Method for the production of laminated ceramic electronic parts

A technology of electronic components and manufacturing methods, which is applied in the field of manufacturing laminated ceramic electronic components, can solve the problems of shrinking force of the constraining layer, obstacles, difficulty in removing the constraining layer, etc., and achieve improved binding force and high-precision manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

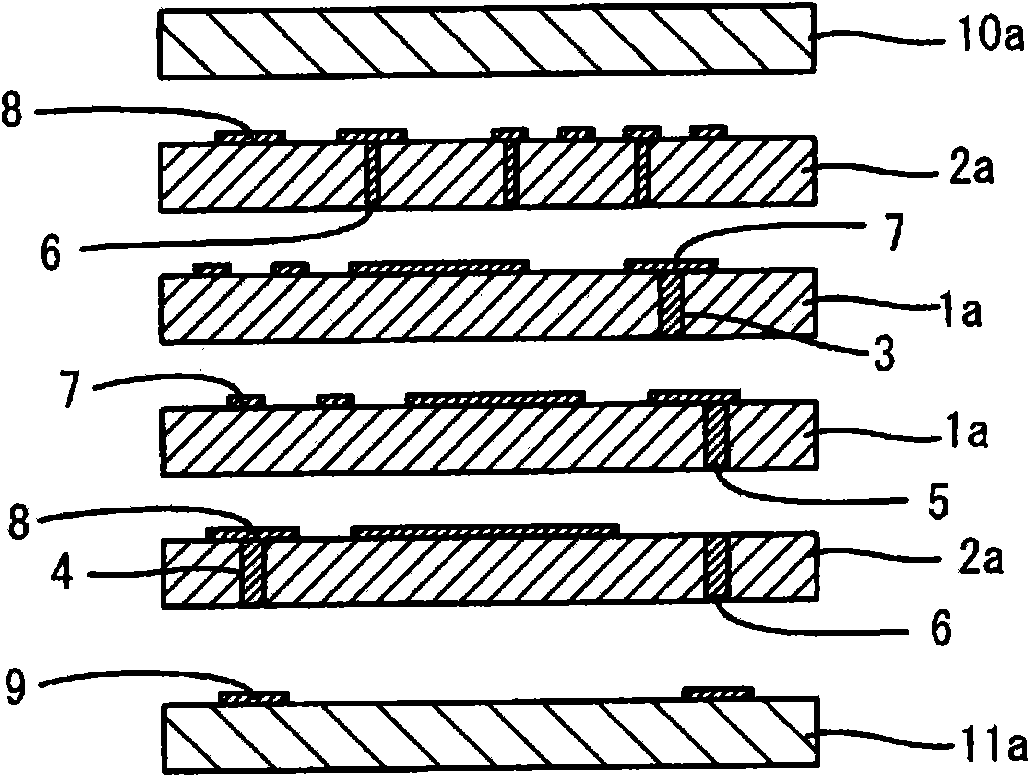

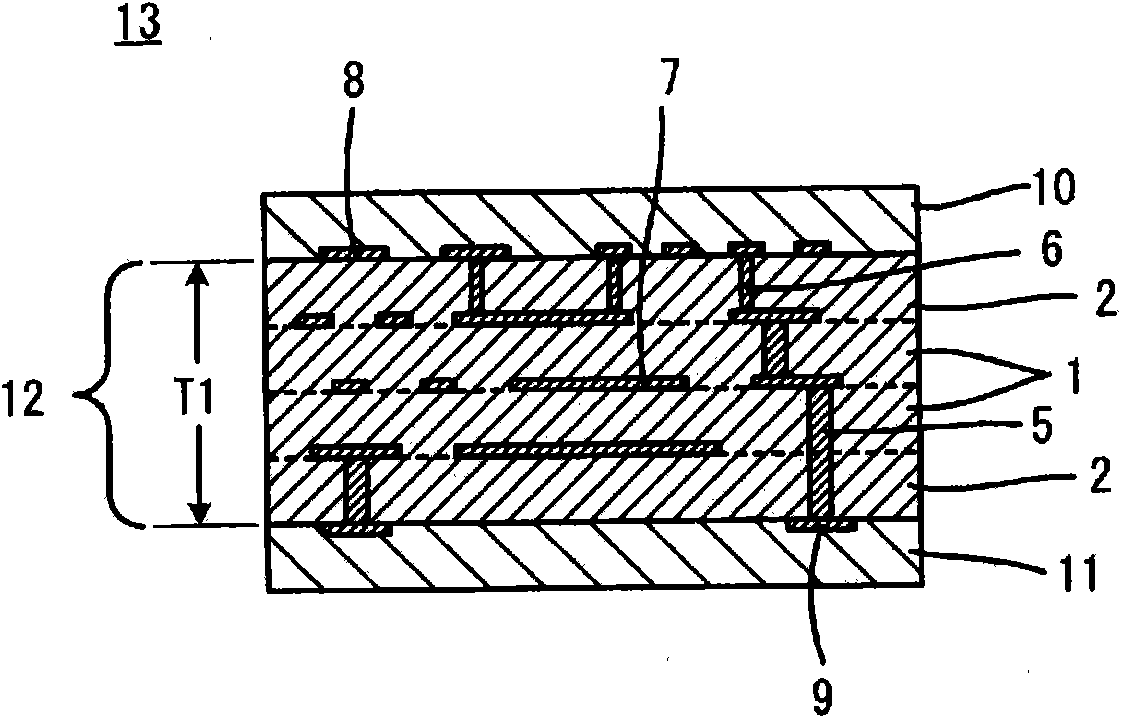

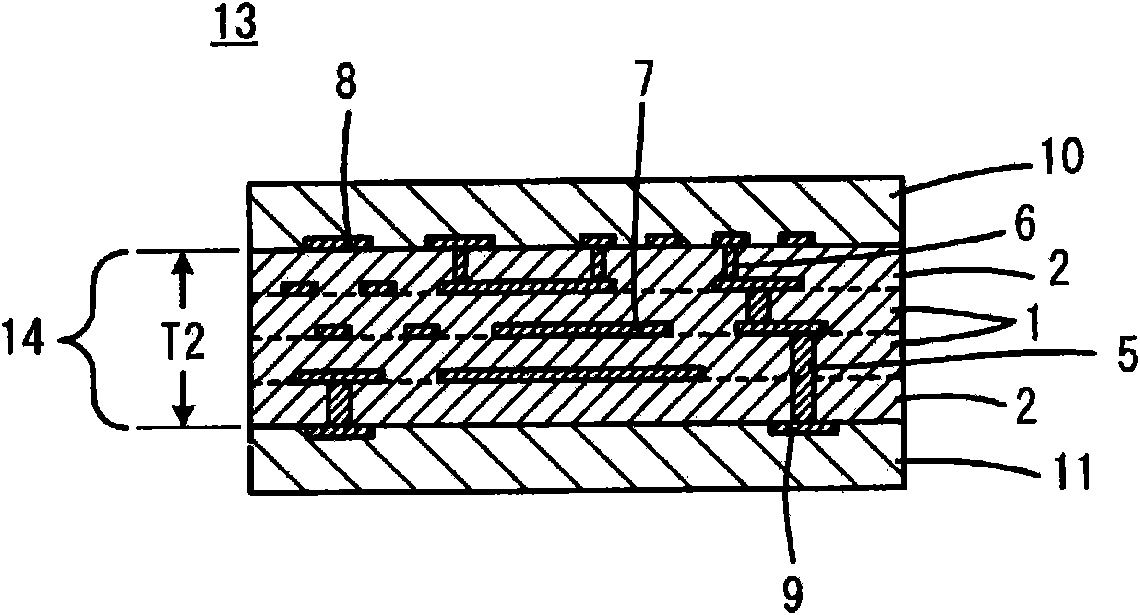

[0050] Figure 1 to Figure 4 It is a sectional view for demonstrating the manufacturing method of the multilayer ceramic electronic component which concerns on one Embodiment of this invention. In particular, a method of manufacturing a multilayer ceramic substrate is shown here.

[0051] First, if figure 1 As shown, prepare the first substrate layer 1 to be green (refer to figure 2 ) green body 1a for the first base material layer, and prepare the second base material layer 2 to be unsintered (refer to figure 2 ) The green body 2a for the second substrate layer. The green body 1a for the 1st base material layer and the green body 2a for the 2nd base material layer contain the 1st and 2nd low temperature sinterable ceramic powder, respectively. These substrate layer green bodies 1a and 2a are produced by dispersing the above-mentioned low-temperature sinterable ceramic powder in a vehicle formed of a binder, a solvent, a plasticizer, etc. to prepare a slurry, and then us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com