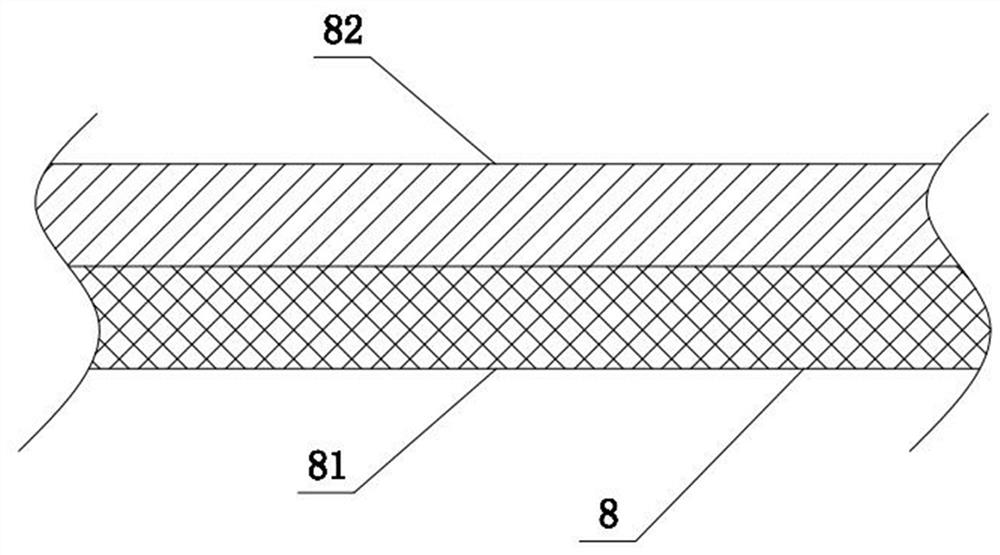

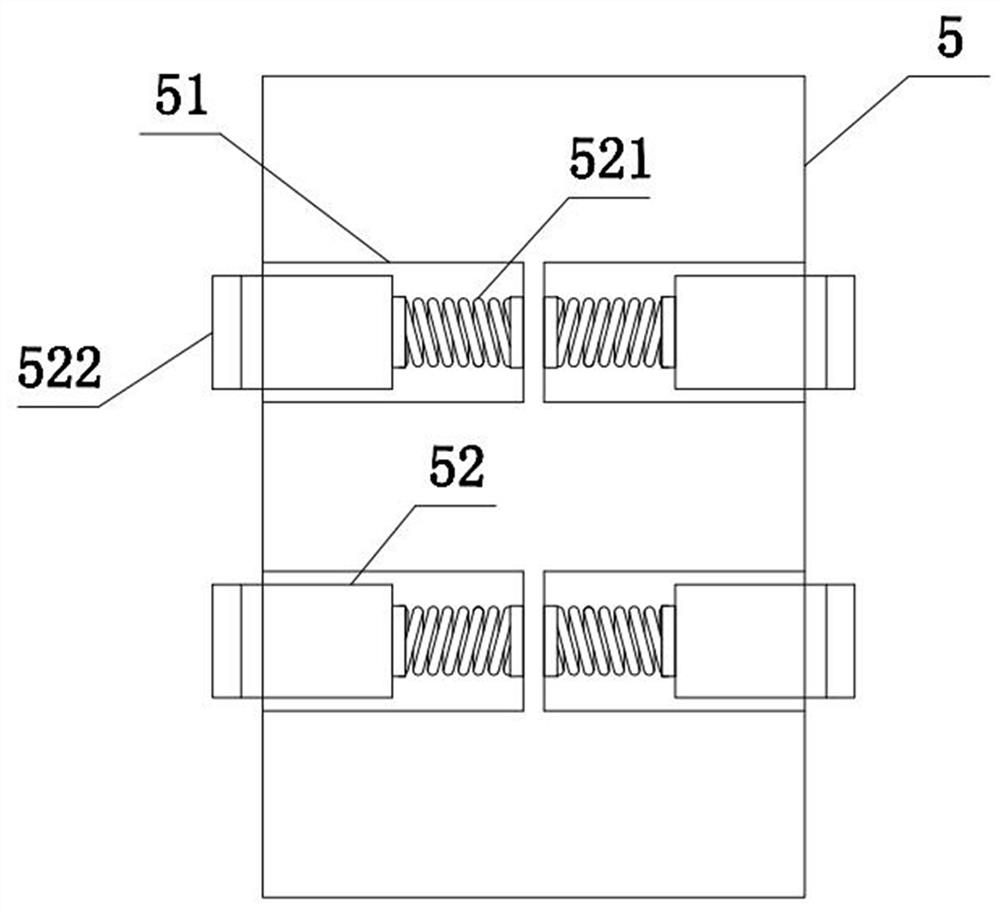

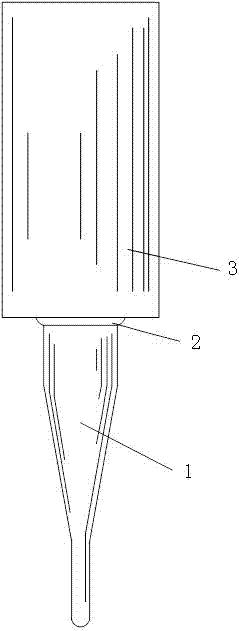

Intelligent wearable device based on Internet of Things

PendingCN112293835AAvoid discomfortStable positionGlovesTransmissionHand partsPhysical medicine and rehabilitation

The invention discloses an intelligent wearable device based on the Internet of Things. The device comprises an intelligent glove body and a glove fabric structure, the lower end of the intelligent glove body is fixedly connected with a connecting assembly, the lower end of the connecting assembly is fixedly connected with a silk connecting belt, and the upper surface of the silk connecting belt is fixedly provided with a controller and a detection device. By analyzing various detection data and setting and adjusting data priorities and thresholds, complex external environment detection and effective management can be realized, and accidents of a user in an outdoor environment can be reduced; and besides, the binding force of the device on the human body is very small, discomfort caused bytoo tight tightening of the wrist is avoided. The ventilation effect can be achieved through a ventilation assembly on the front face of the intelligent glove body; the antiskid effect and the ventilation effect can be achieved through an antiskid assembly on the back face of the intelligent glove body; and through the glove fabric structure, the hand of the wearer can be more comfortable.

Owner:深圳市鸿祥文魔术贴有限公司

Pin structure made of thermoplastic Z-pin reinforced composite and manufacturing method thereof

The invention discloses a pin structure made of a thermoplastic Z-pin reinforced composite and a manufacturing method thereof. The pin structure comprises a thermoplastic composite component I, a thermoplastic composite component II and a Z-pin. The thermoplastic composite component I and the thermoplastic composite component II are connected with each other, and a hole is formed in the joint of the thermoplastic composite component I and the thermoplastic composite component II. The hole penetrates through the thermoplastic composite component I and the thermoplastic composite component II. The Z-pin is used for being planted into the hole, so that the connection strength between the thermoplastic composite component I and the thermoplastic composite component Ii is improved. The two ends of the Z-pin are in a pin shape. On the premise of not or slightly damaging fibers in the components to be connected, the thermoplastic composite component I and the thermoplastic composite component II are connected through the method of planting the Z-pin, and the two ends of the Z-pin are processed into the pin shape, so that the connection strength is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

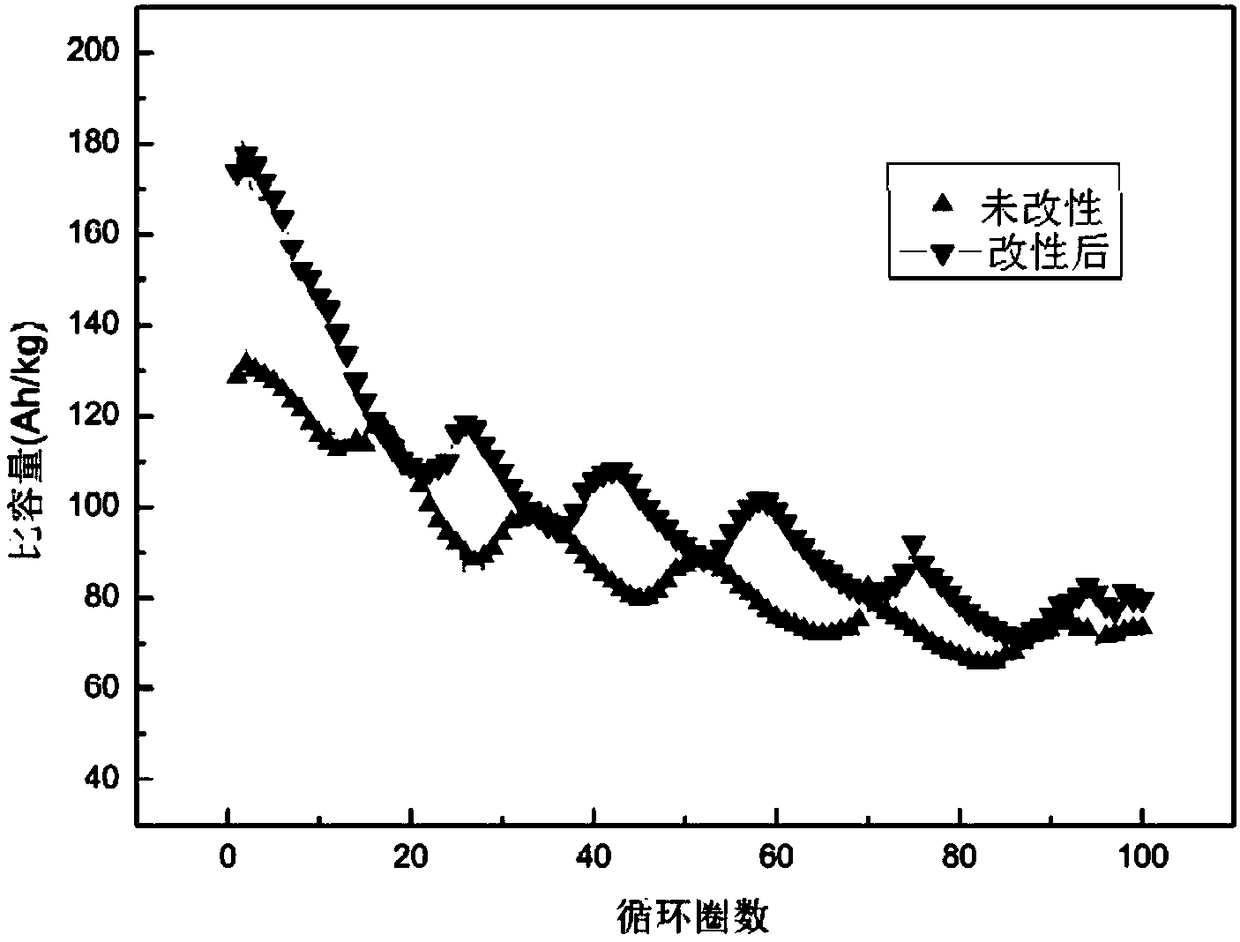

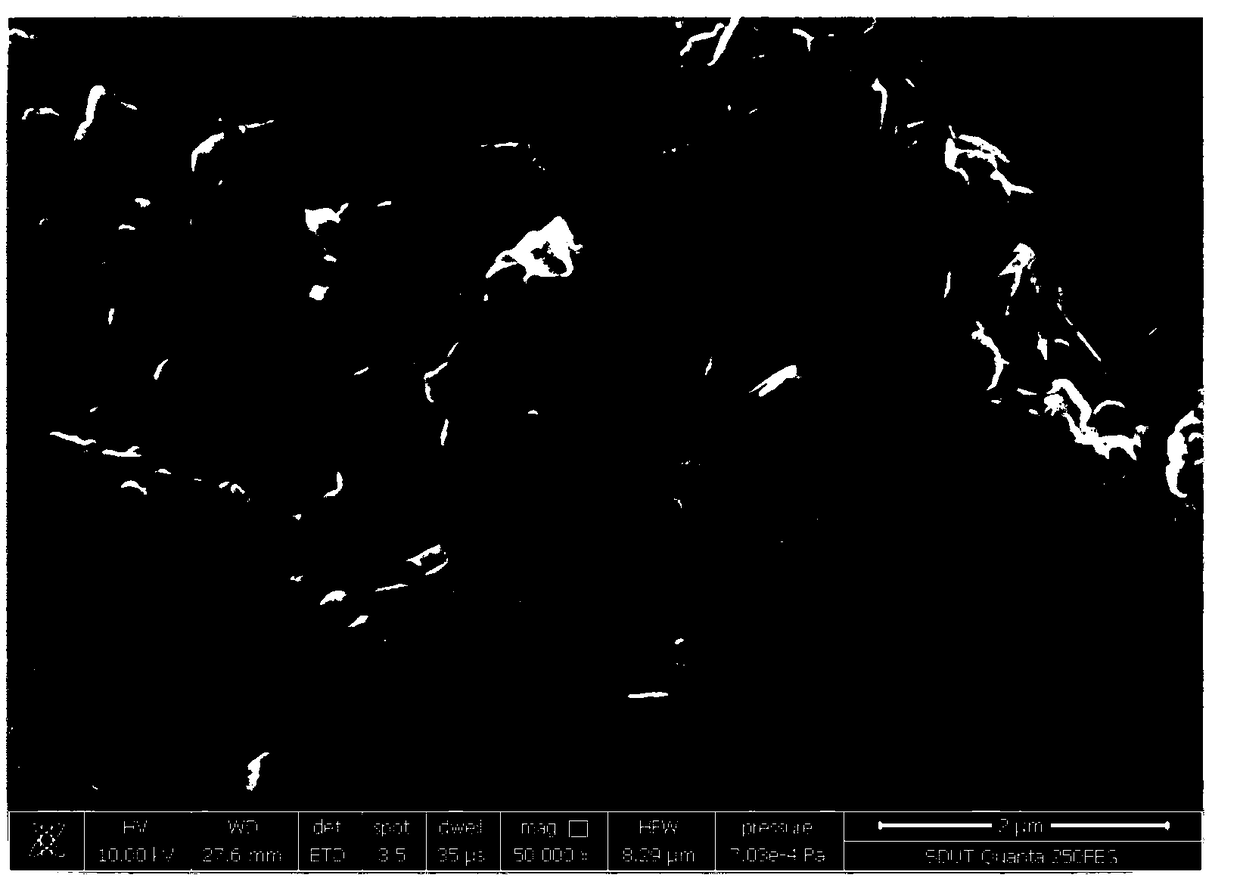

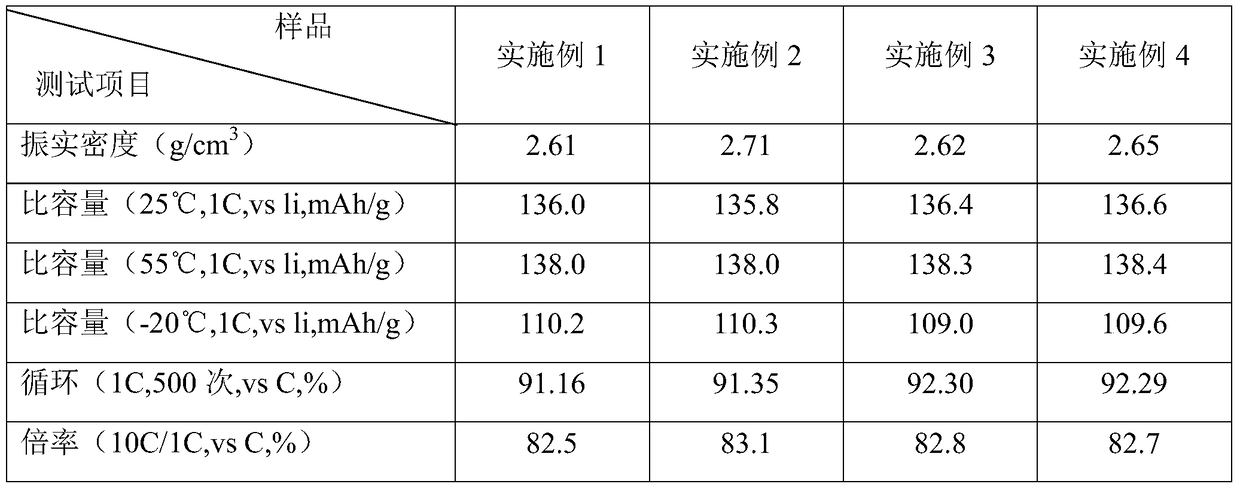

A kind of preparation method of fluorine ion doped nickel manganese oxide lithium

ActiveCN105470497BSmall binding forceImprove high temperature performanceCell electrodesSecondary cellsNickel saltCrystal structure

The invention discloses a preparation method of fluorine ion-doped lithium nickel manganese oxide. The preparation method comprises the following steps: mixing manganese salt and nickel salt materials to prepare a nickel manganese precursor through a sol-gel method; mixing the nickel manganese precursor with lithium salt by adopting a three-dimensional inclined mixer; carrying out pre-sintering and high-temperature sintering, and then doping F for mixing; and finally carrying out low-temperature sintering, fluid energy milling and grading to obtain a lithium nickel manganese oxide finished product. According to the preparation method, the battery material lithium nickel manganese oxide is modified through the doped negative F ions, and the structure change for the doped and modified material crystal is little, so that the diffusion rate of lithium ions in the modified material is quickened, the conductivity is improved, and the high temperature performance and cycle performance of the lithium nickel manganese oxide are effectively improved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

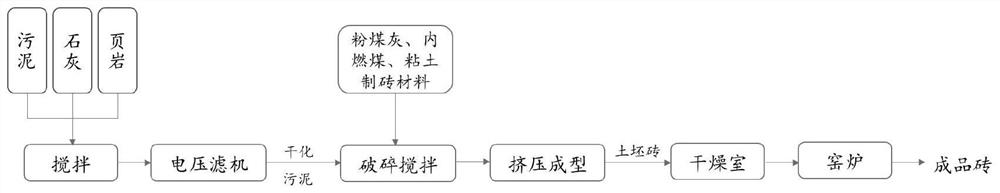

Sludge deep dehydration method and application of sludge

PendingCN113248088AReduce moisture contentImprove dehydration effectSludge treatment by de-watering/drying/thickeningWater contaminantsBrickCapillary water absorption

The invention provides a sludge deep dehydration method and application of sludge, and belongs to the field of sludge treatment and sludge brickmaking. The method comprises the following steps: firstly, adding shale and lime into the sludge, and then carrying out voltage filtration treatment to partially remove free water, interstitial water, adsorbed water and bound water in the sludge, so that the water content of the sludge is reduced to 60% or below from 80% or above, the capillary water absorption time of the sludge is shortened, and the dehydration performance of the sludge is improved. And the original properties of the sludge cannot be changed by adding the shale and the lime, so that the molding and structural performance of bricks cannot be influenced when the dried sludge is used for making the bricks. The operation method is simple, low in energy consumption and cost and high in economic benefit; and the method has important significance on reduction, harmlessness and recycling of the sludge.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

A kind of jatropha drying device

ActiveCN107822175BChange the state of hydrogen bondsSmall binding forceFood treatmentElectric machineAgricultural engineering

The present invention discloses an idesia polycarpa seed drying device. The idesia polycarpa seed drying device comprises a baking tank. A material feeding inlet is opened on a top part of the bakingtank, a bottom part of the baking tank communicates with a top end of a tunnel, microwave emitters and strong magnets are arranged on the tunnel, a hot air inlet is arranged at the top part of the baking tank, a bottom part of the tunnel communicates with a bottom end of a longitudinal lifting channel, a material discharge port is arranged at the bottom end of the longitudinal lifting channel, anda screw propeller is arranged in the longitudinal lifting channel and in a shaft connection with a drive motor. A microwave magnetic field technology is combined with a vacuum technology, and compared with other structures, the drying device can promote a quick evaporation of internal moisture of materials and greatly shortens drying time.

Owner:湖北旭舟林农科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com