Patents

Literature

35results about How to "Firmly bonded state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

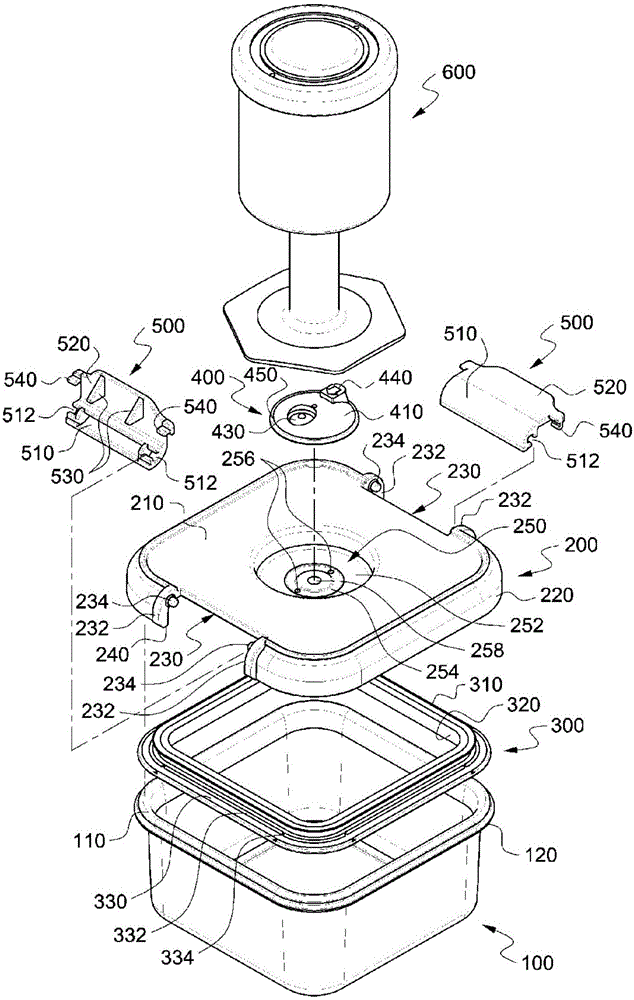

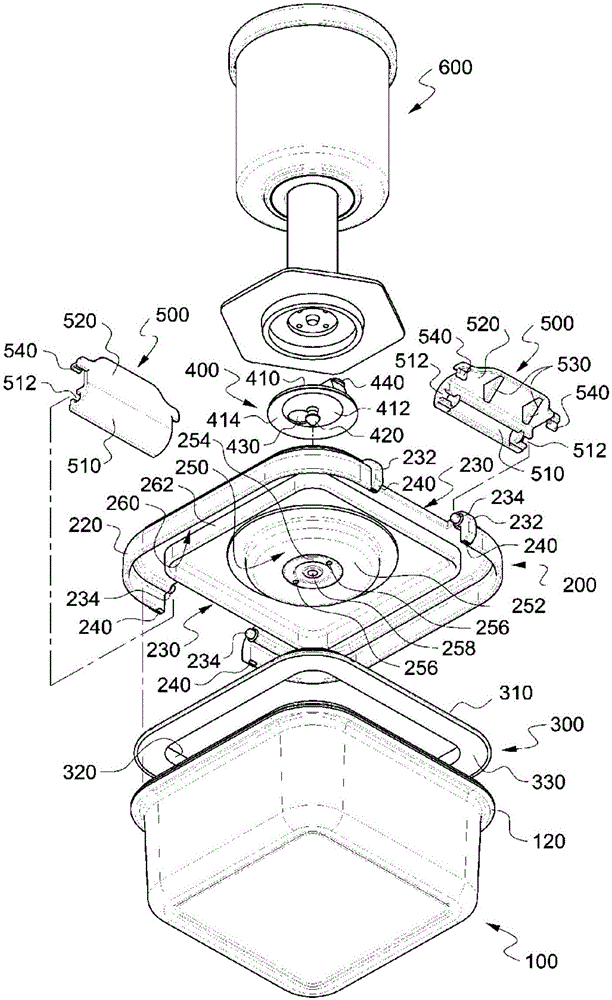

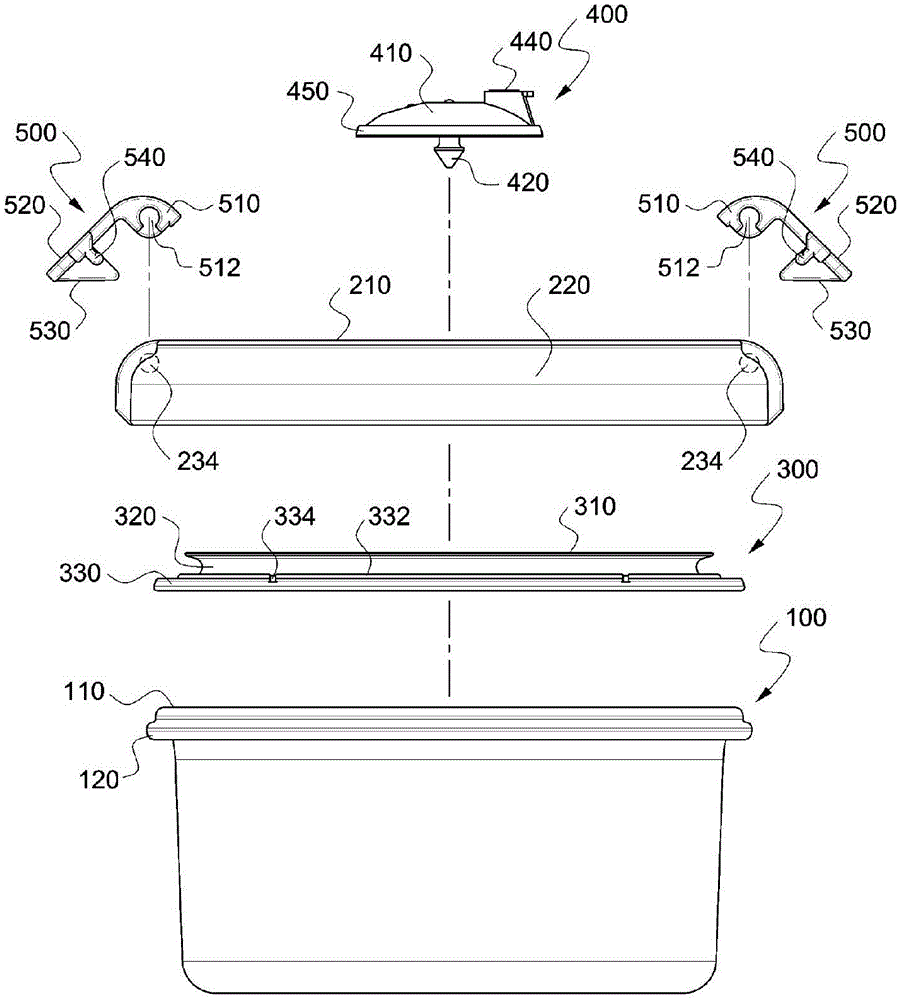

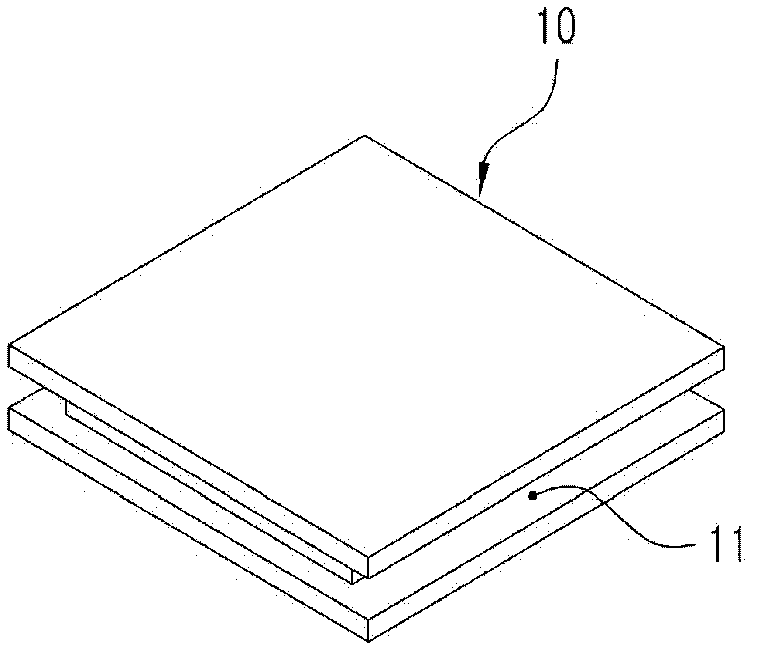

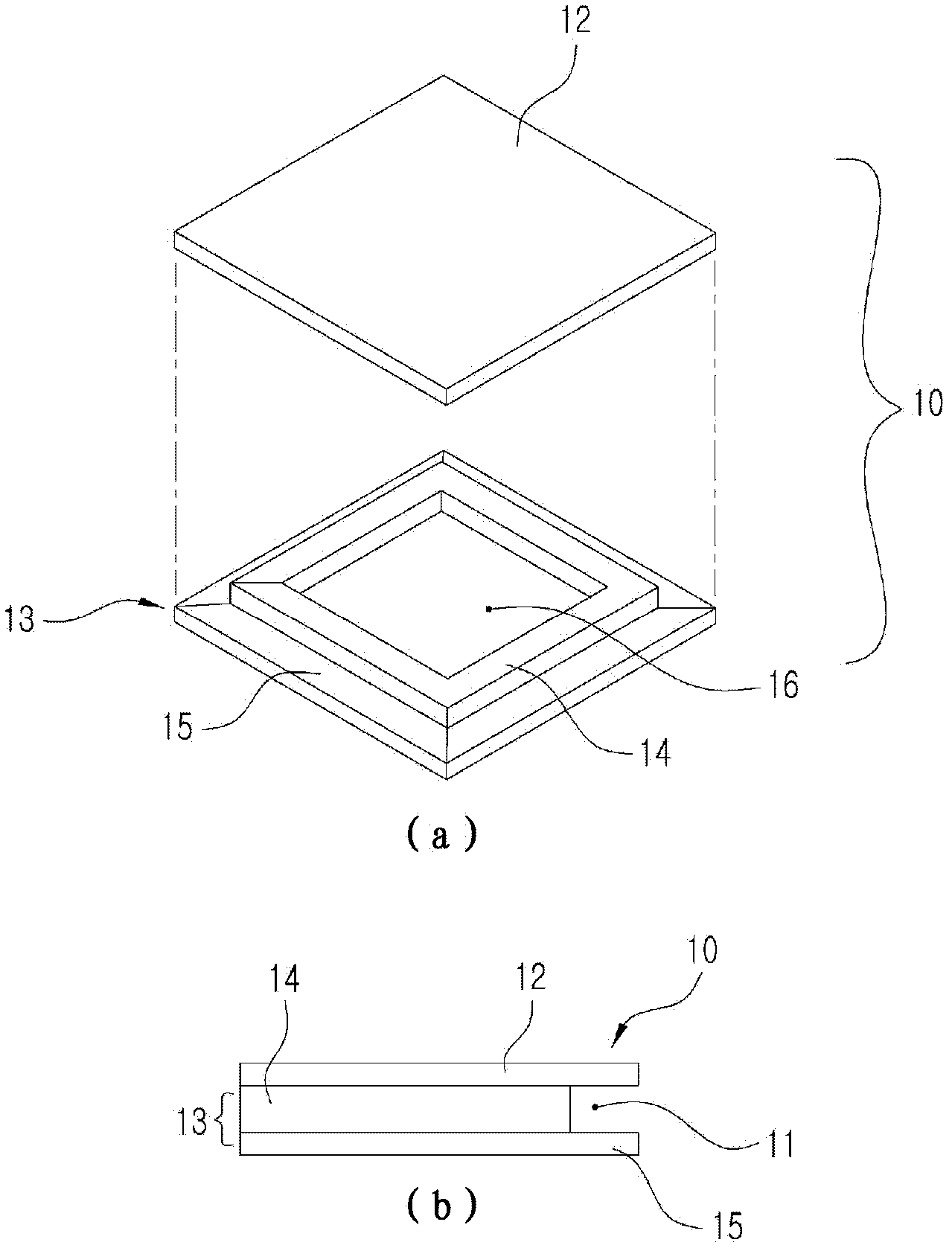

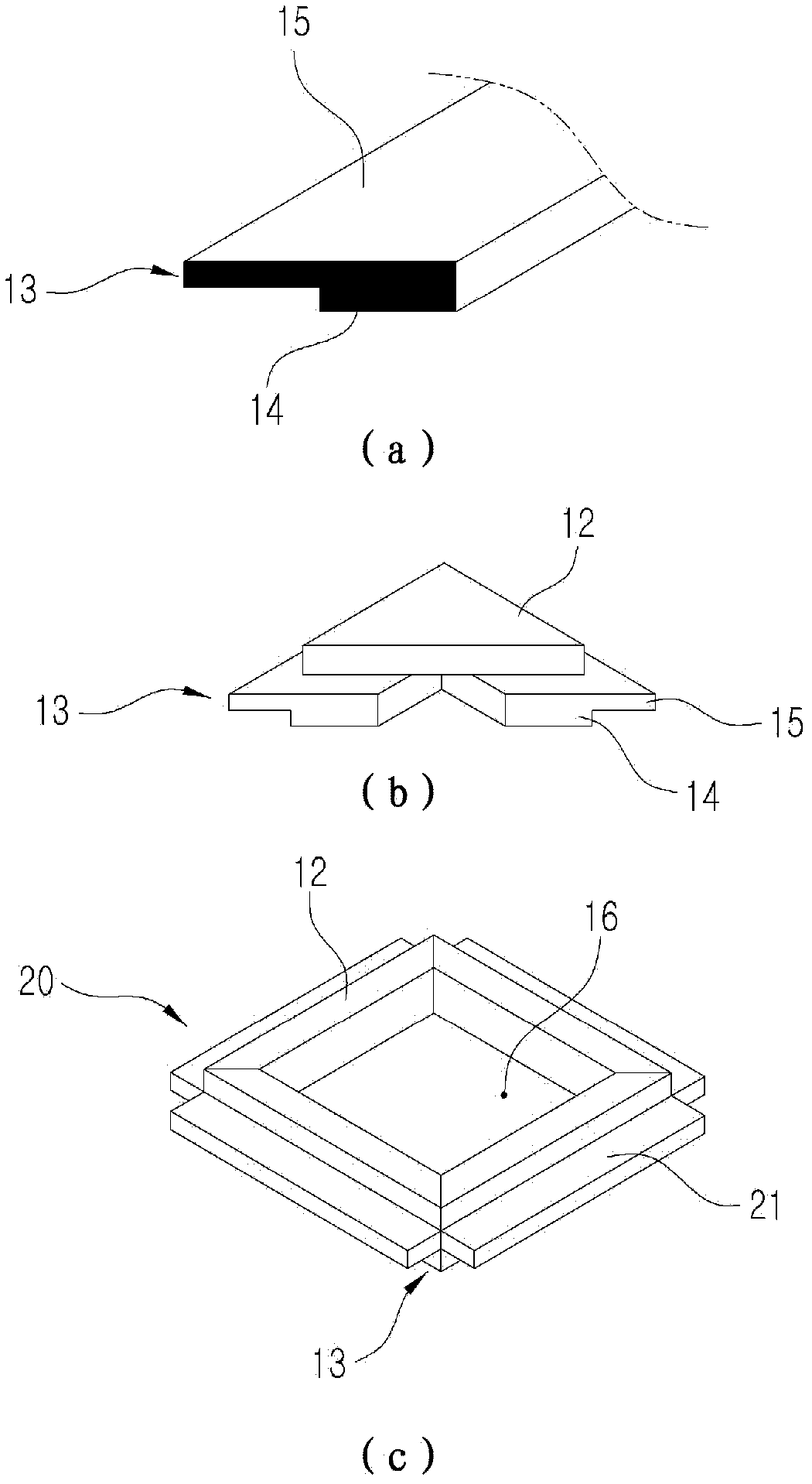

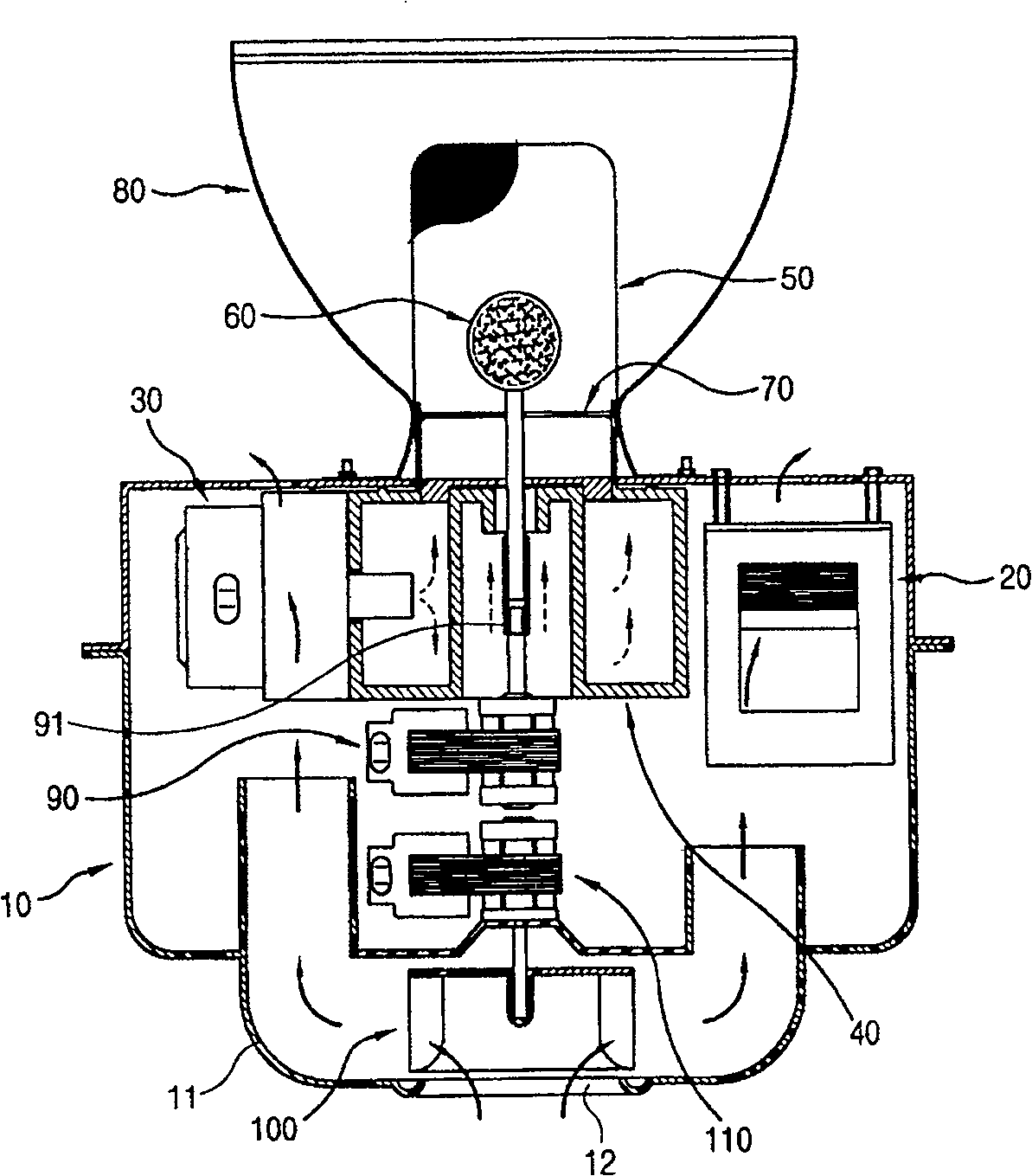

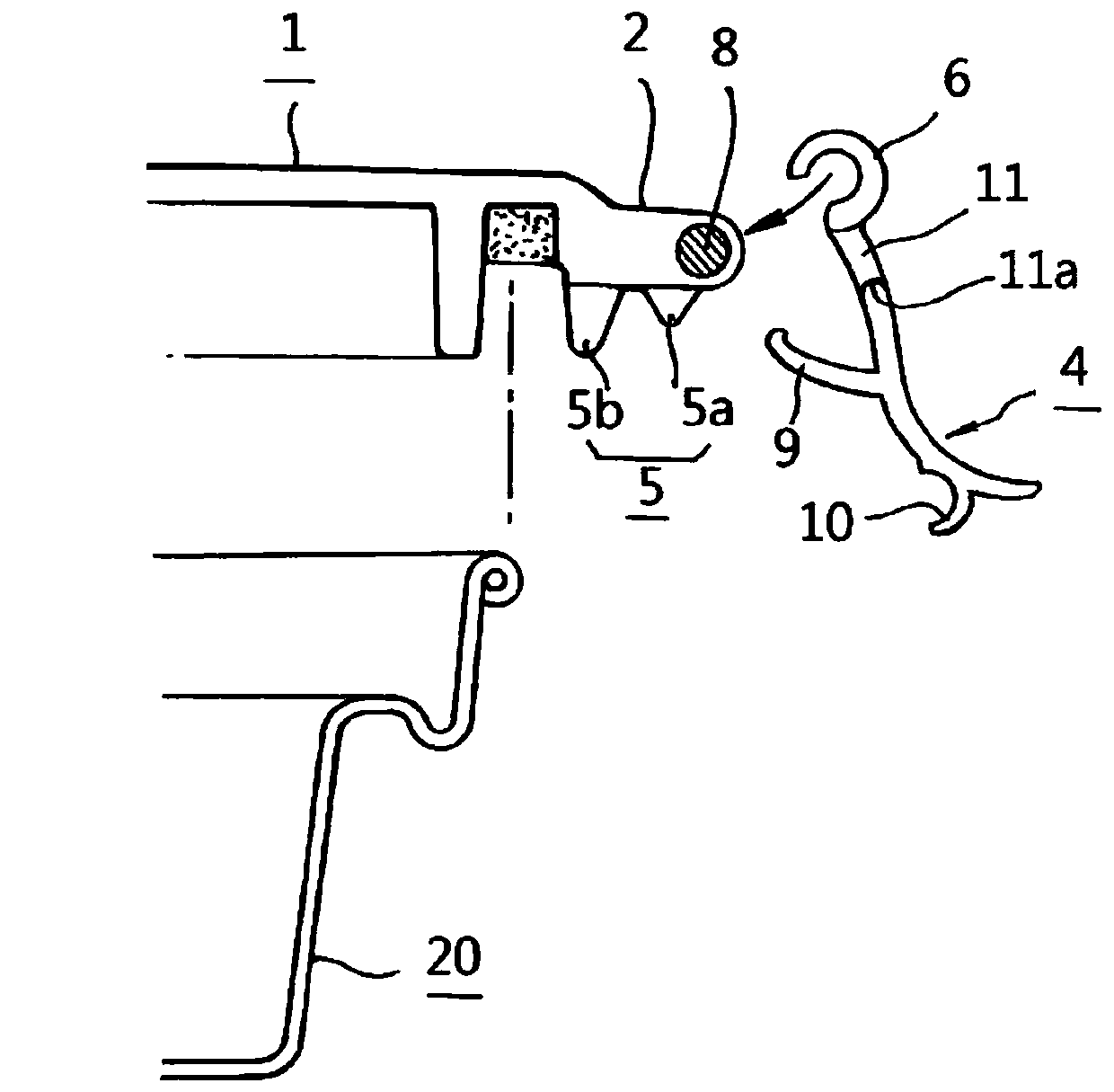

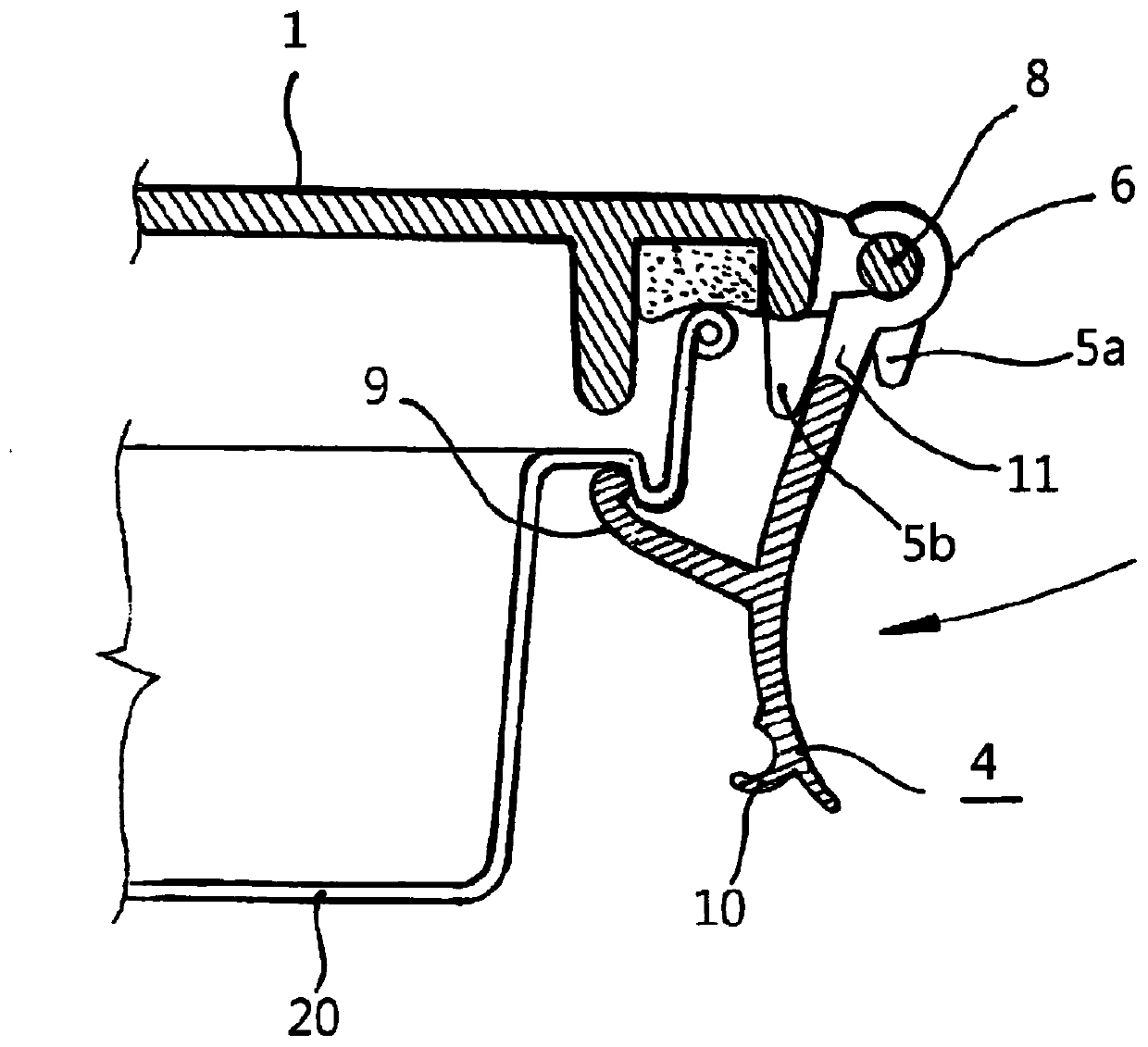

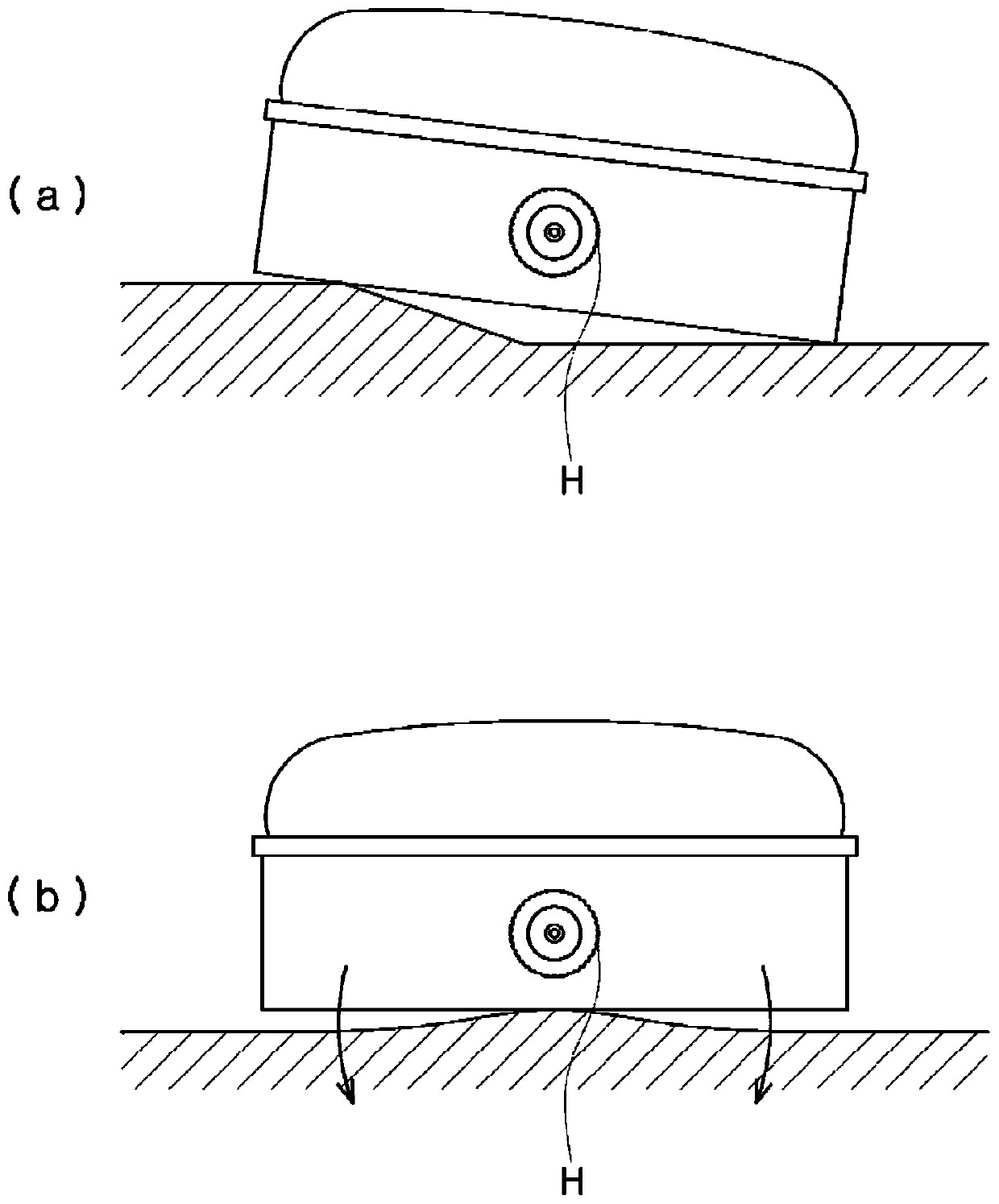

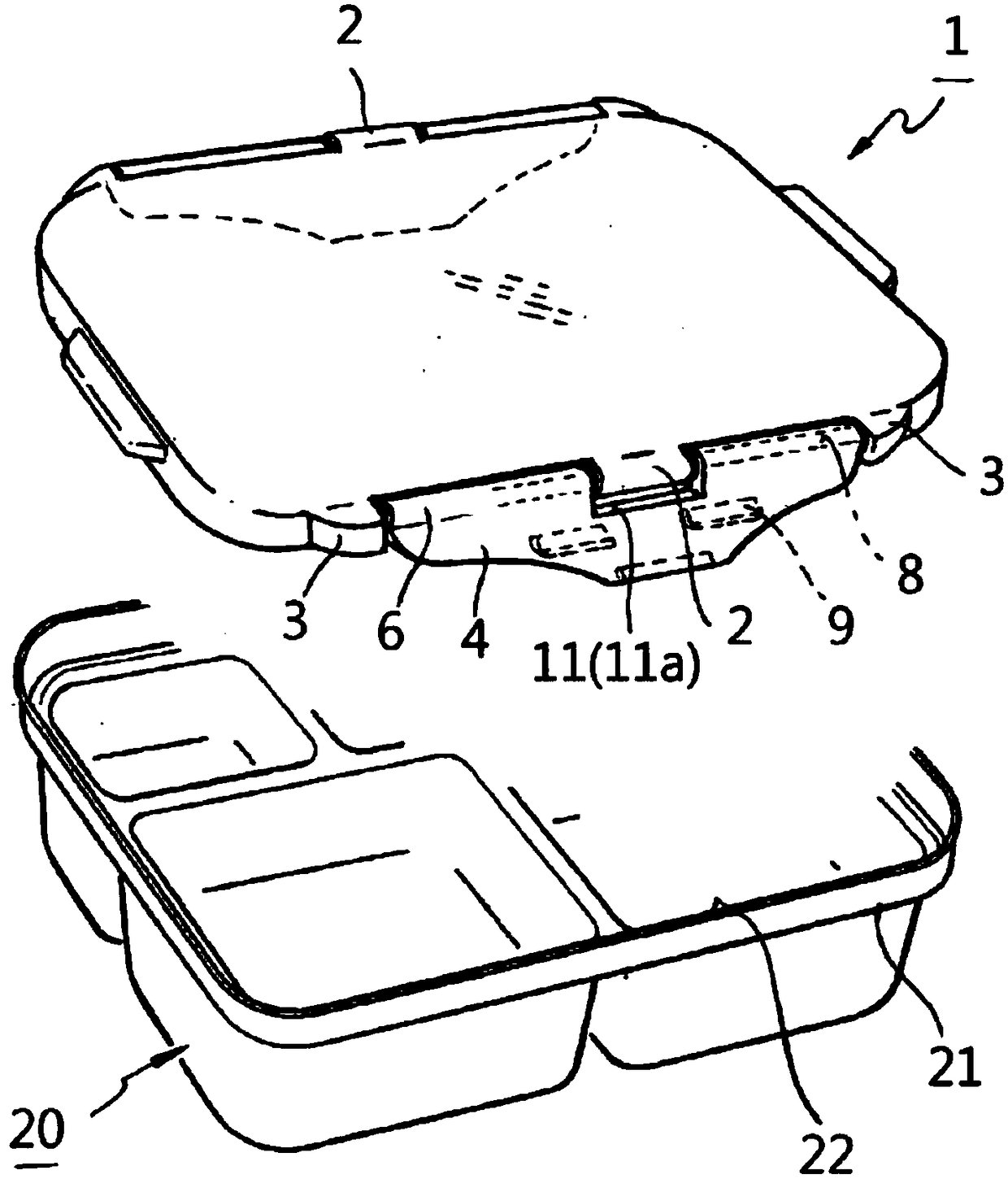

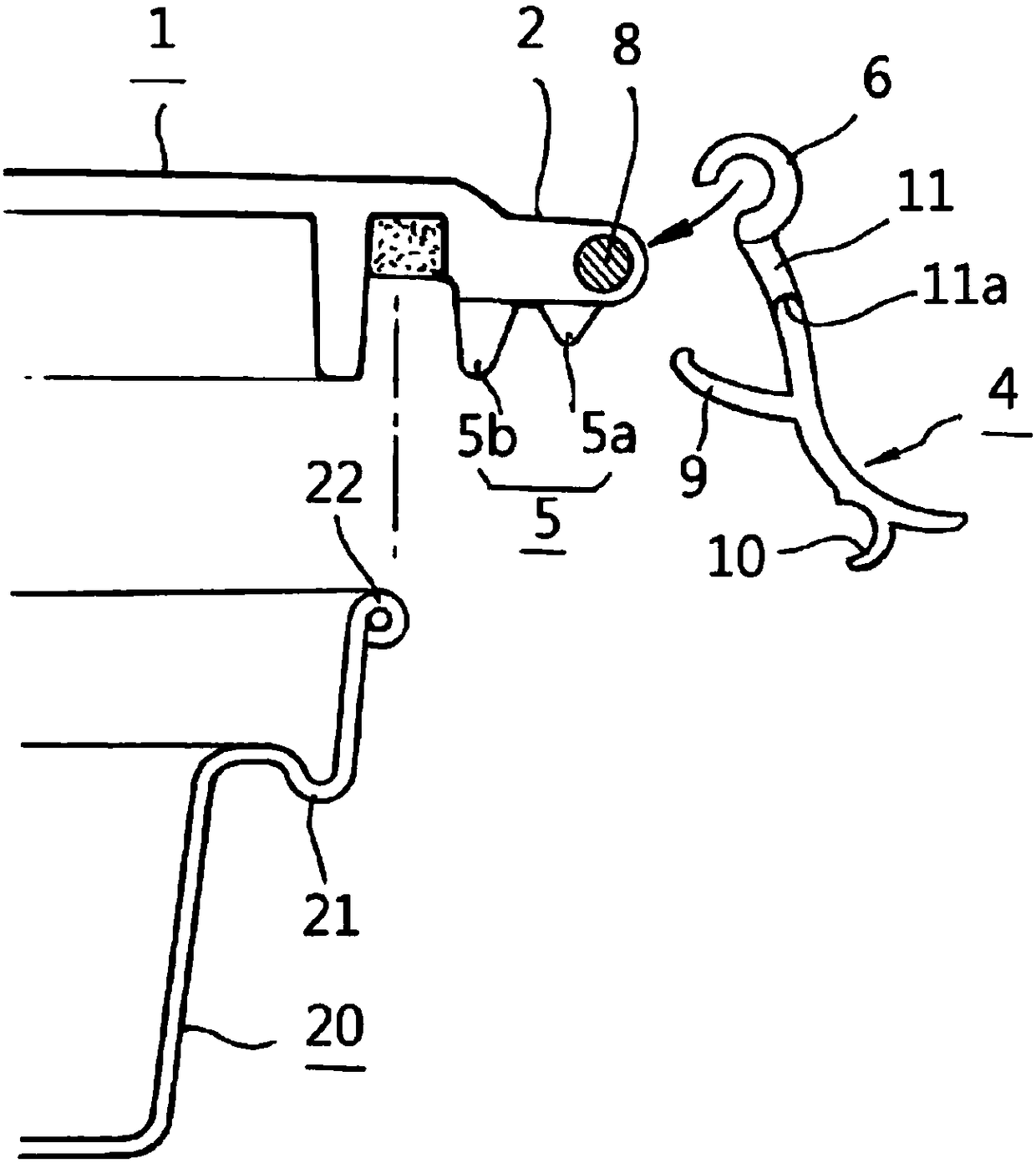

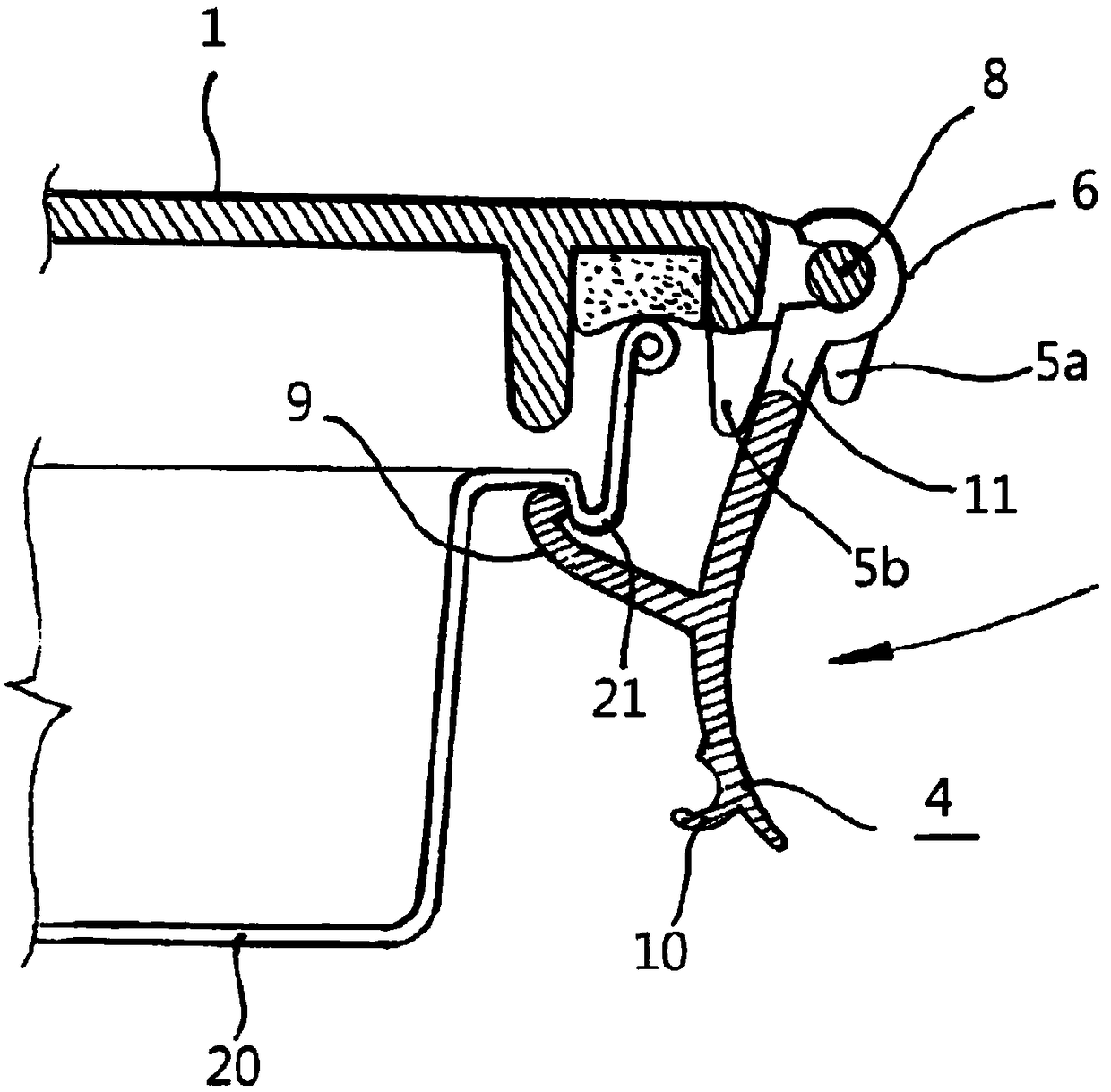

Container lid for vacuum sealing having locking parts and vacuum-sealed container employing same

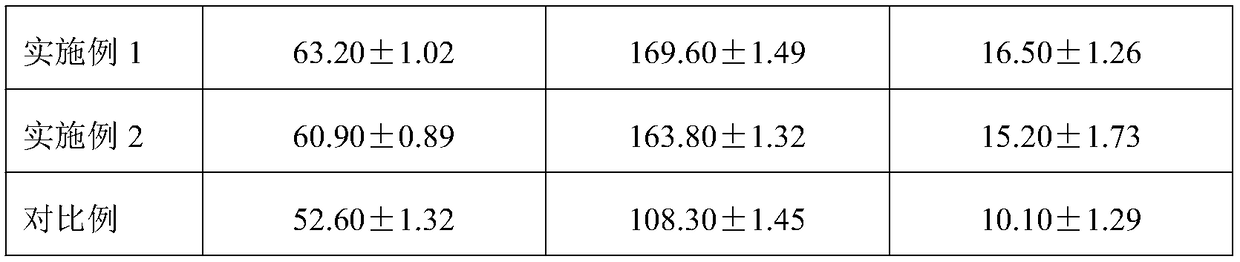

InactiveCN105073593AReduce the binding forceFirmly bonded stateRemovable lids/coversPackaging under vacuum/special atmosphereSelf lockingPressure difference

Disclosed is a container lid for vacuum sealing which generates negative pressure in the internal space of a container, which is provided by covering the open upper part of a container main body, and seals same. An annular packing is mounted so as to go around the inner surface of a lid main body, and a check valve is mounted in the inner part of the outer surface of the lid main body. The check valve generates negative pressure in the internal space of the container by allowing air inside the container to flow to the outside but preventing outside air from flowing into the container when a pressure difference occurs between the inside and outside of the container. A plurality of self catching protrusions are provided respectively at a plurality of points on the edges of the lid main body, and a plurality of locking members are mounted respectively and pivotably in sections adjacent to the plurality of self catching protrusions. Each locking member comprises: self-locking protrusions which are press-fitted and coupled to the self catching protrusions in a closed state so that the locking members are not released; and main body-locking protrusions which prevent the container lid from being taken off from the container main body by being caught by the circumference of the opening part of the container main body or a main body catching protrusion, even if the container lid rises due to the expansion of the packing as a result of a decrease in the negative pressure generated inside the container.

Owner:BORU INT CO LTD

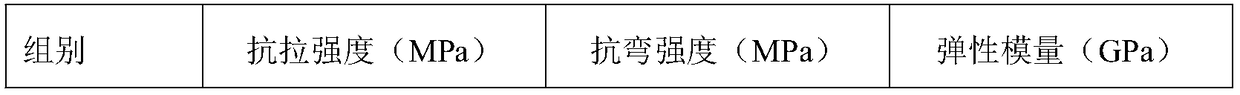

Composite material with titanium diboride intermediate coating

InactiveCN103552312AImprove product qualityGood surface bindingMetal layered productsRare-earth elementCorrosion

The invention relates to a composite material with a titanium diboride intermediate coating, and belongs to the technical fields of wet metallurgy and electrochemical metallurgy. An intermediate coating titanium diboride and a surface active coating are orderly coated on the outer surface of matrix sheet metal; the thickness of the intermediate coating titanium diboride is 0.5-3 microns; the thickness of the surface active coating is 0.2-1mm; the matrix sheet metal is a titanium plate or an aluminum plate (pure aluminium, pure titanium, aluminium alloy plate or titanium-alloy plate); the thickness of the matrix sheet metal is 0.5-5mm; the material of the surface active coating is a multi-component system coating consisting of lead, manganese, and rare-earth element oxide, and comprises the following concrete components: 70-90wt% of lead dioxide, 10-30wt% of manganese dioxide, and 0.1-5.0wt% of rare-earth oxide. The composite electrode plate has the advantages of being good in surface associativity, good in conductivity, good in corrosion resistance, low in cost and the like.

Owner:KUNMING UNIV OF SCI & TECH

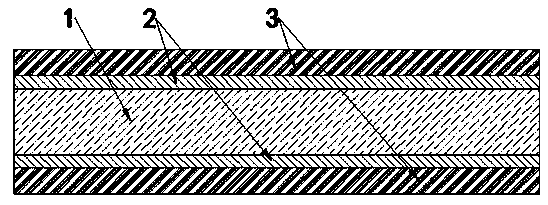

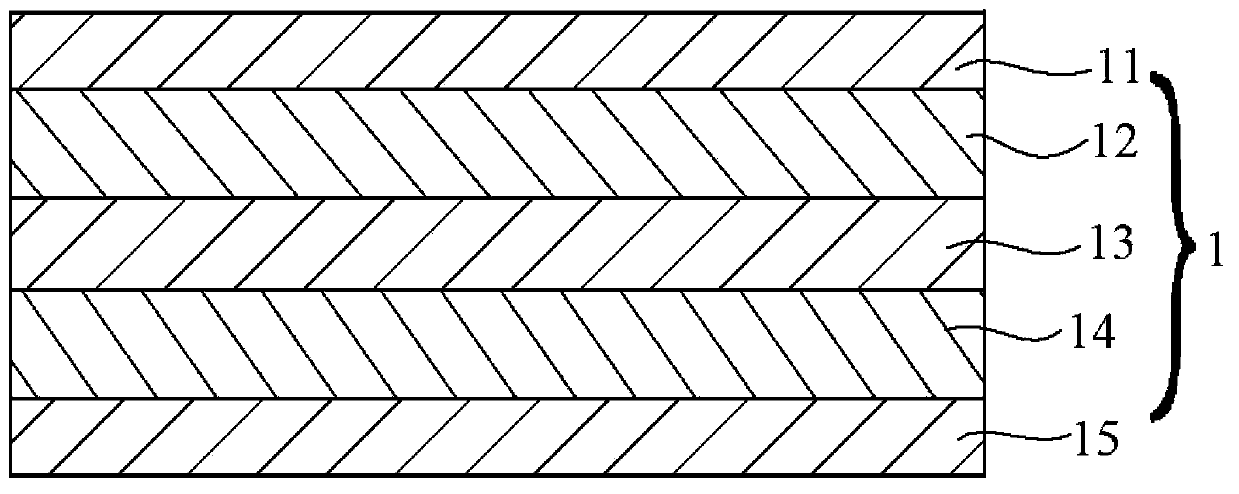

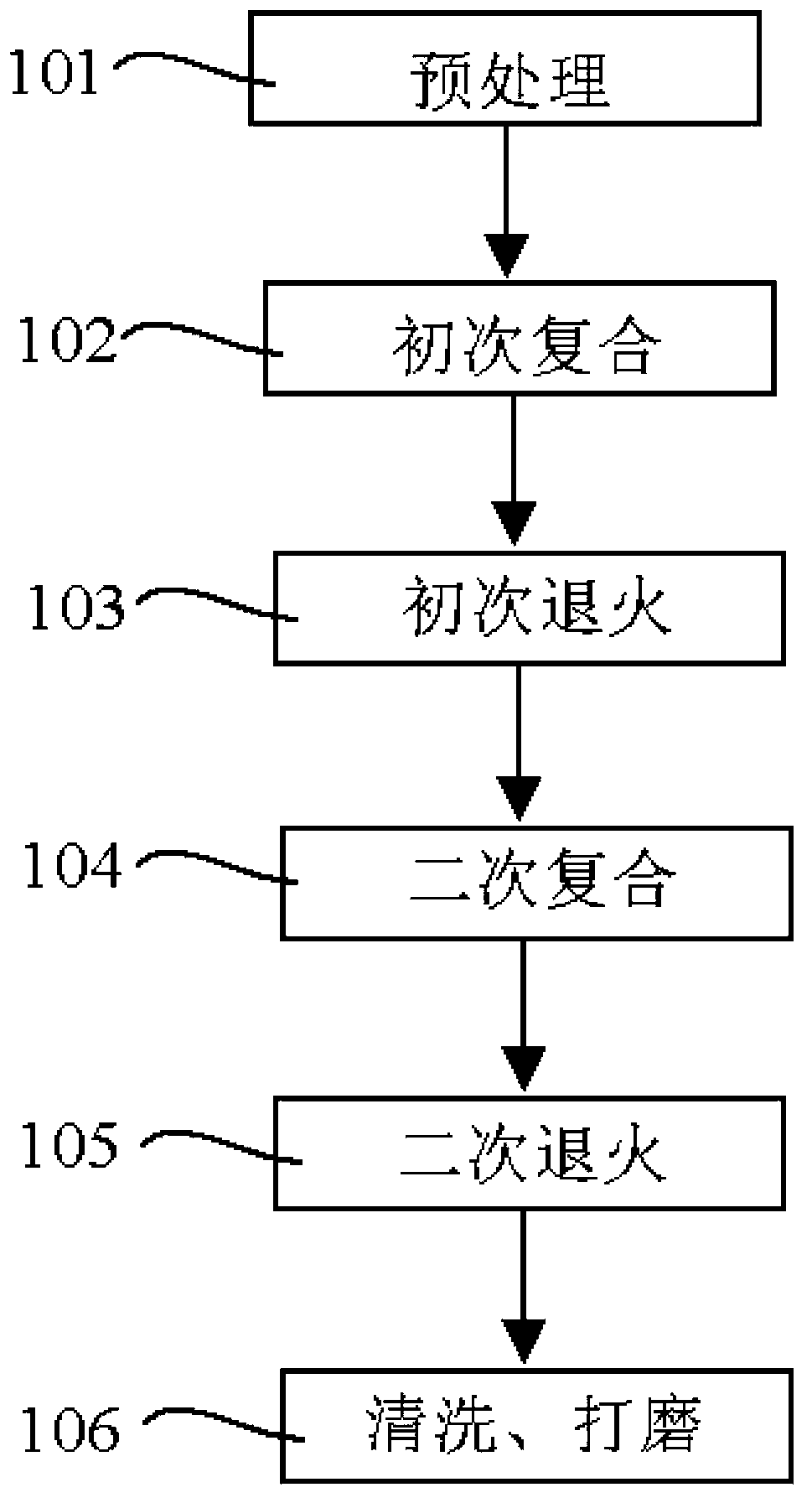

Five-layer metal composite material cookware and metal composite plate preparation method thereof

InactiveCN103417125AFirmly bonded stateLight in massCooking-vessel materialsMetal rolling arrangementsComposite plateMachining process

The invention relates to a five-layer metal composite material cookware. The five-layer metal composite material cookware comprises a cookware body and a handle arranged on the cookware body. The cookware body is formed by punching a five-layer metal composite plate, wherein the five-layer metal composite plate is formed by punching a 304 stainless steel layer with a thickness of 0.5-2 mm, a magnalium alloy layer with a thickness of 0.5-2 mm, a pure aluminum layer with a thickness of 0.5-2 mm, an aluminum alloy layer with a thickness of 0.5-2 mm, and a 430 stainless steel layer with a thickness of 0.5-2 mm. The five-layer metal composite material cookware has the advantage of being still capable of maintaining an original firm combination state due to the fact the metal composite plate is applicable to various cold machining processes such as deep drawing, stretching, expansion, hole punching and edge traction without layering; meanwhile, is light in weight, good and rapid in heat transfer, energy-saving and applicable to various cooking ranges.

Owner:上海乾天厨房用具有限公司

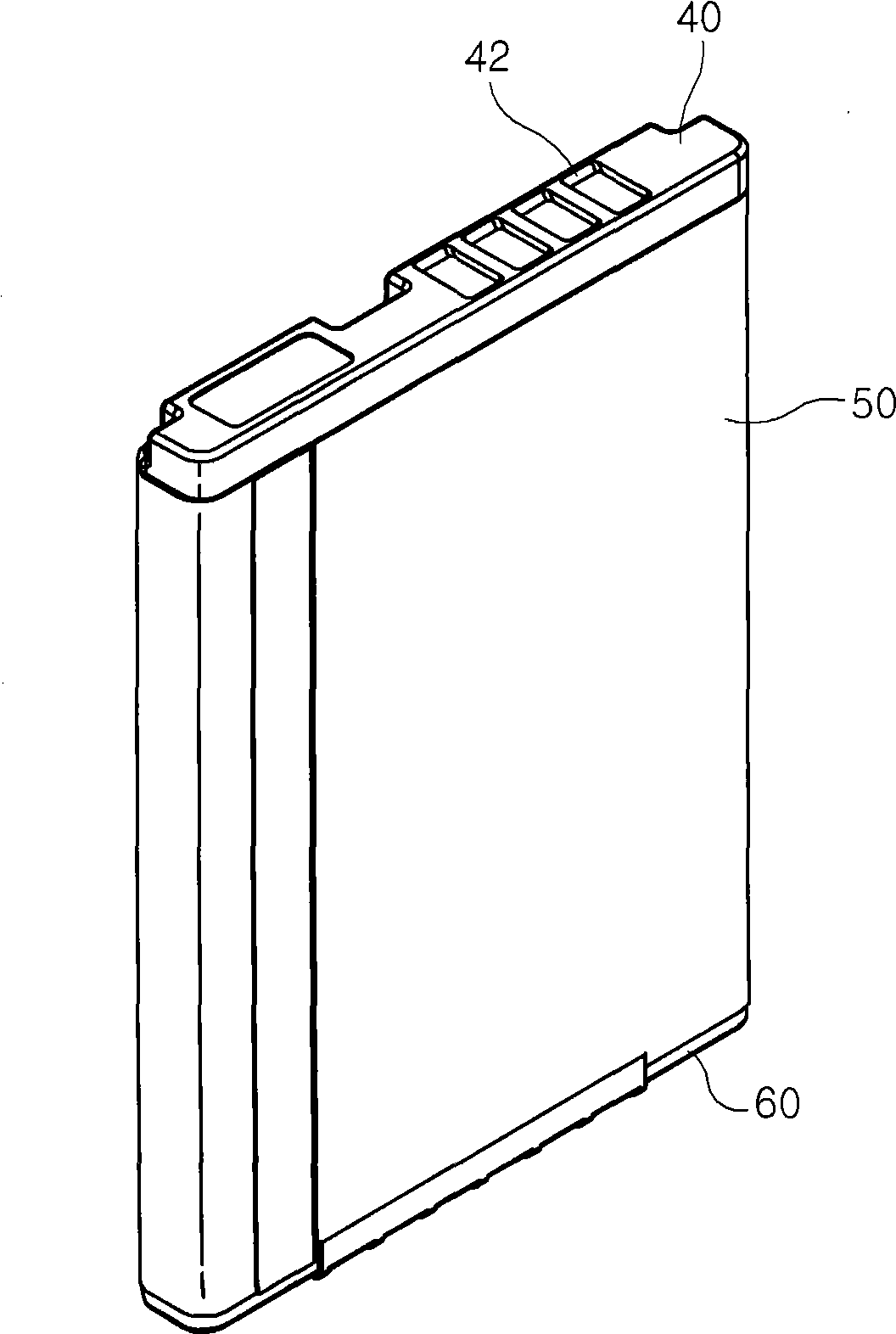

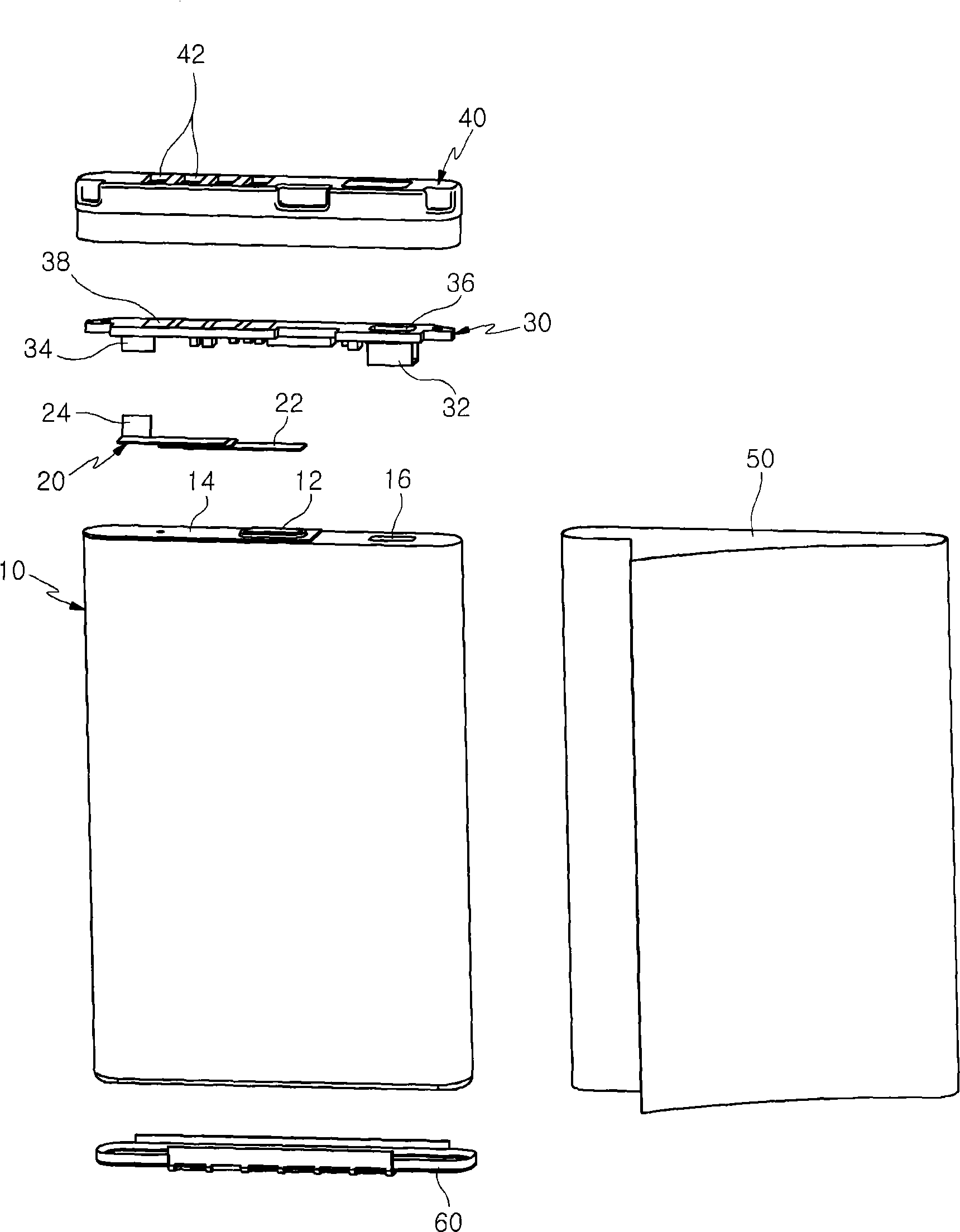

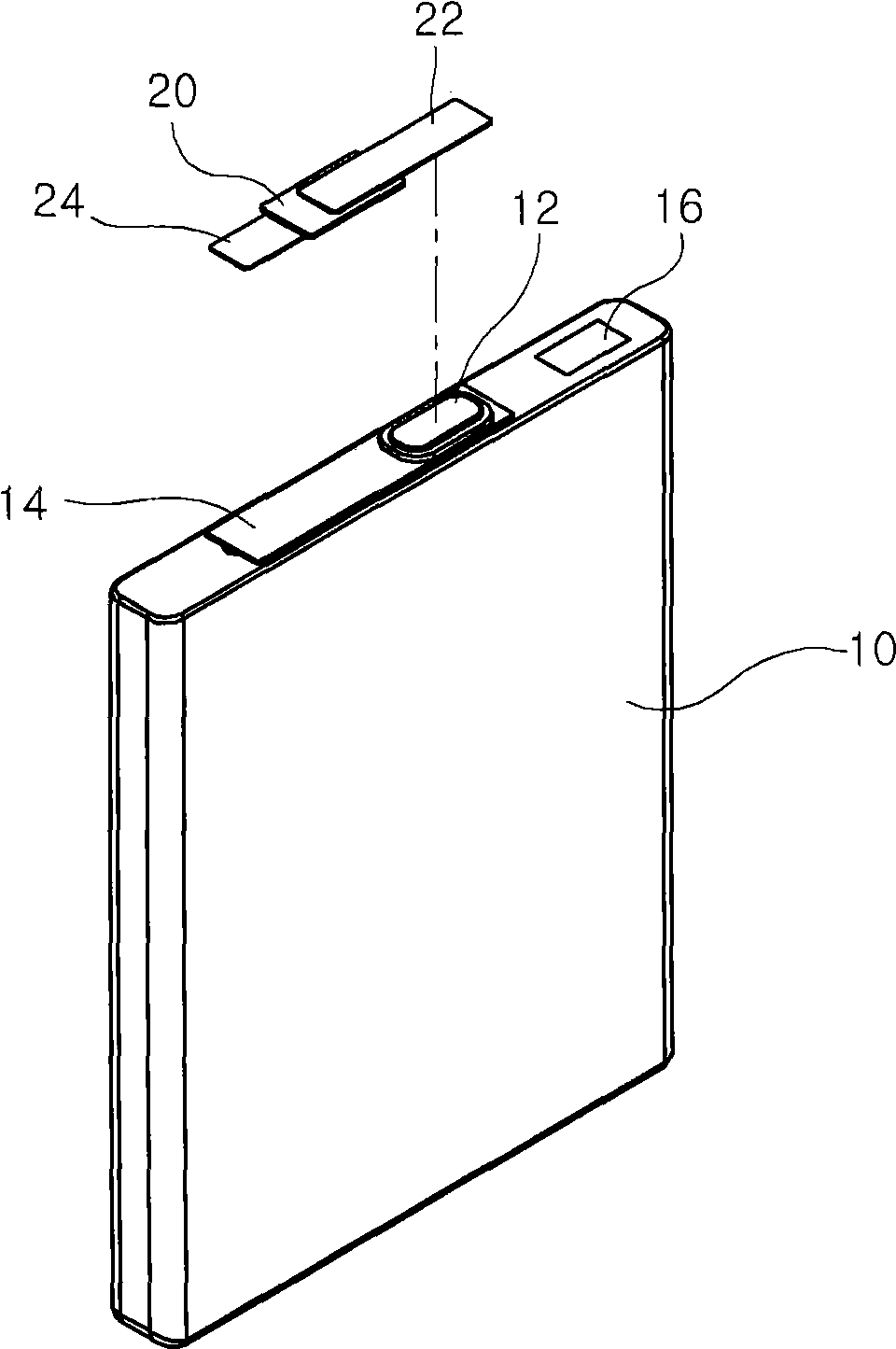

Built-in battery pack for mobile communication terminal and method of manufacturing the same

InactiveCN101533897ASimple processReduce the number of partsBatteries circuit arrangementsCell component detailsSolderingExternal connection

The invention relates to a built-in battery pack for mobile communication terminal and a method of manufacturing the same; for the anode / cathode terminal of the battery pack, the invention does not soldering but uses precise spot welding mode to weld the anode / cathode nickel sheets of PCM and one side connecting portion of PTC, which simplifies the product structure and operating procedures and reduces the badness caused by soldering. The battery pack comprises a battery unit formed with an anode terminal and a cathode terminal at the upper side for charging and discharging; PTC, when mounting, one side connecting portion of bimetal function located at the upper part of the cathode terminal of the battery pack; PCM, the anode and cathode nickel sheets provided at the lower side by surface assemble in raised manner and spot welded one the other side connecting portion of the PTC and the anode terminal of the battery pack formed with corresponding spot welding holes on the upper side; a top cover combined in the upper side of the battery pack and penetrated with corresponding external connecting hole for exposing the external connecting terminal formed on the upper side of the PCM; a bottom cover combined in the lower side of the battery unit; a packing label for packing the battery pack.

Owner:BETESH ENERGY

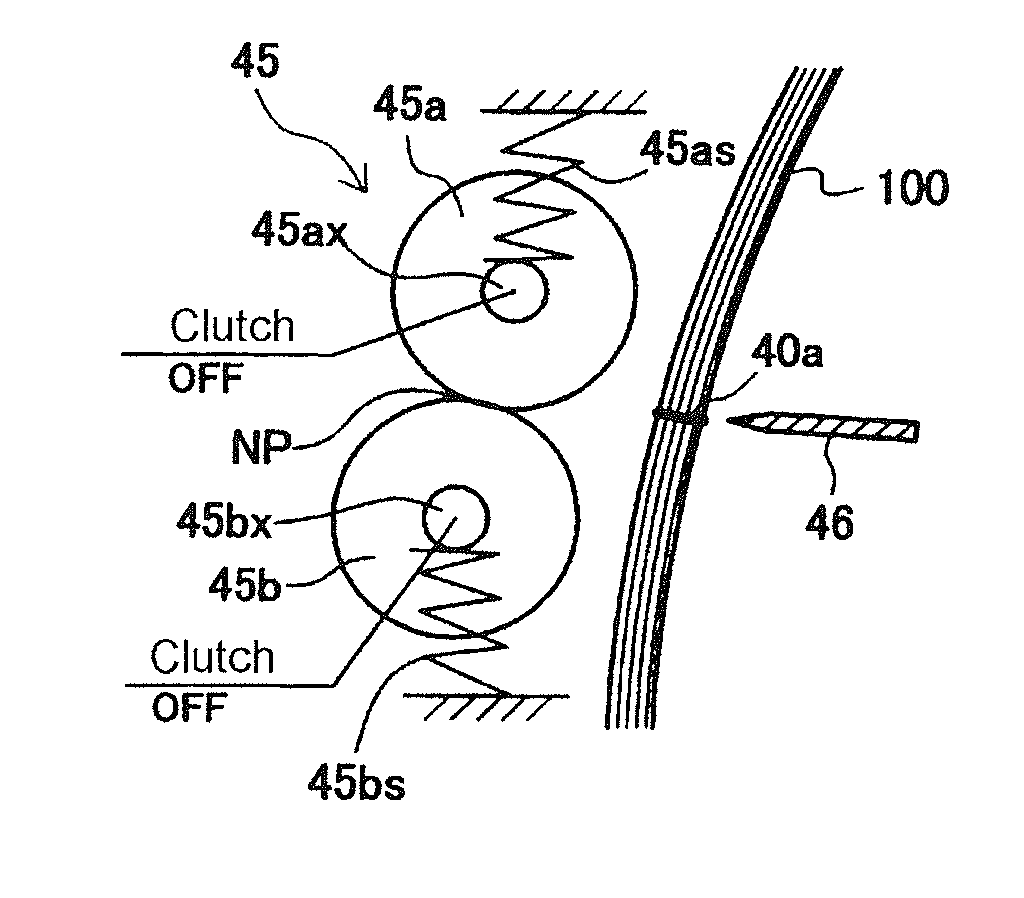

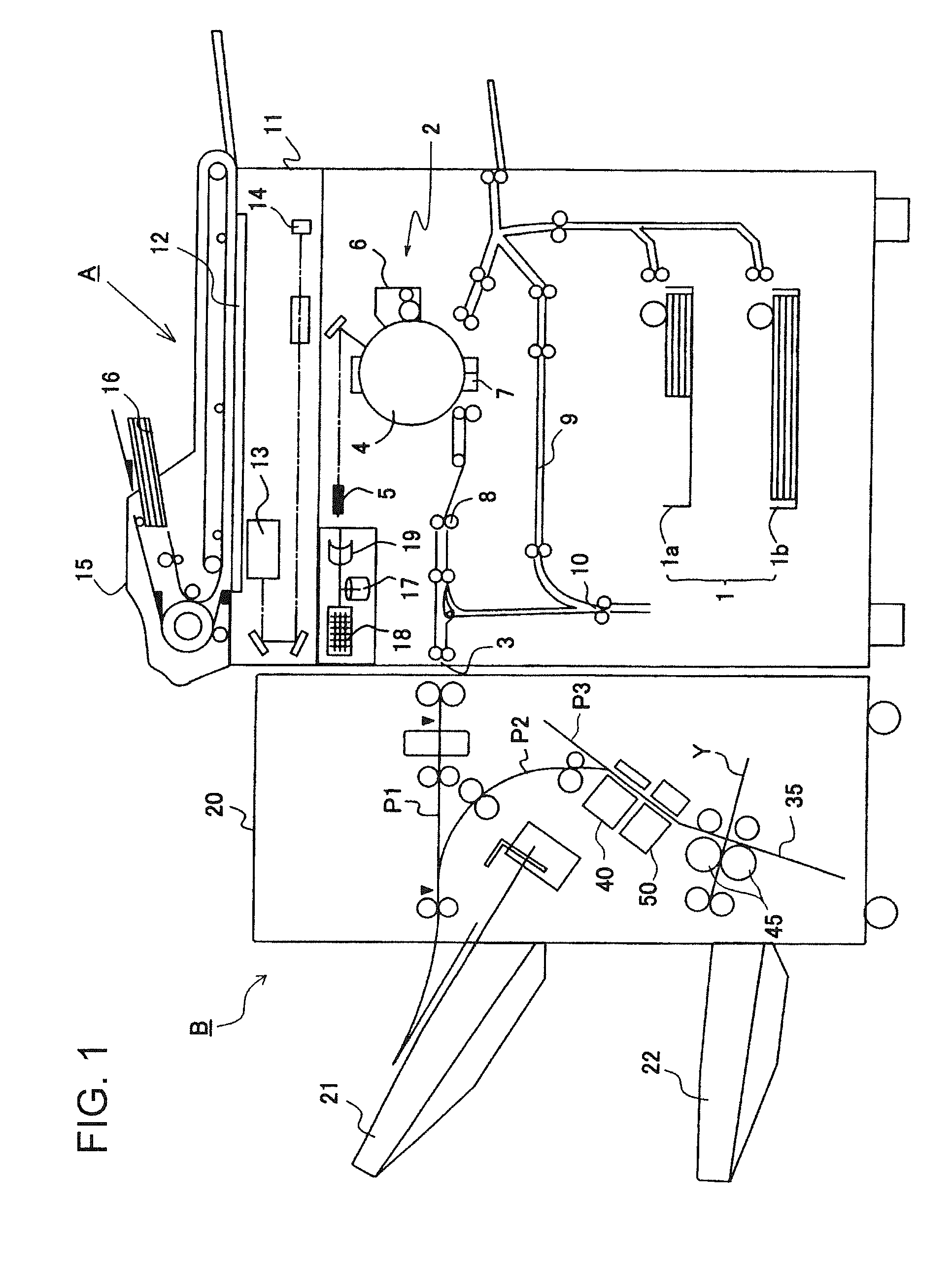

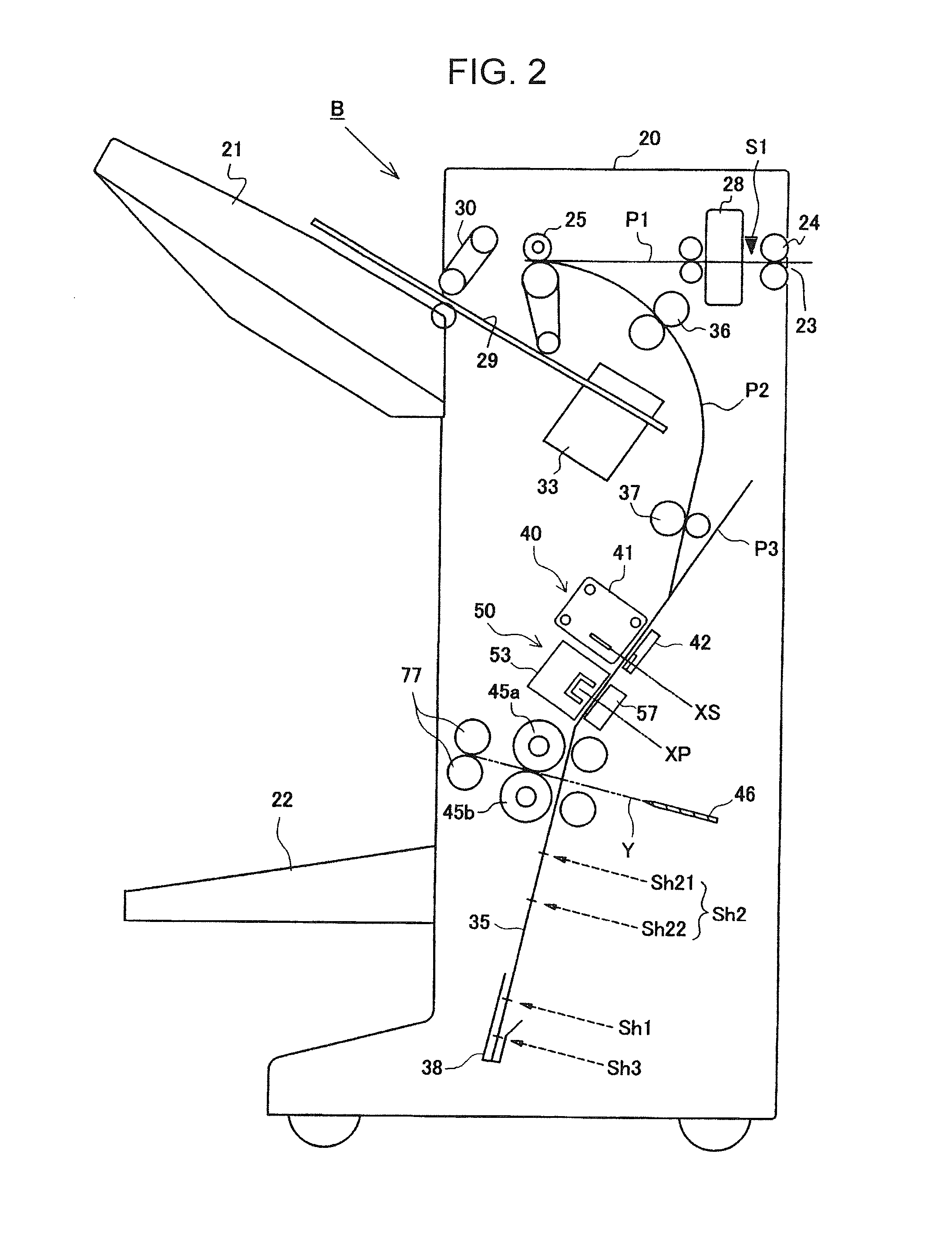

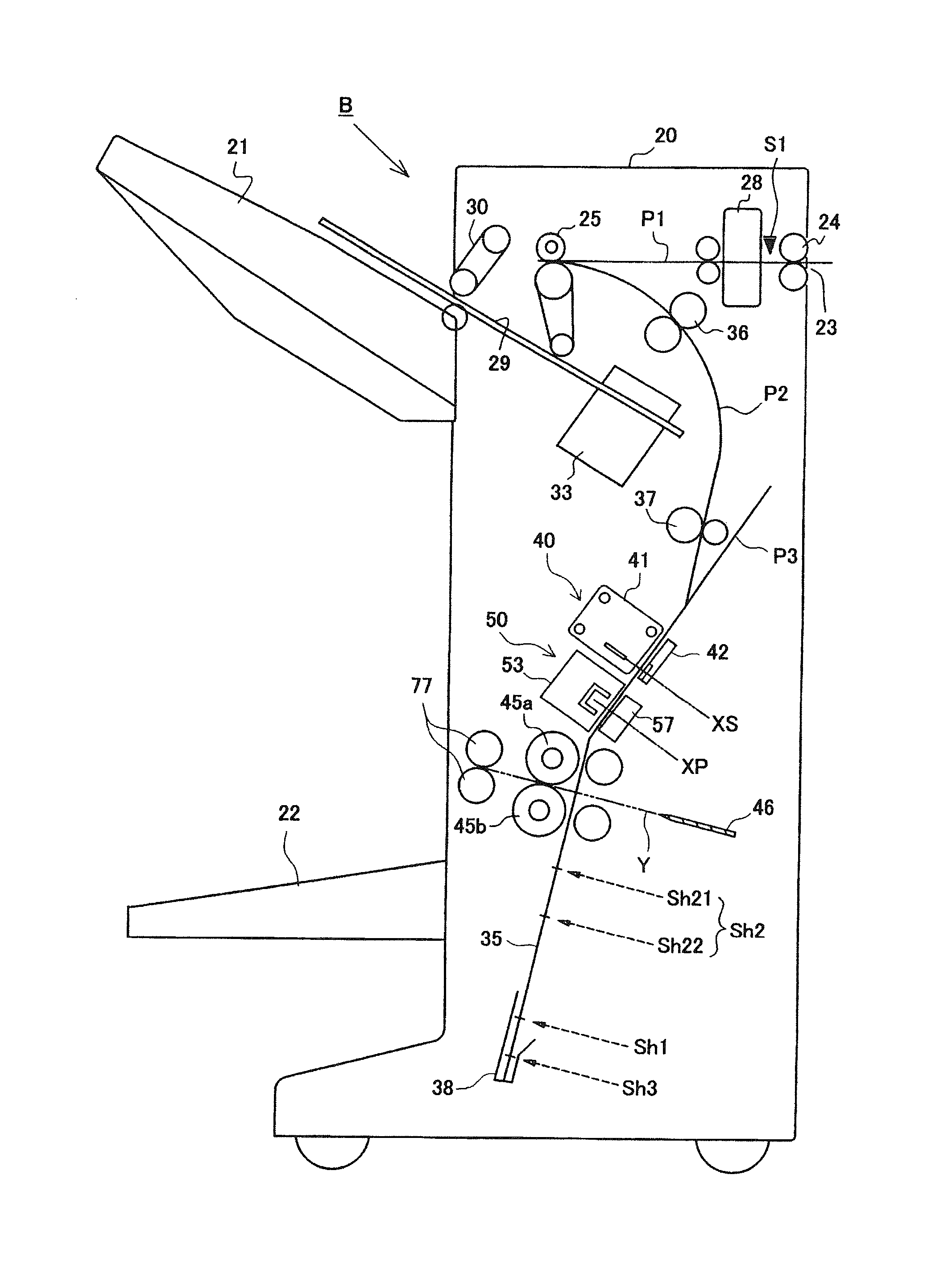

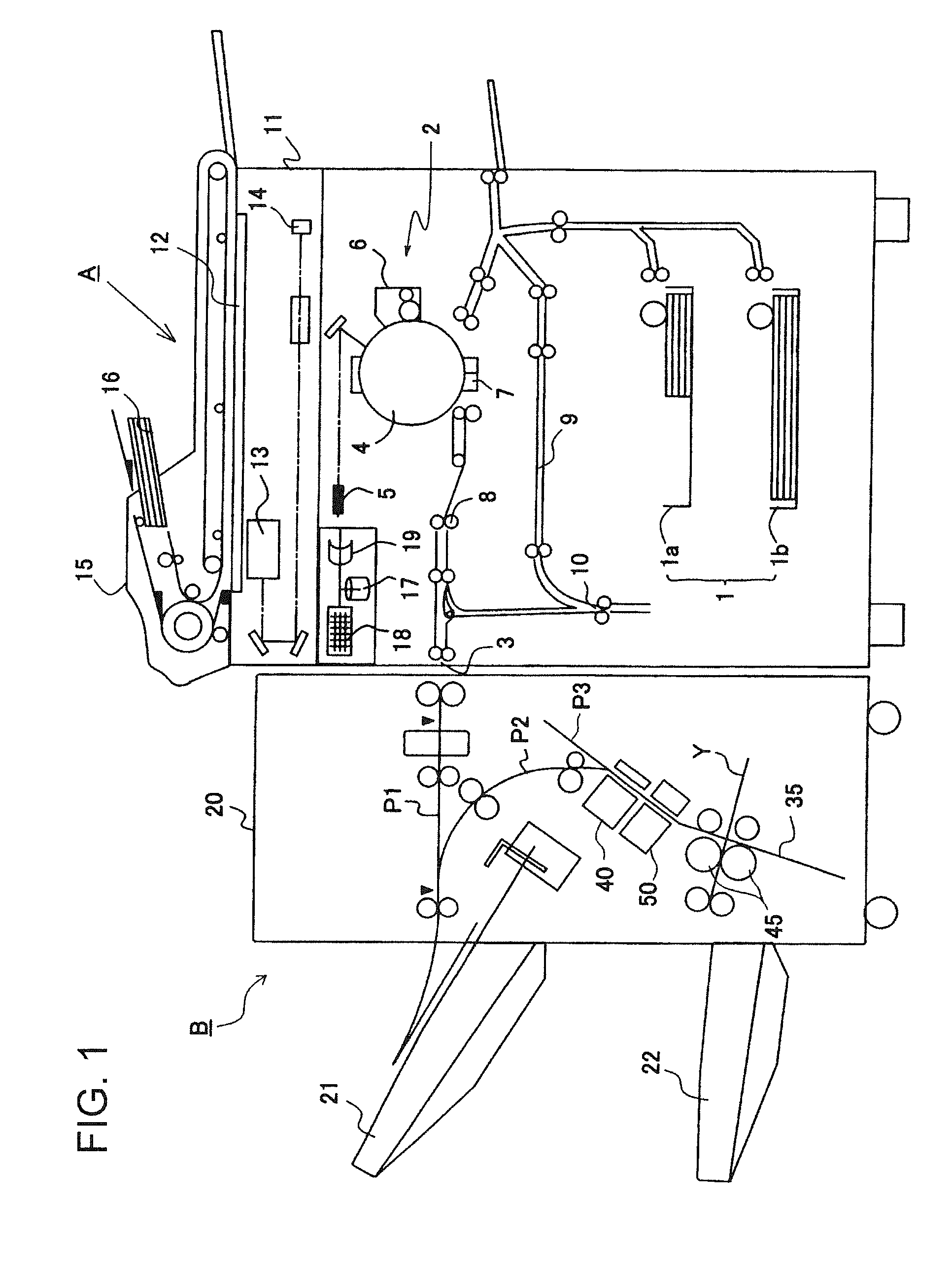

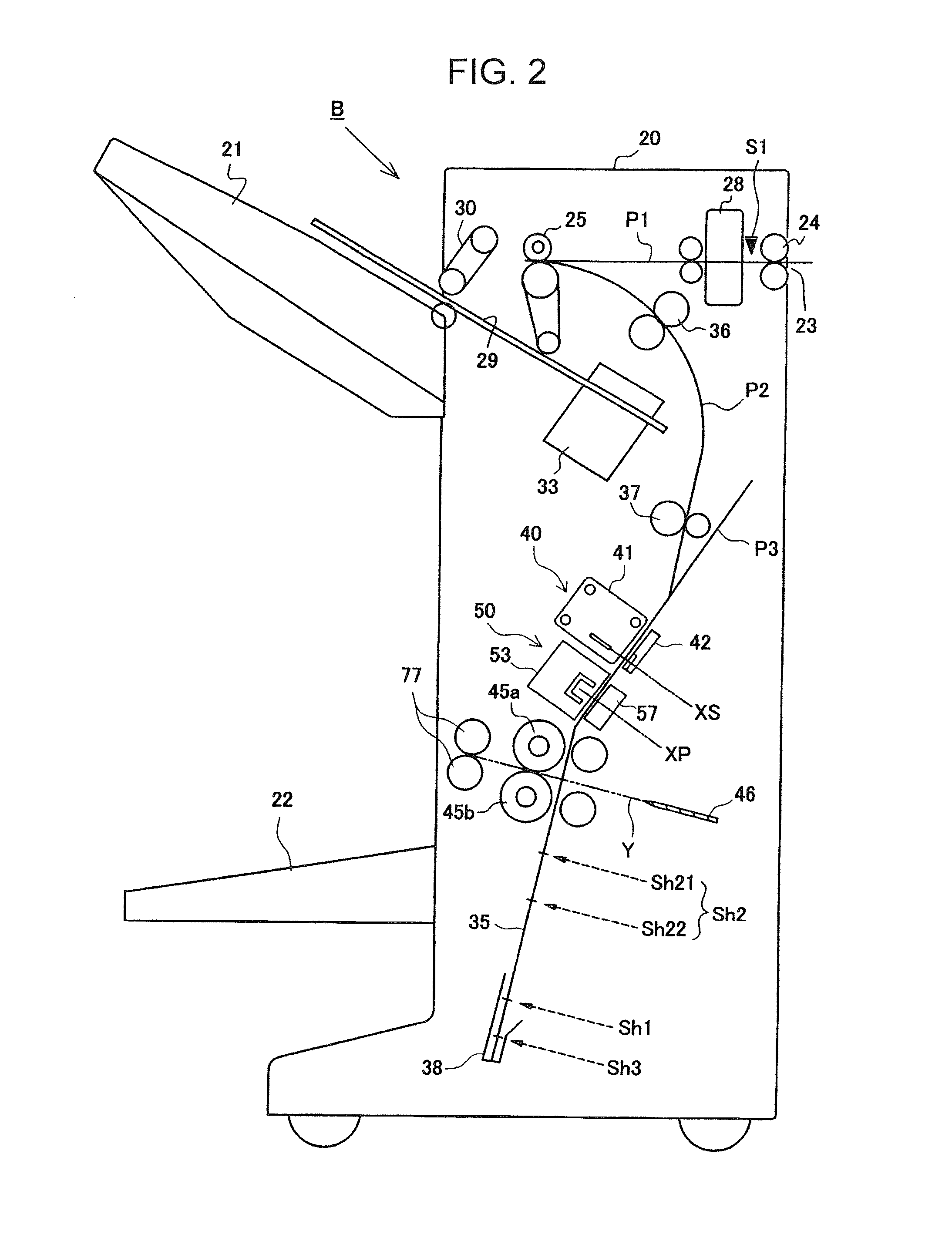

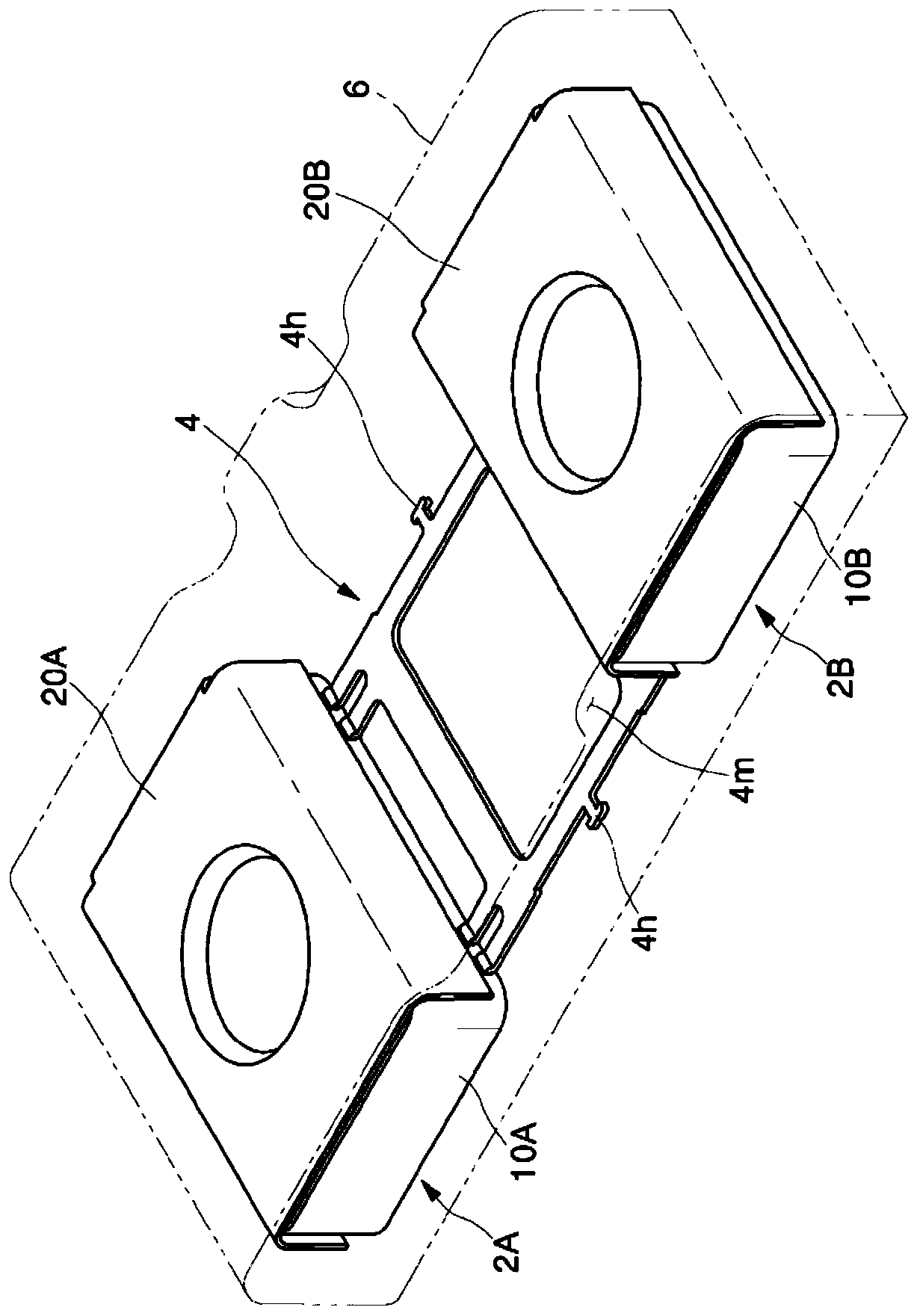

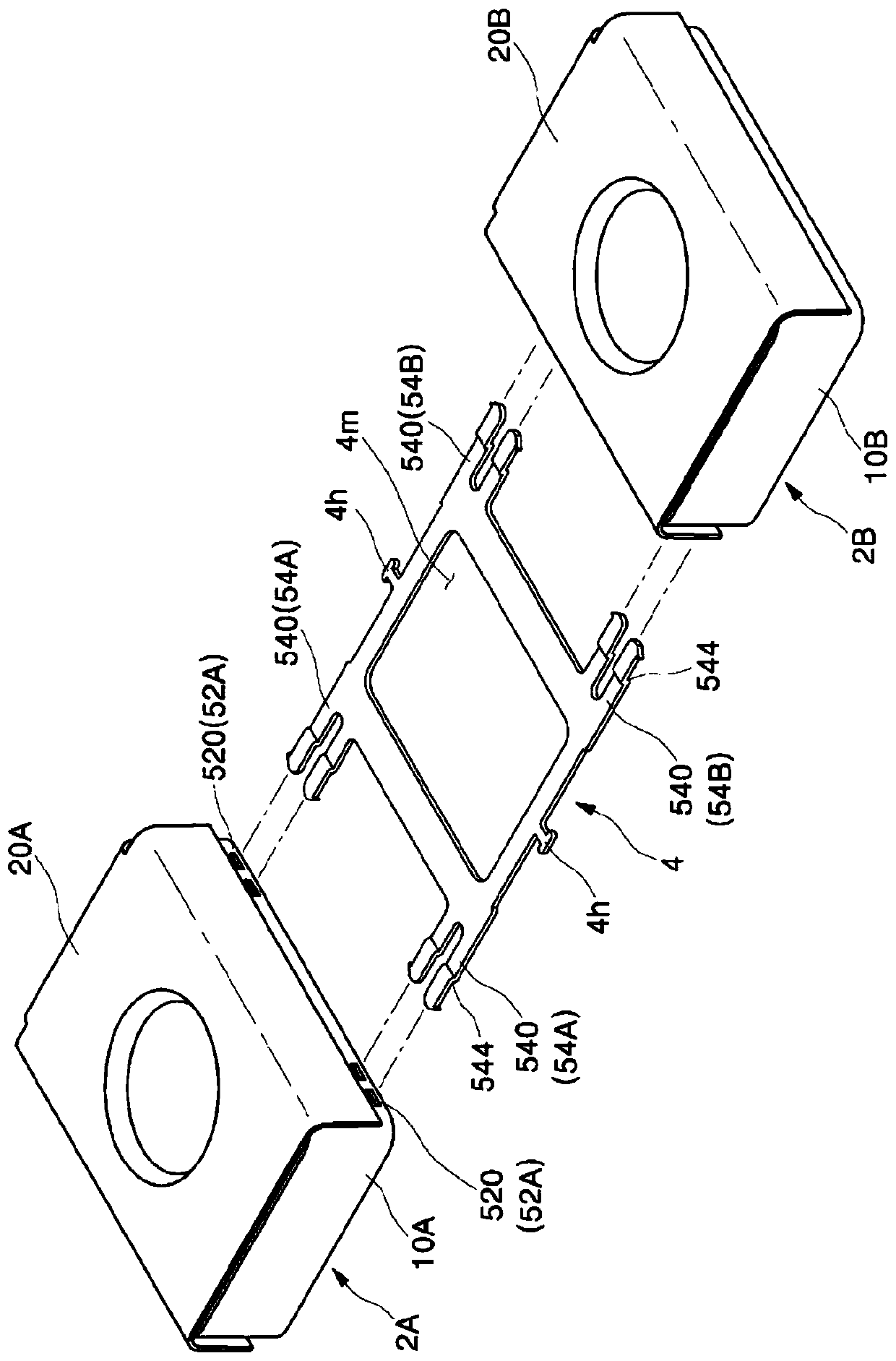

Sheet processing device and image forming device provided with the sheet processing device

ActiveUS20150117983A1Small sizeSmall binding forceMechanical working/deformationBook making processesEngineeringPaper sheet

To provide a sheet processing device that performs saddle stitching processing that binds a bundle of stacked paper sheets at a position around a center thereof and then folds in half the paper sheet bundle at the binding portion, the device being capable of selectively performing both saddle stitching using a metallic staple and saddle stitching not using the metallic staple for environmental protection and capable of reducing a size.A sheet processing device includes a stacker section that temporarily stacks conveyed paper sheets in a substantially vertical attitude, a stopper that regulates the paper sheets stacked in the stacker section, a first binding section that is provided in the stacker and saddle-stitches, with a metallic staple, a paper sheet bundle at a binding position around a center of the paper sheet bundle in a sheet conveying direction, a second binding section that saddle-stitches, without using the metallic staple, the paper sheet bundle at the binding position around the center of the paper sheet bundle in the sheet conveying direction, and a folding section that folds in half the paper sheet bundle. An interval between the second binding section and folding section is set smaller than an interval between the first binding section and folding section.

Owner:NISCA KK

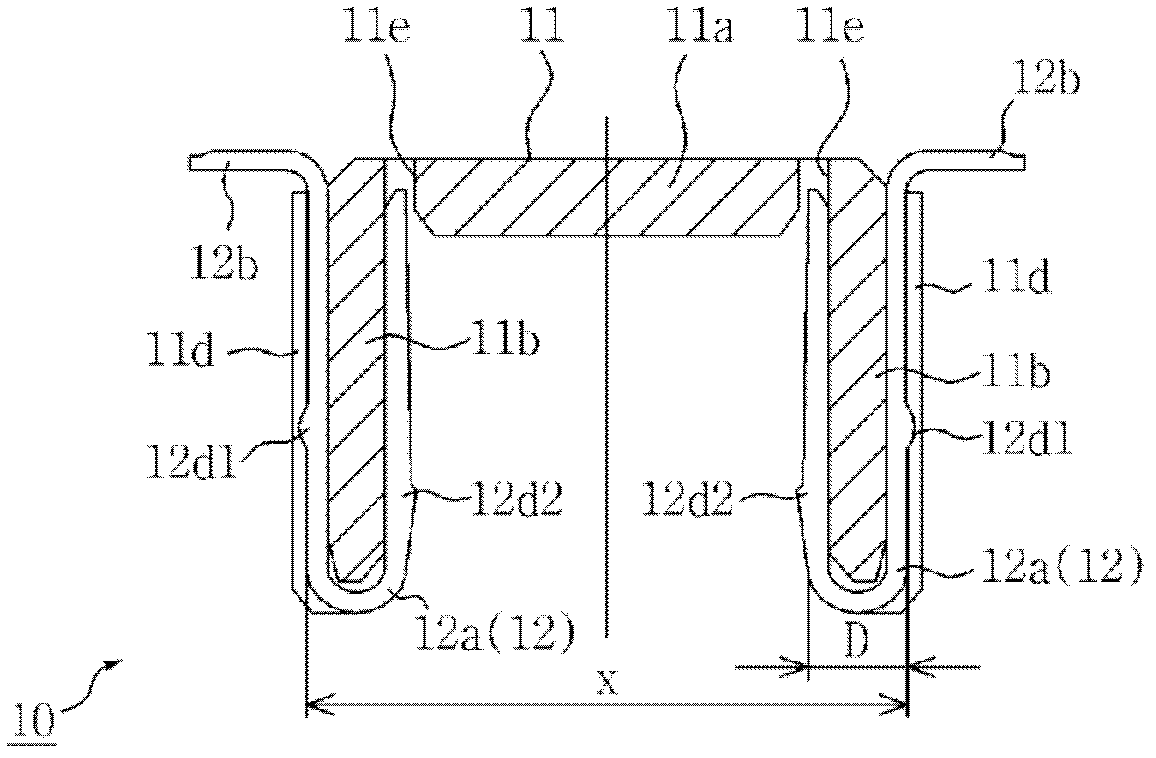

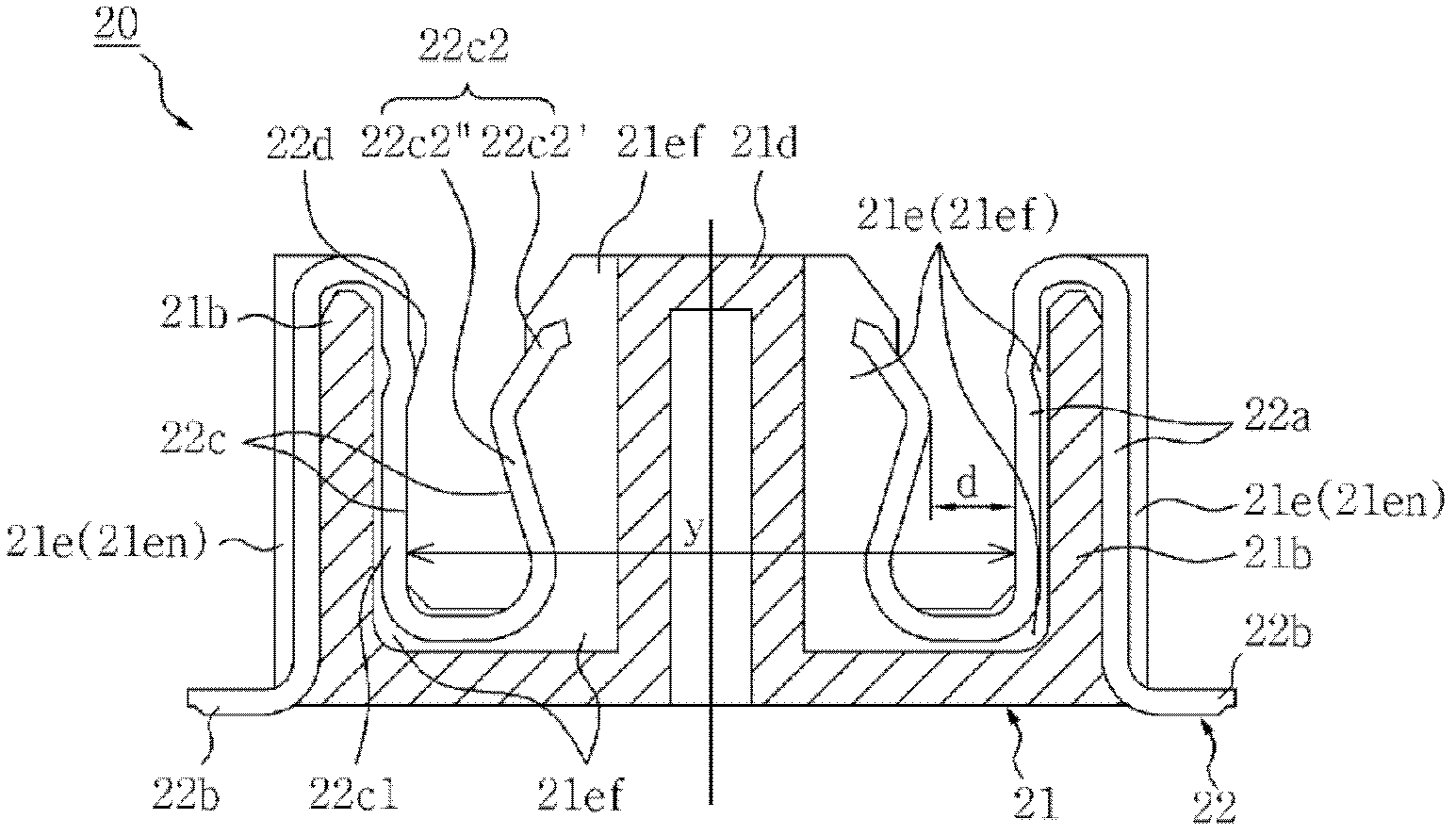

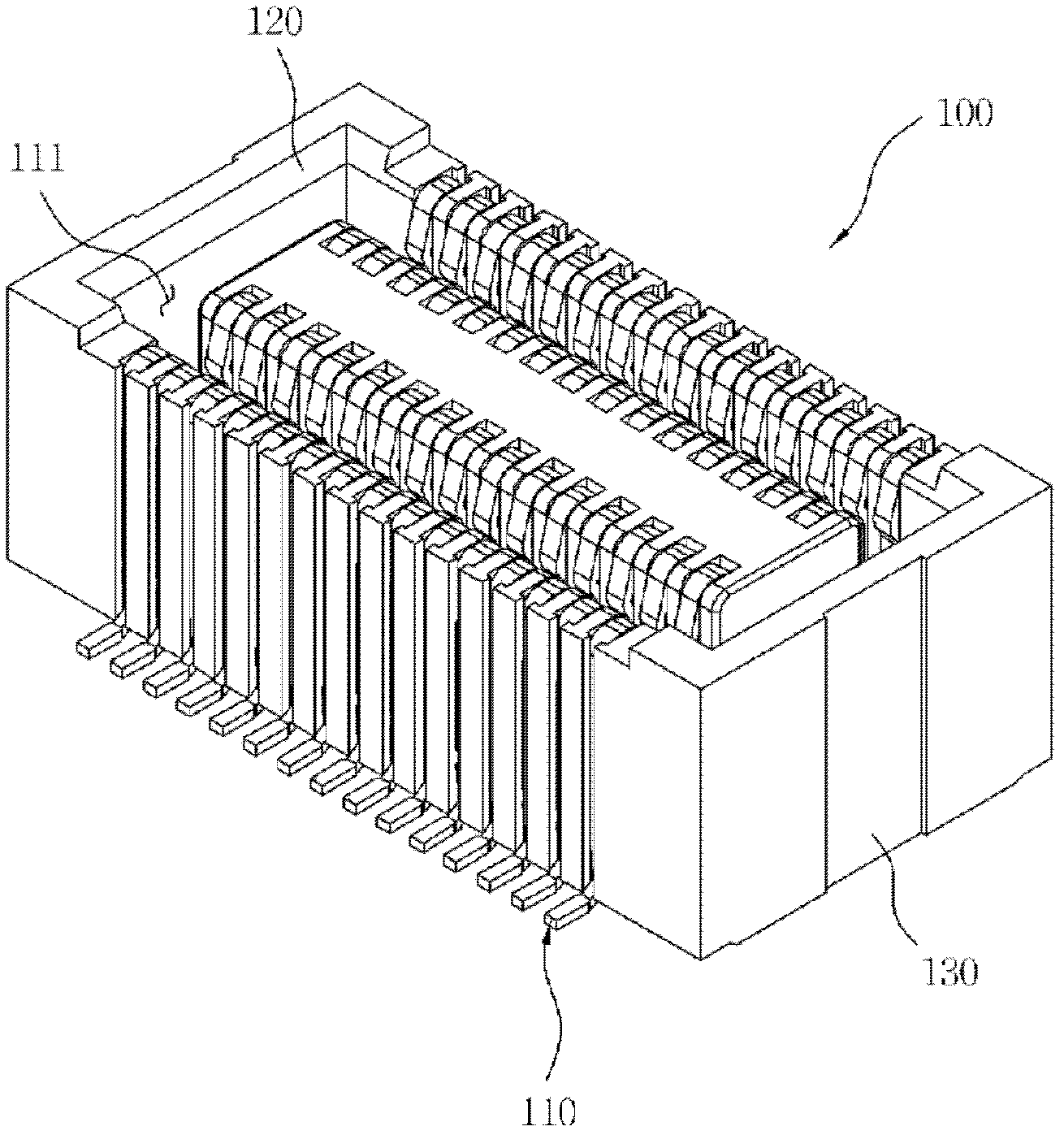

Board-to-board-type connector

InactiveCN102474030AFirmly bonded stateIncrease exposureCoupling contact membersFixed connectionsBoard-to-board connectorEngineering

A patient worn medical monitoring device (10) includes a multi-channel electrical connector (18) for connecting a lead set (22) to a monitoring unit (16) is able to wirelessly transmit a patient's physiological data over a telemetric link to a receiver unit for remote monitoring purposes. The multi-channel electrical connector includes first and second connector elements (40,42) disposed on either one of the monitoring unit or lead set. The first connector element includes a plurality of rigid pins (44) disposed between a plurality of ribs (50). The second connector element includes a compressible substrate carrying flexible electrically conductive pads (46) that flex independently of one another. The connector elements to are configured to such that the pins of the first connector element electrically engage the flexible electrically conductive pads of the second connector element.

Owner:HUMAN ELECTRONICS

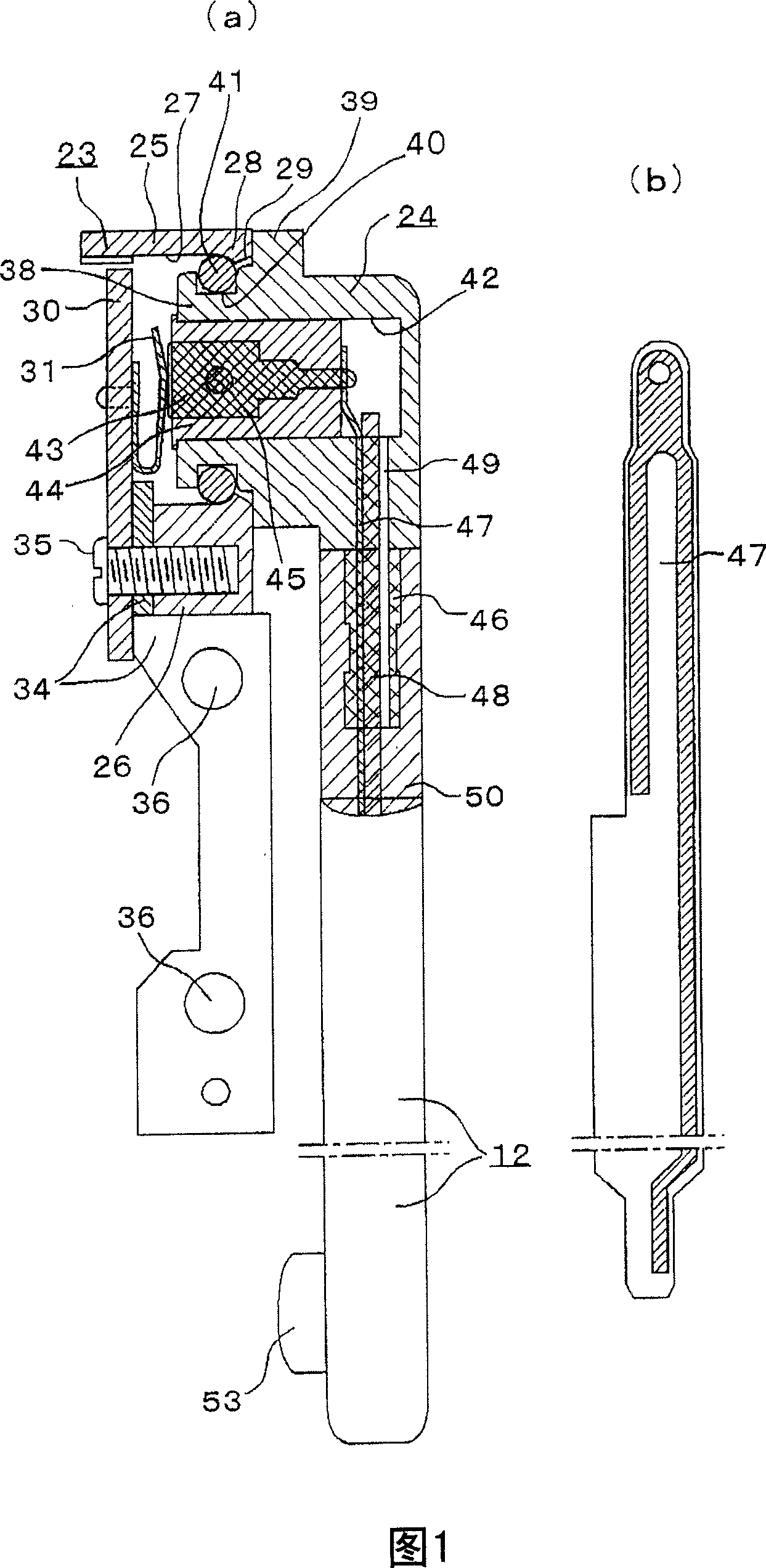

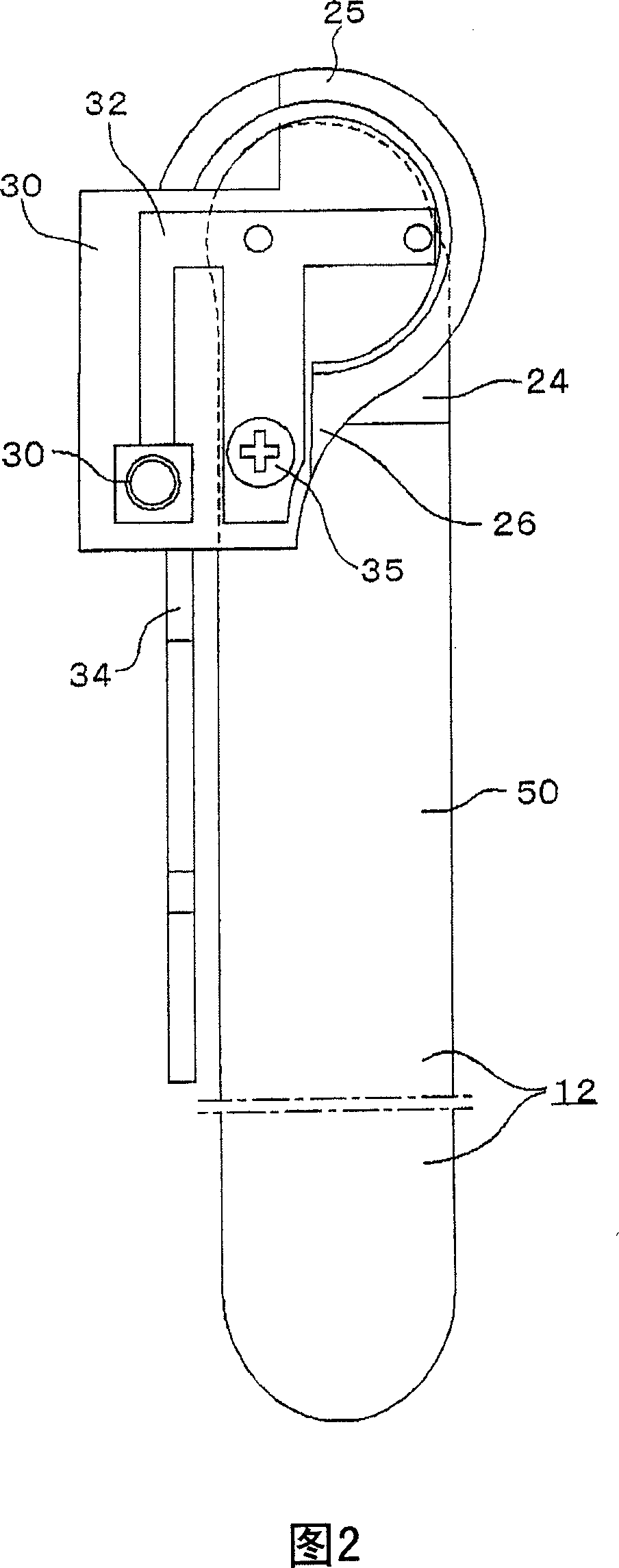

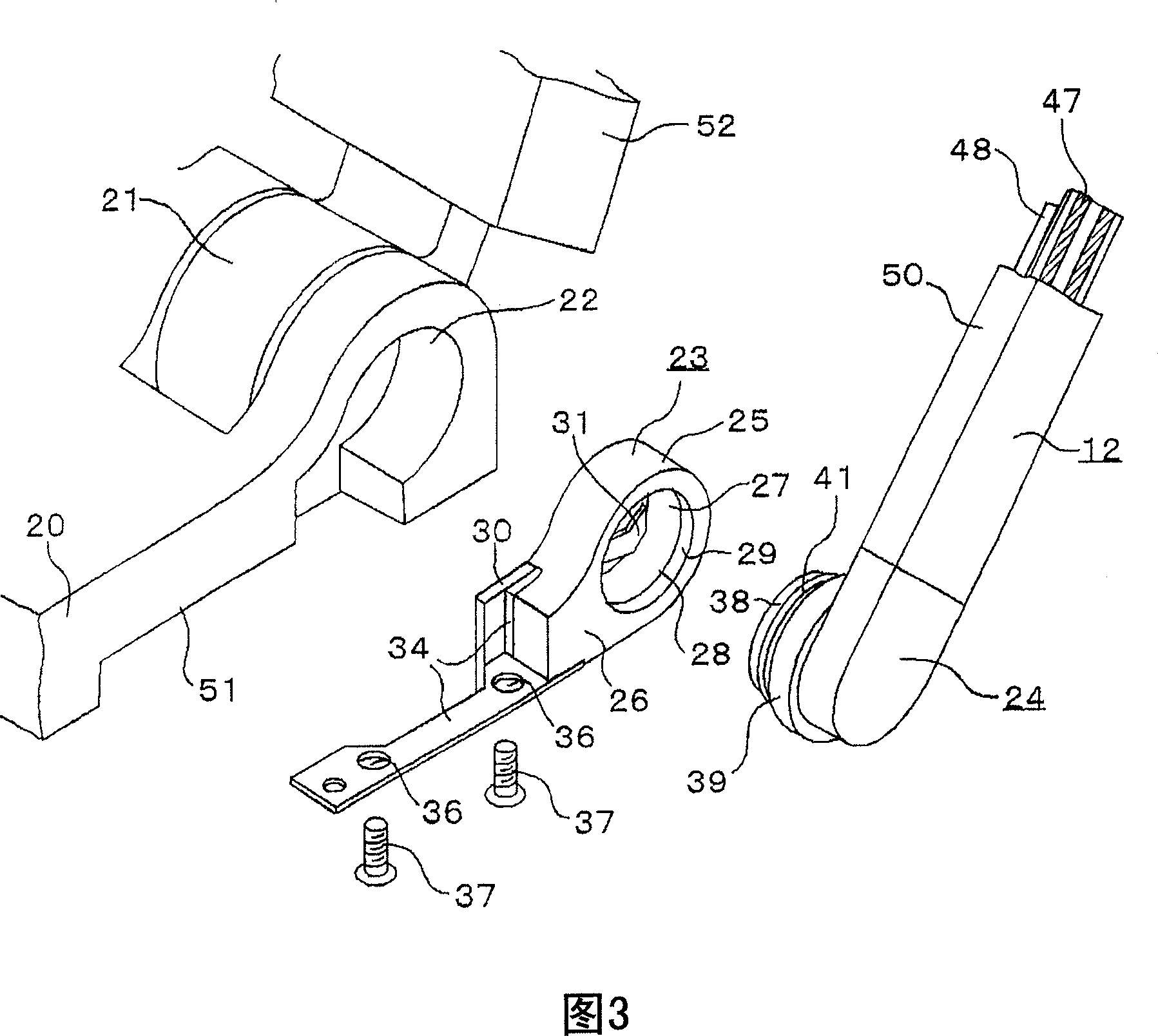

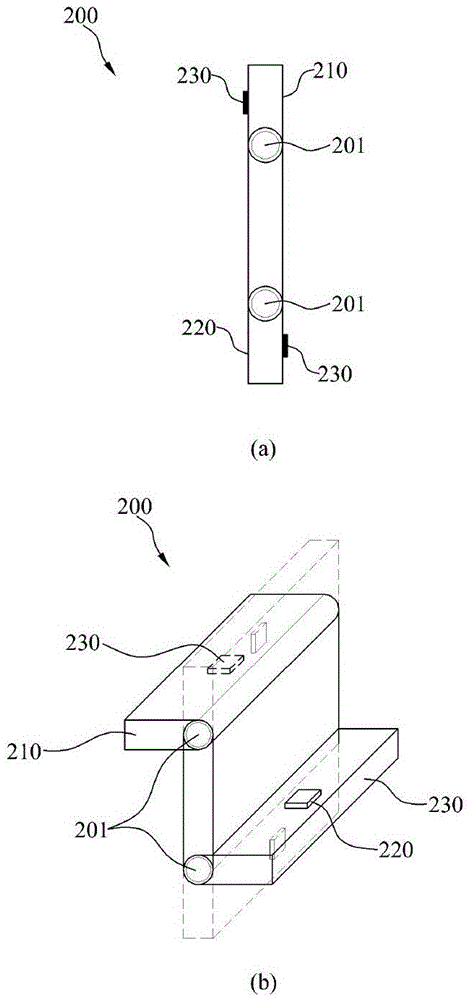

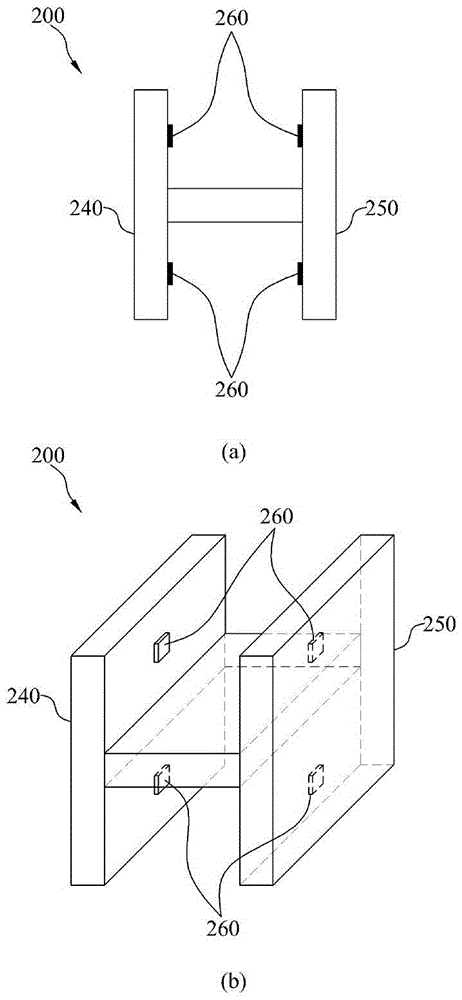

Attachment/detachment mechanism for compact antenna

InactiveCN101030669AFirmly bonded statePivotable antennasAntenna supports/mountingsElectronicsEngineering

To provide an attaching / detaching mechanism of compact antennas which would not damage an antenna or a device even if a force more than a certain strength is applied from any direction of the antenna part. An antenna housing 23 formed in an electronics main body 20 is connected to a rotatory L-shaped connector 24 of an antenna part 12. A fitting groove 40 is formed on the periphery of a male fitting cylinder 38 on the rotatory L-shaped connector 24 side to fit an O-ring 41 and an engaging projection 28 which presses to engage the O-ring 41 is formed on the inner wall of a female fitting cylinder 25 on the antenna housing 23 side so that they can be rotatably and attachably / detachably connected. A contact member 43 whose tip is exposed is attached to the fitted cylinder 38 and a contact spring 31 is prepared oppositely to the contact member 43 so that it can press the O-ring 41 to the engaging projection 28.

Owner:SMK CO LTD

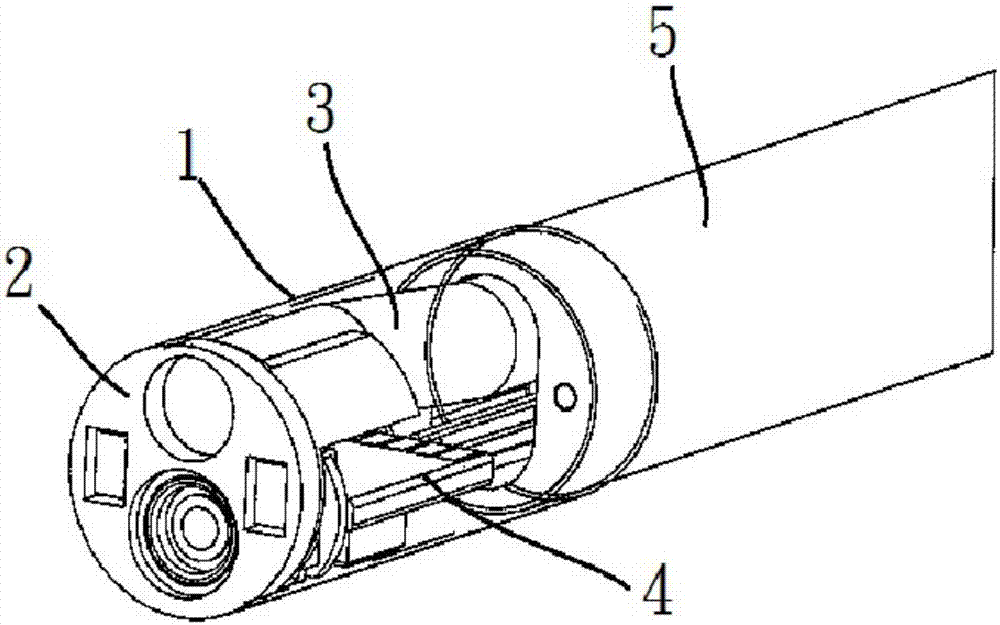

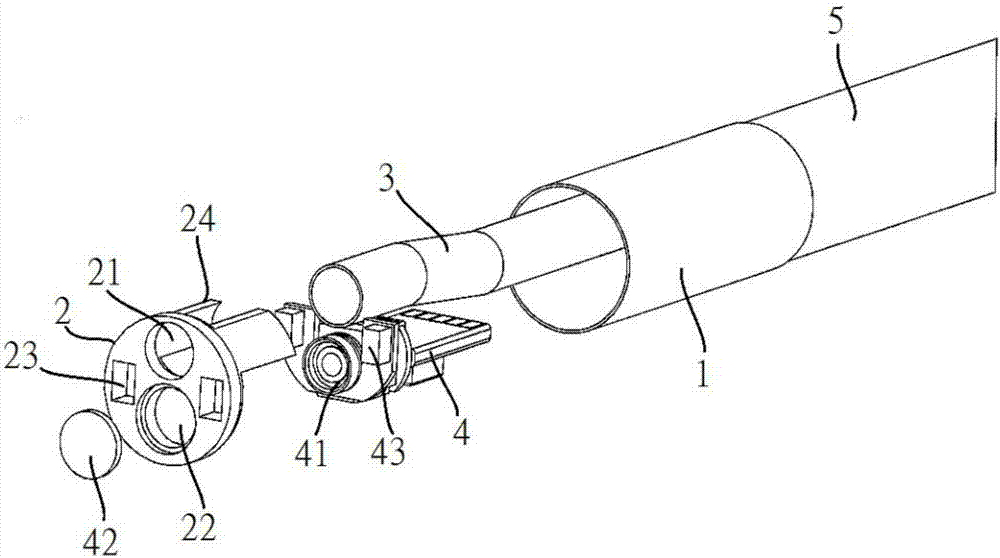

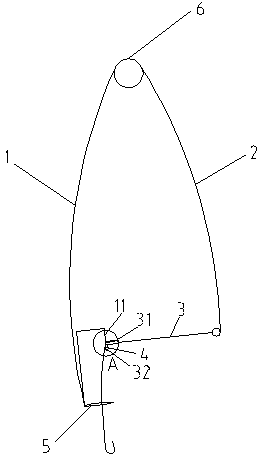

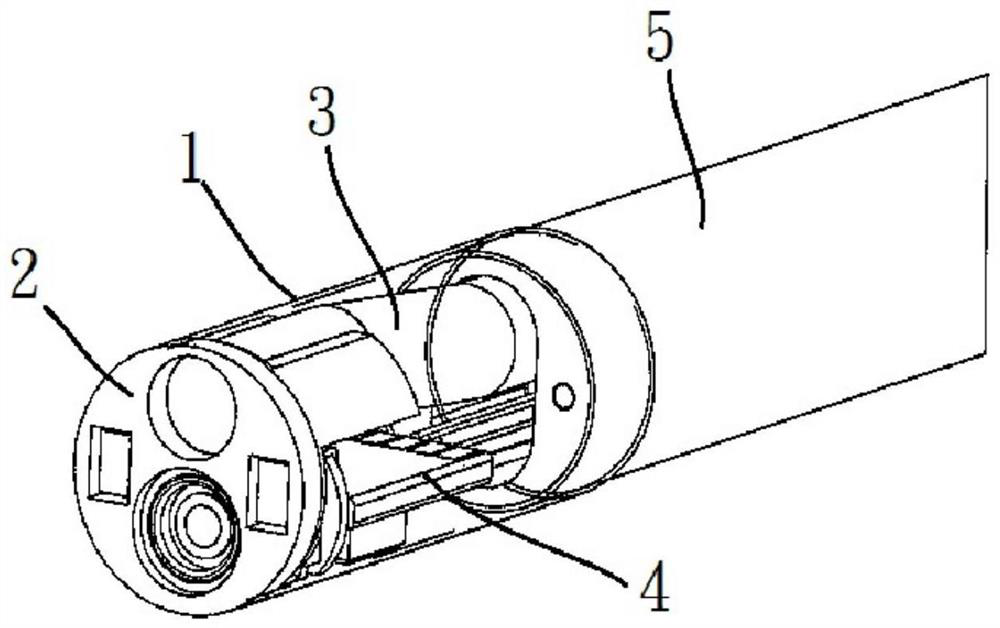

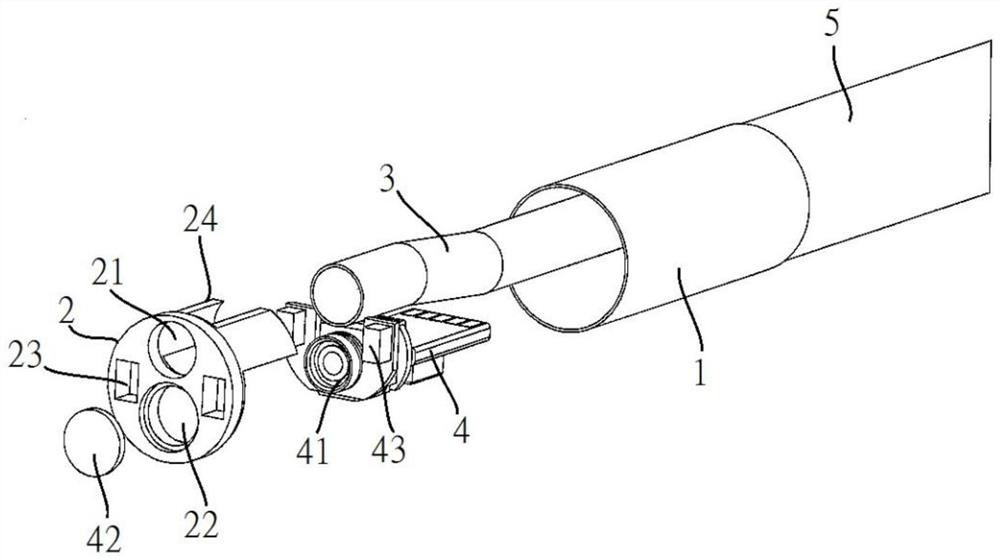

Bronchoscope distal probe having novel structure

The invention discloses a bronchoscope distal probe having a novel structure. The distal probe that a bronchoscope mainly comprises an image pickup module, an apparatus tube and a luminous body has a stably bonded state; during glue pouring and packaging, the various components are prevented from getting displaced and a consistent combined structure is defined, so that an effect of guaranteeing safety when the bronchoscope is used is achieved. The distal probe comprises a hollow outer tube and an end panel which is combined to the outer end of the hollow outer tube, and the outer end of the apparatus tube, a camera of the image pickup module and the luminous body are clamped in corresponding holes of the end panel, so that the various components are kept under a quite stably bonded state; then, a process of water-proofing glue pouring and packaging is implemented on the front part and the rear part of the hollow outer tube, so that the perfect structure of the distal probe is defined; and finally, the outer end of a bronchoscope body of the bronchoscope is combined to the rear end of the hollow outer tube. The bronchoscope distal probe is simple in overall structure, easy for combination, high in economy and obvious in practicability.

Owner:ZHUHAI KADEN MEDICAL IMAGING TECH CO LTD

Fit-Together Tile Connecting Body

Owner:沈贞泽

Sheet processing device and image forming device provided with the sheet processing device

ActiveUS9352604B2Small binding forceFirmly bonded stateMechanical working/deformationBook making processesImage formationEngineering

Owner:NISCA KK

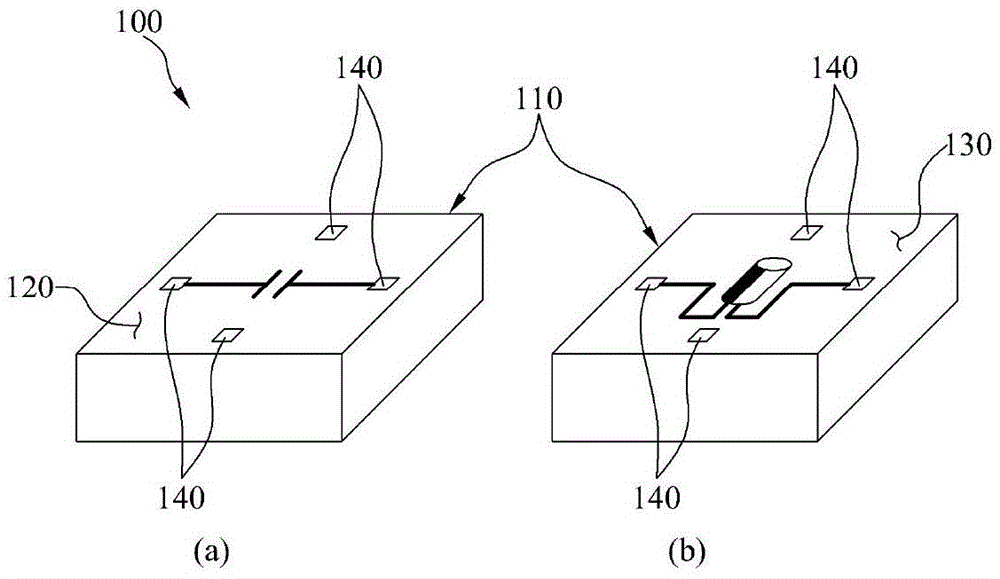

Improved construction kit of modular circuit elements

InactiveCN105659307ASimple associativitySimple separabilityCircuit arrangements on support structuresEducational modelsModularityElectrical connection

According to an improved construction kit of modular circuit elements provided by the present invention, the individual circuit elements for forming an electronic circuit are formed in the shape of a module, and the circuit elements are configured to be connected to a square or rectangular circuit element block module by an I-shaped or H-shaped circuit element coupling module for an electrical connection such that the electrical connection of the electronic circuit for testing a circuit and a coupled state between the modules can be stably maintained.

Owner:康民洙

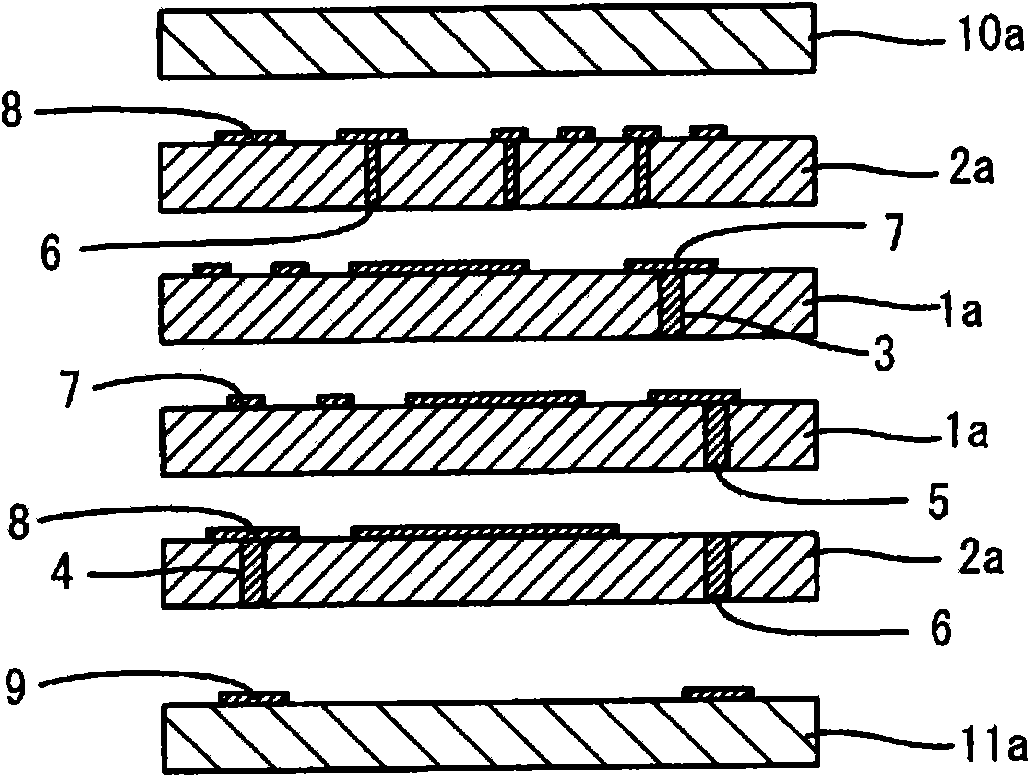

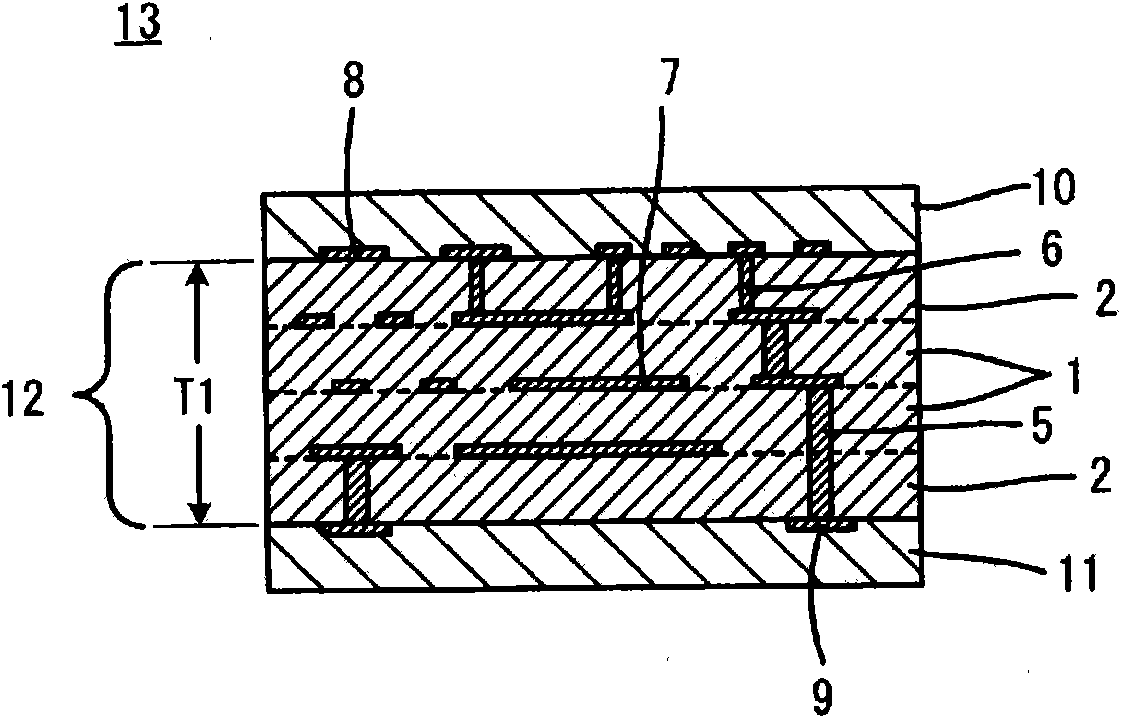

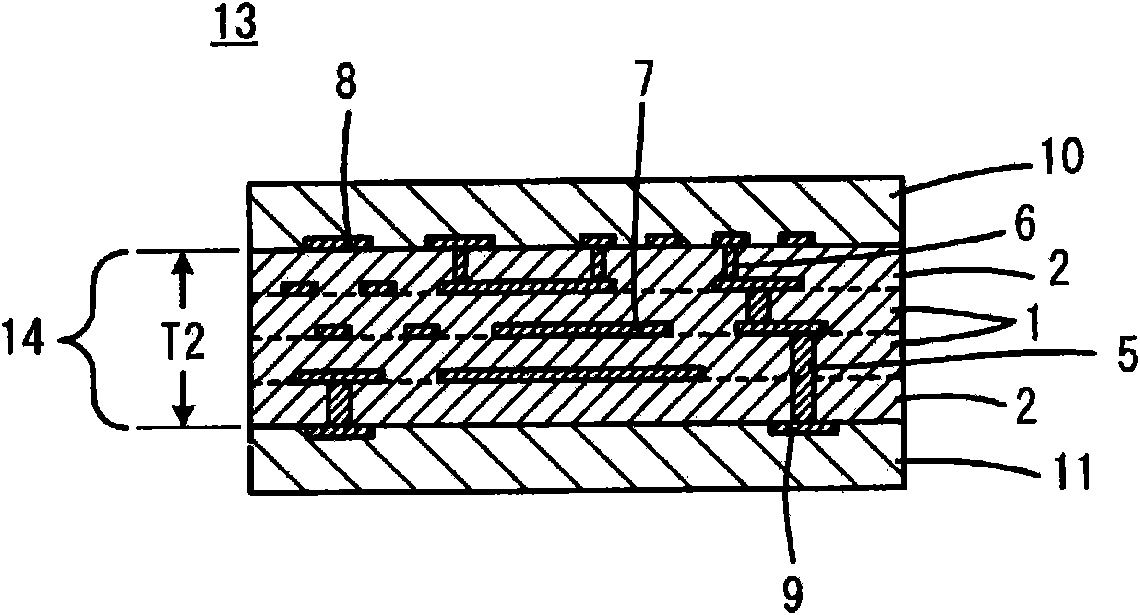

Method for the production of laminated ceramic electronic parts

InactiveCN101683010AIncrease binding forceBinding enoughFixed capacitor dielectricStacked capacitorsElectrical conductorMetallurgy

A method of producing a multi-layer ceramic substrate by firing in a state where bonding layers which are not sintered during firing are arranged on the principal surfaces of an unsintered ceramic laminate and then the bonding layers are removed, wherein removal of the bonding layers becomes more difficult if the bonding strength of the bonding layers is high, whereas the bonding layers can be removed easily if the bonding strength is low. A conductor pattern (5 - 9) which contains Ag as the main component is formed and first base material layers (1) and second base material layers (2) are laminated in the unsintered ceramic laminate (12). The second base material layers (2) are arranged along at least one principal surface of the unsintered ceramic laminate (12) and the bonding layers (10, 11) are arranged so as to be in contact with the second base material layers (2). A composition in which during firing Ag diffuses more easily into the second base material layers (2) than into thefirst base material layers (1) is employed and the bonding strength is improved by reducing the glass softening point without the need to use a means of reducing the particle size of the ceramic powder contained in the bonding layers, which is not readily sintered.

Owner:MURATA MFG CO LTD

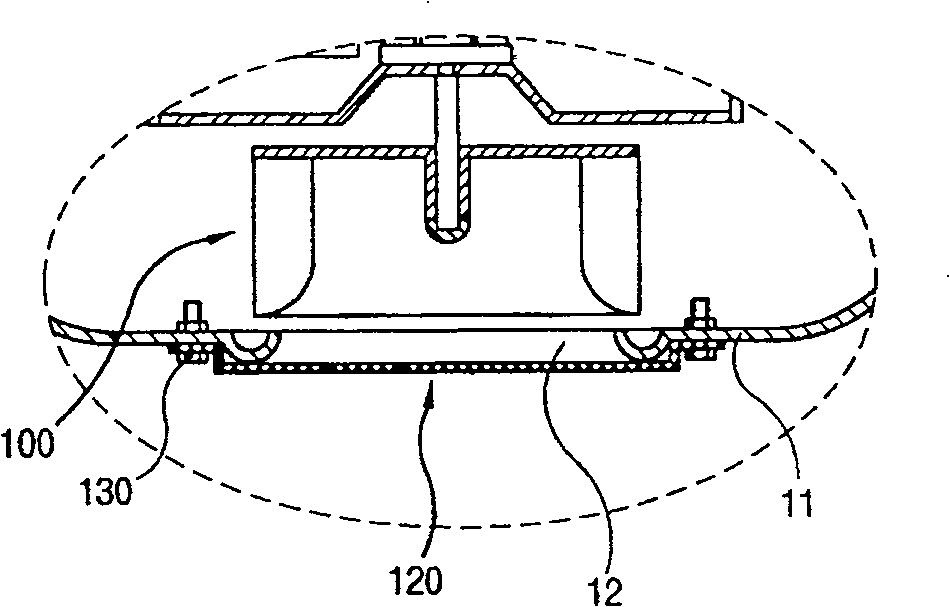

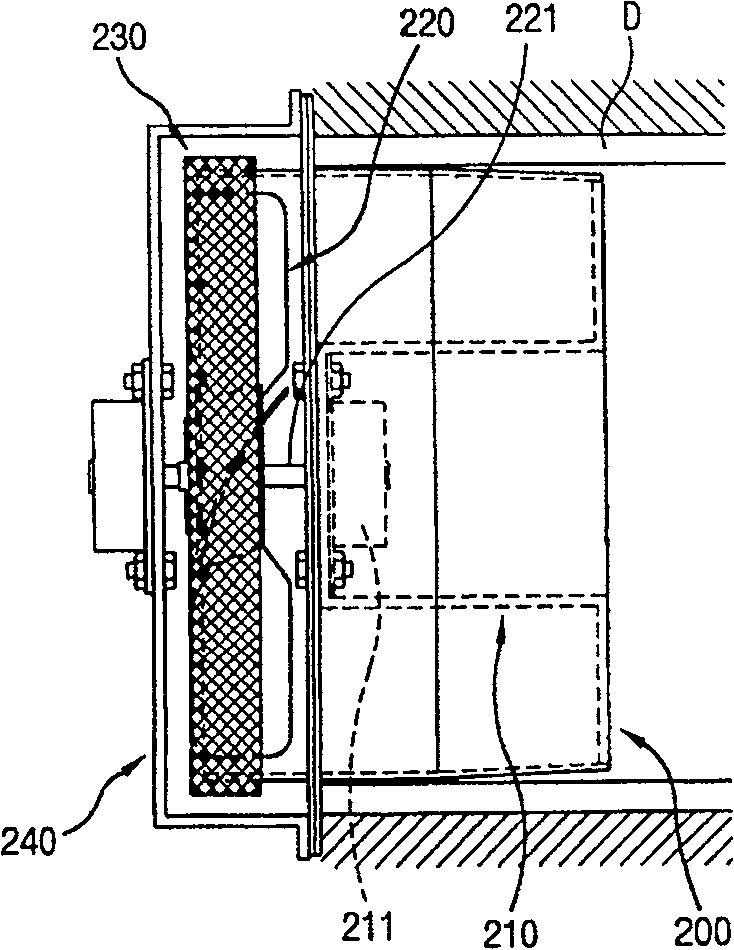

Insect-proof and dust-proof device

InactiveCN100414169CPrevent inflowAvoid damageLighting heating/cooling arrangementsGas-tight/water-tight arrangementsForeign matterDrive motor

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

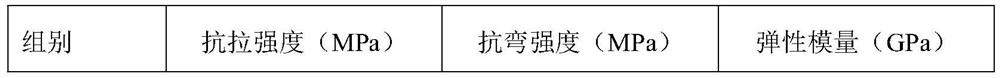

Preparation method of nanometer hydroxyapatite-chitosan artificial bone

ActiveCN109157679AGood dispersionImprove mechanical propertiesPharmaceutical delivery mechanismTissue regenerationNano hydroxyapatiteInjection moulding

The invention discloses a preparation method of a nanometer hydroxyapatite-chitosan artificial bone. In particular, the artificial bone is prepared from surface modified nanometer hydroxyapatite and chitosan through mixing, extruding granulation and injection molding; and the surface of the nanometer hydroxyapatite is modified, the dispersibility of the nanometer hydroxyapatite is improved and thecombining capacity of the nanometer hydroxyapatite and the chitosan is improved, so that the finally obtained artificial bone has higher mechanical property and hydrophilcity.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

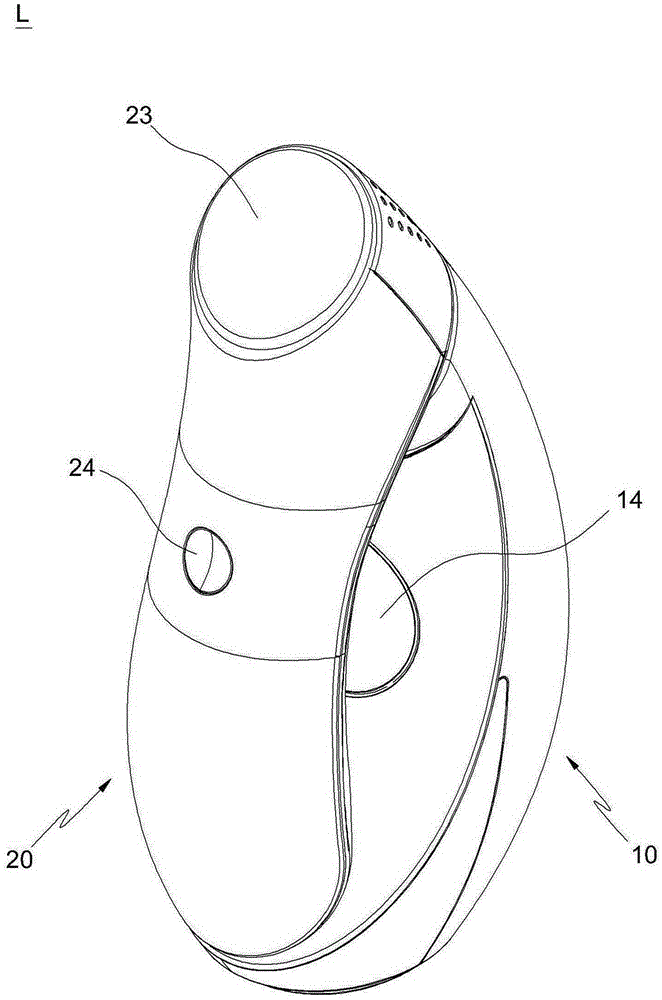

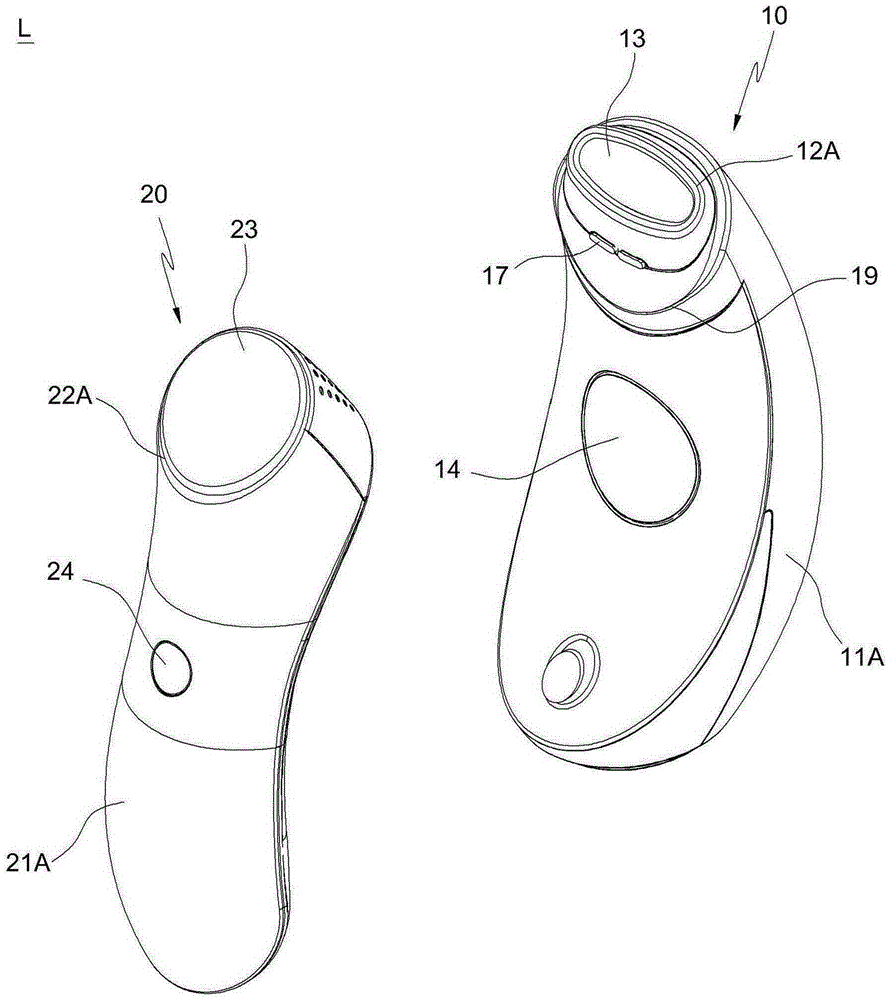

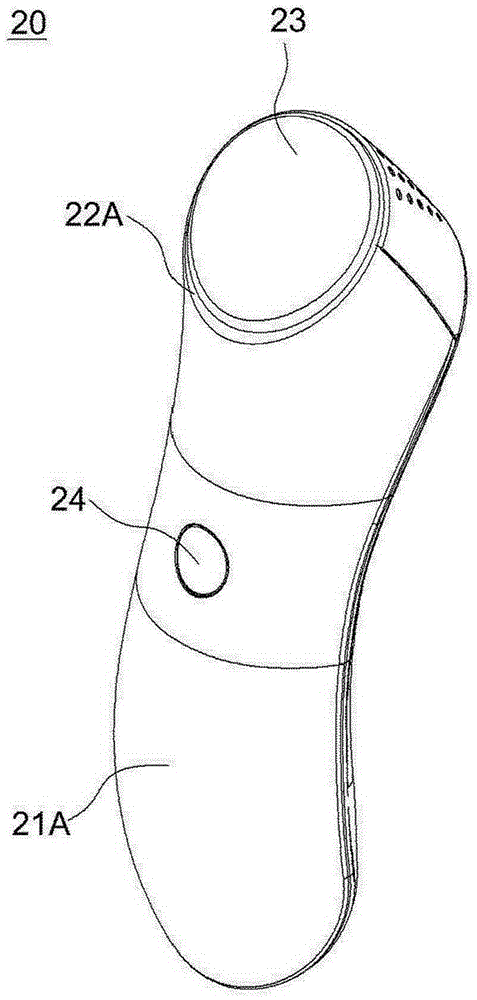

Hair removing apparatus

InactiveCN105597236AAvoid skin damageGood portabilityUltrasound therapyHair-singeingSkin damageCooling Units

The present invention relates to a light irradiation apparatus using light for skin care, and more specifically, to a hair removal device. The hair removal device can calm the skin irritation due to heat after the hair is removed using light to prevent skin damage. The hair removal device also can be utilized in various skin care operations such as massaging, whitening, or exfoliating the skin as well as removing the hair. The hair removal device also includes a hair removing unit having a light irradiation unit and a cooler having a cooling unit. Both of the hair removing unit and the cooler can store the heads of other coolers or other hair removing units respectively so as to improve the portability and usage.

Owner:HABALAN MED & BEAUTY

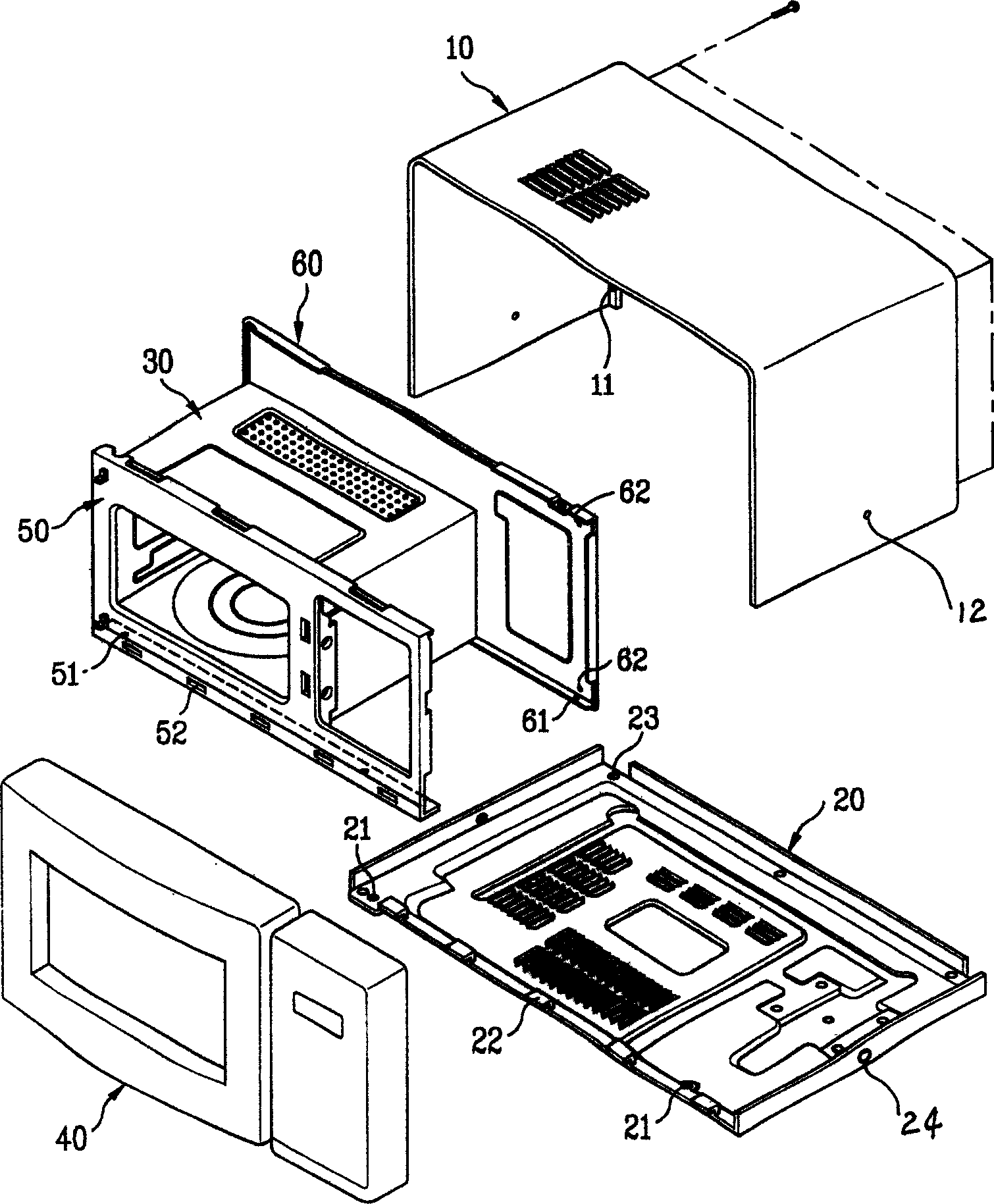

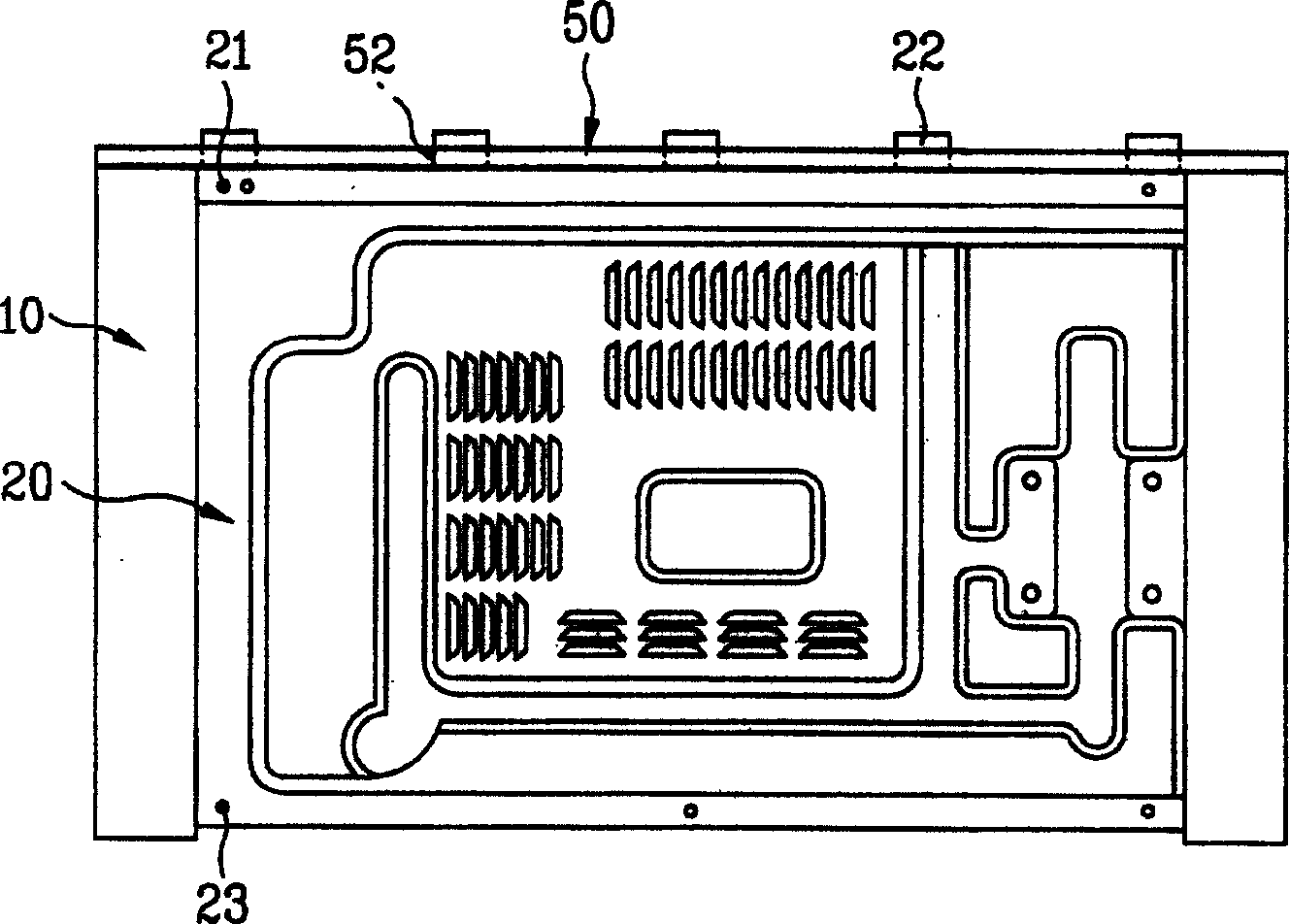

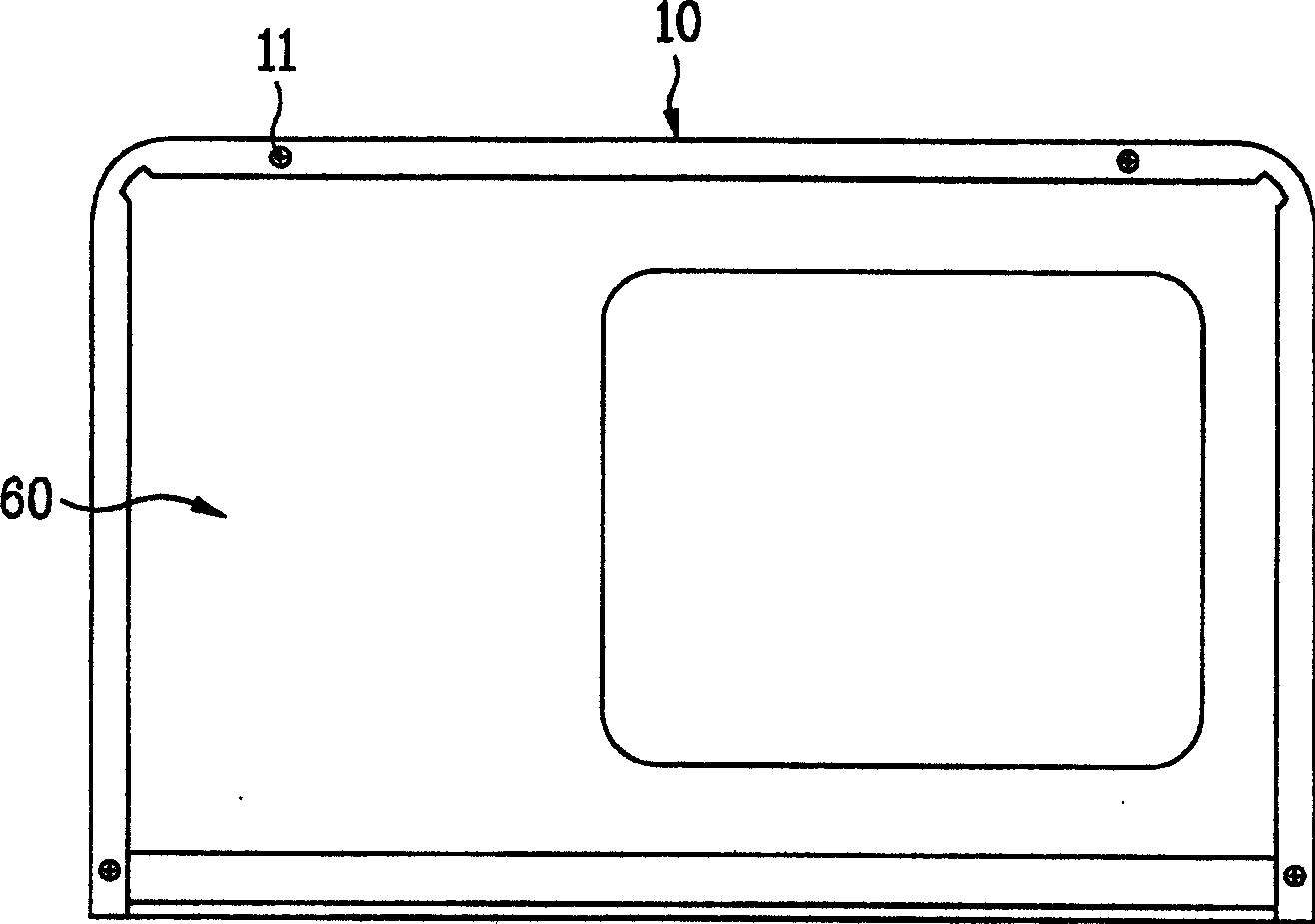

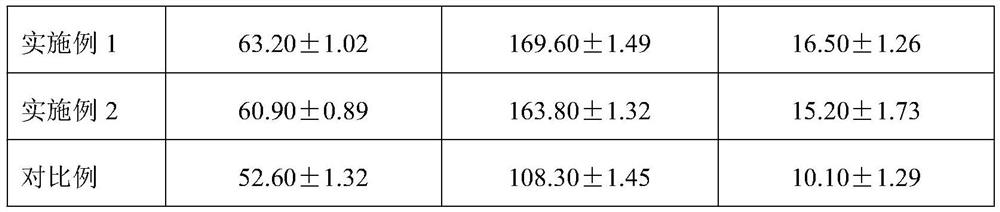

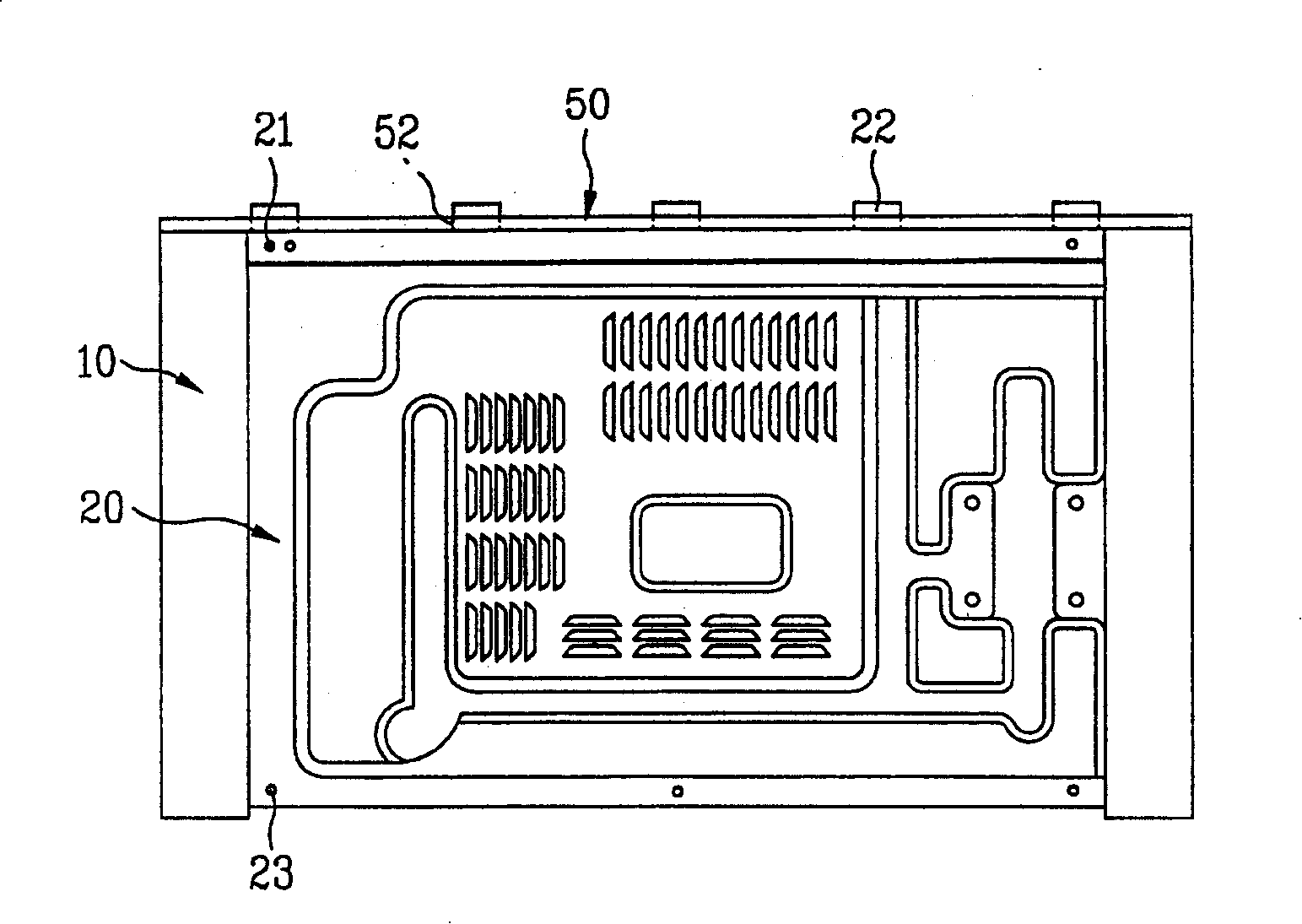

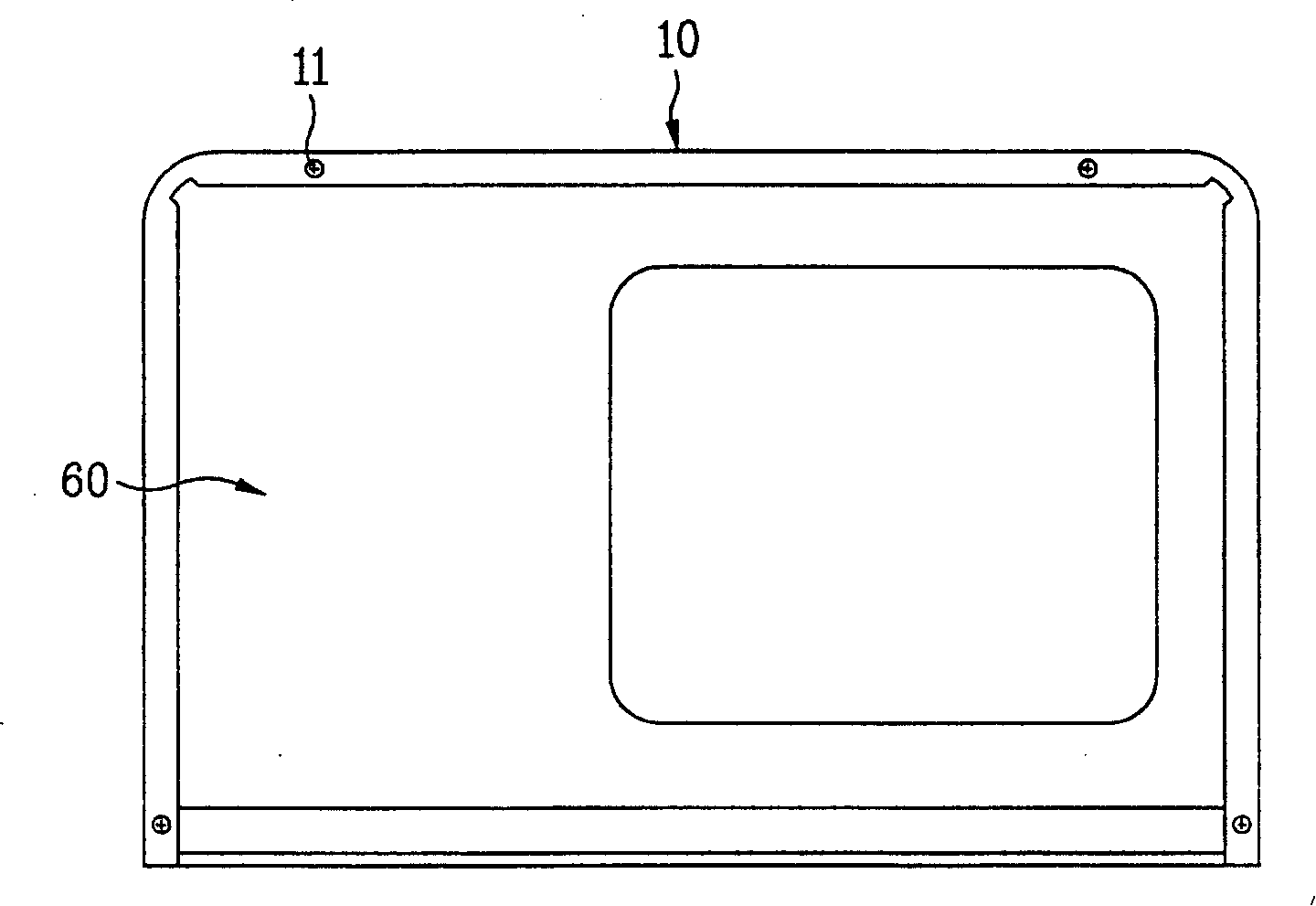

Assembling structure of microwave oven

InactiveCN1540238ASimplify the assembly processReduce the numberDomestic stoves or rangesLighting and heating apparatusMicrowave ovenAgricultural engineering

An assembling structure for microwave oven is composed of an empty cavity with cooking chamber, base plate as the bottom of microwave oven, casing surrounding said empty cavity, front frame and back frame. It features that the holes on the bottom of front frame and the lugs on the bottom of back frame are respectively matched with the lugs at front end of base plate and the holes at back end of base plate. Its advantages are easy assembling, less screws, and high stability.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

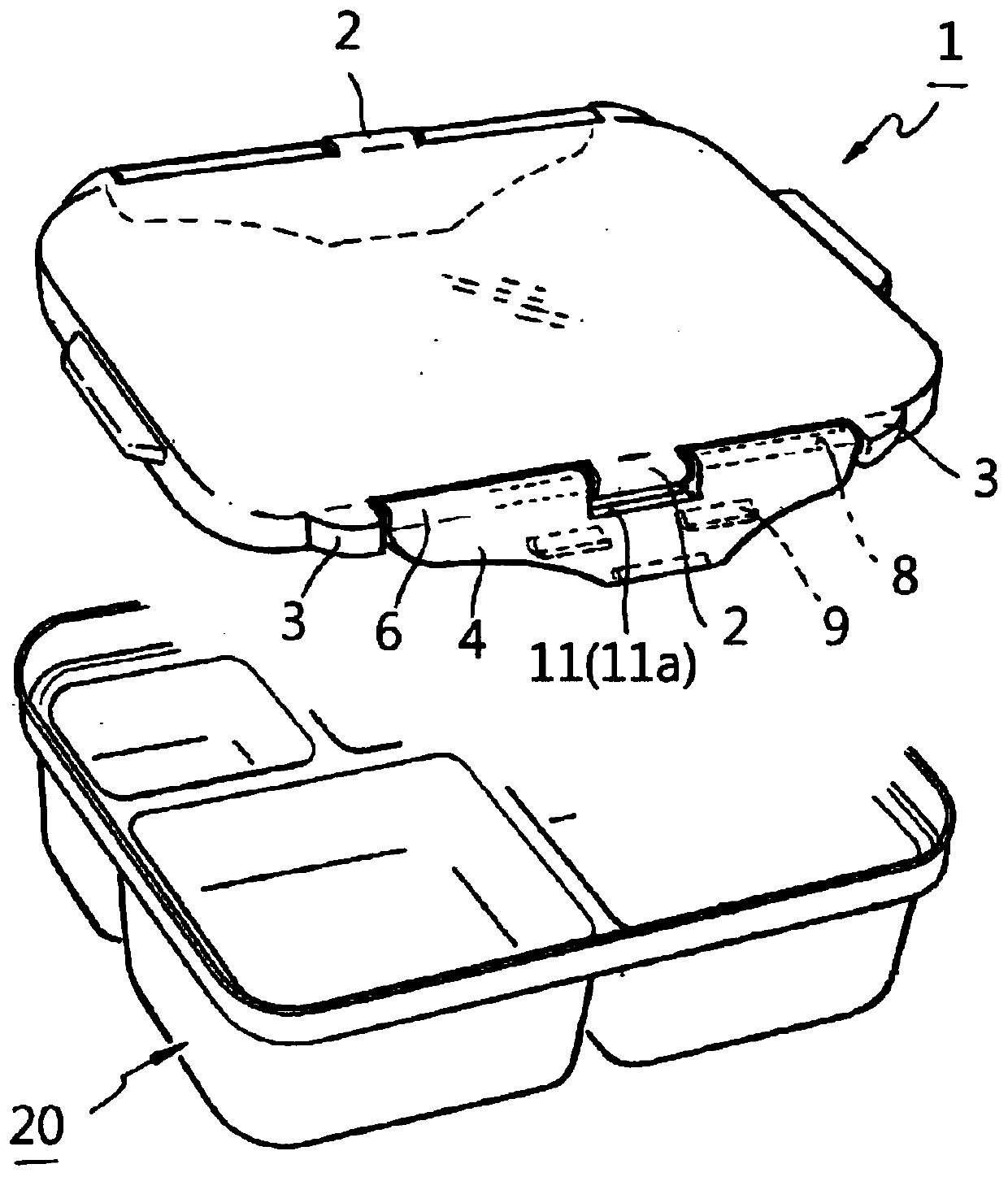

children's meal container

InactiveCN109315903BGrips and snaps securelySafe to hold and useOther accessoriesPhysical medicine and rehabilitationEngineering

The invention provides an eating container with high safety for children. The eating container can be flexibly used as a tray cushioned on the bottom part of the eating container. The eating containerfor children is provided with handles capable of being clamped into locking hooks on the front, the back and the sides of the eating container. The eating container for children provided by the invention comprises detachable handles combined on two symmetrical sides and the center of a cover body, partially opened hinges formed at the upper ends of the handles, the locking hooks for the cover body formed on one sides of the handles, a locking hook for the tray, and a restraining mass with the small first section of edge and the large second section of edge formed on the bottom surface of thecentral flange, wherein a space with the open lower part and the sealed upper part is formed at the lower end of each handle.

Owner:慎熙范

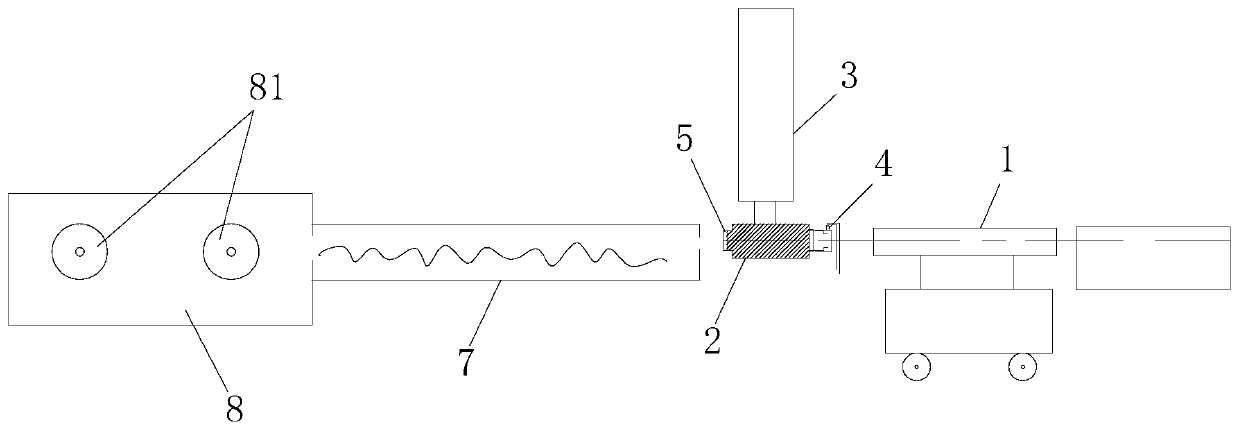

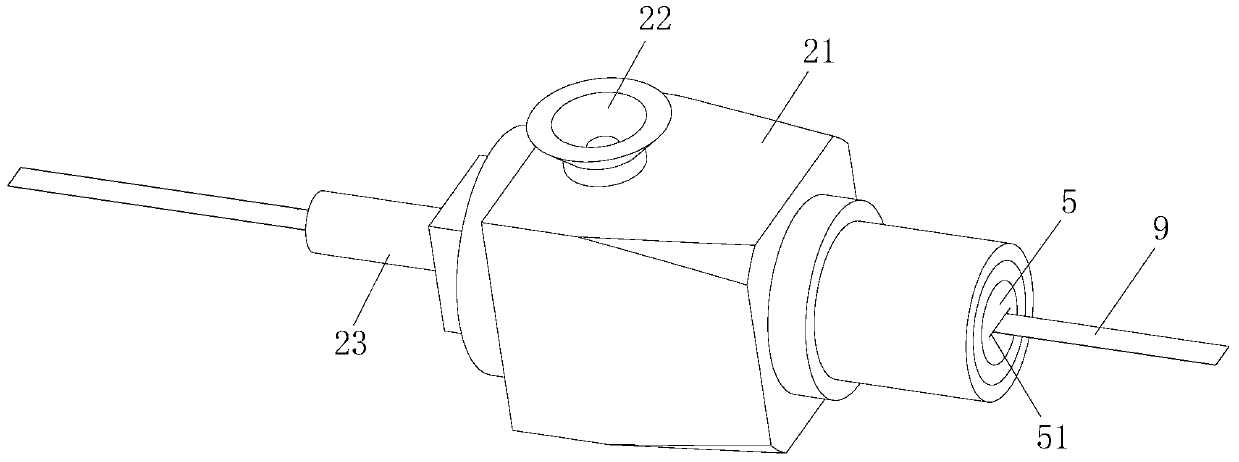

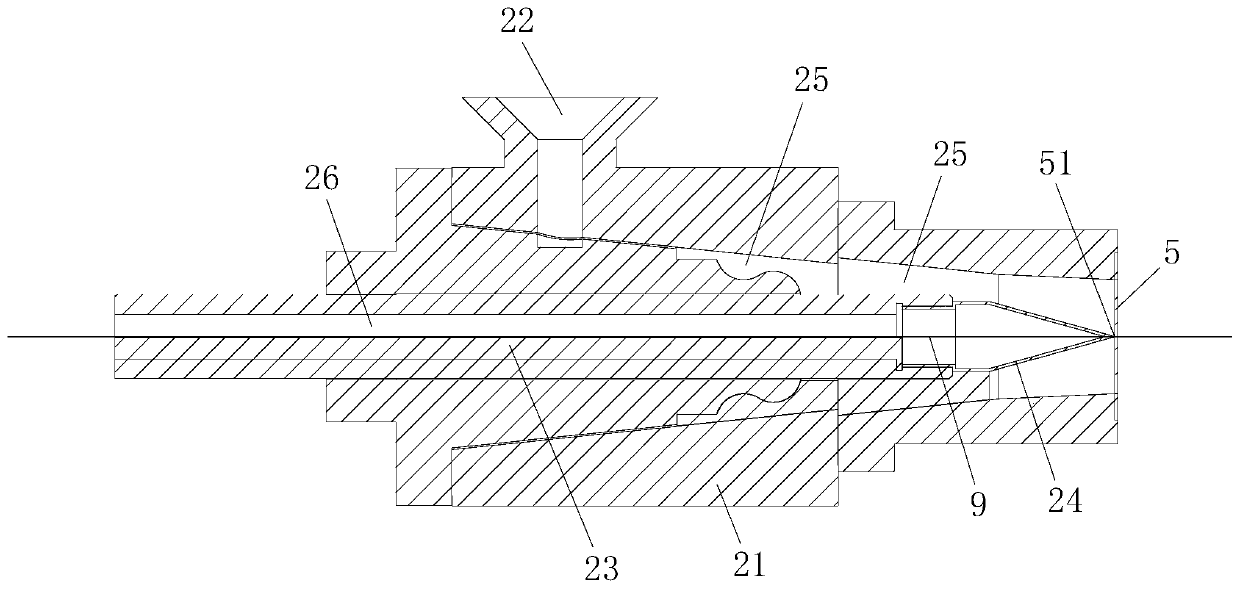

Production process and device for TPU laminating ornamental band

The invention discloses a production process and device for a TPU laminating ornamental band. The device comprises a laminating handpiece and a laminating machine, and the laminating handpiece is internally provided with a die sleeve and a pressure die; the front end of the die sleeve is provided with a die sleeve hole for the ornamental band to penetrate, and a flow channel extends to the front end of the exterior of the die sleeve; and the interior of the laminating handpiece is vacuumized; and the pressure die is arranged dead ahead the die sleeve, and internally provided with a forming hole. According to the production process and device, the ornamental band is preheated at high temperature, and the degree of bonding between the preheated ornamental band and TPU glue can be improved; then, the bonding between the TPU glue and the ornamental band is accelerated and promoted through vacuum negative pressure creatively, and the TPU glue and the ornamental band are formed through the pressure die after the TPU glue and the ornamental band are combined completely; in this way, a TPU film and the ornamental band can be combined stably; and the ornamental band can not fall off in useeven though the ornamental band is subjected to larger torsion, so that the product quality is improved, and the service life is prolonged.

Owner:深圳市致胜腾达电业有限公司

Height adjustment pillow with bottom-mounted handle

The present invention provides a height adjustment pillow including a lifting device for adjusting the height of an upper member with respect to a lower member, the lifting device comprising: a driveshaft having a lower end, which is penetrated through the lower member and protruded from the bottom of the lower member, and an operation handle provided on a lower end thereof; at least one or morerotation members mounted on the lower member so as to be rotatable around a vertical directional shaft; a power train equipment for transmitting the rotation force of the drive shaft to the rotation members; and a lifting operation equipment for converting the rotational motion of the rotation members into the linear motion in the vertical direction so as to lift the upper member.

Owner:MOTEX PROD CO LTD

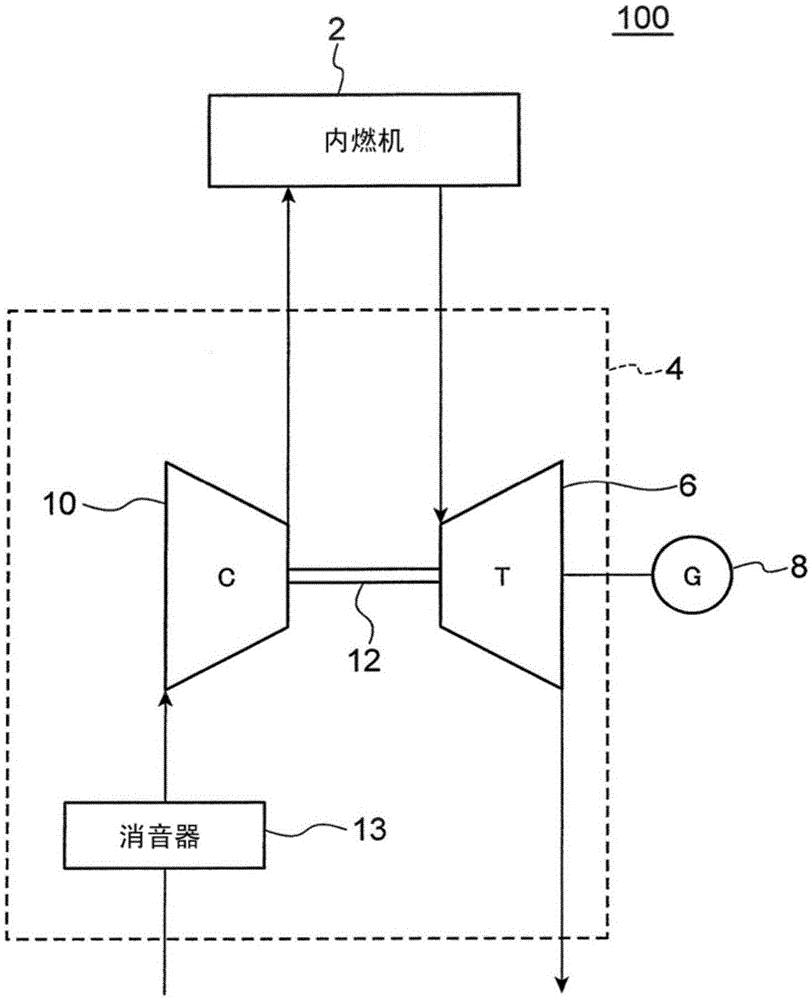

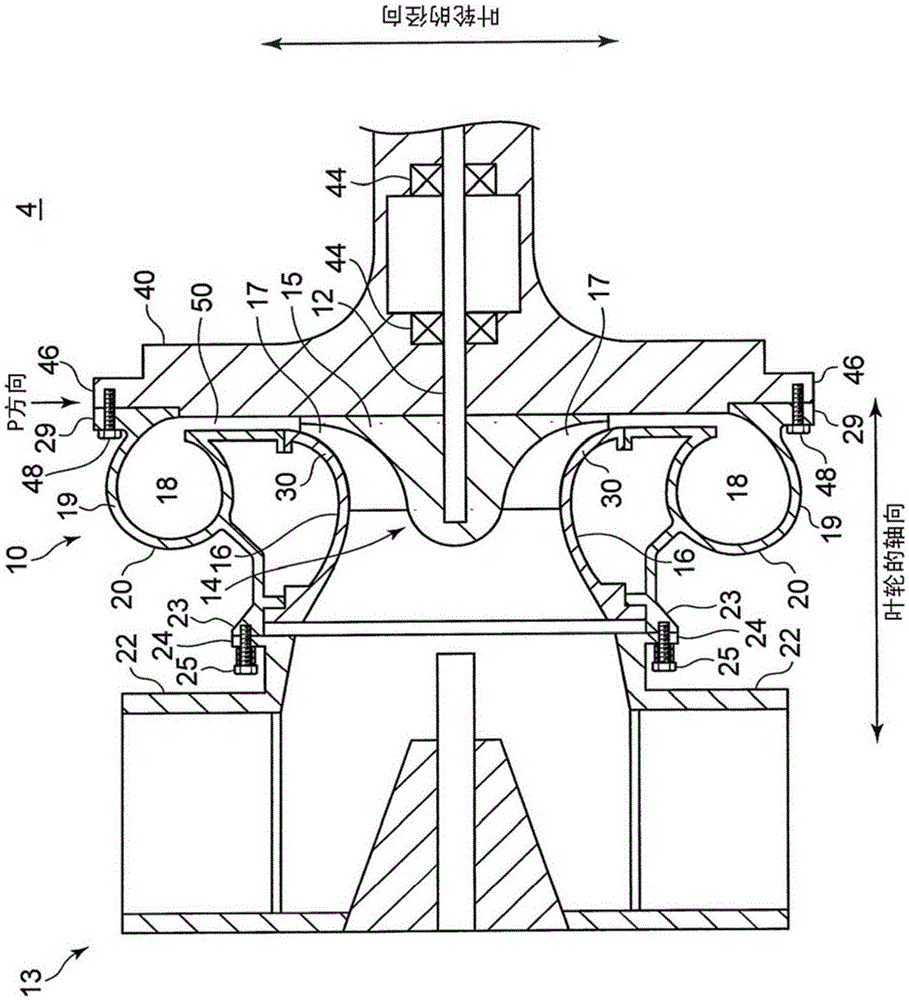

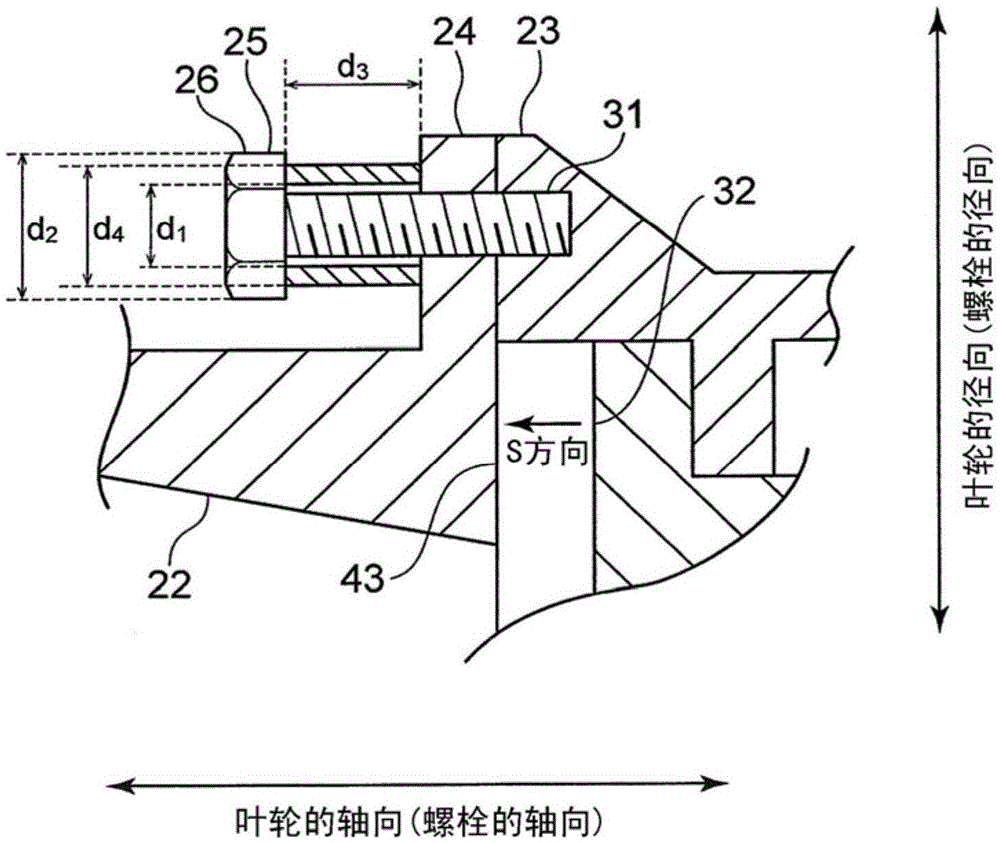

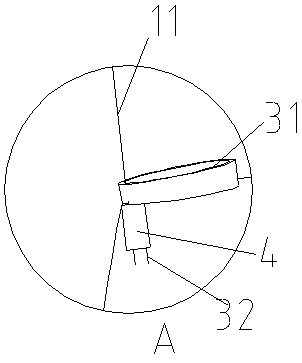

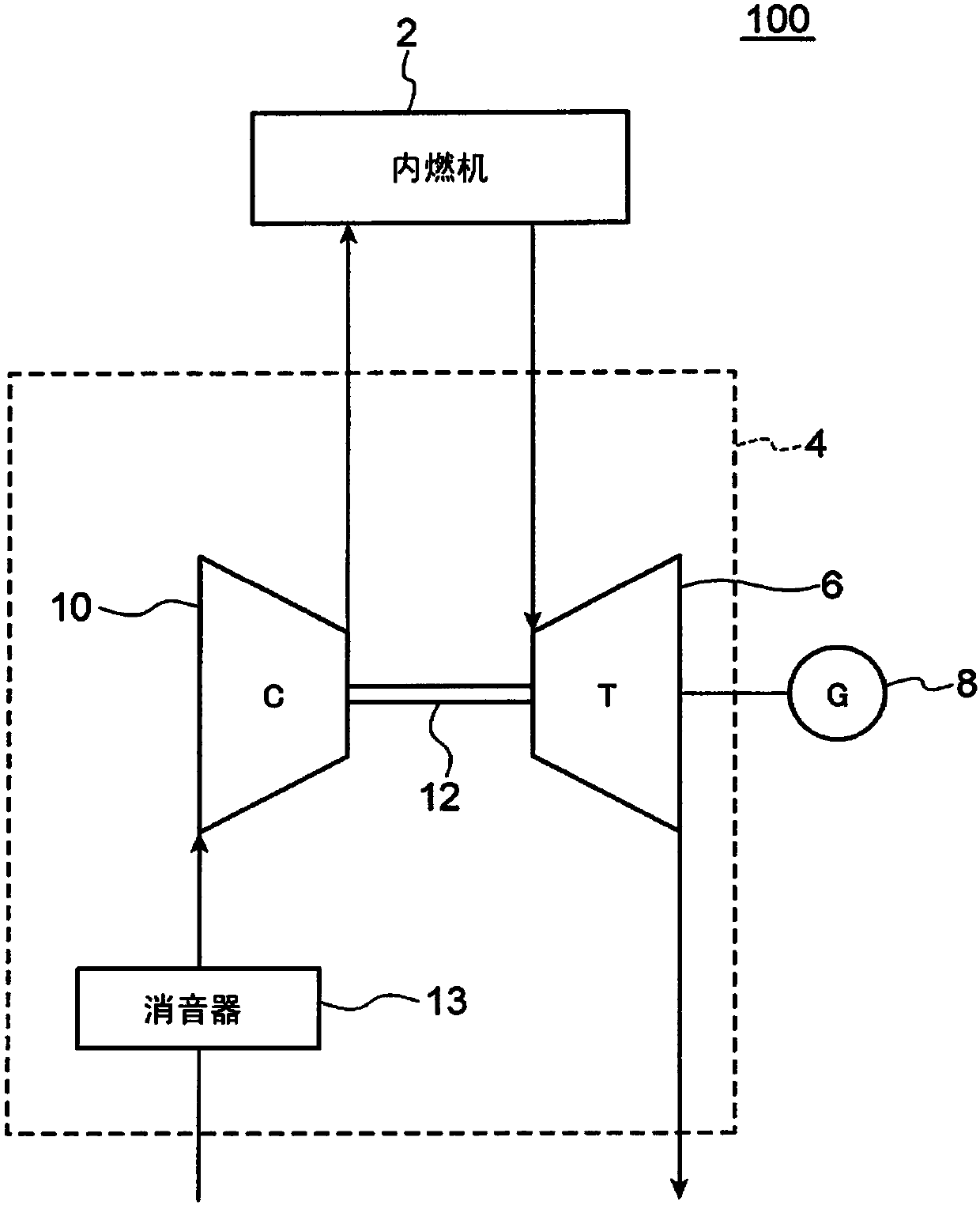

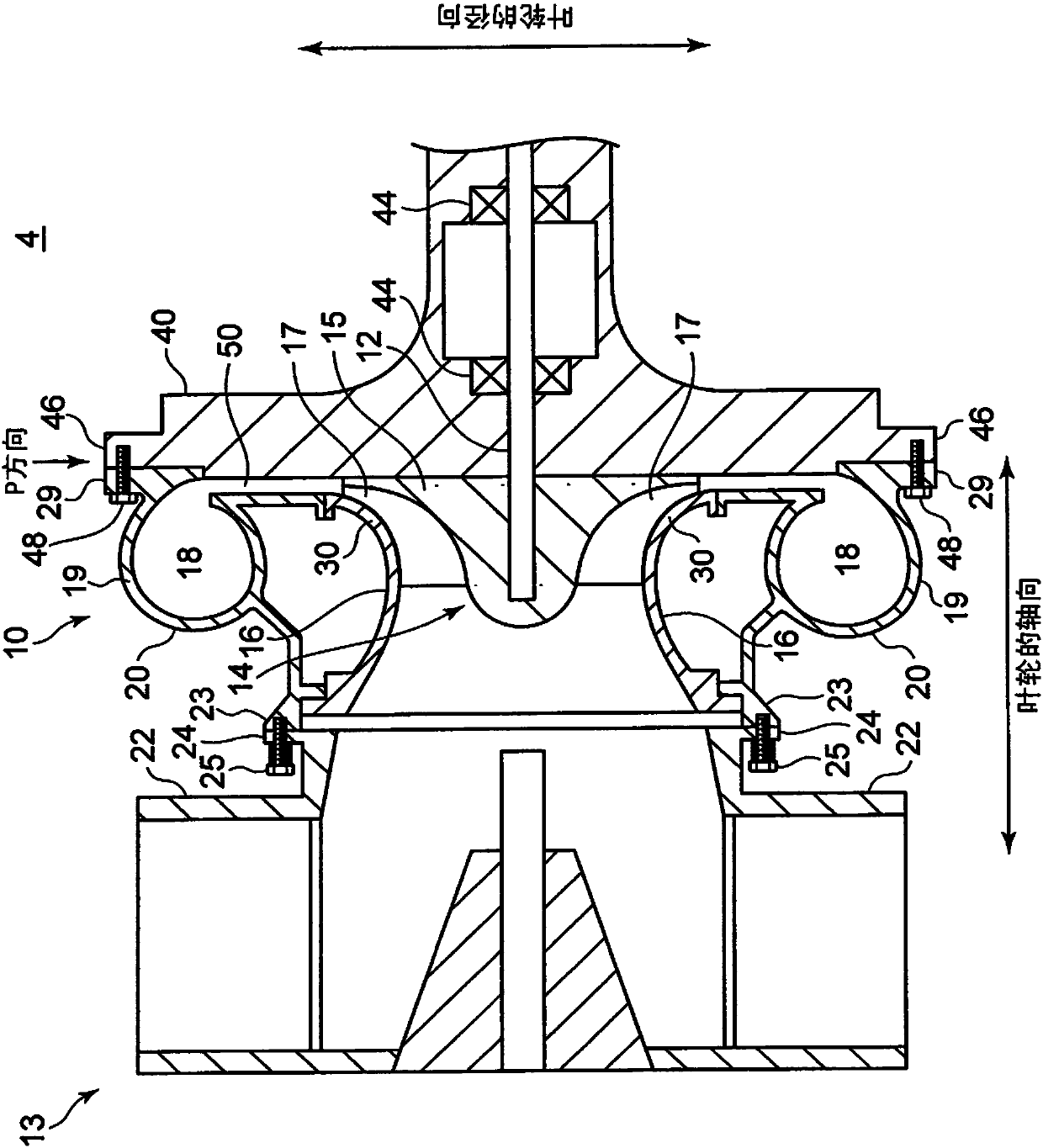

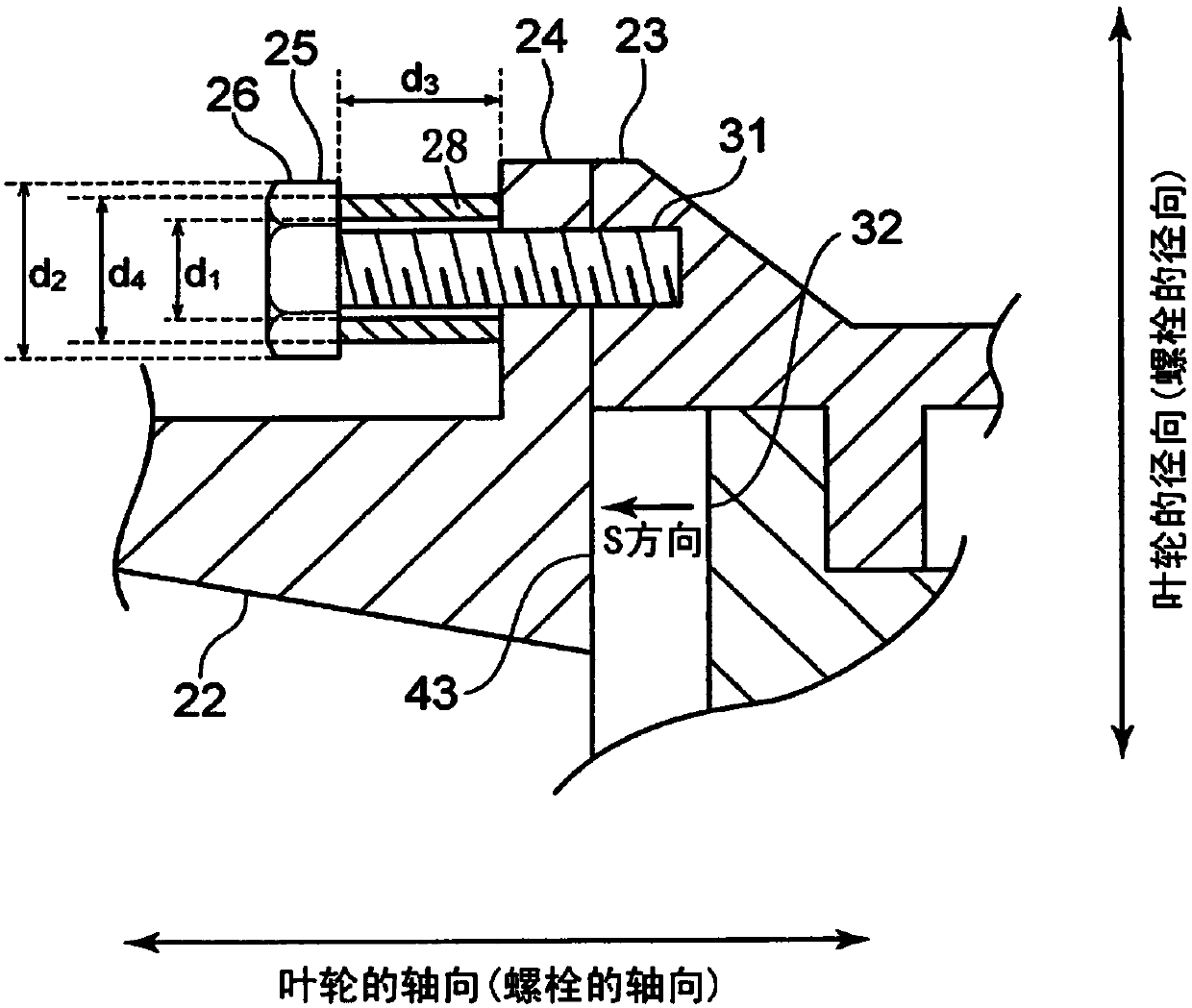

Compressor and supercharger

ActiveCN105531460AInhibition of fractureFirmly bonded stateEngine manufacturePump componentsImpellerEngineering

The purpose of the present invention is to provide a compressor and a supercharger, the compressor and the supercharger being configured to effectively prevent the breakage of bolts for fastening together a scroll chamber frame and frames which are adjacent to the scroll chamber frame, thereby enabling the frames to be consistently joined together. A compressor (10) has: an impeller (14) for compressing air; an air guide cylinder (16) for housing the impeller (14) and guiding air; a scroll chamber frame (20) provided adjacent to the air guide cylinder (16) and forming a scroll chamber (18) for guiding the air, which has passed through the air guide cylinder (16), to the outside; frames (22, 40) provided adjacent to the scroll chamber frame (20); bolts (25, 48) for fastening the scroll chamber frame (20) and the frames (22, 40) together; and spacers (28) provided between the heads (26, 52) of the bolts (25, 48) and the scroll chamber frame (20).

Owner:MITSUBISHI HEAVY IND LTD

Fishing mechanism provided with casing pipe

PendingCN109526902AImprove effectivenessFirmly bonded stateOther angling devicesEngineeringWater soluble

The invention discloses a fishing mechanism provided with a casing pipe. The fishing mechanism comprises an ejection mechanism which comprises an ejection component and a main component, wherein an annular elastic ring enabling the ejection component and the main component to restore an equilibrium state is arranged between the ejection component and the main component; a downward pole piece and ahollow part allowing a fishing thread and a fishing hook to pass are arranged on the ejection component; a connecting piece provided with a hollow piece at the top end is connected to the main component; the hollow piece is connected with the fishing hook through the fishing thread; a cooperating pole piece cooperating with the pole piece as well as a water-soluble component is arranged on the hollow piece; in a working state, the downward pole piece is sleeved with the annular hollow piece, a bending structure with resilience is formed by the ejection component and the main component under cooperation of the hollow annular part and the pole piece and the action of the annular elastic ring, and the pole piece and the cooperating pole piece are sleeved with the water-soluble component. Through the adoption of the fishing mechanism, the fishing rate of a fishing tool can be increased greatly.

Owner:张安然

Compressor and supercharger

ActiveCN107701298AInhibition of fractureFirmly bonded stateEngine manufacturePump componentsImpellerTurbocharger

An object of the present invention is to provide a compressor and a turbocharger whereby it is possible to suppress breakage of a bolt fastening a frame adjacent to a scroll-chamber frame and the scroll-chamber frame effectively and to join the frames stably. A compressor (10) includes: an impeller (14) for compressing air; an air-guide cylinder (16) for housing the impeller (14) and guiding the air; a scroll-chamber frame (20) disposed adjacent to the air-guide cylinder (16), the scroll-chamber frame (20) forming a scroll chamber (18) for guiding the air having passed through the air-guide cylinder (16) to outside; a frame (22, 40) disposed adjacent to the scroll-chamber frame (20); a bolt (25, 48) for fastening the scroll-chamber frame (20) and the frame (22, 40); and a spacer 28 disposed between a head portion (26, 52) of the bolt (25, 48) and the scroll-chamber frame (20).

Owner:MITSUBISHI HEAVY IND LTD

A kind of preparation method of nano-hydroxyapatite-chitosan artificial bone

ActiveCN109157679BGood dispersionImprove mechanical propertiesPharmaceutical delivery mechanismTissue regenerationNano hydroxyapatiteArtificial bone

The invention discloses a method for preparing nano-hydroxyapatite-chitosan artificial bone. Specifically, the invention uses surface-modified nano-hydroxyapatite and chitosan as raw materials, and mixes, extrudes, granulates, Preparation of artificial bone by injection molding, through the surface modification of nano-hydroxyapatite, the dispersion of nano-hydroxyapatite is improved, and its binding ability with chitosan is improved, so that the final artificial bone has better mechanical properties properties and hydrophilicity.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Assembling structure of microwave oven

InactiveCN100398911CSimplify the assembly processReduce the numberDomestic stoves or rangesLighting and heating apparatusMicrowave ovenAgricultural engineering

An assembling structure for microwave oven is composed of an empty cavity with cooking chamber, base plate as the bottom of microwave oven, casing surrounding said empty cavity, front frame and back frame. It features that the holes on the bottom of front frame and the lugs on the bottom of back frame are respectively matched with the lugs at front end of base plate and the holes at back end of base plate. Its advantages are easy assembling, less screws, and high stability.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

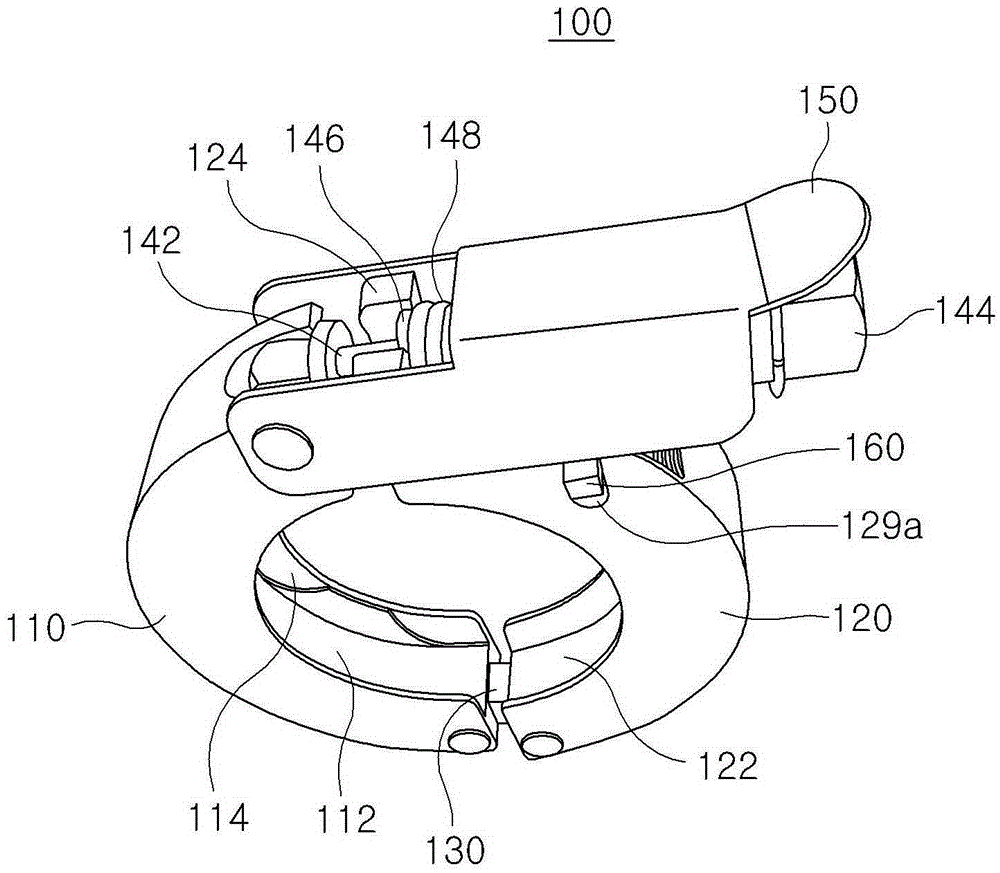

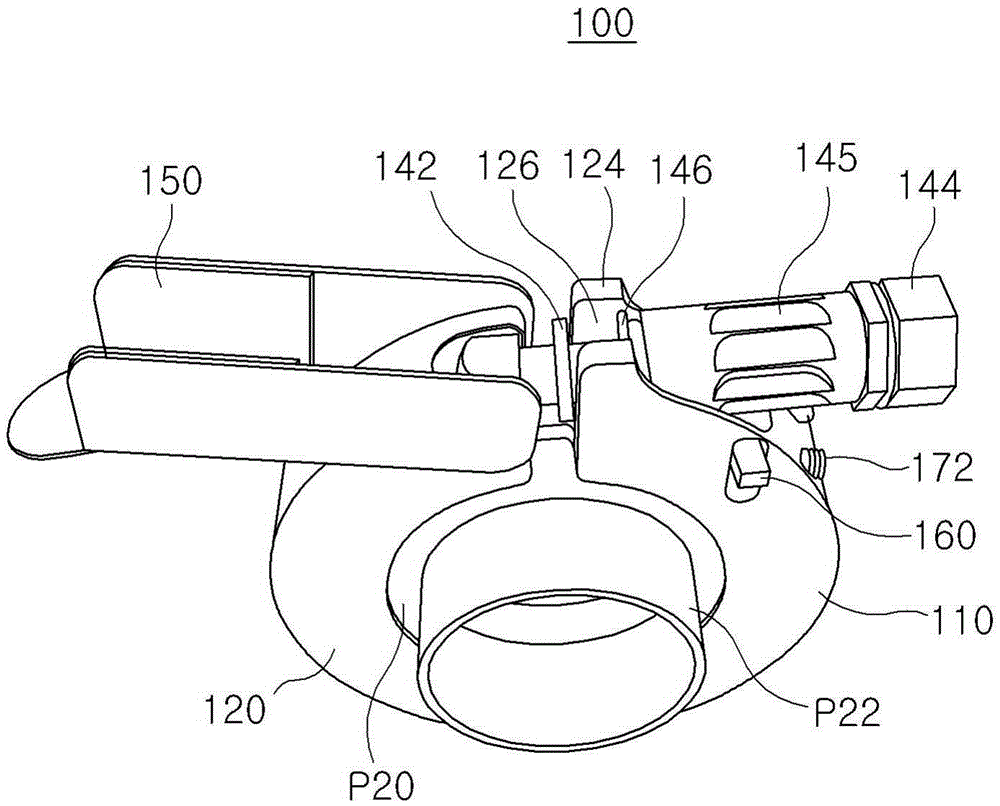

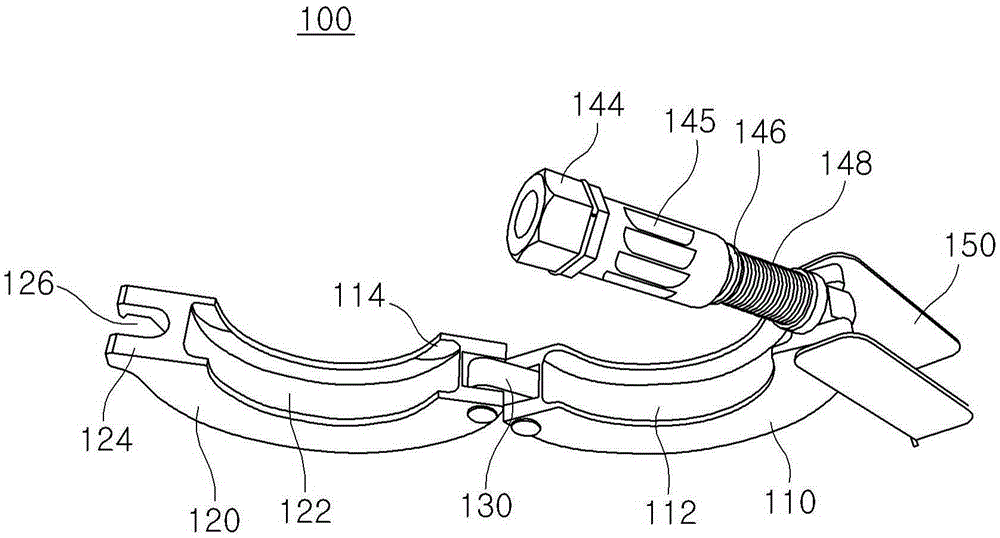

Clamps for Vacuum Piping

ActiveCN103862403BPrevent looseningFirmly bonded stateSleeve/socket jointsNutsEngineeringSemiconductor

The present invention relates to an improved clamp for vacuum lines that comprises vacuum lines for maintaining a vacuum state in the main equipment in a semiconductor manufacturing process and stably maintains the connection state of the vacuum lines in an airtight state without loosening due to the vibration of the vacuum lines. The clamp for vacuum lines is arranged between the center rings, separates a first flange of a first line and a second flange of a second line in a contact state, and includes a first semicircular clamp formed in the first insertion hole of the first and the second flange as an inner diameter. A second semicircular clamp is formed in the second insertion hole of the first and the second flange as an inner diameter. A connection link is hinge-combined with both sides to rotate in regard to the free end of the first and second clamps. One end of a locking member is hinge-combined with the first clamp and the other end is detachable from the second clamp. A fixing protrusion having a fixing groove is formed in the free end of the second clamp. At least one sub fixing member moves through an entrance hole formed on the outer surface of the first and the second clamp.

Owner:MI

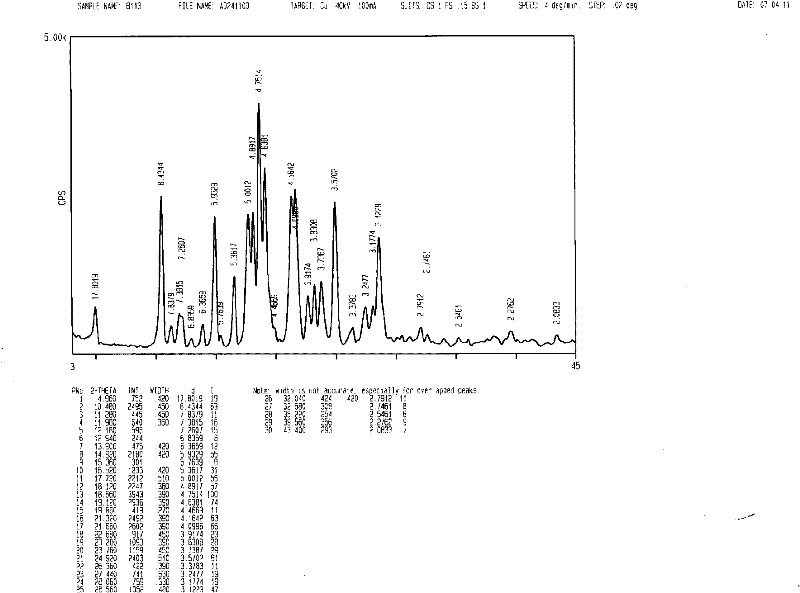

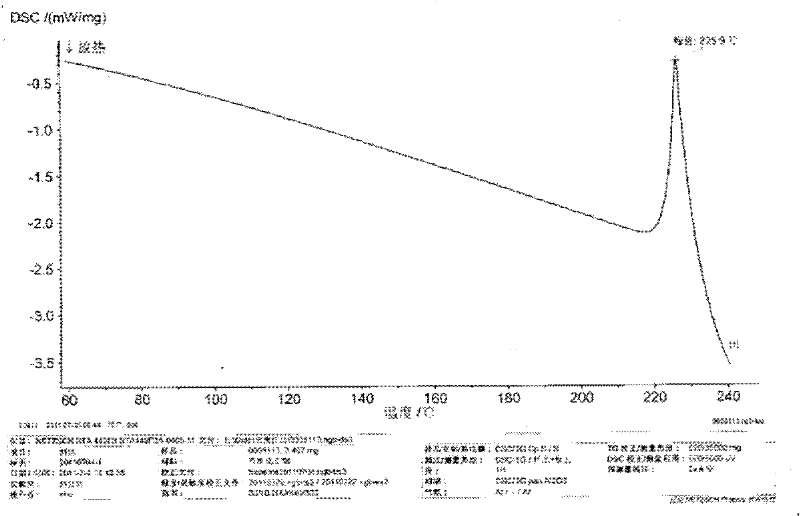

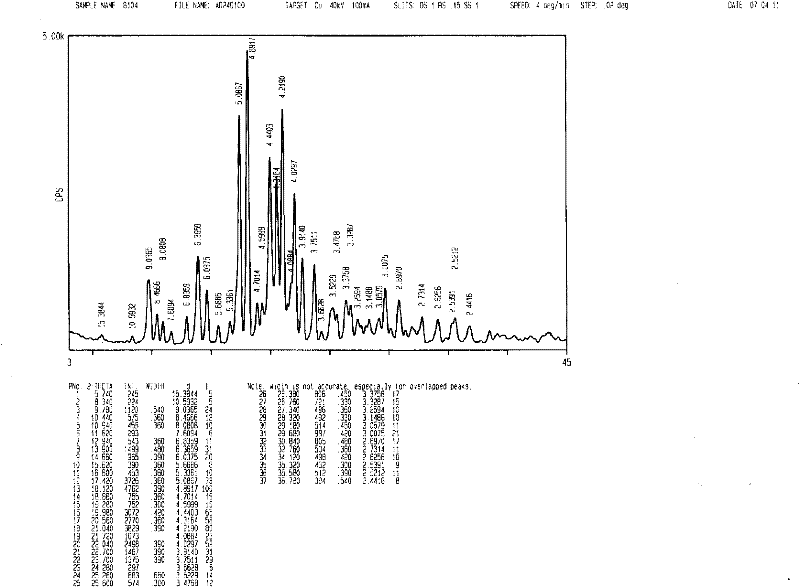

Ultrasonic preparation method for imatinib mesylate crystal

The invention discloses a preparation method for an imatinib mesylate crystal, which belongs to the technical field of anti-tumor medicaments. The ultrasonic preparation method of the imatinib mesylate crystal comprises the following steps of: under an ultrasonic condition, dropwise adding a ketone solution of methanesulfonic acid into a ketone suspension containing imatinib alkali; and cooling, filtering, washing, and drying in vacuum to obtain the imatinib mesylate crystal, wherein the ratio of the total volume of ketone to the weight of imatinib mesylate is (5-50):1; the volume of the ketone is counted by ml; and the weight of the imatinib mesylate is counted by g. In the invention, a solvent ultrasonic synergetic nucleation method is adopted, so that the imatinib mesylate crystal of which the granularity is uniform and the impurity adsorption is small can be obtained, and the crystal has the advantages of high stability, firm combining state, low solvent residue content, low process cost, easiness in operating and long-time storage under an economic condition.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

A kind of bronchoscope distal probe

ActiveCN107049223BFirmly bonded stateImprove economyBronchoscopesLaryngoscopesEngineeringMechanical engineering

The invention discloses a bronchoscope distal probe having a novel structure. The distal probe that a bronchoscope mainly comprises an image pickup module, an apparatus tube and a luminous body has a stably bonded state; during glue pouring and packaging, the various components are prevented from getting displaced and a consistent combined structure is defined, so that an effect of guaranteeing safety when the bronchoscope is used is achieved. The distal probe comprises a hollow outer tube and an end panel which is combined to the outer end of the hollow outer tube, and the outer end of the apparatus tube, a camera of the image pickup module and the luminous body are clamped in corresponding holes of the end panel, so that the various components are kept under a quite stably bonded state; then, a process of water-proofing glue pouring and packaging is implemented on the front part and the rear part of the hollow outer tube, so that the perfect structure of the distal probe is defined; and finally, the outer end of a bronchoscope body of the bronchoscope is combined to the rear end of the hollow outer tube. The bronchoscope distal probe is simple in overall structure, easy for combination, high in economy and obvious in practicability.

Owner:ZHUHAI KADEN MEDICAL IMAGING TECH CO LTD

Eating container for children

The invention provides an eating container with high safety for children. The eating container can be flexibly used as a tray cushioned on the bottom part of the eating container. The eating containerfor children is provided with handles capable of being clamped into locking hooks on the front, the back and the sides of the eating container. The eating container for children provided by the invention comprises detachable handles combined on two symmetrical sides and the center of a cover body, partially opened hinges formed at the upper ends of the handles, the locking hooks for the cover body formed on one sides of the handles, a locking hook for the tray, and a restraining mass with the small first section of edge and the large second section of edge formed on the bottom surface of thecentral flange, wherein a space with the open lower part and the sealed upper part is formed at the lower end of each handle.

Owner:慎熙范

Welding active agent for aluminum alloy part in grain throwing machine

ActiveCN112157372APrevent volatile failure problemsHigh bonding strengthWelding/cutting media/materialsSoldering mediaActive agentHeat stability

The invention relates to the technical field of mechanical welding research and discloses a welding active agent for an aluminum alloy part in a grain throwing machine. The active agent prepared in the invention is applied to soldering flux, and can be slightly added to change properties of a soldering flux system, so that a rate of expansion is increased, chemical activity and thermal stability are stronger, performance weakening or failure caused by heating in welding can be prevented, adaptability to an aluminum alloy material is good, and workpiece shrinkage and deformation is small, and thus, welding is continuous and repeatable, the active agent is prevented from volatilizing and losing effect at a high temperature in a welding process of the aluminum alloy part of the grain throwingmachine, welding efficiency is improved, intensive heat is transmitted to a welding region, welding seam porosity is reduced, and welding quality is improved; and a formed interface is high in bond strength, is strong in thermal impact resistance and is remarkably improved in corrosion resistance and wear resistance.

Owner:ANHUI FEISONG MASCH TECH CO LTD

Welding flux for aluminum alloy parts in a grain thrower

ActiveCN112157373BImprove adaptabilityStrong adhesionWelding/cutting media/materialsSoldering mediaToxic gasHeat stability

The invention relates to the technical field of mechanical welding research, and discloses a welding flux for aluminum alloy parts in a grain thrower. The flux prepared by the invention has strong chemical activity and thermal stability, and is suitable for aluminum alloy materials. It has good properties, high expansion speed and strong adhesion effect, which can prevent the re-oxidation of the solder and the welded surface of the aluminum alloy parts of the grain thrower during the welding process, significantly reduce the surface tension of the solder, and enhance the surface wettability, which is conducive to concentration. The heat is transferred to the welding area, no spatter and toxic gas are generated during welding, the residue is easily removed after welding, and no metal oxides that cause corrosion are generated. The invention solves the problem that the existing inorganic fluxes are easy to cause corrosion and local failure while removing oxides on the aluminum alloy welding surface.

Owner:ANHUI FEISONG MASCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com