Wire structure and backlight module group applying same

A backlight module and wire technology, applied in nonlinear optics, conductors, optics, etc., can solve problems such as limiting high-voltage wires, low-voltage wires 120 breakage, and lamp failure to operate, so as to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

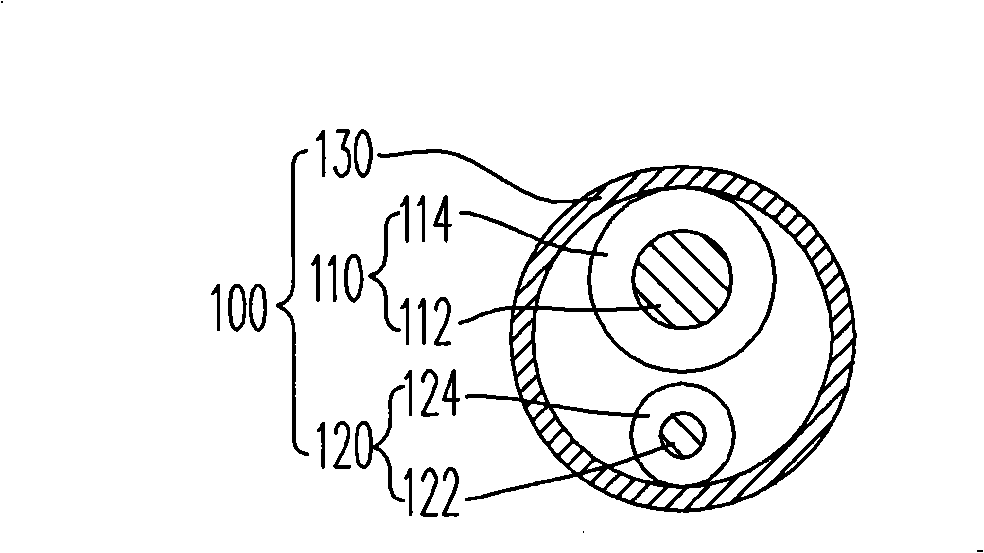

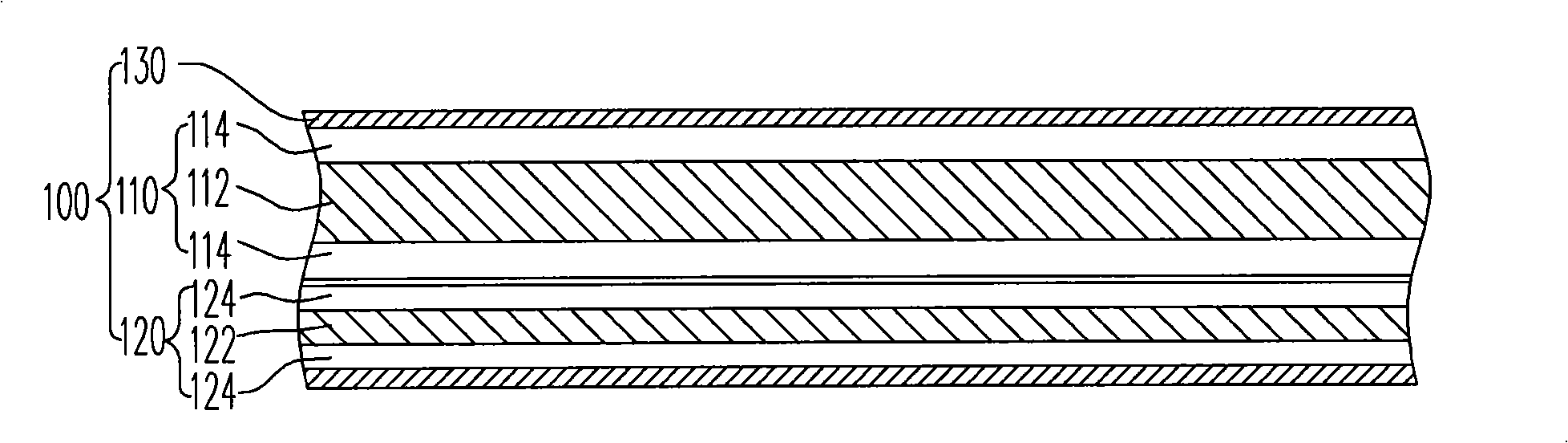

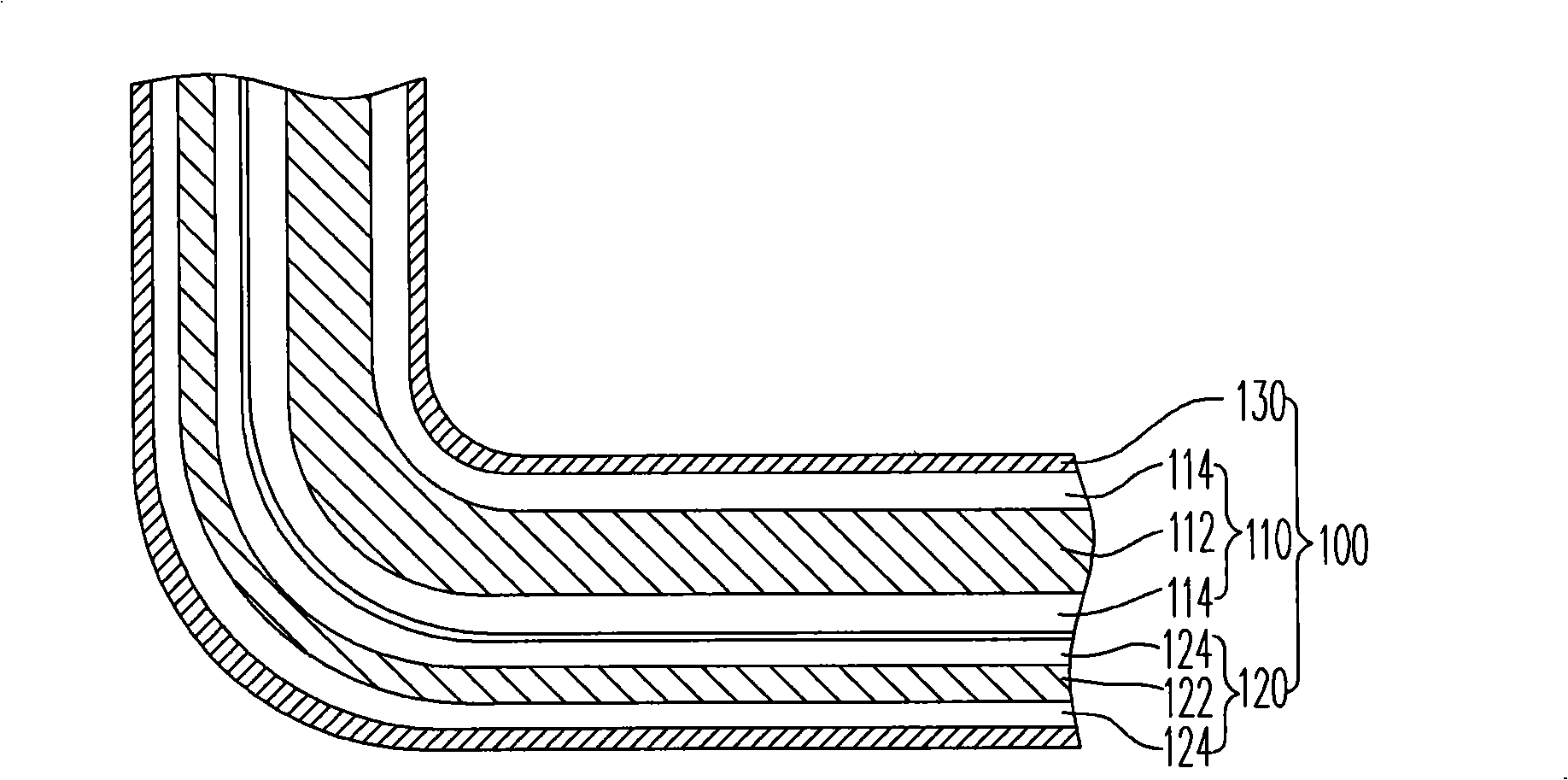

[0023] Figure 3A Shown is a transverse cross-sectional view of a wire structure according to a preferred embodiment of the present invention; Figure 3B shown along the Figure 3A The longitudinal cross-sectional view of the wire structure drawn by the I-I' section line. Please also refer to Figure 3A and 3B , the wire structure 200 mainly includes a high voltage wire 210 , a low voltage wire 220 and a heat shrinkable sleeve 230 .

[0024] The high-voltage wire 210 is composed of a thicker metal wire 212 and an insulating layer 214 covering its periphery to provide high-voltage current. The low-voltage wire 220 is composed of a thinner metal wire 222 and an insulating layer 224 surrounding it to provide low-voltage current. The heat-shrinkable sleeve 230 is wrapped around the high-voltage wire 210 and the low-voltage wire 220 for protection and insulation.

[0025] The feature of the present invention is that a plurality of perforations 232 are formed on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com