A kind of jatropha drying device

A drying device and the technology of jatropha, applied in the fields of application, food science, food processing, etc., can solve the problems of long drying time, reduced drying energy consumption, and poor drying efficiency, so as to promote faster evaporation, The effect of shortening the drying time and reducing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

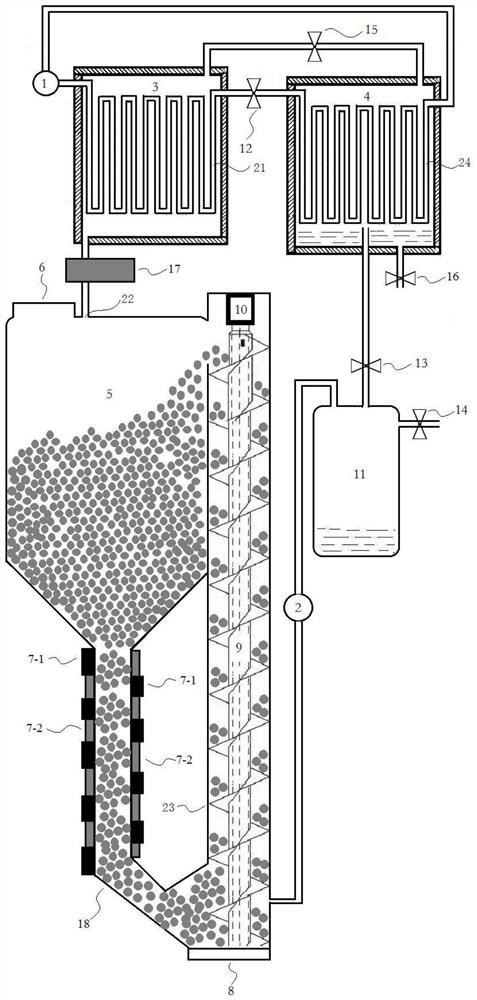

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

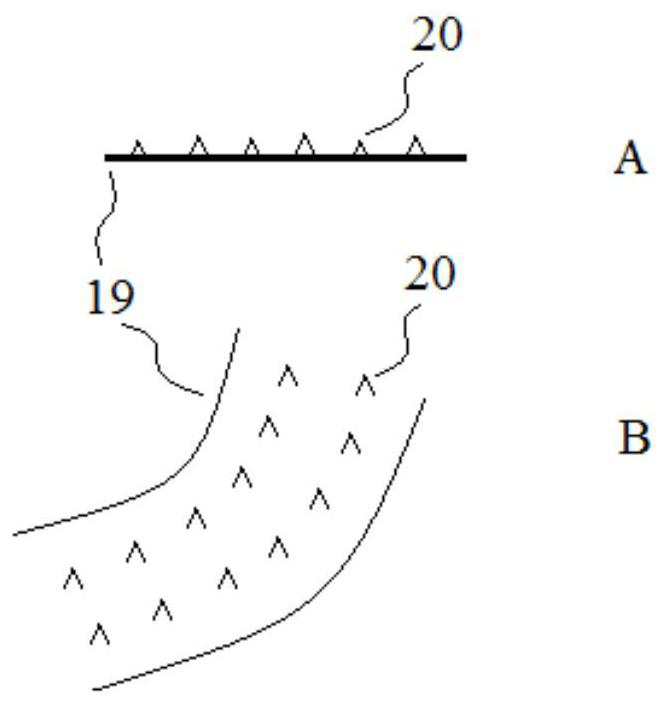

[0018] Such as figure 1 As shown, a kind of jatropha drying device includes a baking tank 5, the top of the baking tank 5 is provided with a feeding port 6, the bottom of the baking tank 5 communicates with the top of the tunnel 18, and the tunnel 18 is provided with a microwave transmitter 7-1 With a strong magnet 7-2, the top of the baking tank 5 is provided with a hot air inlet 22, the bottom of the tunnel 18 communicates with the bottom of the longitudinal lifting channel 23, the bottom of the longitudinal lifting channel 23 is provided with a discharge port 8, and the longitudinal lifting channel 23 is provided with a The screw propeller 9 is connected with the drive motor 10 shaft. It also includes a heating chamber 3 and a cooling chamber 4. The heating chamber 3 is provided with a first serpentine pipe 21, and the cooling chamber 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com