Assembling structure of microwave oven

An assembly structure and microwave oven technology, applied in the field of microwave ovens, can solve the problems of difficult assembly, complex manufacturing process, increased production cost, etc., and achieve the effects of maintaining a combined state, reducing production costs, and stabilizing a combined state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

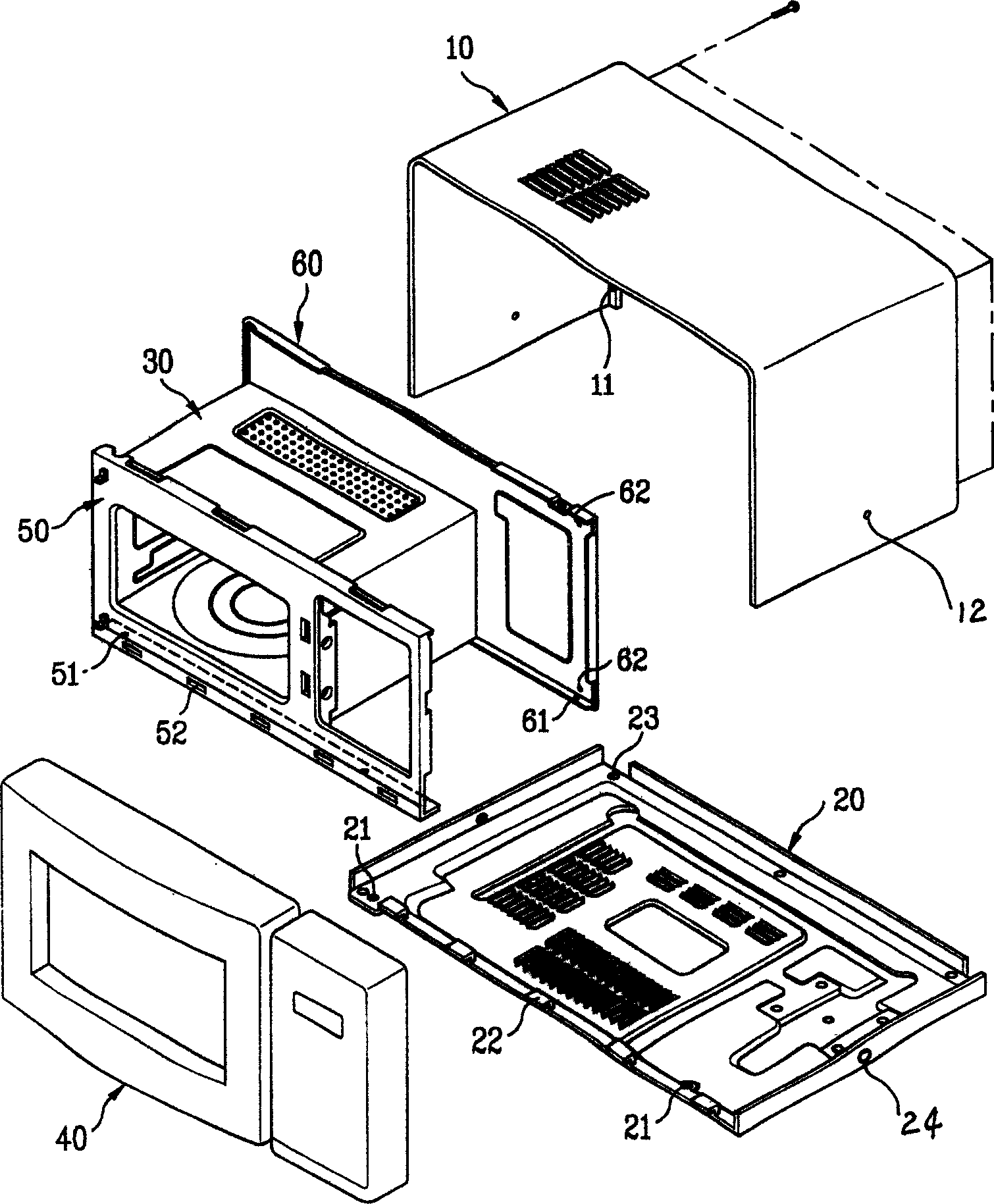

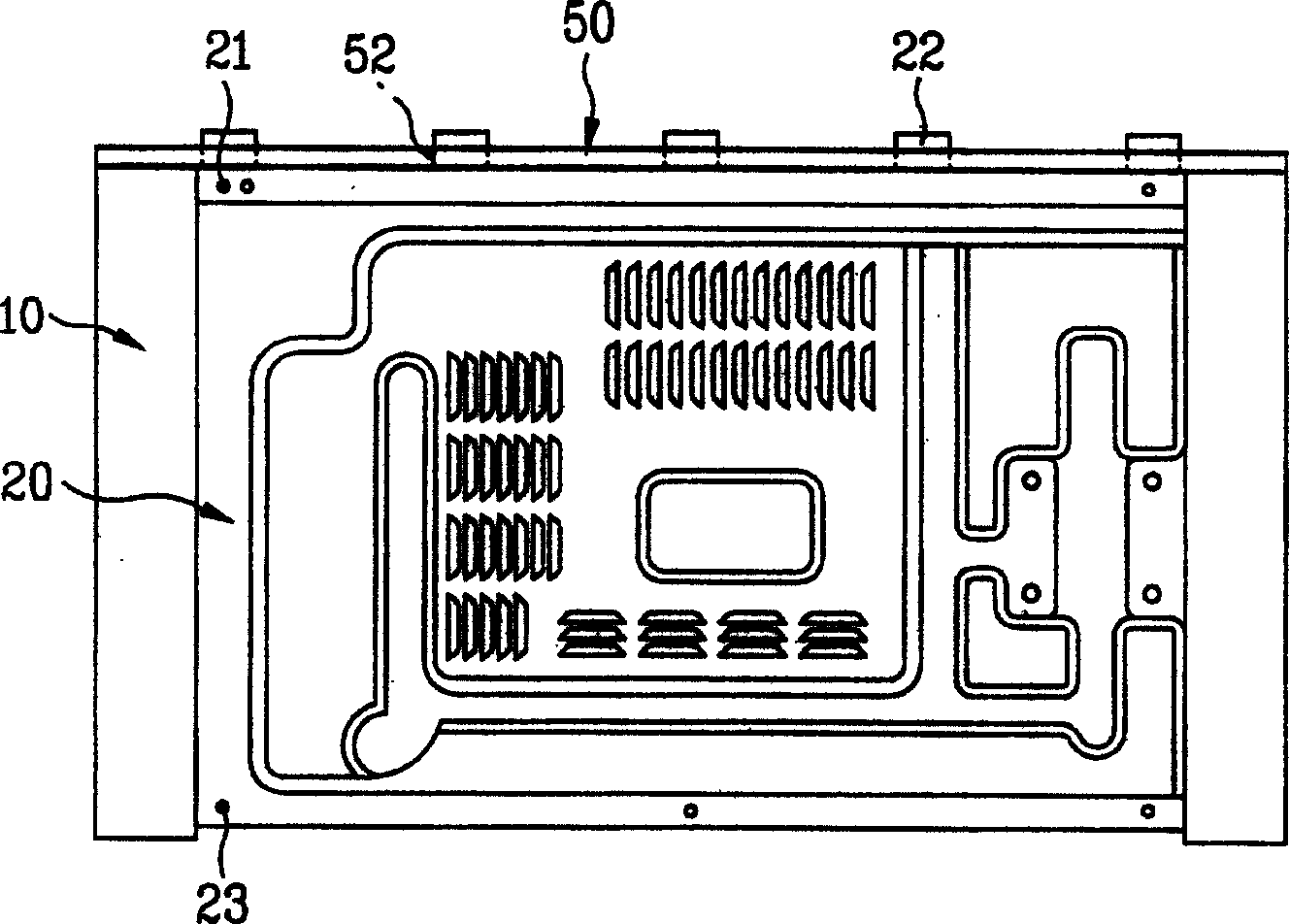

[0030] Embodiments of the present invention are described below with reference to the accompanying drawings:

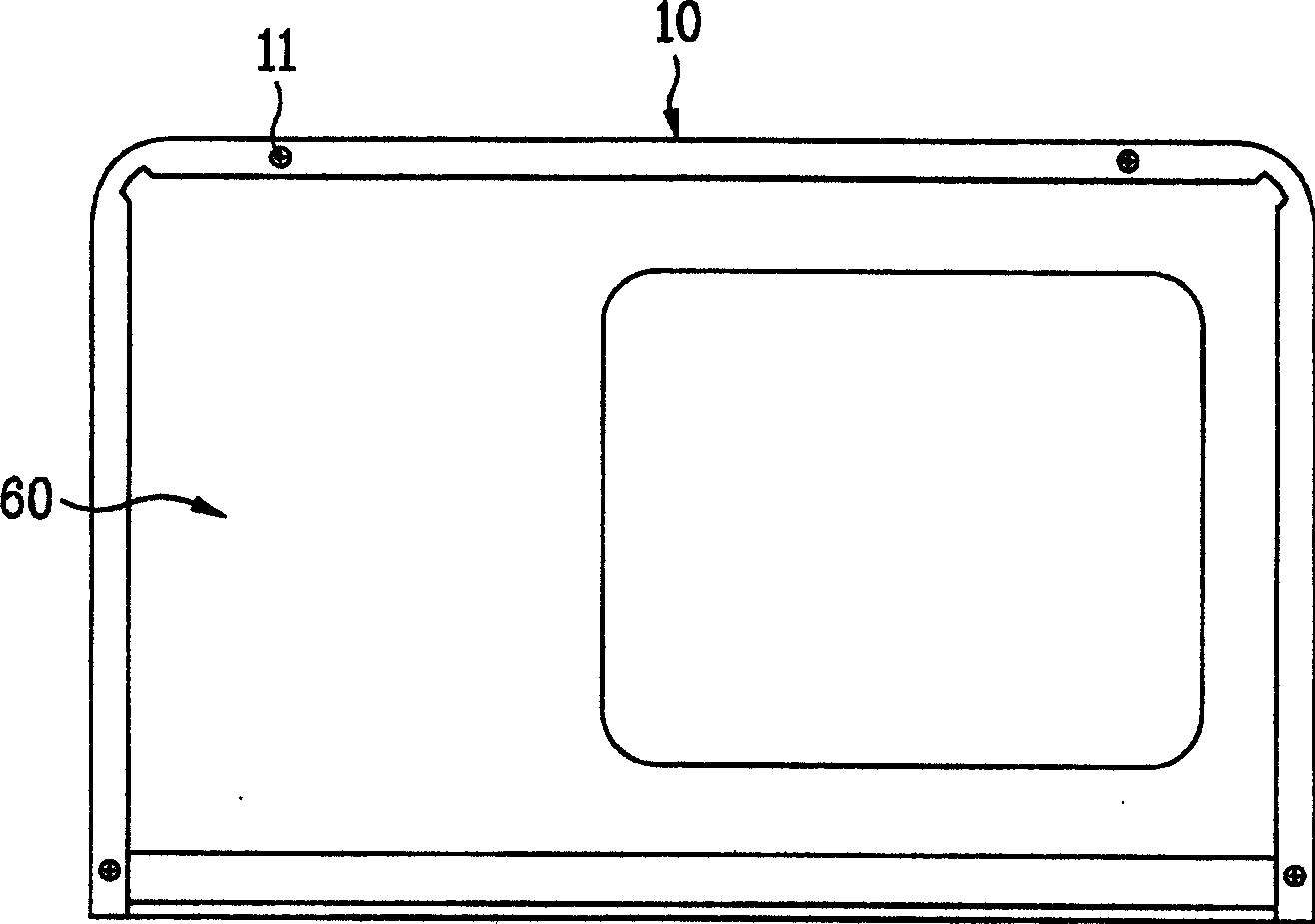

[0031] The present invention is an assembly structure of a microwave oven, which mainly includes a cavity 300 with a cooking chamber, a base plate 200 located at the bottom of the microwave oven and a shell 100 surrounding the cavity; a front frame 500 is arranged on the front side of the cavity , the rear side of the cavity has a rear frame 600, the bottom of the front frame 500 has a first opening 510, the bottom of the rear frame 600 has a second combination protrusion 610, and the front end of the base plate 200 has a The first coupling protrusion 210 corresponds to the first opening 510 of the front frame 500 , and the second opening 220 corresponds to the second protrusion 610 of the rear frame 600 at the rear end of the base plate 200 .

[0032] The first combining protrusion 210 of the base plate 200 is formed by cutting its bottom to the left or right and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com