Container lid for vacuum sealing having locking parts and vacuum-sealed container employing same

A technology of vacuum sealing and locking parts, which can be used in the directions of detachable cover/cover, packaging and application under vacuum/special atmosphere, and can solve the problems of not having limit edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

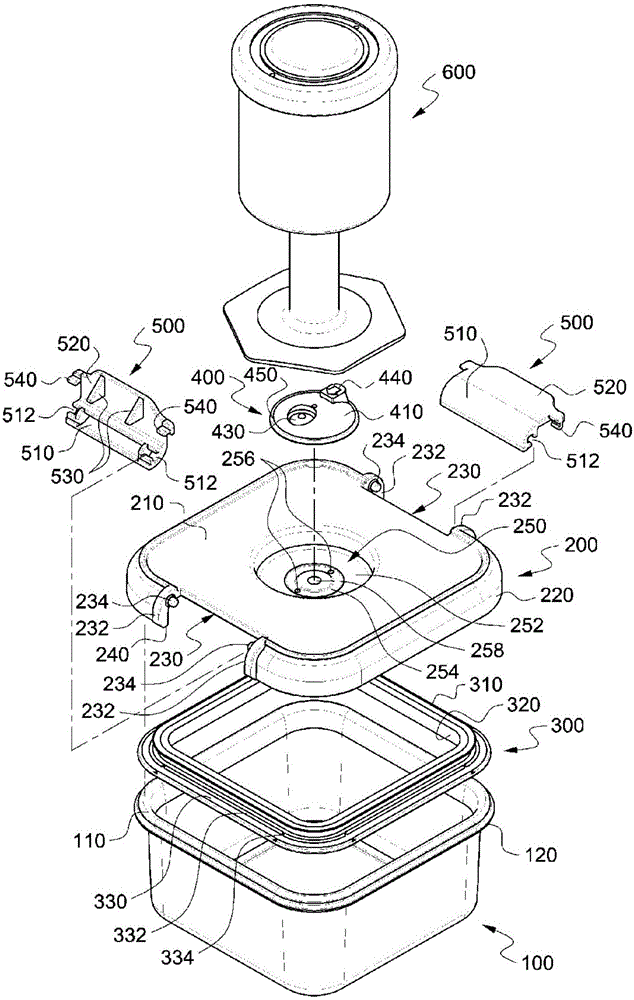

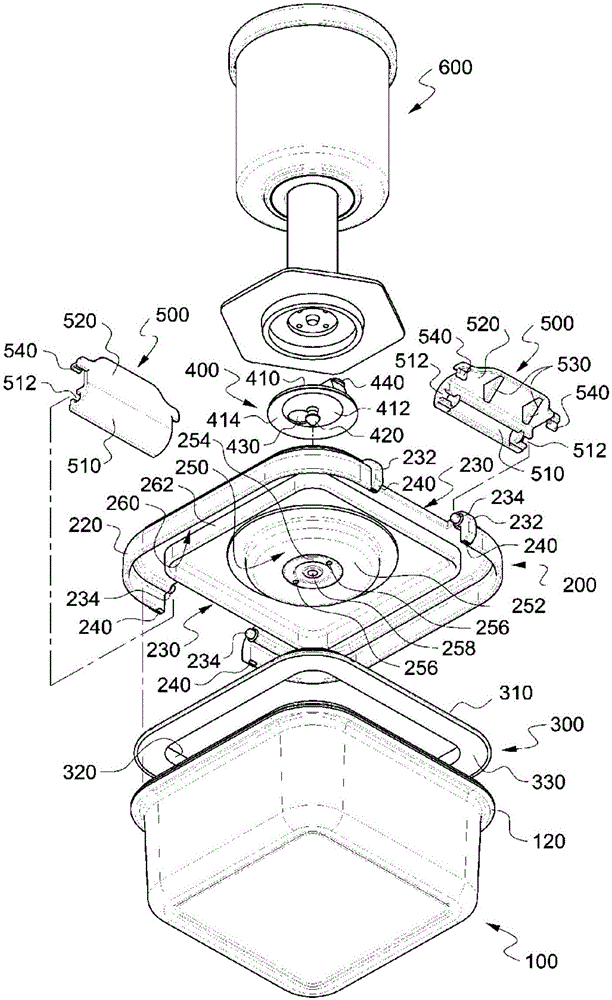

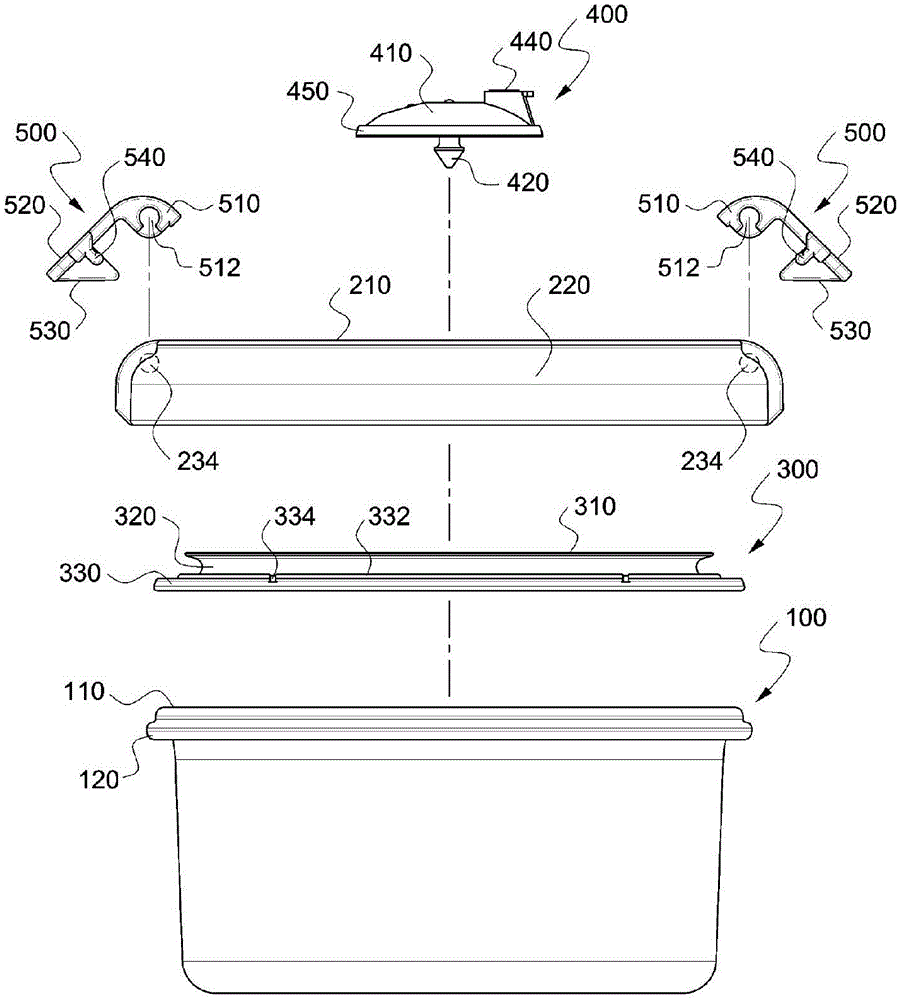

[0052] Regarding the first embodiment, the structure of the locking member (500) and the structure of the corresponding locking member mounting groove (230) will be described in accordance with the second and third embodiments described below.

[0053] First, refer to Figure 8 to Figure 11 The container lid (1200) of the second embodiment of the present invention will be described. Figure 8 (a) and (b) are plan view and sectional view of container lid (1200) main body, Figure 9 To show a sectional view of the locking part (1500), Figure 10 and Figure 11 It is a plan view and a side view of the container lid (1200) in a closed state with the locking member (1500) mounted on the body of the container lid (1200). Compared with the container lid (200) of the first embodiment, the difference of the container lid (1200) of the second embodiment lies in the locking part (1500) and its installation structure, therefore, in Figure 8 to Figure 11 In order to avoid the complexity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com