Mandril adjusting device for shaping die set of powder sintering part

A technology for sintering parts and adjusting devices, applied in the field of important parts, can solve the problems of fixed stroke, inability to adjust and damage of mandrels, and achieve the effects of avoiding wear, prolonging service life and reducing binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

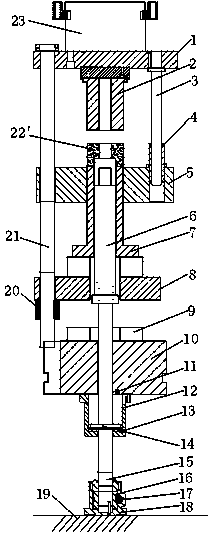

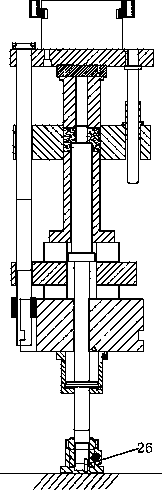

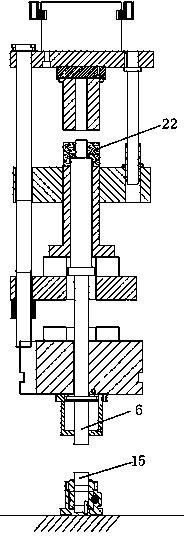

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] The upper punch 2 is fixed on the lower surface of the upper punch plate 1 with screws, and the upper punch plate 1 is fixed on the lower surface of the shaping power slider 23 with screws, and the guide posts 3 connected with the guide sleeve 4 are installed at two opposite angles, and the upper punch The punching plate 1 and the female template 5 are connected as a whole.

[0021] There is a through hole in the middle of the formwork fixing plate 10, a guide groove 101 is arranged in the middle of the side wall, a lower backing plate 9 is fixed on the periphery of the upper surface, and a cylinder 12 with a lower chamber air pipe 13 and an upper chamber air pipe 11 are fixed in the middle of the lower surface. on the side wall of the rack (not shown).

[0022] The upper end of the ejection rod 21 is fixed on the upper punching plate 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com