Lithium aluminum magnesium titanium phosphate LAMTP single-phase ceramic wave-absorbing material, preparation method and application thereof

A technology of titanium magnesium aluminum lithium phosphate and single-phase ceramics, which is applied in the direction of magnetic field/electric field shielding and electrical components, and can solve the problems of deepening absorption peak, low reflectivity, and needs to be expanded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

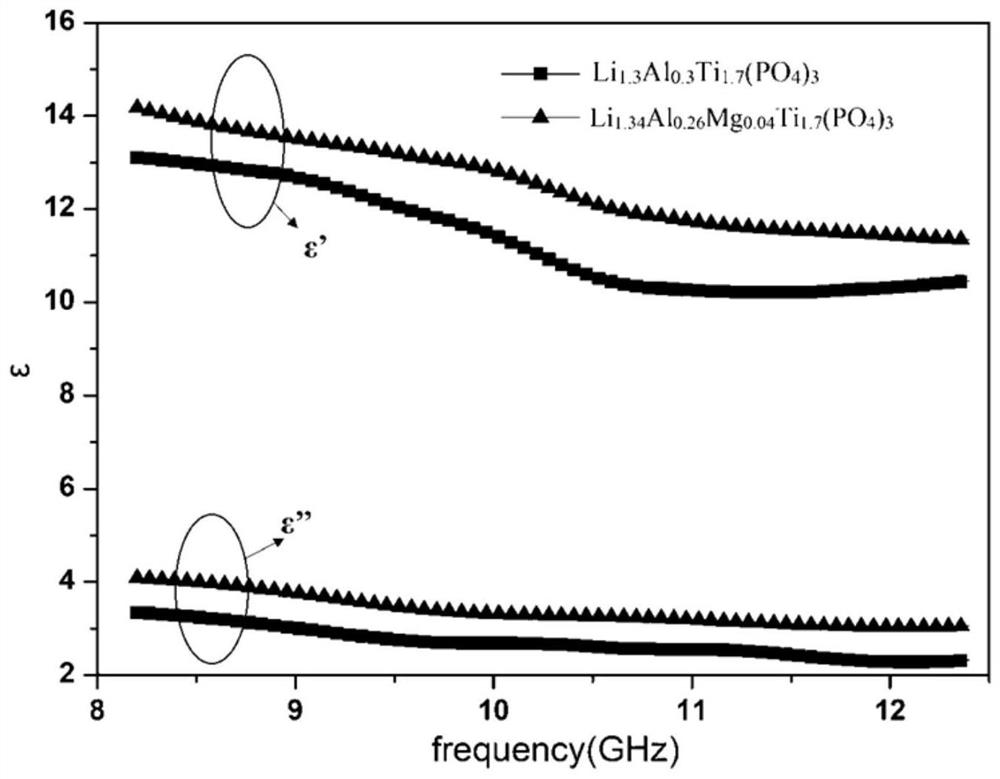

[0044] A kind of Li 1.31 Al 0.29 Mg 0.01 Ti 1.7 (PO 4 ) 3 The preparation method of single-phase ceramic wave-absorbing material comprises the following steps:

[0045] (1), prepare raw materials: weigh Li respectively according to the ratio of the amount of substances to 0.7205:3:1.7:0.145:0.01 2 CO 3 , NH 4 h 2 PO 4 、TiO 2 、Al 2 o 3 , MgO; wherein, the purity of each raw material is greater than 99.99%;

[0046] (2), one-time ball milling: mix the raw materials prepared in (1) and pour them into a polytetrafluoroethylene ball milling tank and add zirconia grinding balls, the mass ratio of the balls to materials is 20:1, and add absolute ethanol to submerge the grinding balls and Mix the raw materials to 2 / 3 of the ball mill tank, and then perform a ball mill treatment at a speed of 250rad / min for 8h to obtain a precursor slurry;

[0047] (3), one-time drying: after the first ball milling, pour the precursor slurry in the ball mill tank into a clean stainless st...

Embodiment 2

[0054] A kind of Li 1.4 Al 0.2 Mg 0.1 Ti 1.7 (PO 4 ) 3 The preparation method of single-phase ceramic wave-absorbing material comprises the following steps:

[0055] In addition to (1), weigh Li according to the ratio of the amount of substances to 0.77:3:1.7:0.1:0.1 2 CO 3 , NH 4 h 2 PO 4 、TiO 2 、Al 2 o 3 , MgO;

[0056] (3) heat up to 920°C at a heating rate of 5°C / min, and keep warm for 8h;

[0057] In (7), under the pressure condition of 40 MPa, the temperature was raised to 1020° C. at a heating rate of 120° C. / min, and kept for 8 minutes.

[0058] All the other steps are the same as in Example 1.

[0059] The Li that embodiment 2 makes 1.4 Al 0.2 Mg0.1 Ti 1.7 (PO 4 ) 3 The conductivity of the single-phase ceramic absorbing material is 4×10 - 3 S cm -3 .

Embodiment 3

[0061] A kind of Li 1.34 Al 0.26 Mg 0.04 Ti 1.7 (PO 4 ) 3 The preparation method of single-phase ceramic wave-absorbing material comprises the following steps:

[0062] In addition to (1), the ratio of the amount of substances is 0.737: 3: 1.7: 0.13: 0.04, respectively weigh Li 2 CO 3 , NH 4 h 2 PO 4 、TiO 2 、Al 2 o 3 , MgO;

[0063] (3) heat up to 900°C at a heating rate of 5°C / min, and keep warm for 6 hours;

[0064] In (7), under the pressure condition of 30 MPa, the temperature was raised to 1000° C. at a heating rate of 100° C. / min and kept for 5 minutes.

[0065] All the other steps are the same as in Example 1.

[0066] The Li that embodiment 3 makes 1.34 Al 0.26 Mg 0.04 Ti 1.7 (PO 4 ) 3 The conductivity of the single-phase ceramic absorbing material is 5×10 - 3 S cm -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com