Patents

Literature

98 results about "Deterioration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deterioration Rate. Deterioration Rate is a Stat: The rate at which this item deteriorates when left outside, in average hit points of damage per day. Things deteriorate faster than normal in some weather, like rain.

Method and system of mass and multiple casualty triage

InactiveUS7761309B2Maximize survivabilityMaximize savingMental therapiesDiagnostic recording/measuringTriageDeterioration rate

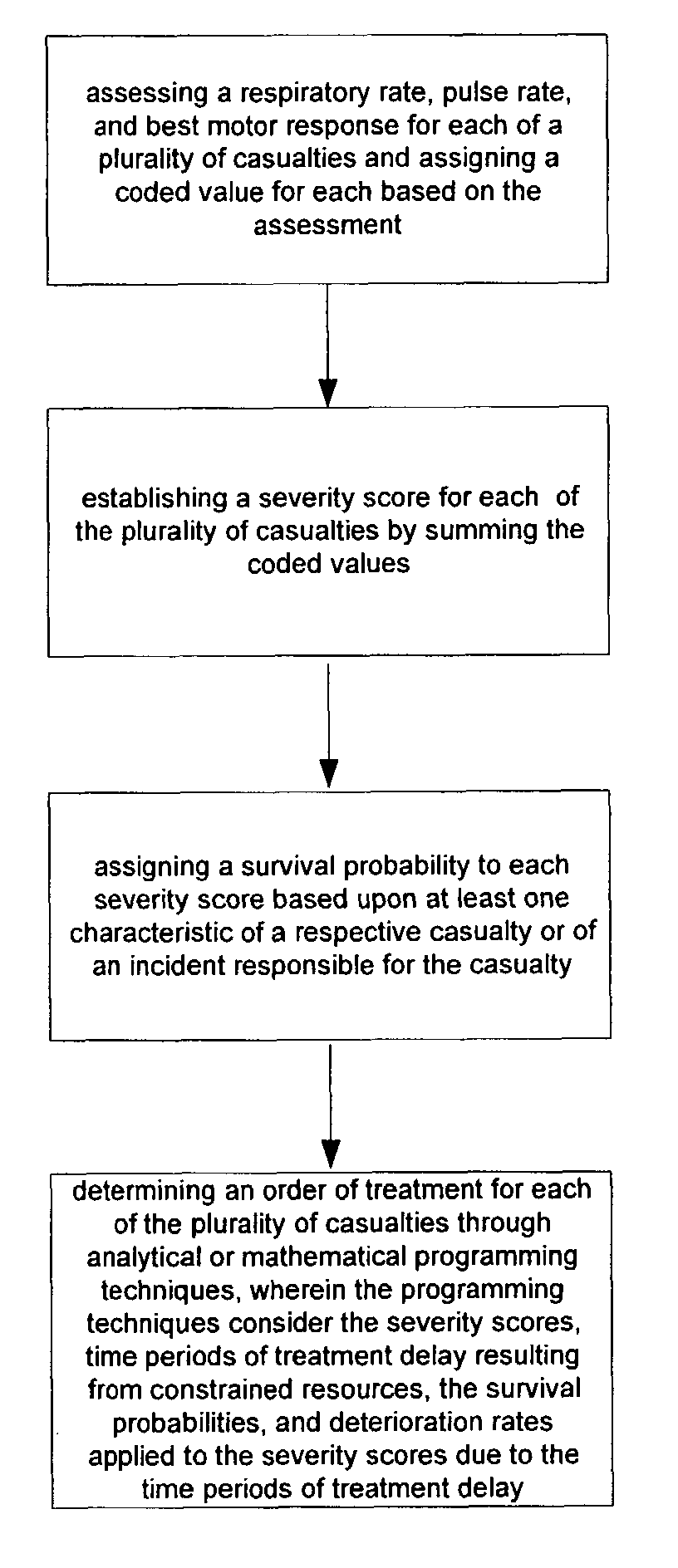

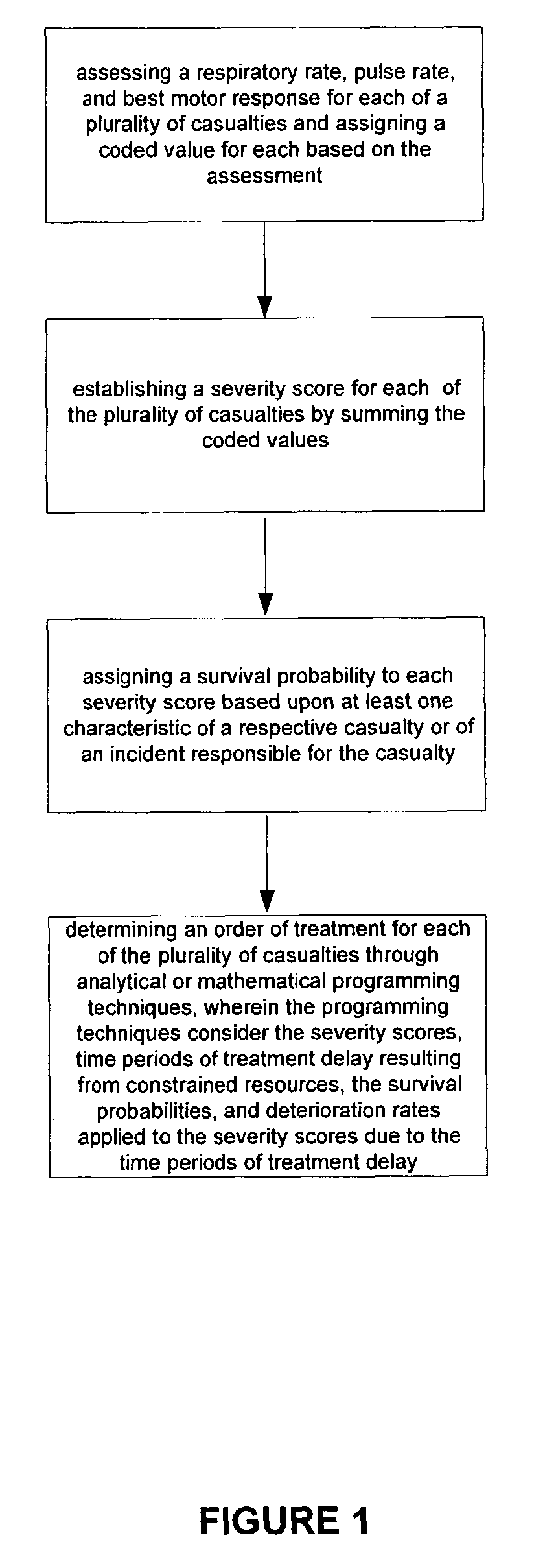

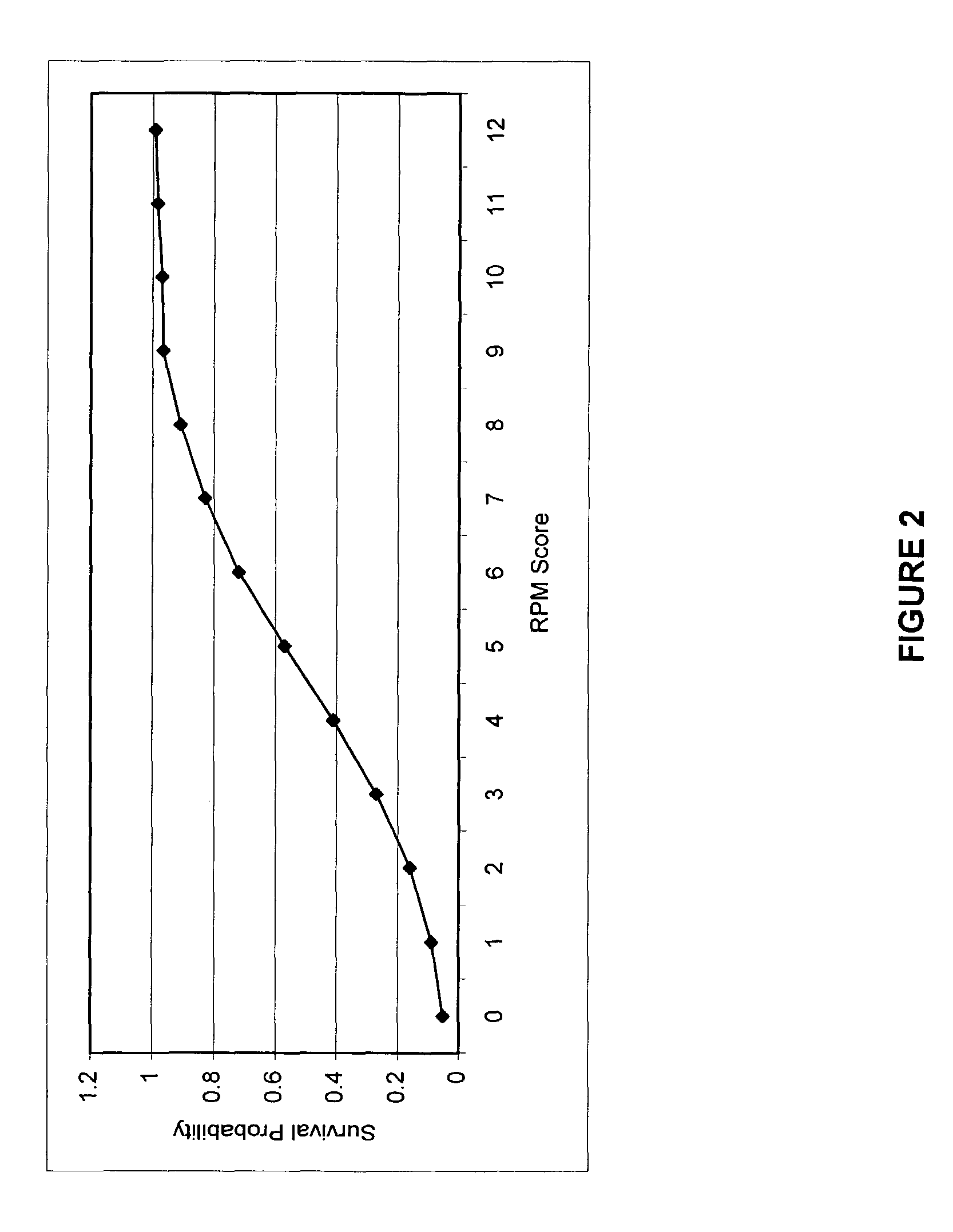

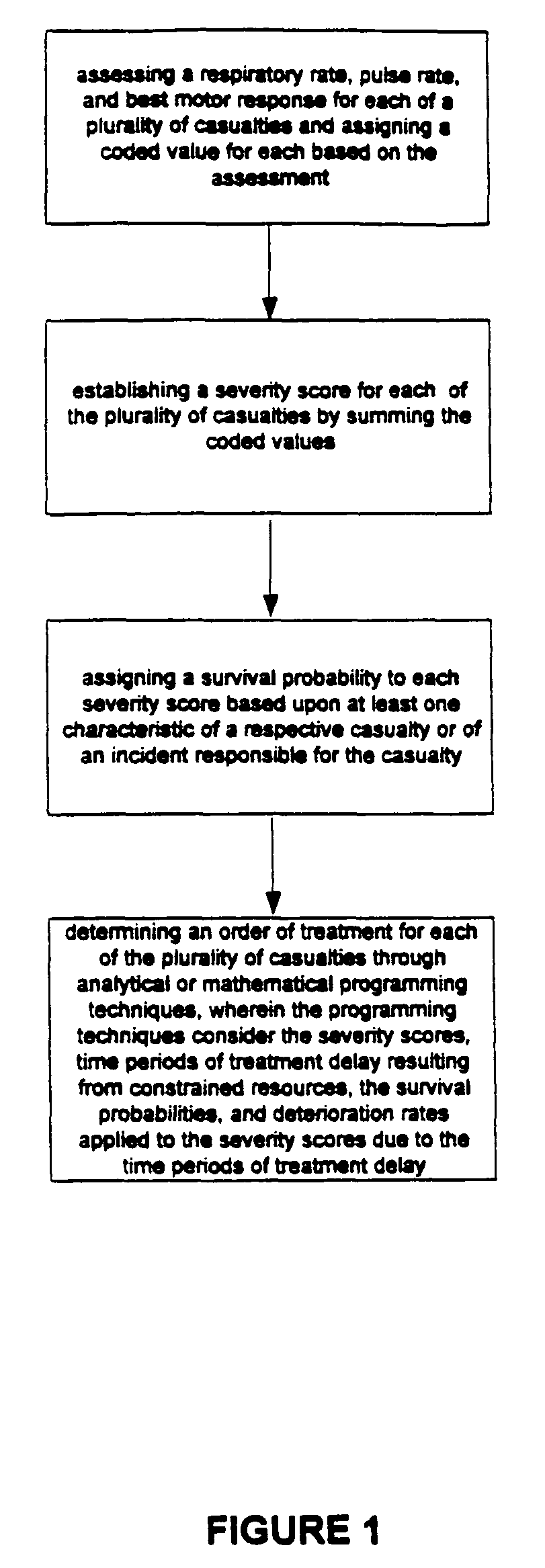

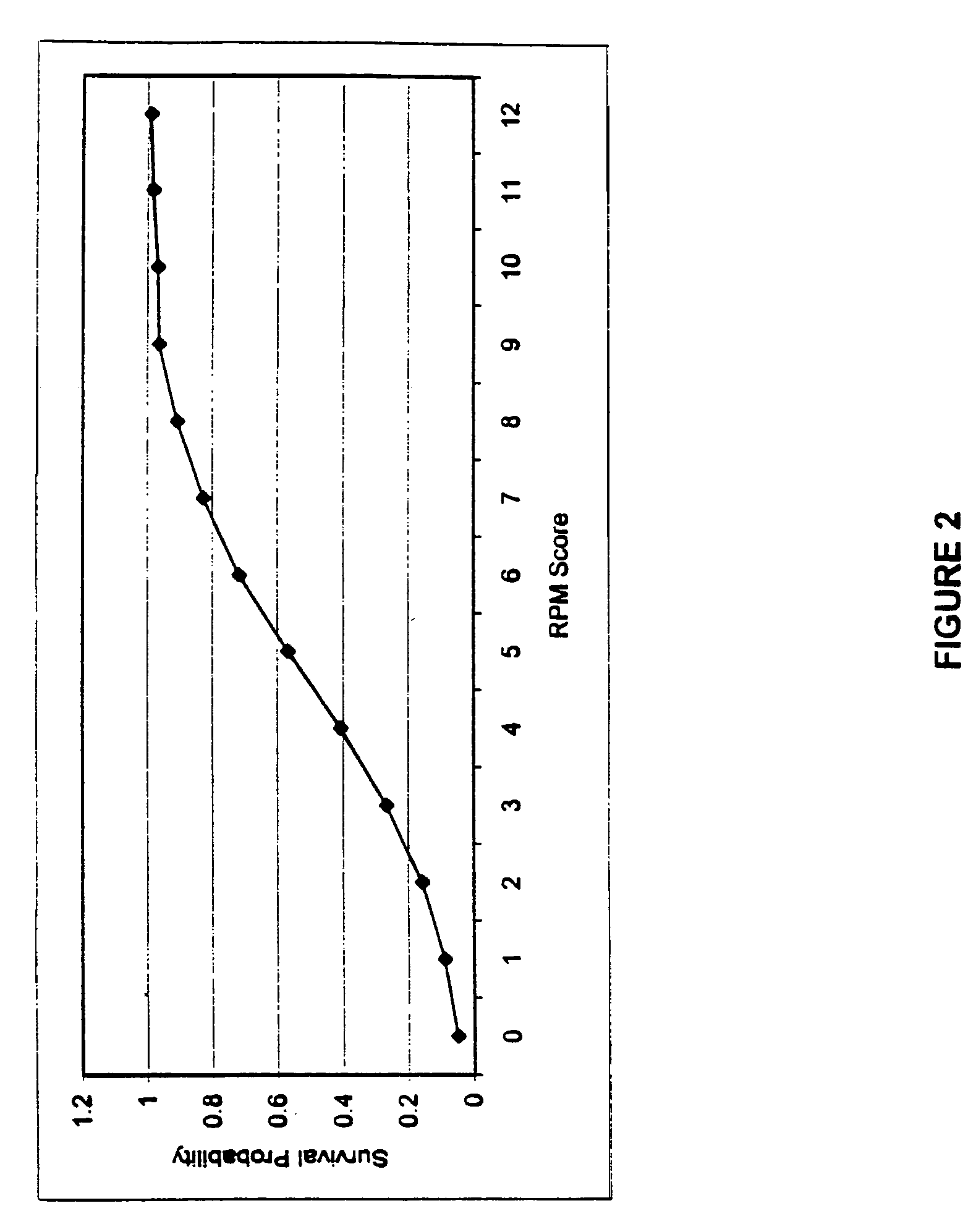

The present invention is a method and system of triage that assesses a severity score for each casualty, and determines a treatment prioritization plan to maximize the number of survivors. The present invention includes a score-based mathematical algorithm for resource-constrained triage, where an optimal number of survivors is determined through a methodology that can be mathematically modeled and solved, a methodology that considers victim survival probabilities, victim deterioration rates, and resource availability. First, each casualty is assessed and an RPM severity score is assigned based upon a sum of coded values for respiratory rate, pulse rate, and best motor response. Next, treatment priorities are determined from analytical or mathematical techniques, such as dynamic or linear programming, in consideration of survival probabilities associated with each RPM score, and deterioration-with-time rates for each RPM score for victims awaiting transport and treatment and the availability and timing of transport and treatment services.

Owner:THINKSHARP

Method and system of rule-based triage

InactiveUS7899682B2Maximize survivabilityMaximize savingFinanceEpidemiological alert systemsTriageData dredging

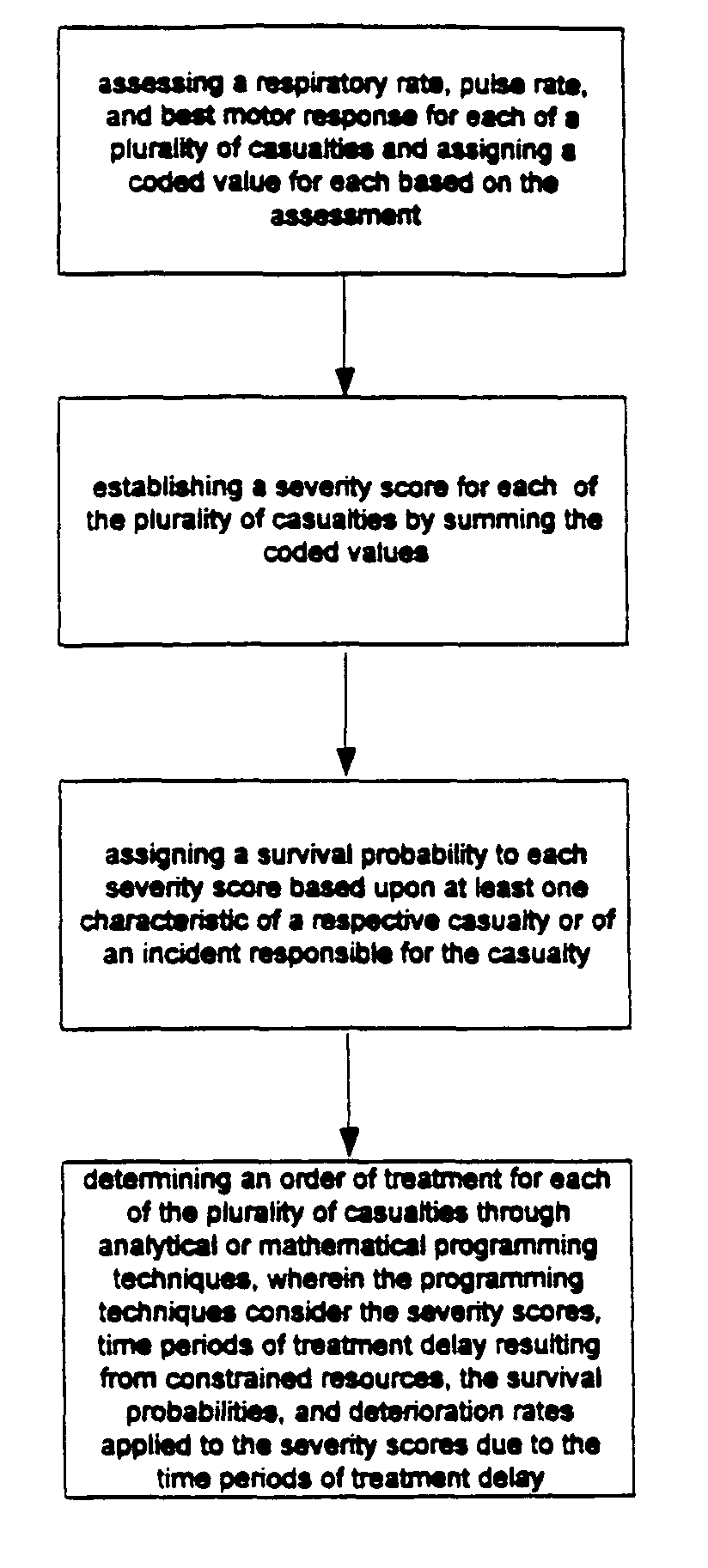

A method and system for ordering treatment or transport of victims of a mass casualty incident, prior to the incident, by establishing simulated casualty severity scores for each of the victims and considering the casualty severity scores and simulated resource availability. The order of treatment is provided on a card, chart, table or graph. Ordering treatment occurs through an analysis of triage simulations using analytical or mathematical programming techniques considering the severity scores, time periods of treatment delay resulting from constrained resources, estimated survival probabilities, and / or deterioration rates applied to the severity scores due to treatment delay. Alternatively, the order of treatment can be determined through data mining, pattern recognition, or greedy algorithm optimization techniques analyzing survival probability estimates associated with the simulated casualty severity scores, and changes to the survival probability estimates due to time periods of treatment delay resulting from constrained resources.

Owner:THINKSHARP

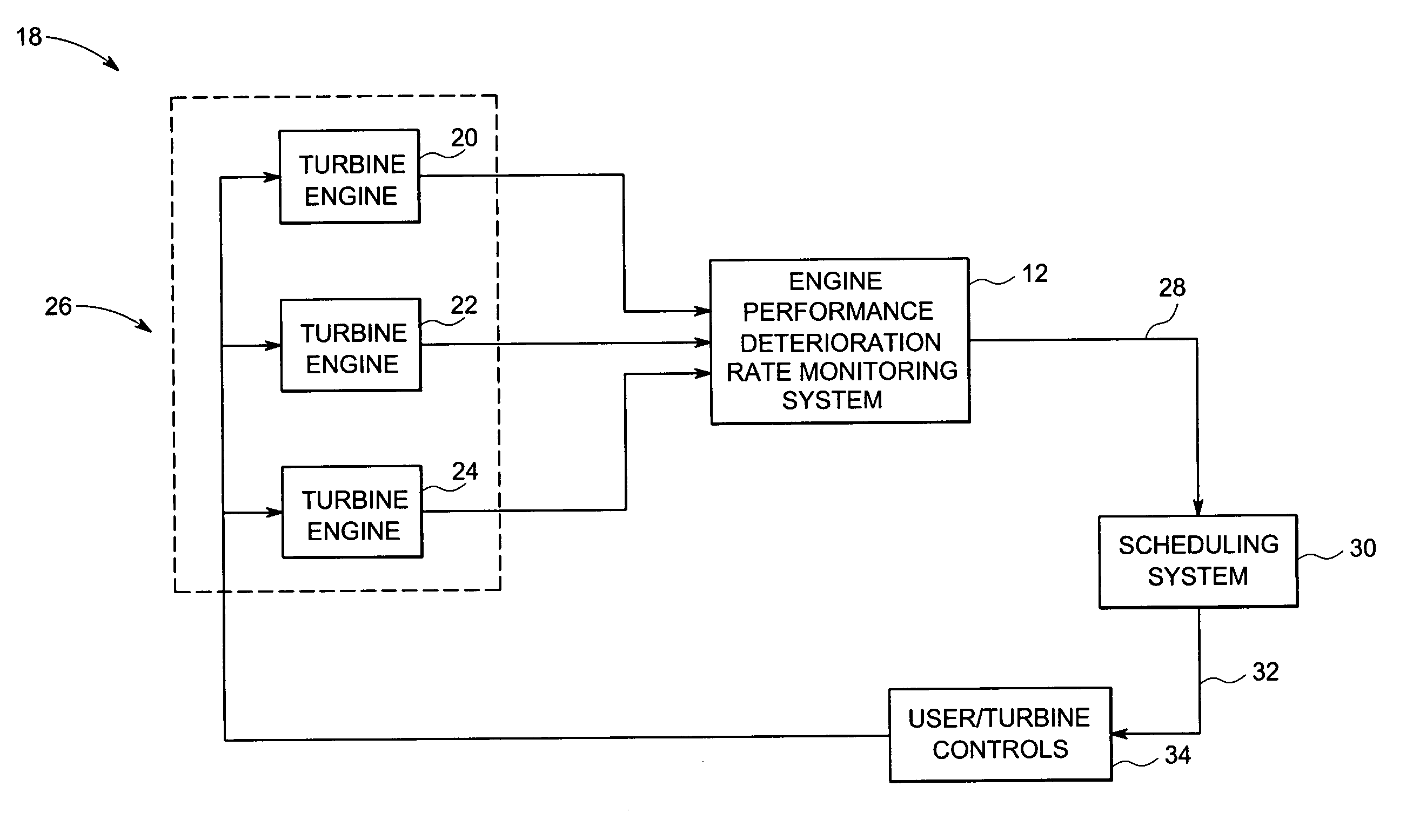

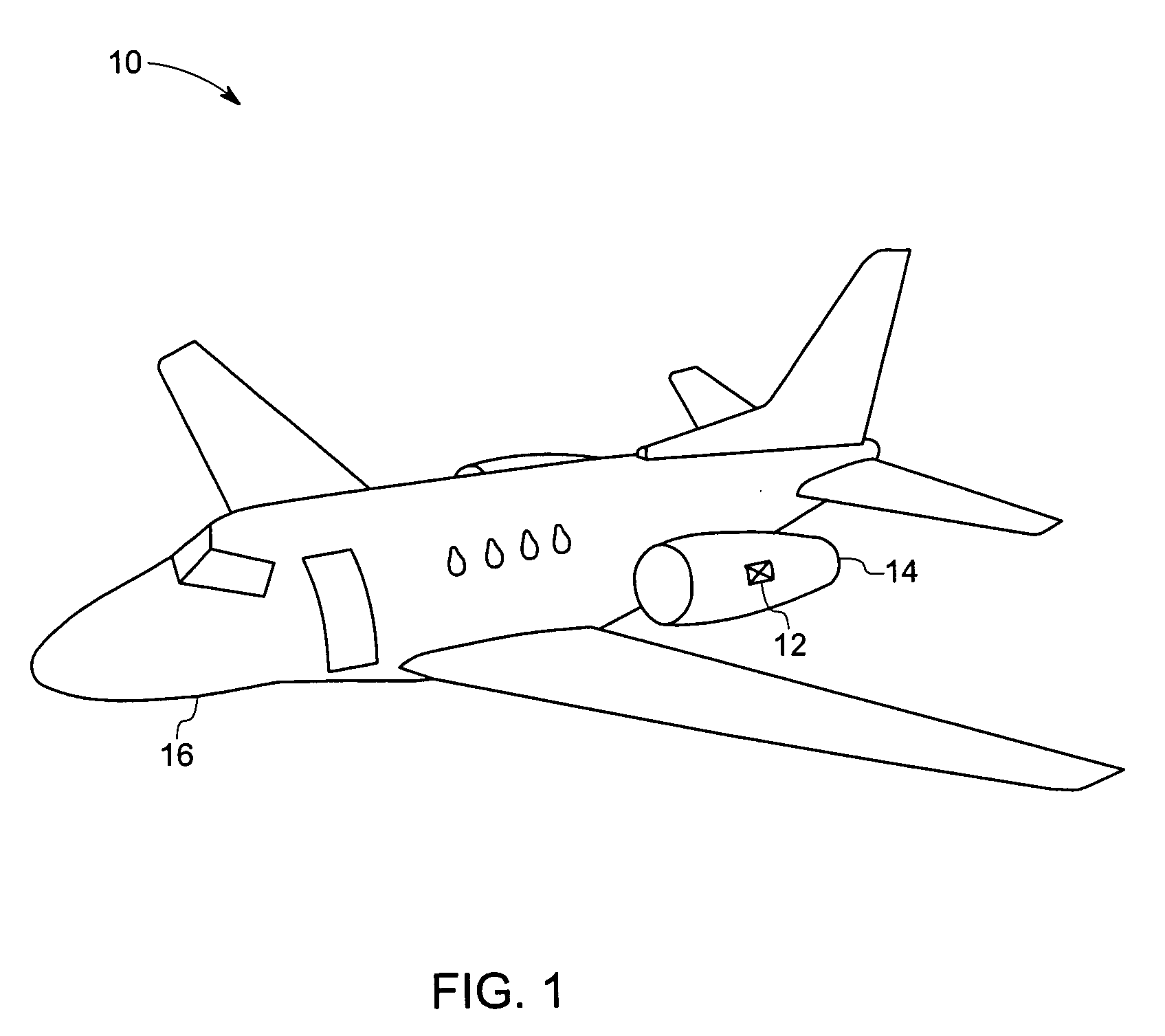

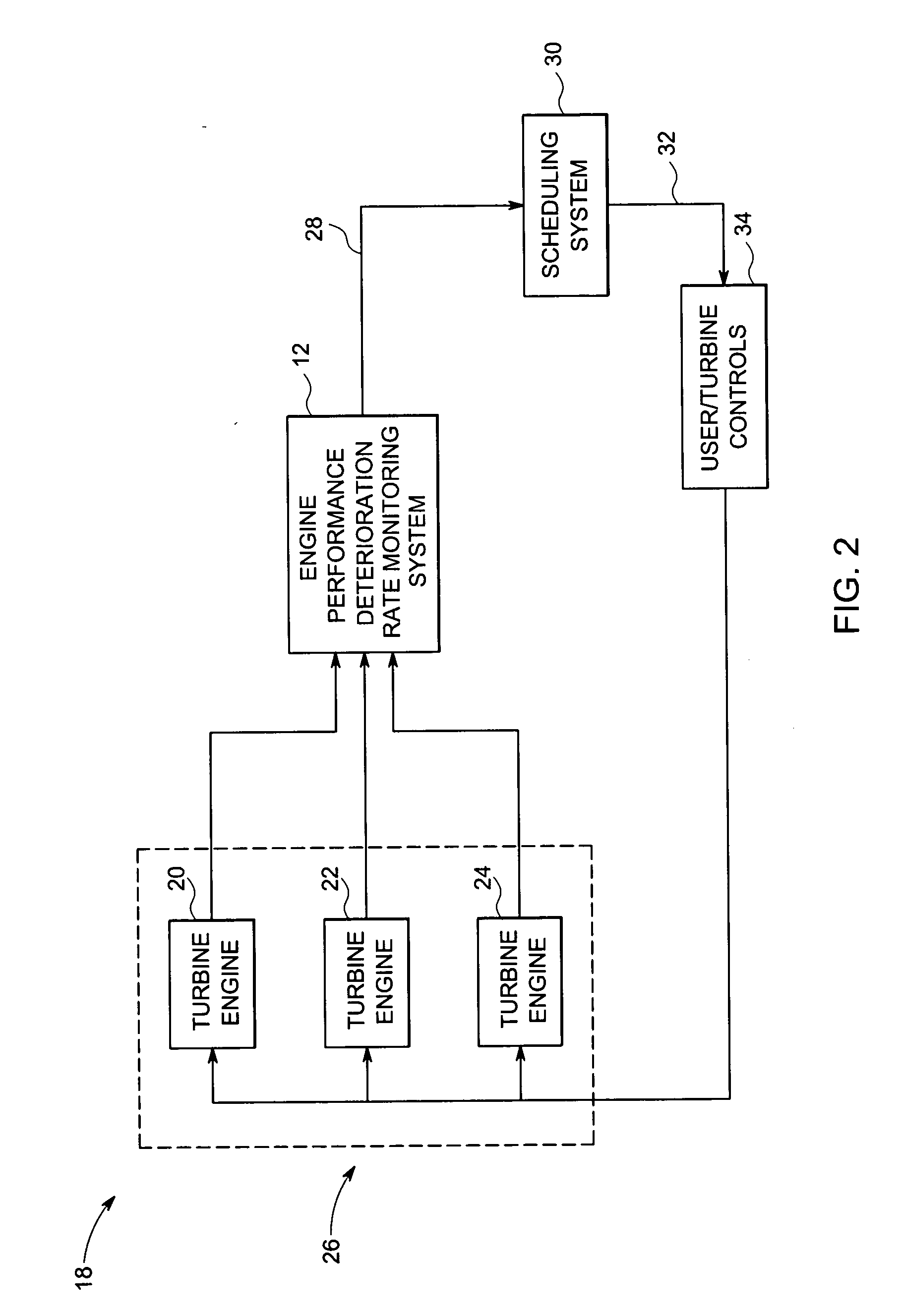

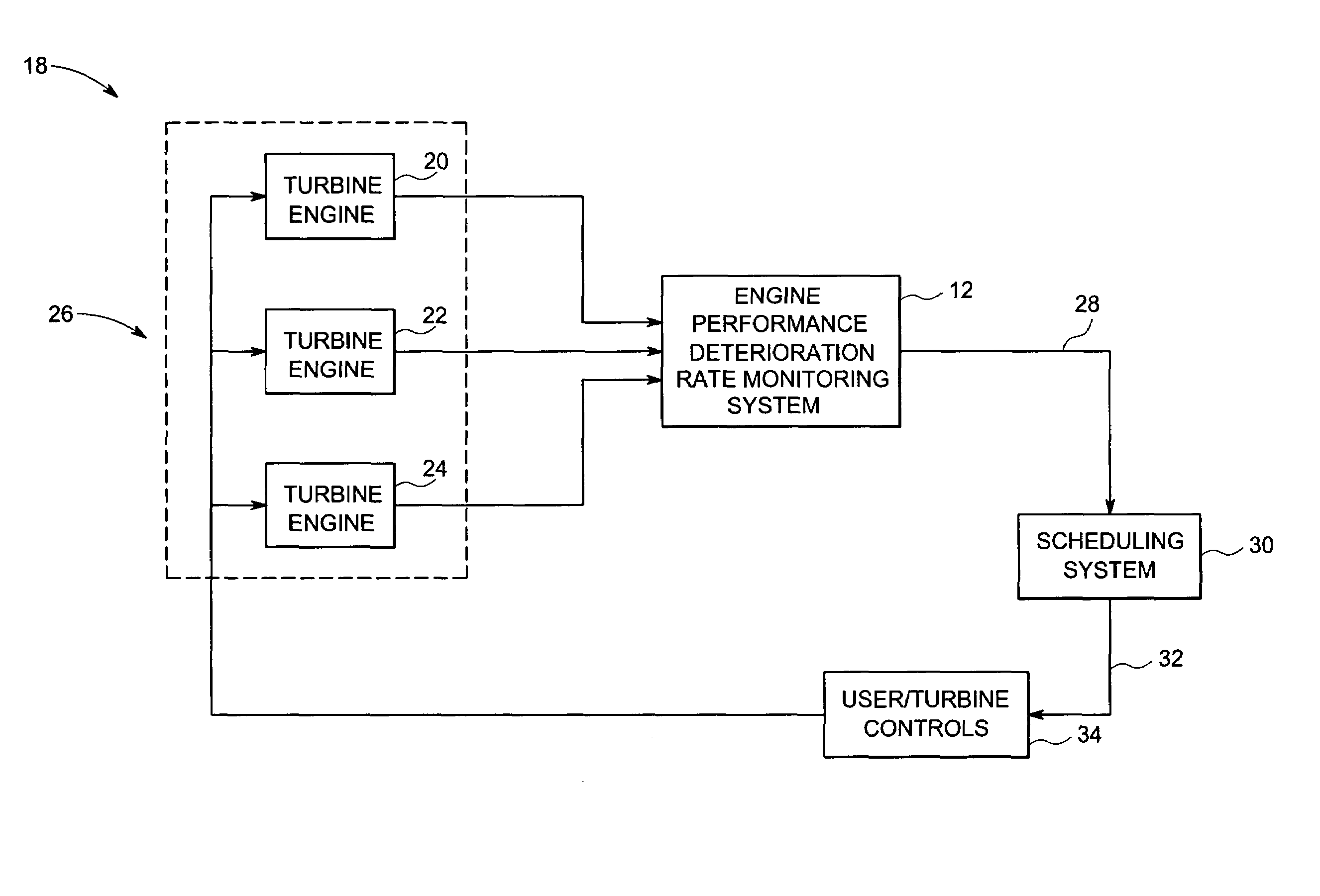

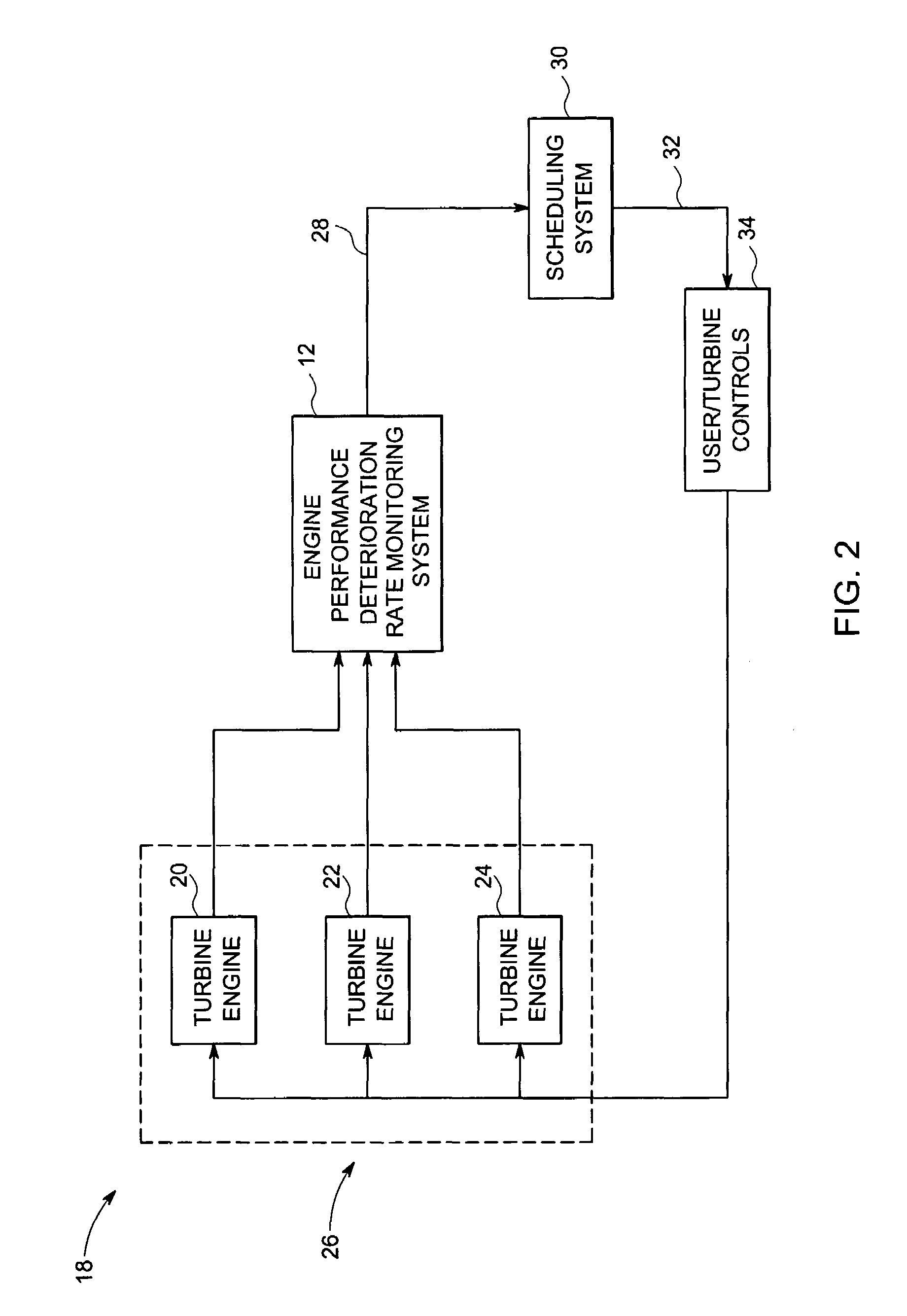

System and method for estimating turbine engine deterioration rate with noisy data

A method for monitoring engine performance includes sampling exhaust gas temperature associated with a turbine engine over an interval of operational time of the turbine engine. The method further includes applying a first test to identify statistical outliers on the sampled exhaust gas temperature data and removing identified statistical outliers from the sampled exhaust gas temperature data. Subsequently, the method includes applying a second test to identify step changes in slope of the exhaust gas temperature data and dividing the interval of operational time into one or more segments based upon the identified step changes. Finally, the method includes determining a slope for each segment and combining the segments to obtain a rate of performance deterioration of the turbine engine.

Owner:GENERAL ELECTRIC CO

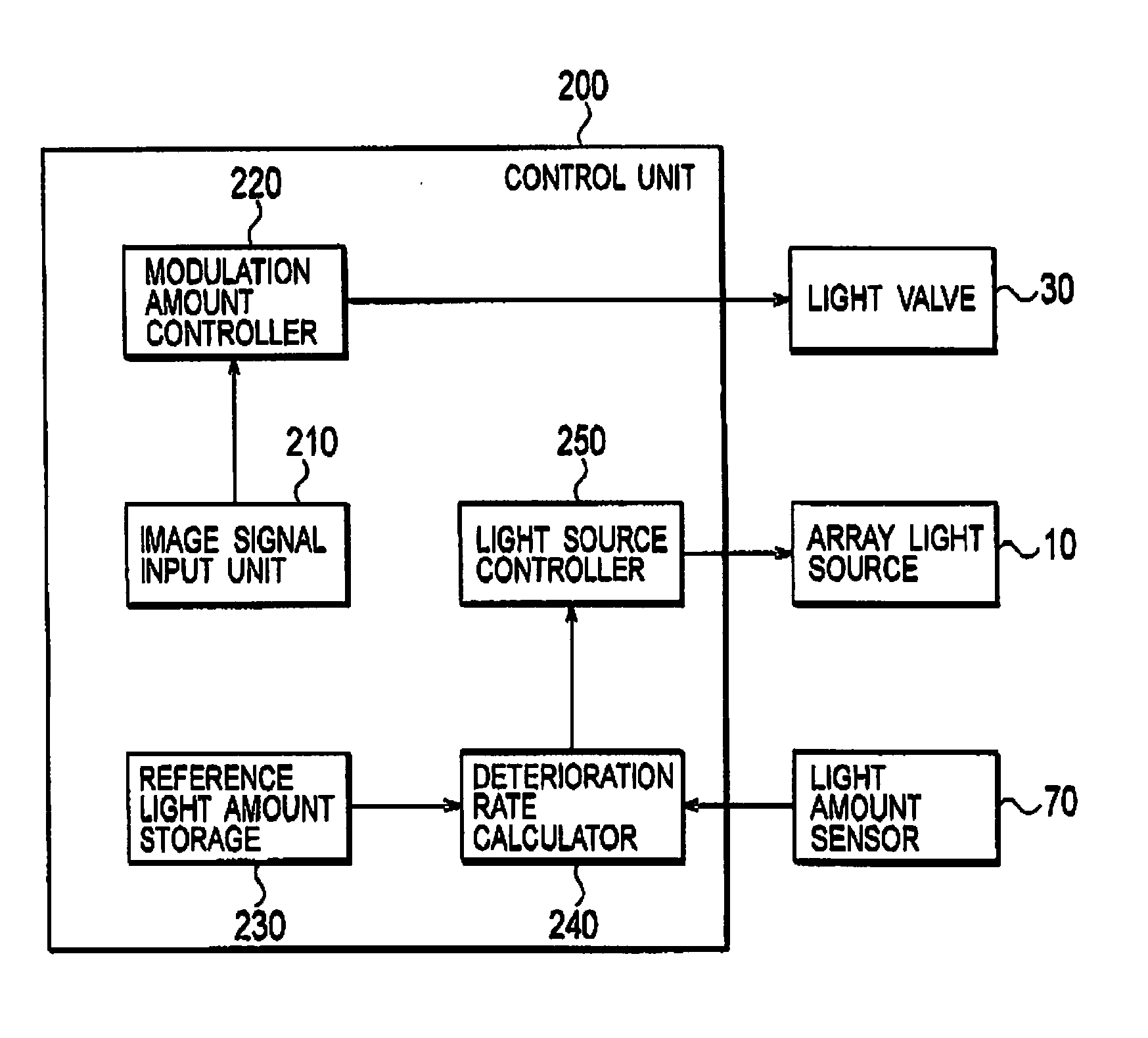

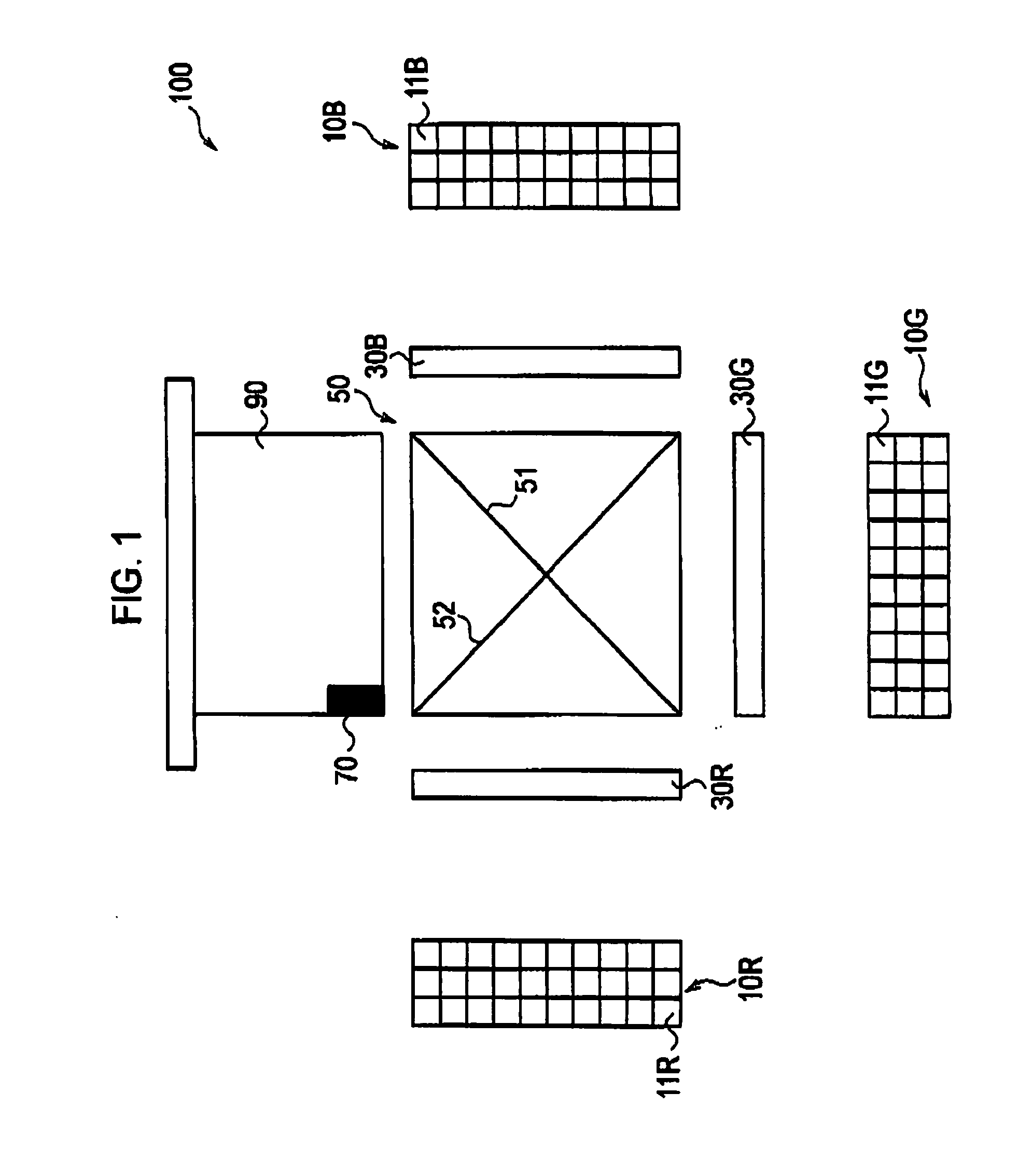

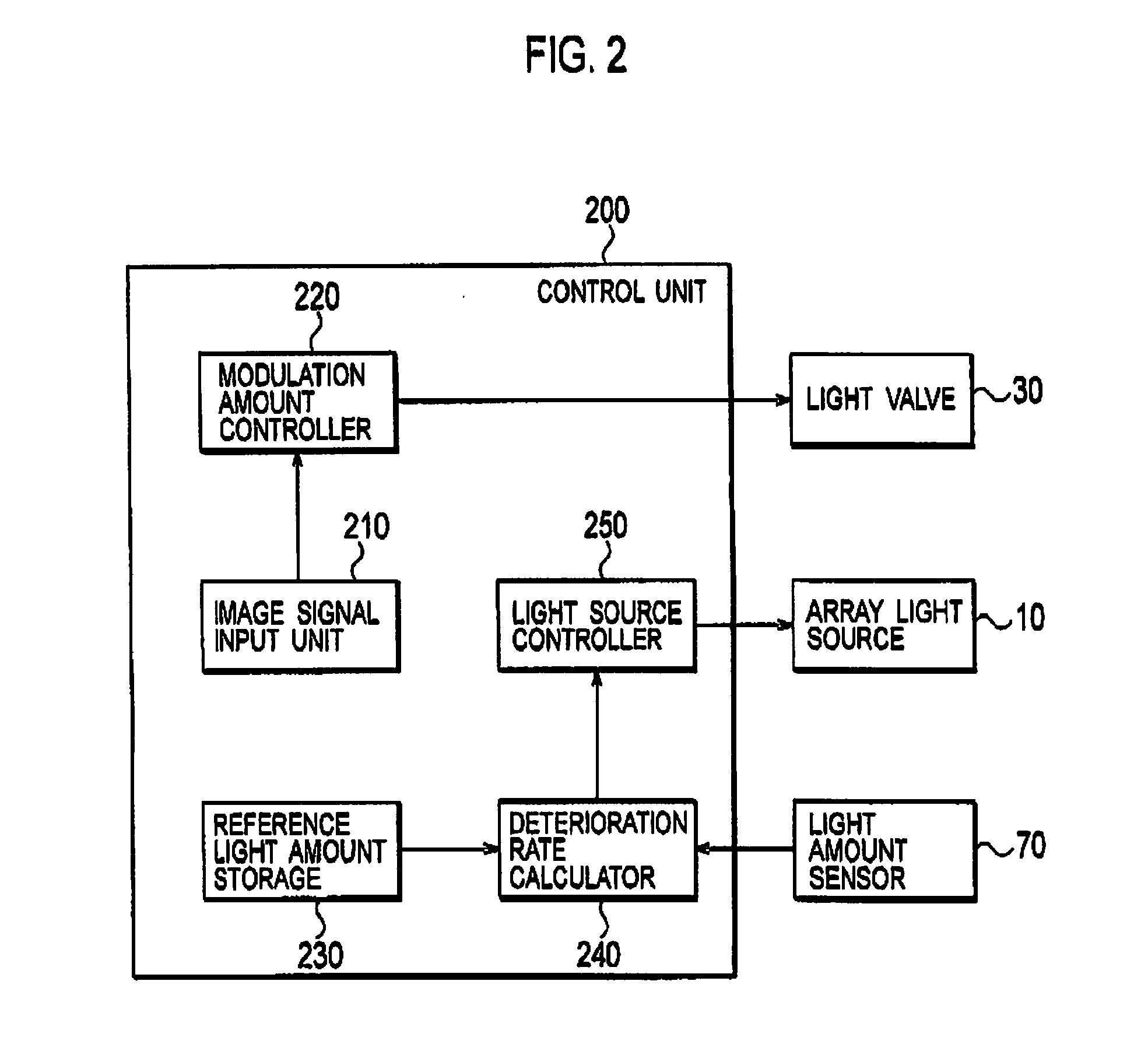

Projection display apparatus

ActiveUS20080246927A1Reduce the amount of lightIncrease the amount of lightPhotometry using reference valueStatic indicating devicesDeterioration rateOptoelectronics

A projection display apparatus includes: a light amount sensor which detects an amount of light emitted from an array light source; a deterioration rate calculator which acquires an amount of light of a measurement target light source from the amount of light detected by the light amount sensor; a reference light amount storage which stores a reference amount of light of an amount of light emitted from plurality of solid state light sources, for each of the solid state light sources; and a light source controller which controls the amount of light emitted from the plurality of solid state light sources for each of the solid state light sources, and the deterioration rate calculator determines whether the measurement target light source has deteriorated, in accordance with a result of a comparison between the amount of light detected by the light amount sensor, and the reference amount of light.

Owner:SANYO ELECTRIC CO LTD

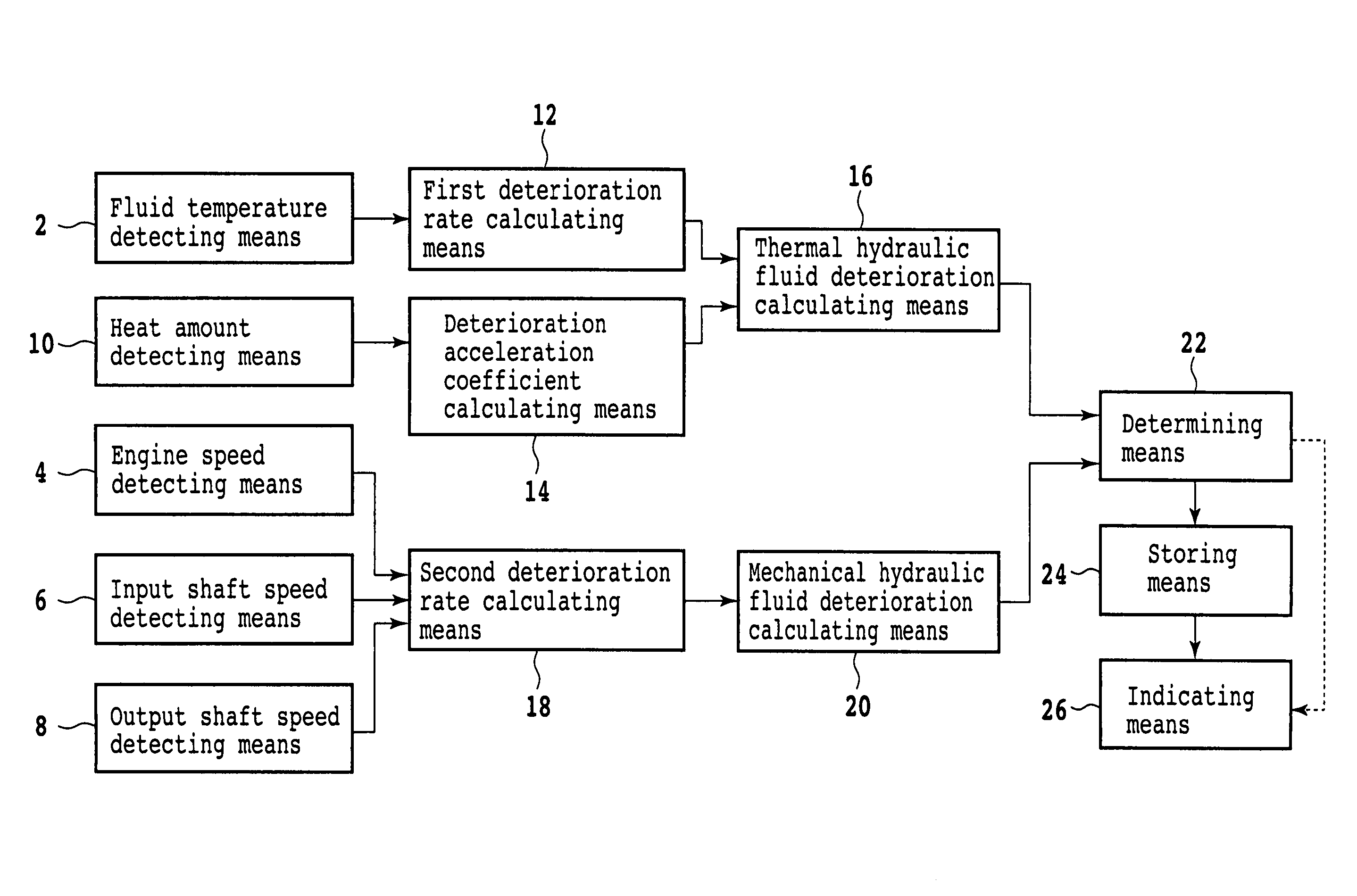

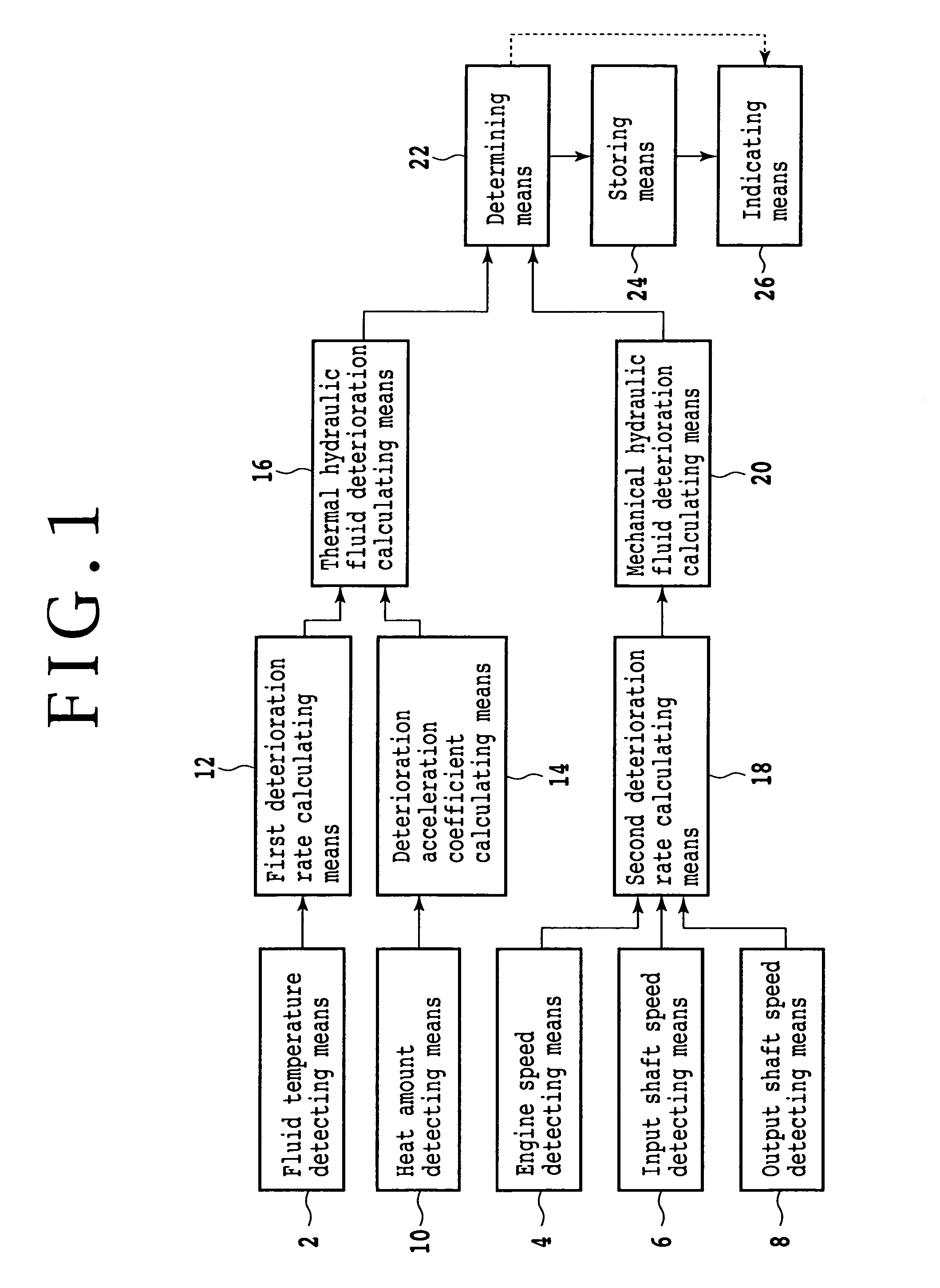

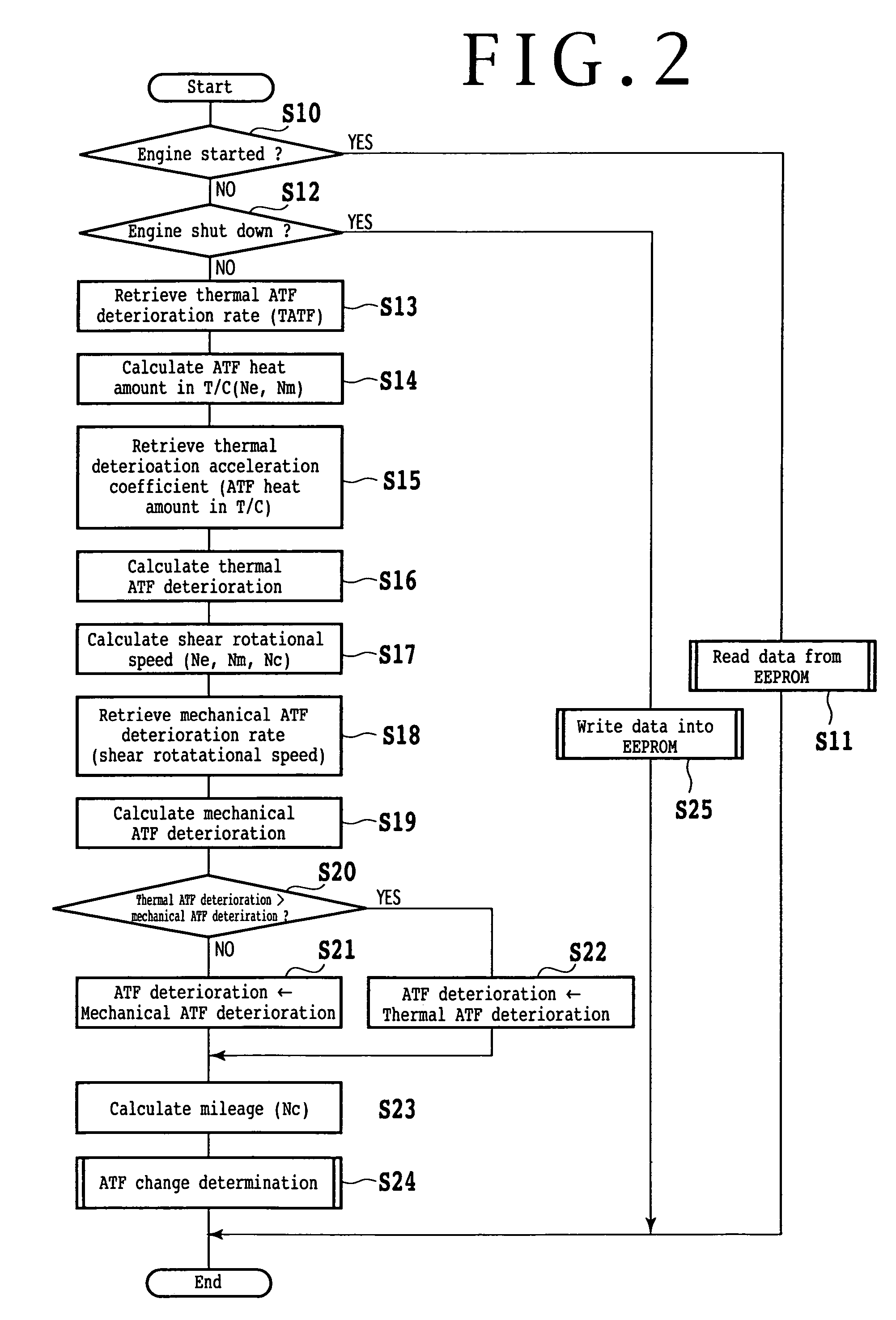

Hydraulic fluid change indicating device for automatic transmission

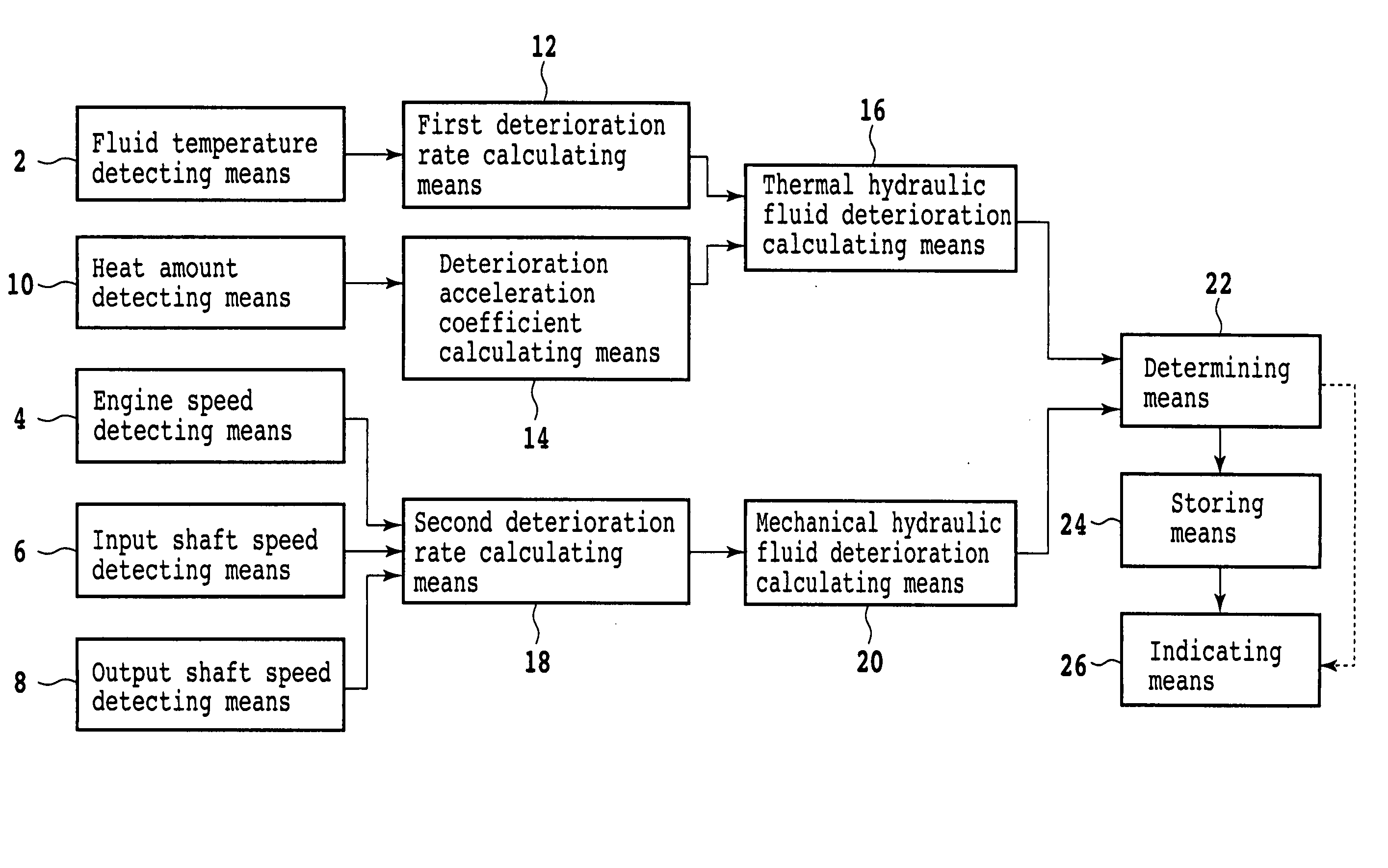

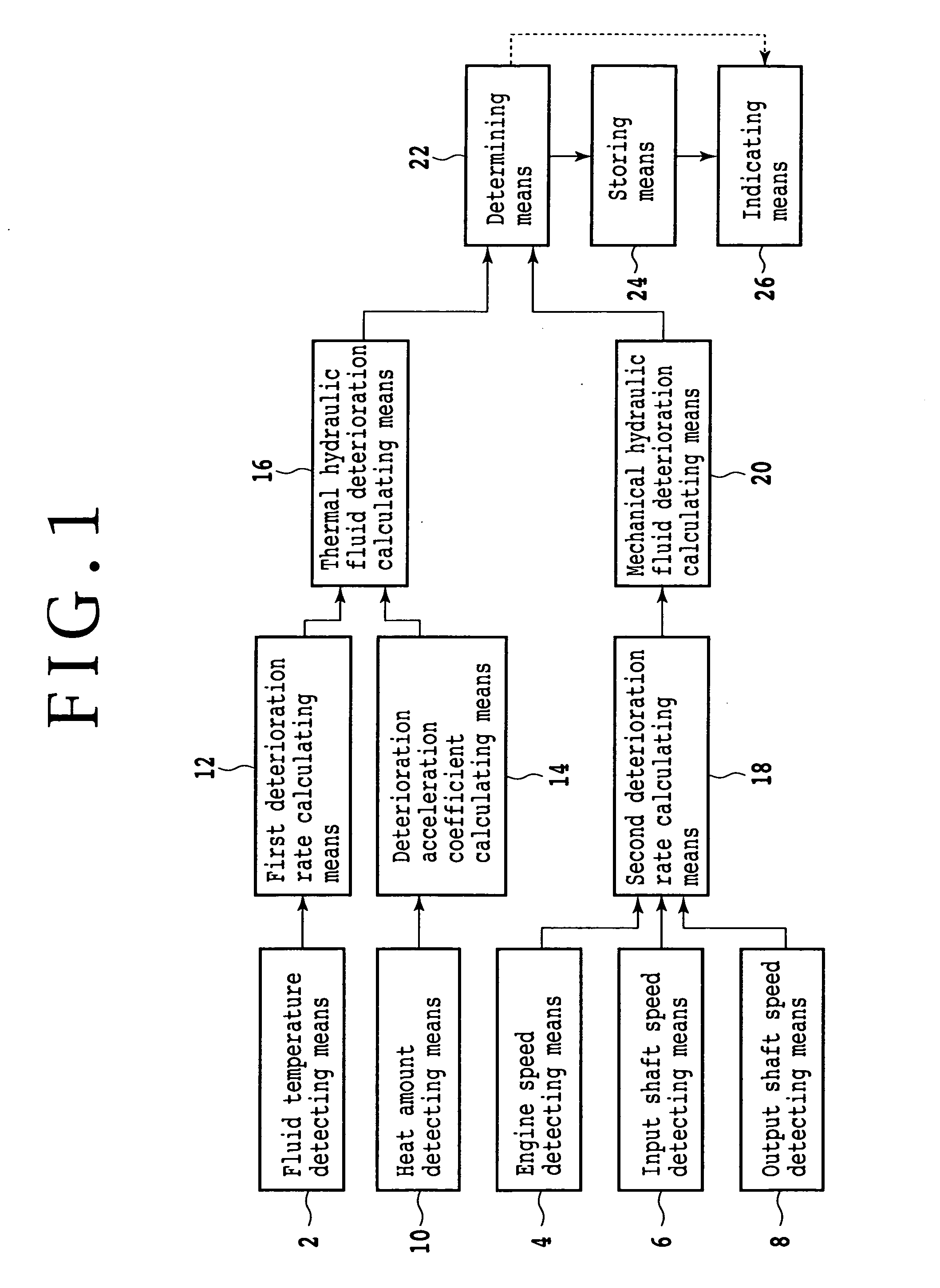

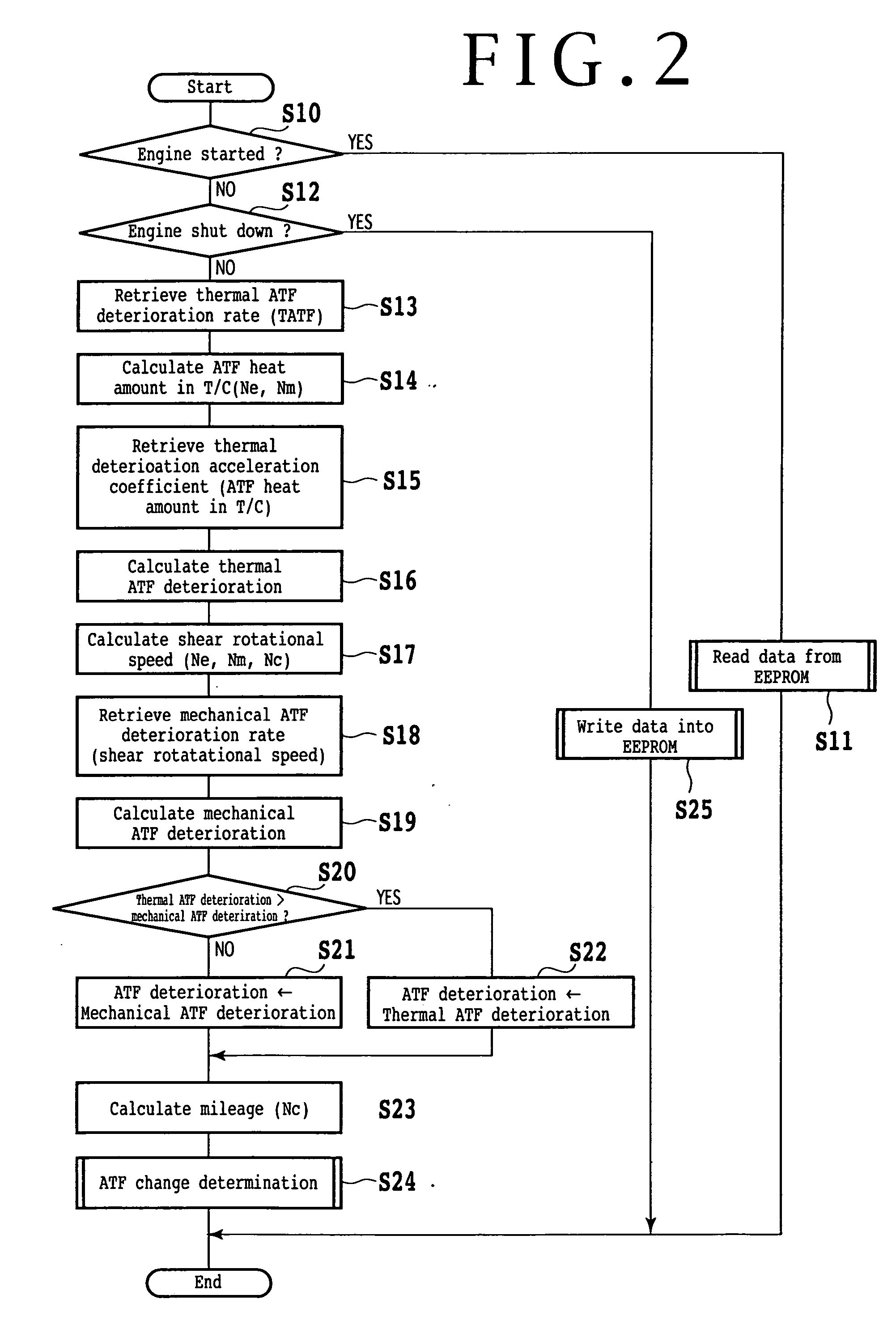

InactiveUS20050131599A1Improve detection accuracyImprove accuracyVehicle testingRegistering/indicating working of vehiclesDeterioration rateAutomatic transmission

A hydraulic fluid change indicating device for an automatic transmission includes a first deterioration rate calculating unit; a deterioration acceleration coefficient calculating unit; and a thermal hydraulic fluid deterioration calculating unit for calculating a thermal hydraulic fluid deterioration according to the first deterioration rate and the deterioration acceleration coefficient. The device further includes a second deterioration rate calculating unit according to an engine speed, input shaft speed, and output shaft speed; a mechanical hydraulic fluid deterioration calculating unit for calculating a mechanical fluid deterioration according to the second deterioration rate; and a determining unit for determining whether or not the thermal hydraulic fluid deterioration or the mechanical hydraulic fluid deterioration is greater than a predetermined hydraulic fluid change threshold.

Owner:HONDA MOTOR CO LTD

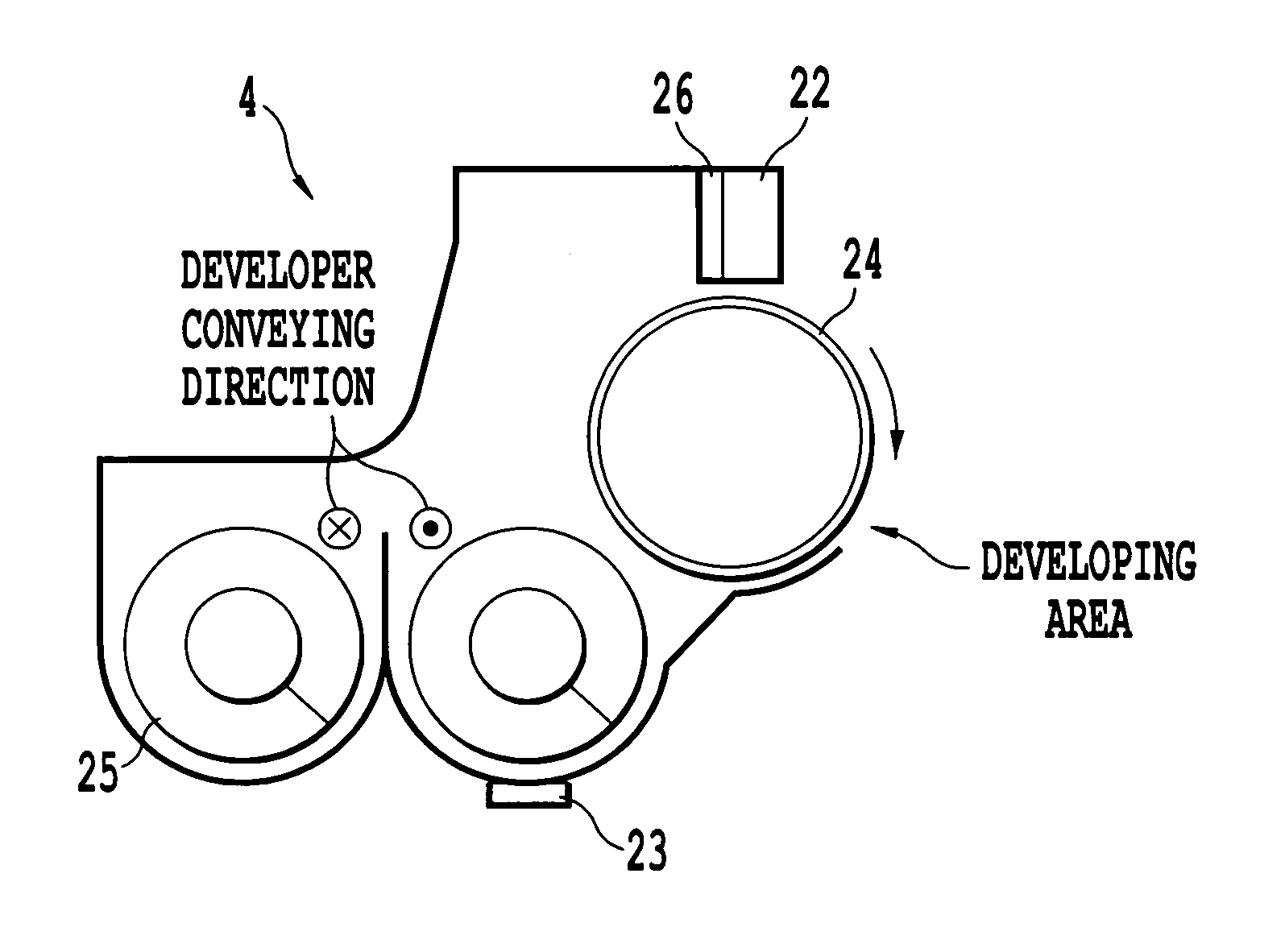

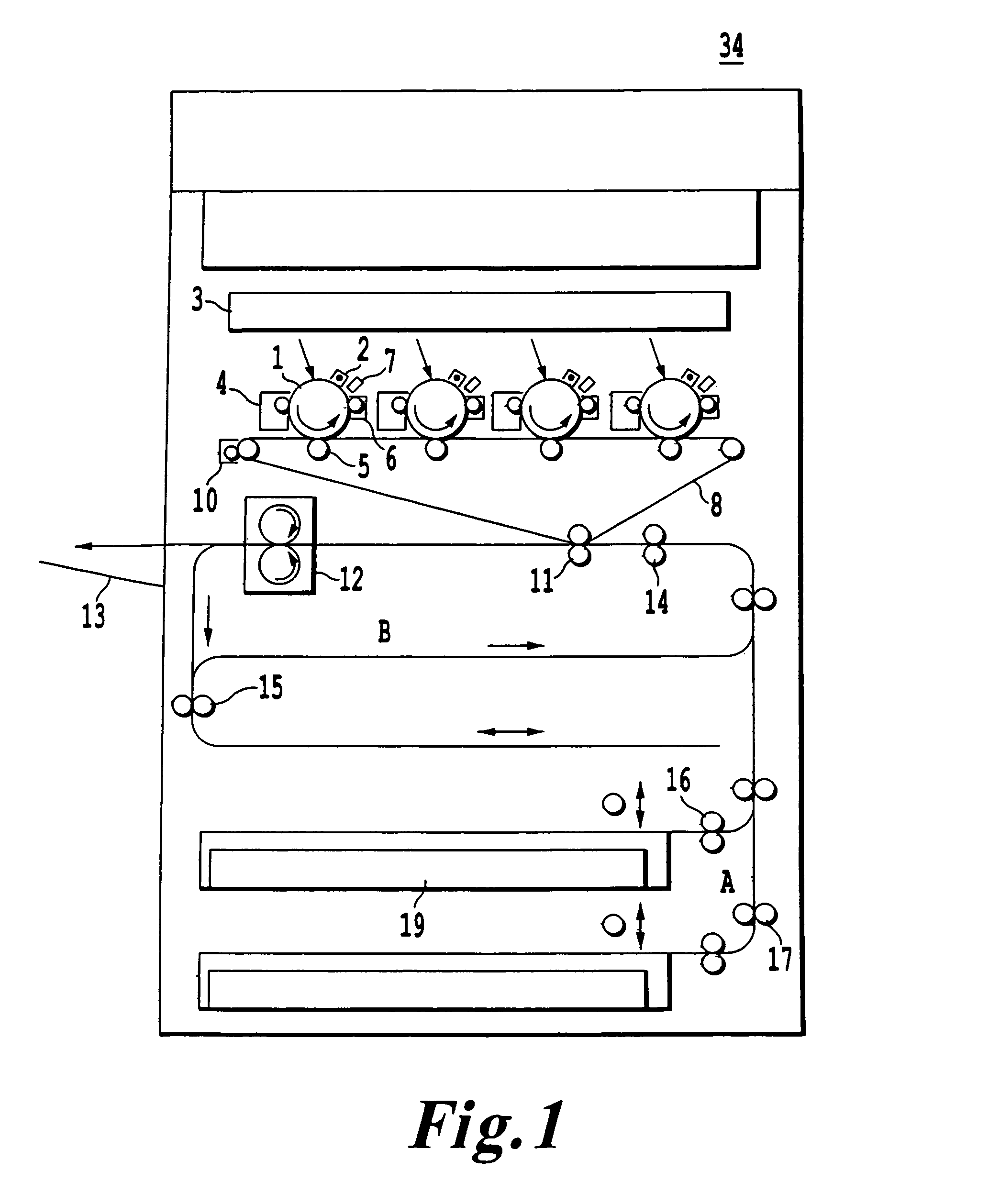

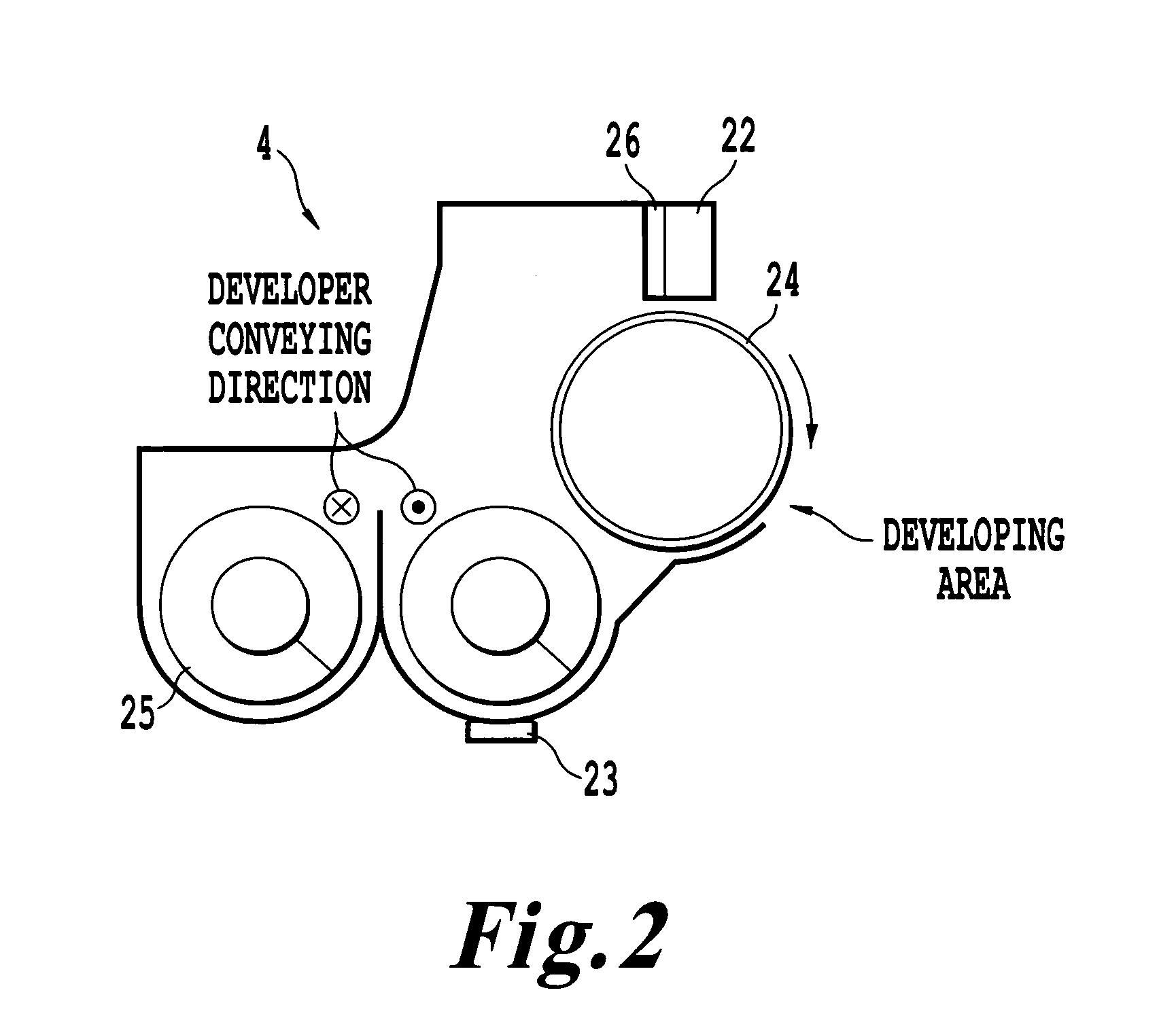

Image forming apparatus and associated method of detecting developer deterioration

InactiveUS7151901B2Accurate measurementMaintain image qualityElectrographic process apparatusCorona dischargeMeasurement deviceDeterioration rate

An image forming apparatus including a latent carrier and a charging device. The charging device is configured to charge a surface of the latent carrier. An exposure device is configured to expose a surface of the latent carrier for forming a latent image thereon. A transfer device is provided to transfer a developed toner image on the latent carrier to a recording medium. The image forming apparatus includes a developing device having a pooling portion configured to pool a two-component developer and an agitating device configured to agitate developer in the pool portion. A developer carrier replenishes developer to the latent carrier. A first measurement device and a second measurement device are configured to measure developer characteristics wherein the first and second measurement devices compare their respective outputs to measure a deterioration rate of the developer.

Owner:RICOH KK

Hydraulic fluid change indicating device for automatic transmission

InactiveUS7433770B2Improve detection accuracyImprove accuracyVehicle testingRegistering/indicating working of vehiclesAutomatic transmissionDeterioration rate

A hydraulic fluid change indicating device for an automatic transmission includes a first deterioration rate calculating unit; a deterioration acceleration coefficient calculating unit; and a thermal hydraulic fluid deterioration calculating unit for calculating a thermal hydraulic fluid deterioration according to the first deterioration rate and the deterioration acceleration coefficient. The device further includes a second deterioration rate calculating unit according to an engine speed, input shaft speed, and output shaft speed; a mechanical hydraulic fluid deterioration calculating unit for calculating a mechanical fluid deterioration according to the second deterioration rate; and a determining unit for determining whether or not the thermal hydraulic fluid deterioration or the mechanical hydraulic fluid deterioration is greater than a predetermined hydraulic fluid change threshold.

Owner:HONDA MOTOR CO LTD

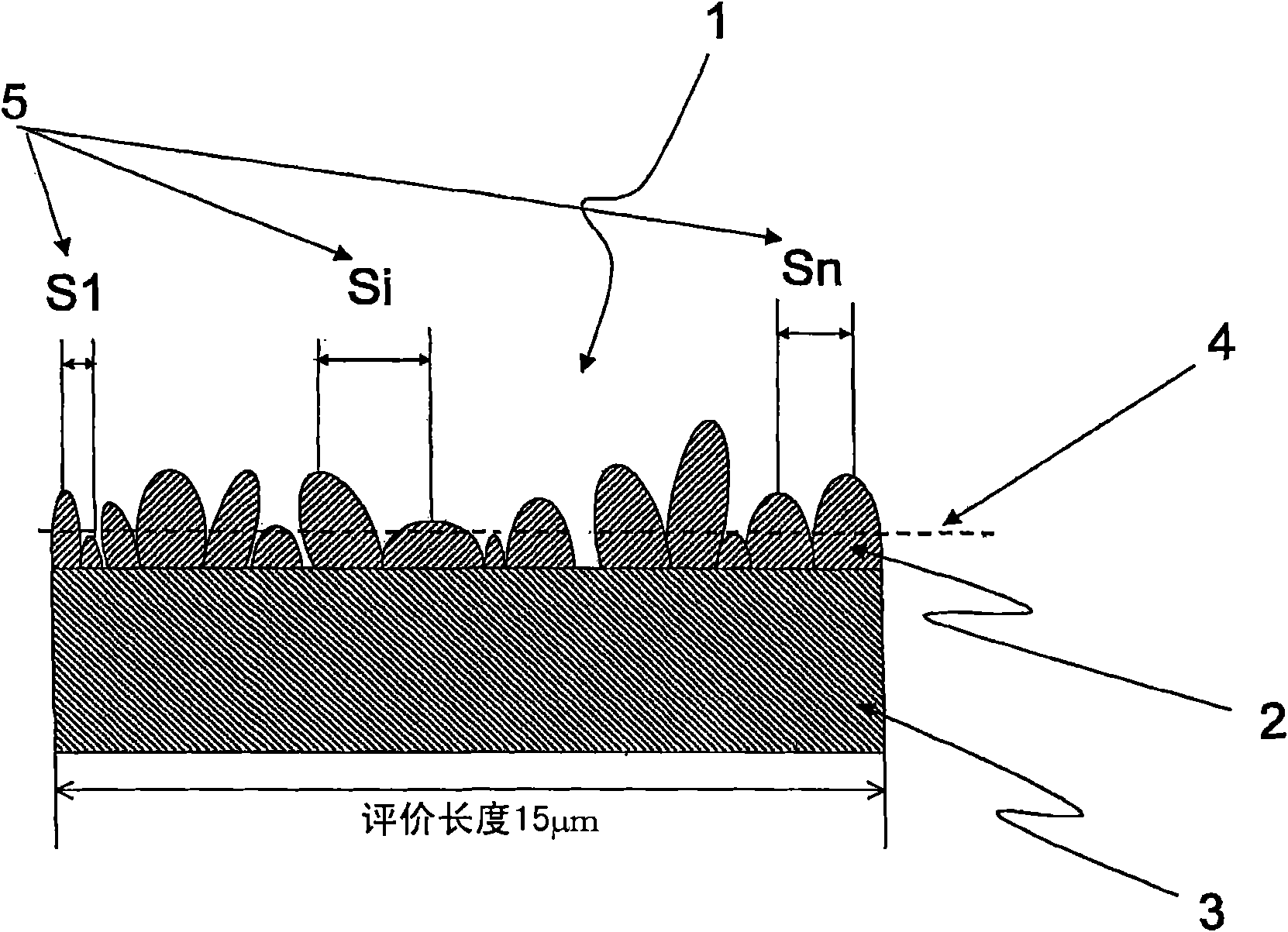

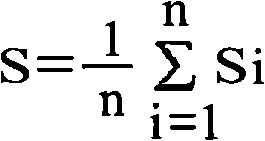

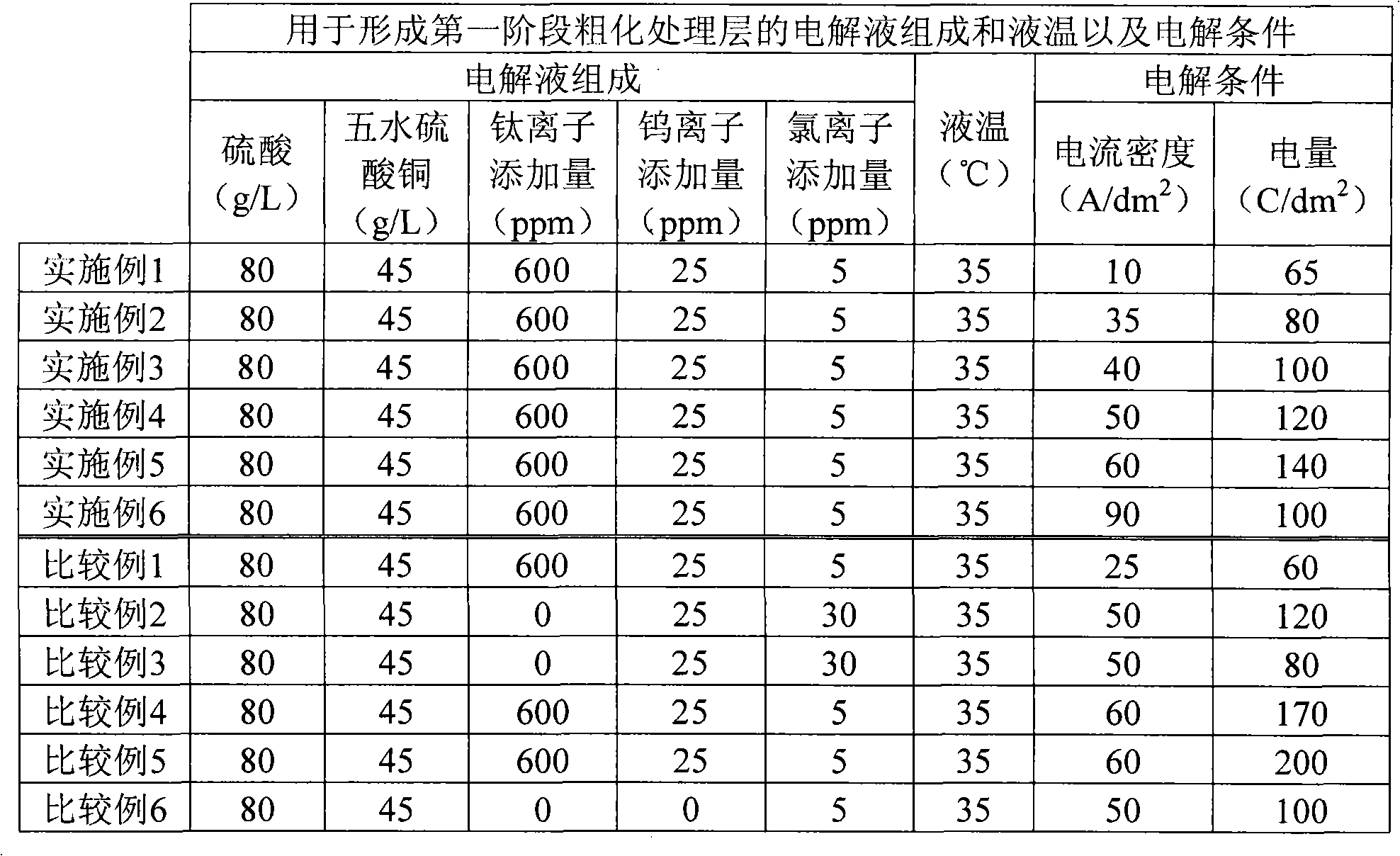

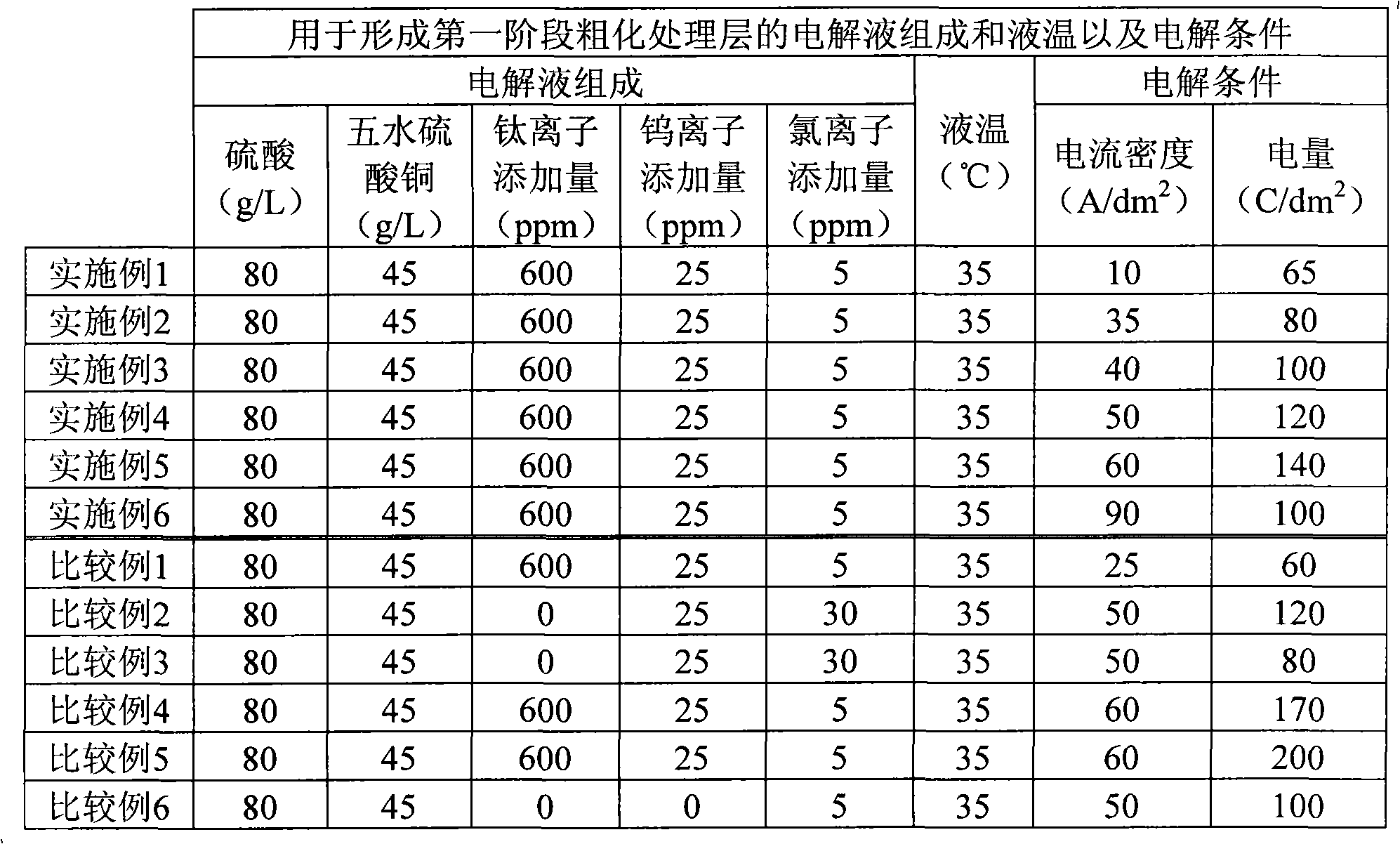

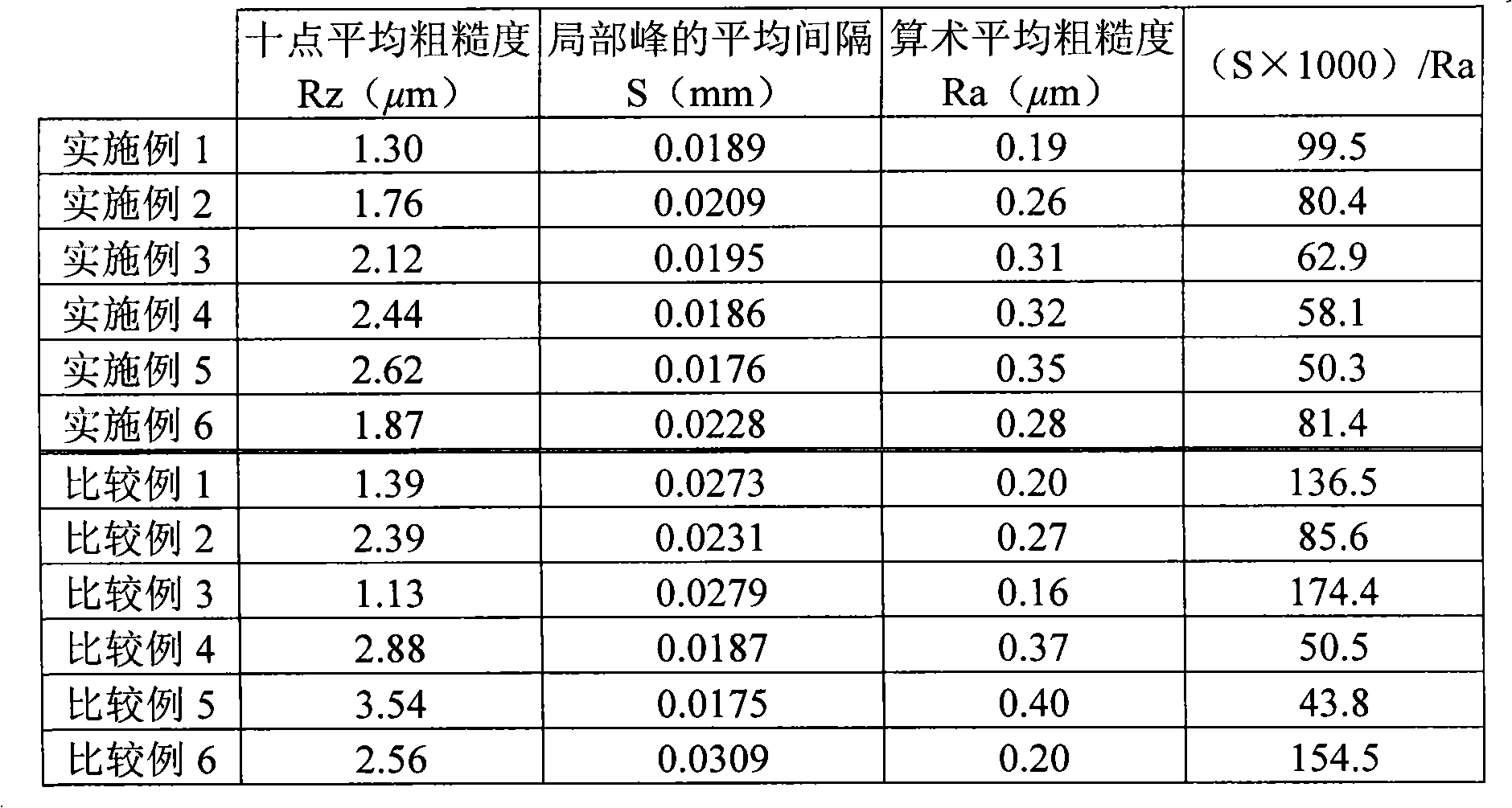

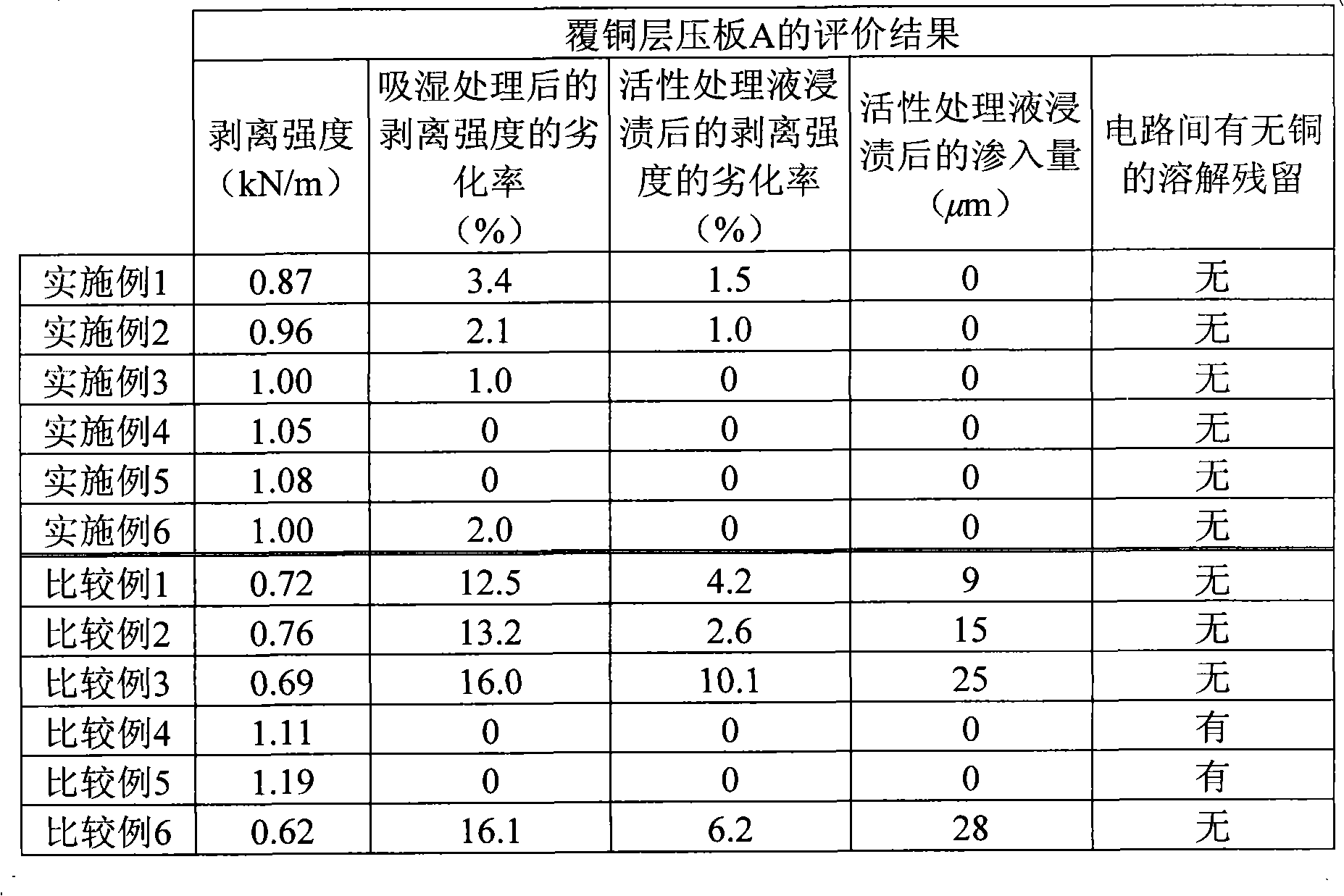

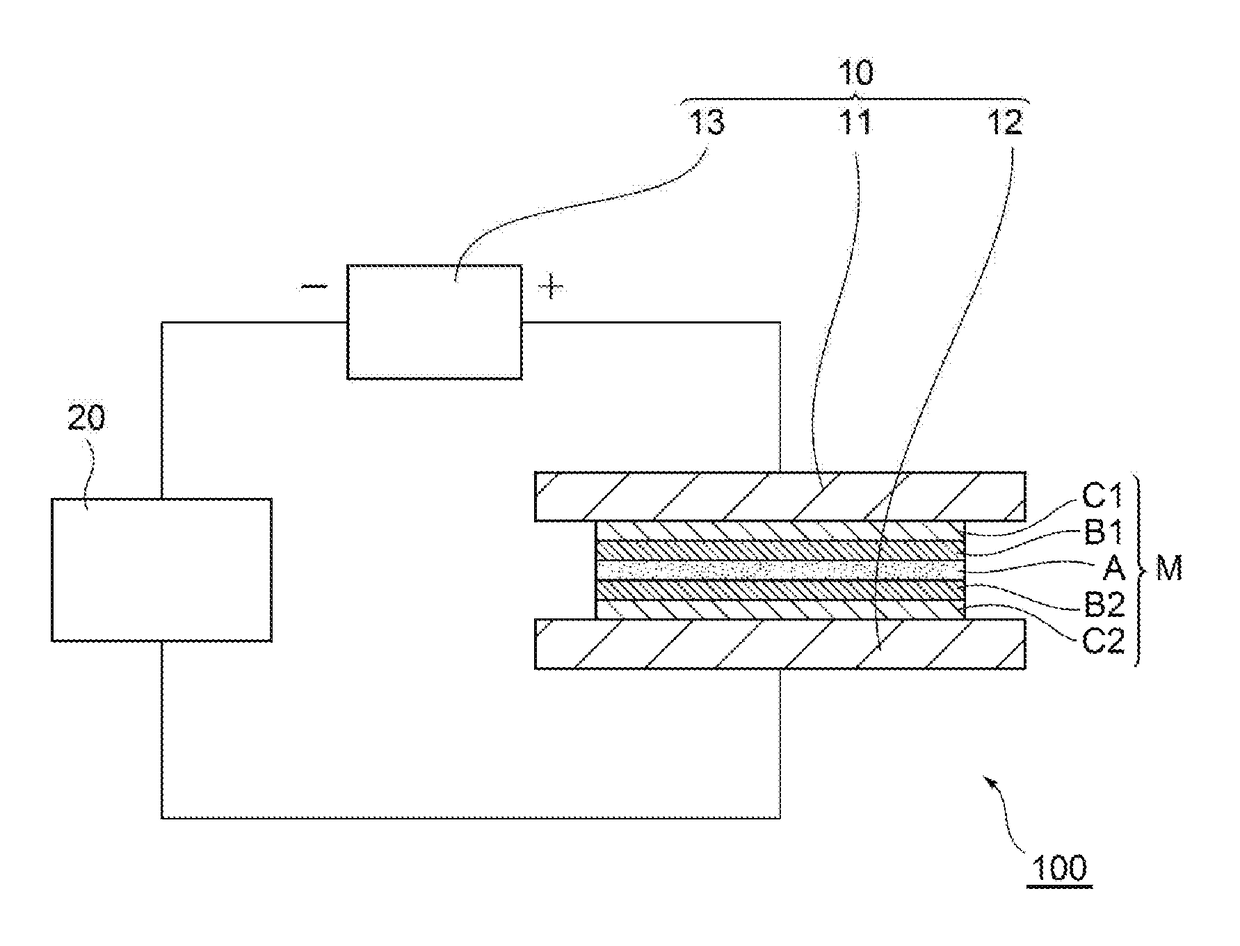

Copper foil for processing copper clad laminate, copper clad laminate and printed wiring board equipped with copper clad laminate

ActiveCN102215635AReduce deterioration rateImprove etching effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentDeterioration rateSilanes

The invention provides a treatment copper foil, which is low in roughness and high in peeling strength with an insulating resin substrate. After an absorption treatment, an active processing liquid after being impregnated is low in deterioration rate of the peeling strength, less in penetration amount and excellent in etching property. The copper foil is characterized in that the surface of the copper foil is sequentially equipped with a roughening treatment layer, a chromate layer and a silane coupling agent layer. The ten-point average roughness Rz of the copper foil surface is 1.0 mu m to 2.7 mu m. When the surface of the copper coil with the area thereof 177 mu M2 is measured by purple laser of visible light with the wavelength thereof 408 nm, the average interval S of local peaks is below 0.0230 mm and S does not include 0.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

Copper foil for processing copper clad laminate, copper clad laminate and printed wiring board equipped with copper clad laminate

ActiveCN102215632AReduce deterioration rateImprove etching effectMetallic pattern materialsMetal layered productsDeterioration rateSilanes

The invention provides a treatment copper foil, which is low in roughness and high in peeling strength with an insulating resin substrate. After an absorption treatment, an active processing liquid after being impregnated is low in deterioration rate of the peeling strength, less in penetration amount and excellent in etching property. The copper foil is characterized in that the surface of the copper foil is sequentially equipped with a roughening treatment layer, a chromate layer and a silane coupling agent layer. The ten-point average roughness Rz of the copper foil surface is 1.0 mu m to 2.7 mu m. Meanwhile, the average interval S of local peaks is below 0.0230 mm and S does not include 0.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

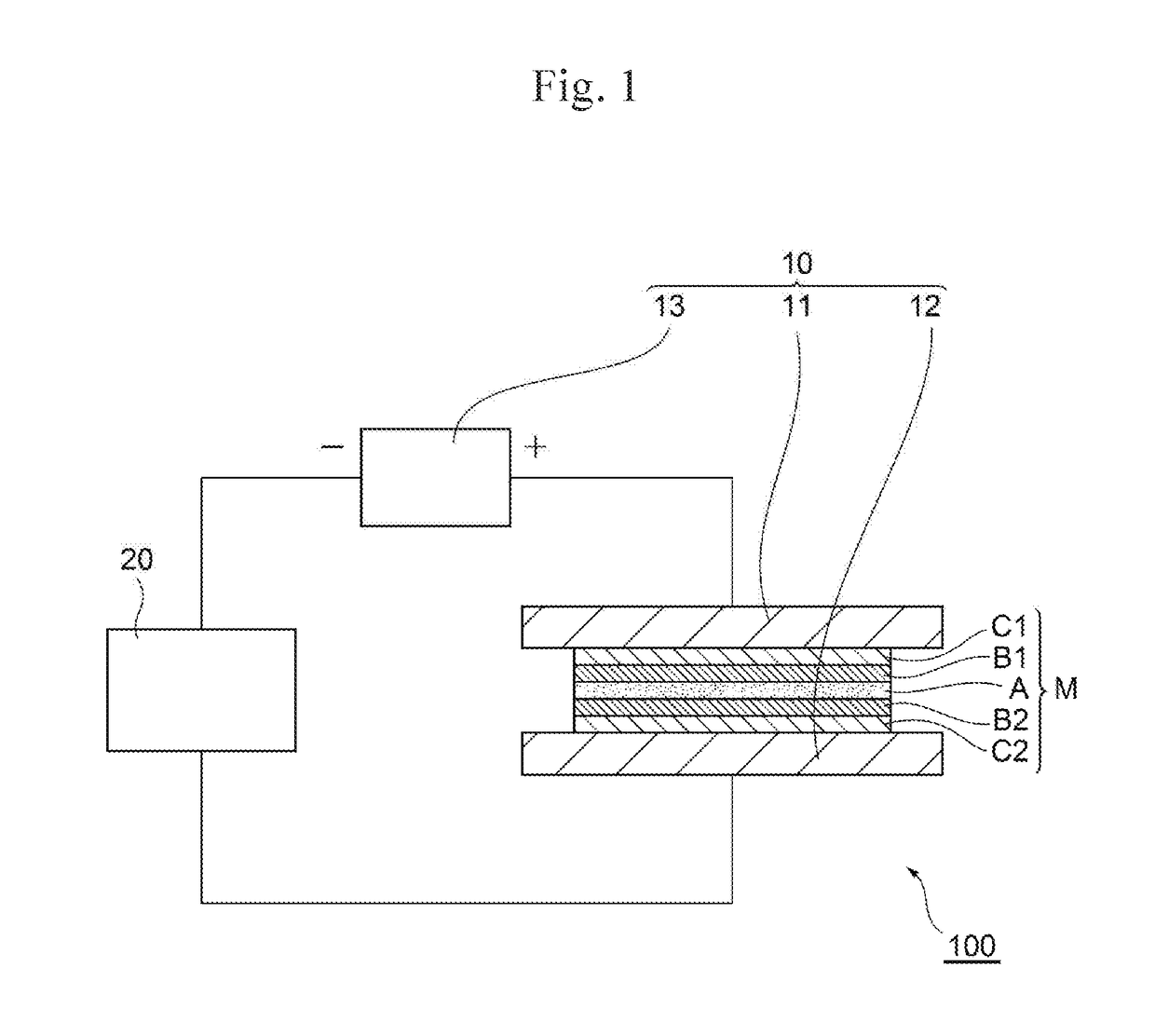

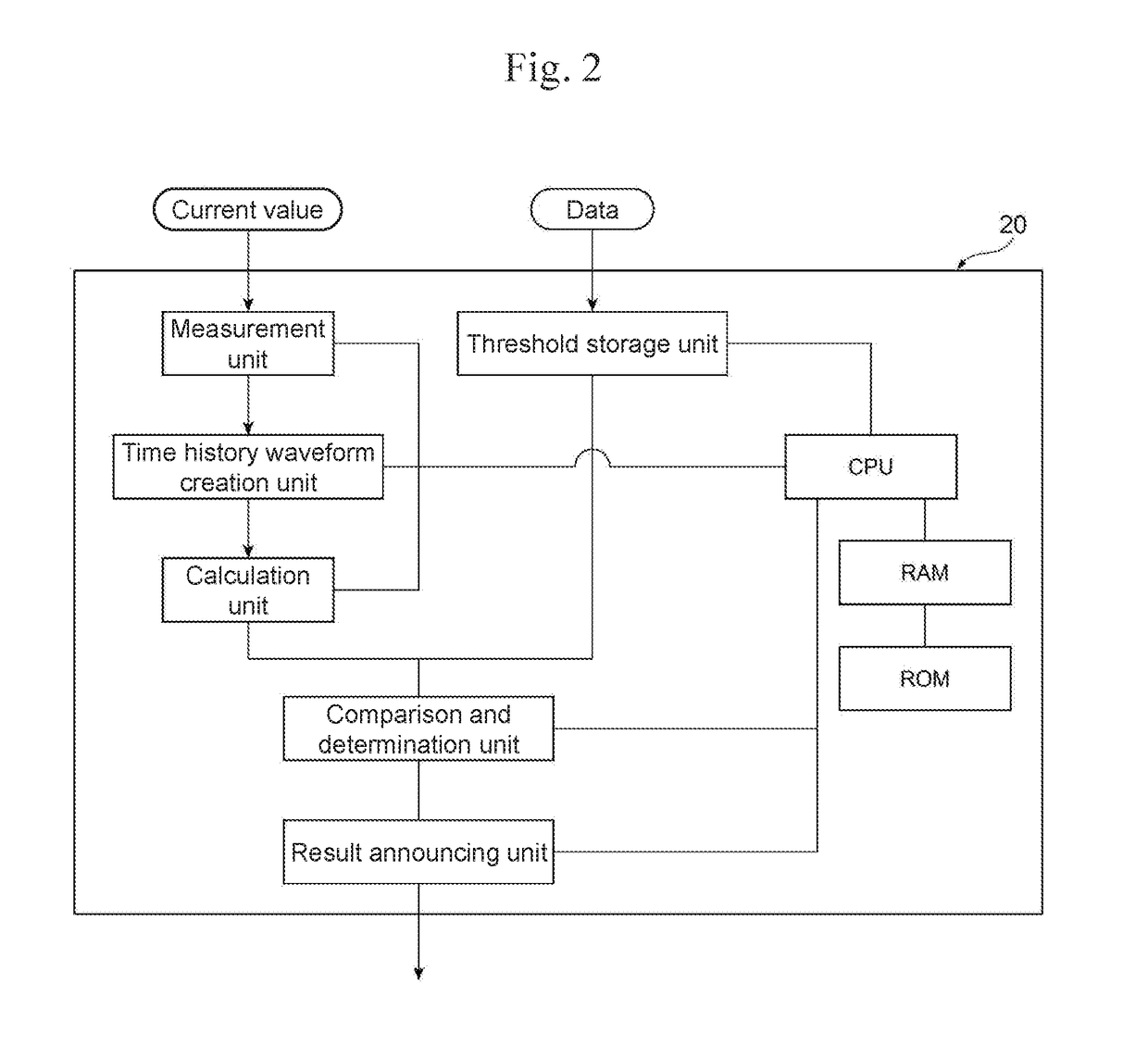

Inspection apparatus and inspection method for membrane electrode assembly

ActiveUS20180292464A1Prevent degradationAvoid loopsElectrical testingFuel cellsDeterioration rateFuel cells

Provided are an inspection apparatus and method capable of accurately detecting a defective membrane electrode assembly based on the rate of deterioration of carbon forming an electrode catalyst layer or the like of the assembly. The apparatus is an inspection apparatus for a membrane electrode assembly including an electrolyte membrane and anode-side and cathode-side electrode catalyst layers made of carbon materials to form a fuel cell, the apparatus including a voltage application unit that applies voltage to the assembly; and a measurement and operation determination unit that measures a time history waveform of current that flows upon application of the voltage for an inspection time and calculates the time integral value of current for the inspection time, and compares the time integral value of current with a threshold of the time integral value of current preset based on a predetermined carbon deterioration rate so as to determine the assembly to be defective if the time integral value of current is greater than the threshold.

Owner:TOYOTA JIDOSHA KK

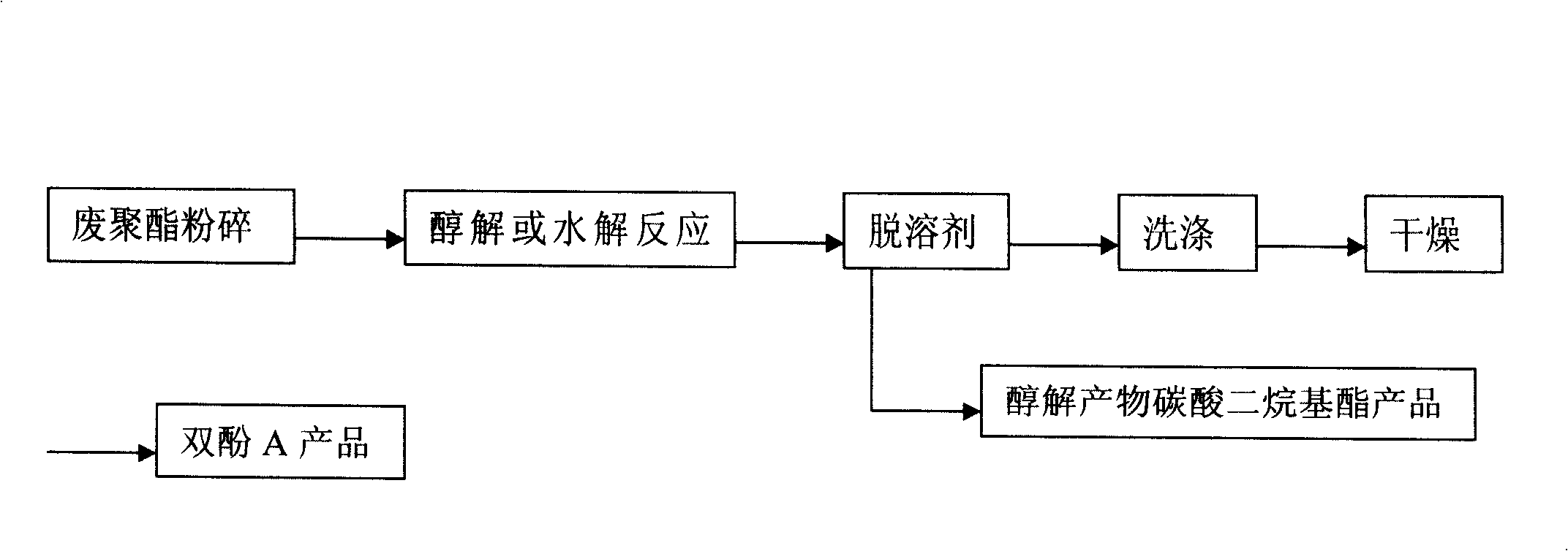

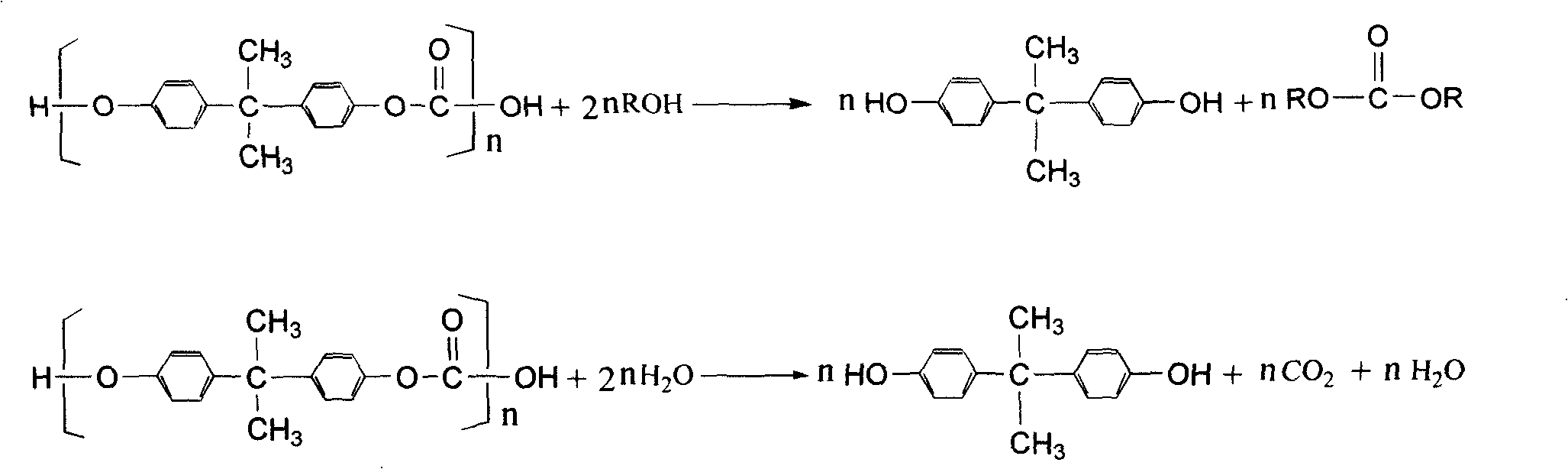

Chemical recovery method for waste polycarbonate material

InactiveCN101407450AMild reaction conditionsQuick responseOrganic compound preparationChemical recyclingDeterioration rateMethyl carbonate

The invention relates to a new method for generating bisphenol A and dimethyl carbonate by solvent waste polycarbonate and chemical degradation waste polycarbonate material under a moderate condition to realize recycling of waste polycarbonate material. The method is characterized in that tetrahydrofuran, drewamine, N-methyl-pyrrolidone, 1, 2-dichloroethane, N, N-dimethyl formamide, diethylamine, ethylene dimine or composite material thereof which are easy to be recycled are used as reaction media, and with the presence of catalysts of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, lithium hydroxide or composite material thereof, and the like, an alcoholysis reaction is carried out under a normal pressure or a high pressure and at reaction temperature of 20 DEG C-80 DEG C; and a hydrolysis reaction is carried out at reaction temperature of 50 DEG C-160 DEG C. After the reactions, product bisphenol A is obtained (alkyl dimethyl easter product is also obtained in the alcoholysis reaction) after operation processes of solvent removing, washing, drying, and the like are carried out to the reaction liquid. The deterioration rate is over 98 percent. Compared with the traditional methods, the new method for generating bisphenol A and dimethyl carbonate by solvent waste polycarbonate and chemical degradation waste polycarbonate material under a moderate condition to realize recycling of waste polycarbonate material is characterized in that: (1) the reaction conditions are moderate; the reaction speed is high; and the operation is easy and simple; and (2) the problems of long reaction time period and strict requirements for equipment condition existing in the background technology, and the like, are overcome.

Owner:QINGDAO UNIV OF SCI & TECH

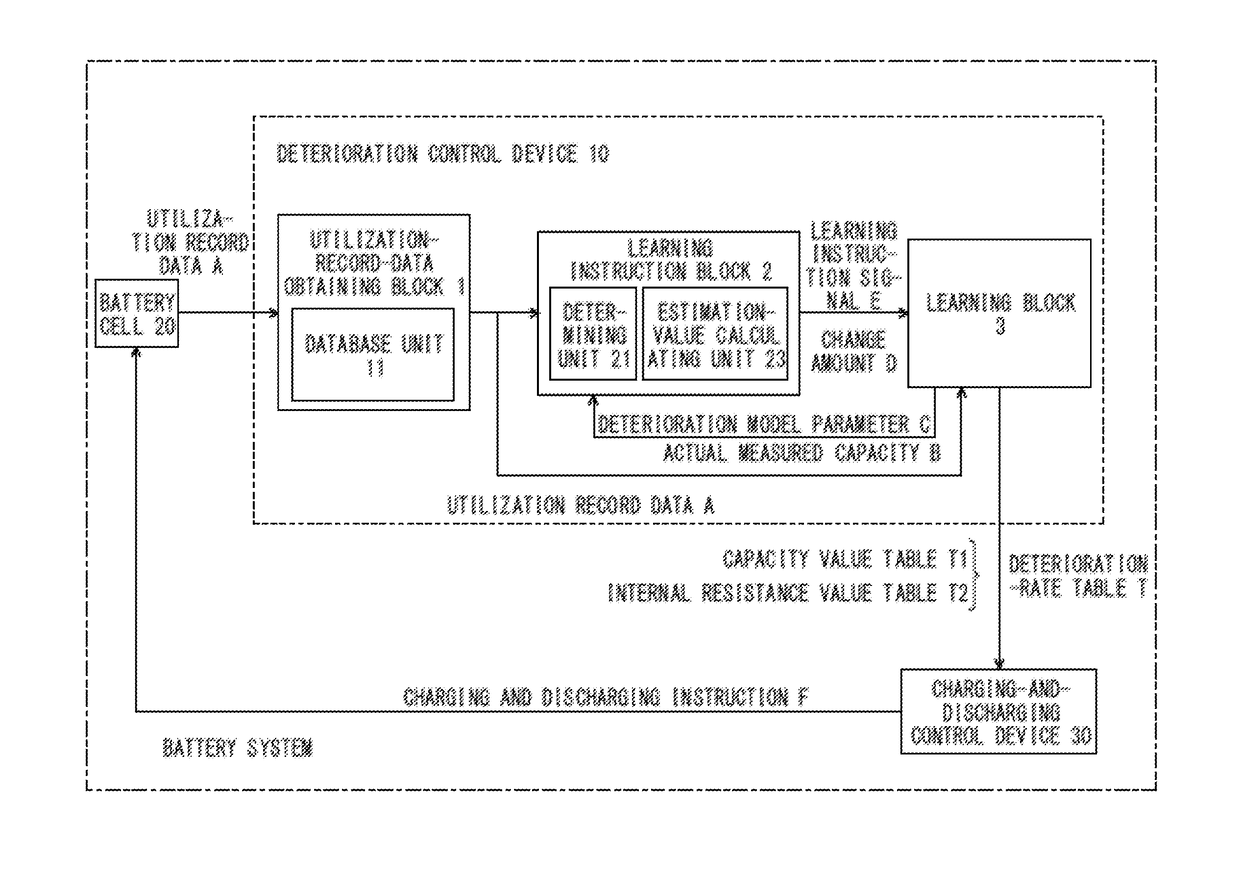

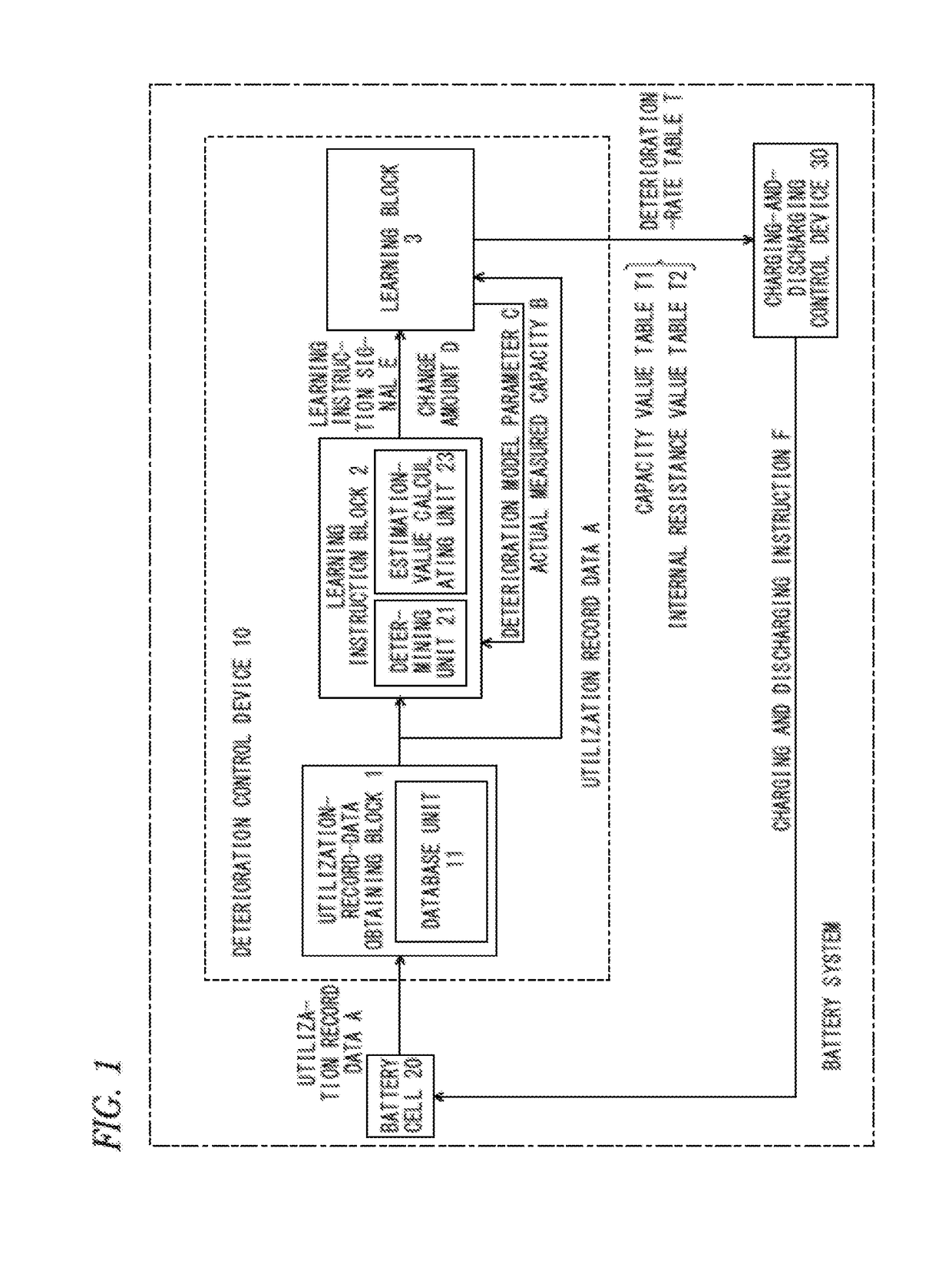

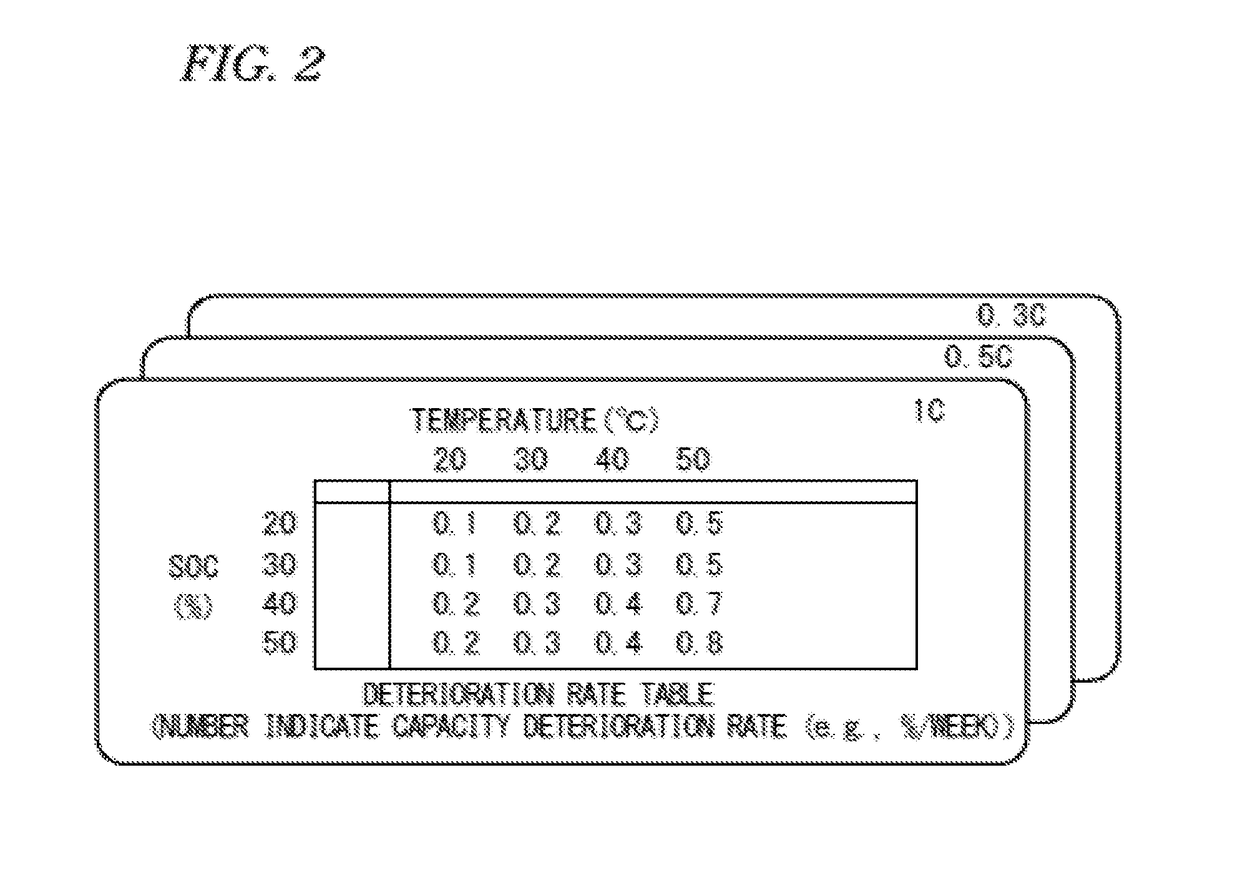

Battery-system-deterioration control device, and method thereof

InactiveUS20170294689A1Eliminate the effects ofHighly precise deterioration modelCircuit monitoring/indicationElectrical testingLearning unitDeterioration rate

A battery-system deterioration control device compatible to diversification of applications by appropriately learning a necessary deterioration model for a deterioration control. The battery-system deterioration control device includes a utilization-record-data obtaining block, a learning instruction block, and a learning block. The utilization-record-data obtaining block obtains utilization record data of a battery cell. The learning block updates a data amount of a deterioration model parameter indicating the deterioration state of the battery cell based on the utilization record data, learns the deterioration model parameter, and outputs the learnt result that is a deterioration rate table. The learning instruction block compares the utilization record data and the data amount that is the estimation value, determines the necessity of learning of the deterioration model parameter, and outputs a learning instruction signal to the learning unit.

Owner:KK TOSHIBA

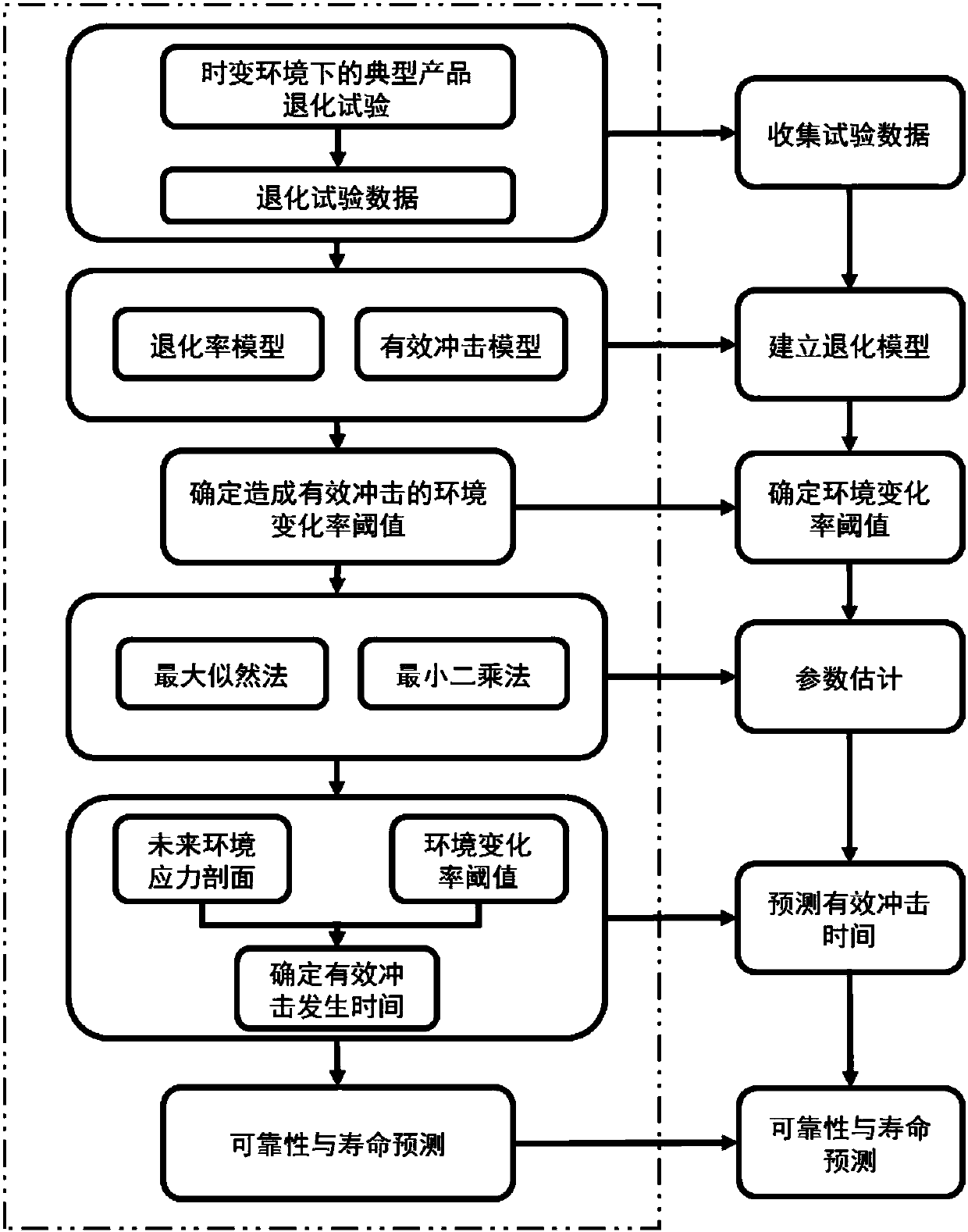

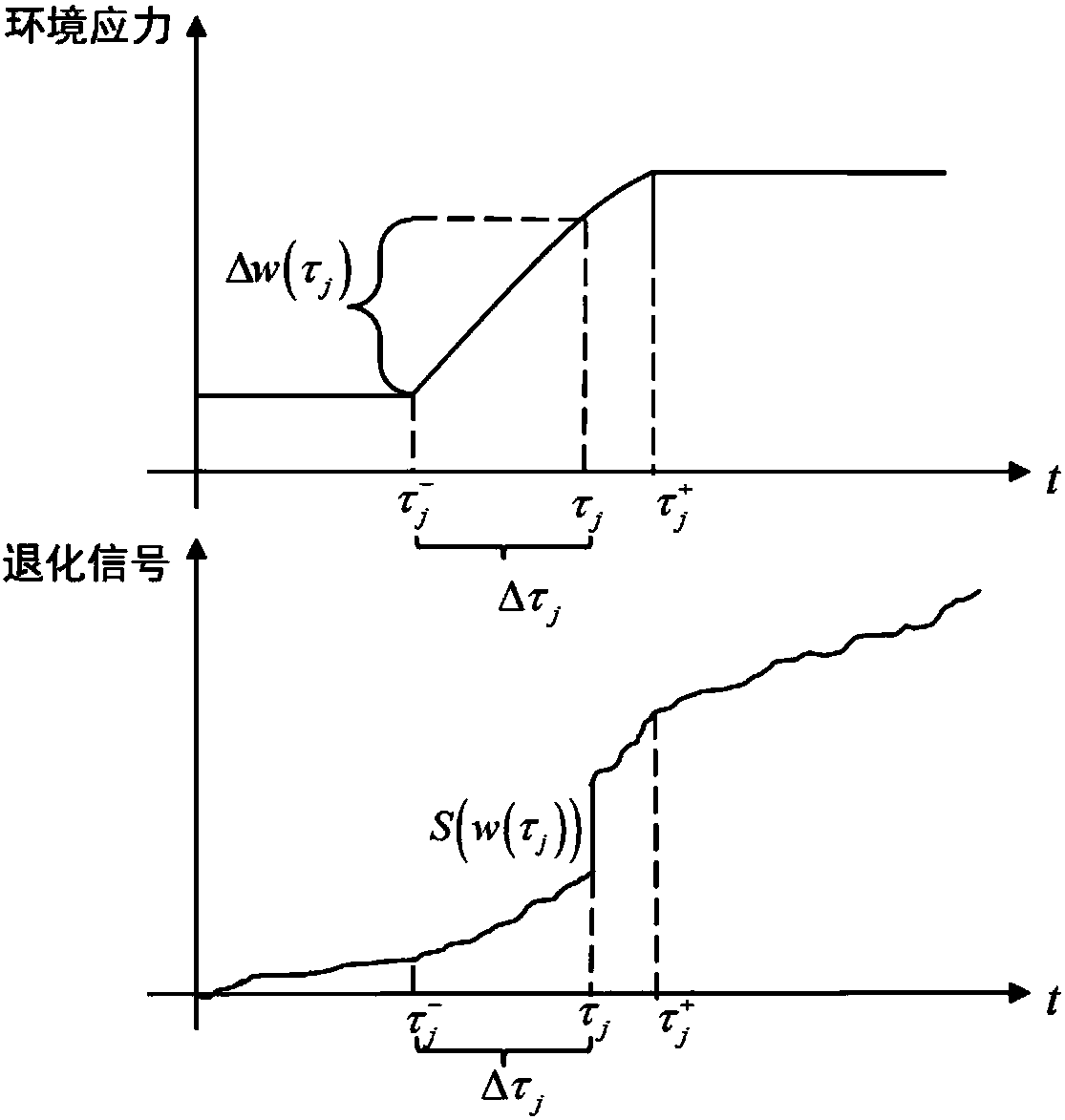

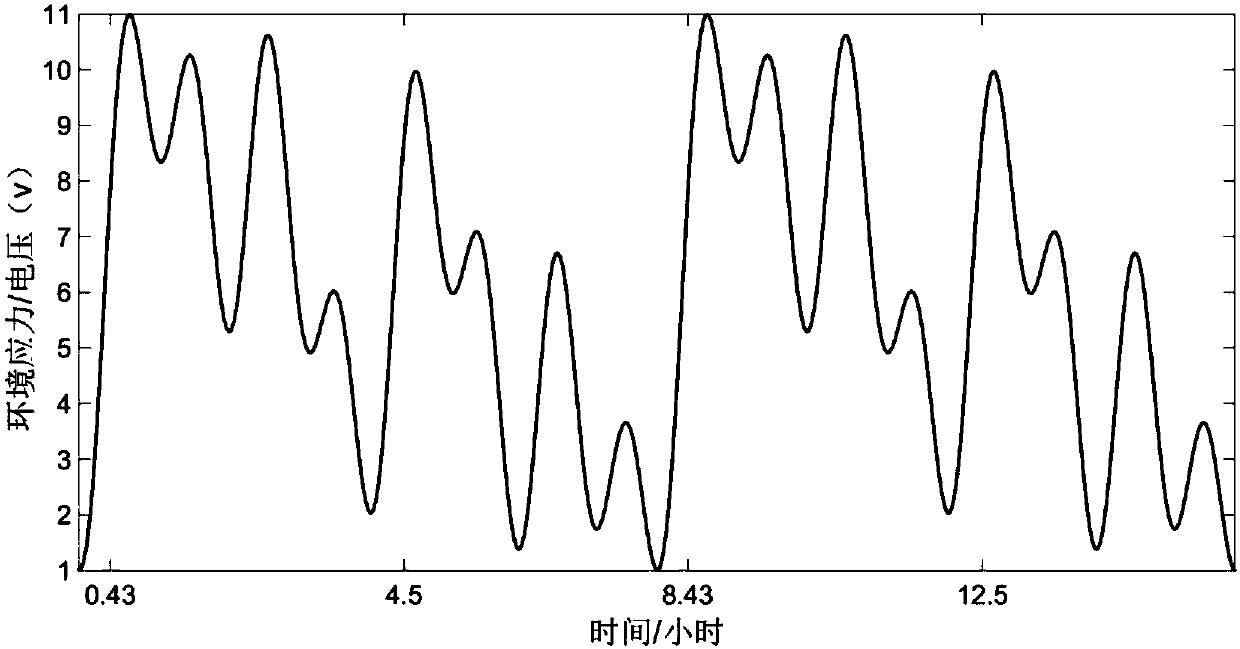

Degradation modeling and life prediction method considering effective impact

ActiveCN108959676AThe prediction method is in line with realityImprove forecast accuracyMathematical modelsDesign optimisation/simulationDeterioration rateSimulation

The invention provides a degradation modeling and life prediction method considering an effective impact. Firstly, test data are collected, and then a performance index degradation model is built; anenvironmental change rate threshold of a product subjected to the effective impact of an environment load is determined according to the test data, and unknown parameters in the model are estimated; and finally, the time of occurrence of the effective impact is determined and then life and reliability prediction is performed. The method comprises the following specific steps: step 1, collecting the test data; step 2, building the degradation model; step 3, determining the environmental change rate threshold; step 4, estimating parameters to be estimated; step 5, predicting the time of occurrence of the effective impact; and step 6, performing reliability prediction and verification. According to the method provided by the invention, the influence of changes of environment and load on product performance degradation is considered, namely, the performance degradation rate and the effective impact on a degradation index are considered at the same time, so that the prediction method can better meet the actual requirements and the prediction accuracy is improved.

Owner:天航长鹰(江苏)科技有限公司

System and method for estimating turbine engine deterioration rate with noisy data

A method for monitoring engine performance includes sampling exhaust gas temperature associated with a turbine engine over an interval of operational time of the turbine engine. The method further includes applying a first test to identify statistical outliers on the sampled exhaust gas temperature data and removing identified statistical outliers from the sampled exhaust gas temperature data. Subsequently, the method includes applying a second test to identify step changes in slope of the exhaust gas temperature data and dividing the interval of operational time into one or more segments based upon the identified step changes. Finally, the method includes determining a slope for each segment and combining the segments to obtain a rate of performance deterioration of the turbine engine.

Owner:GENERAL ELECTRIC CO

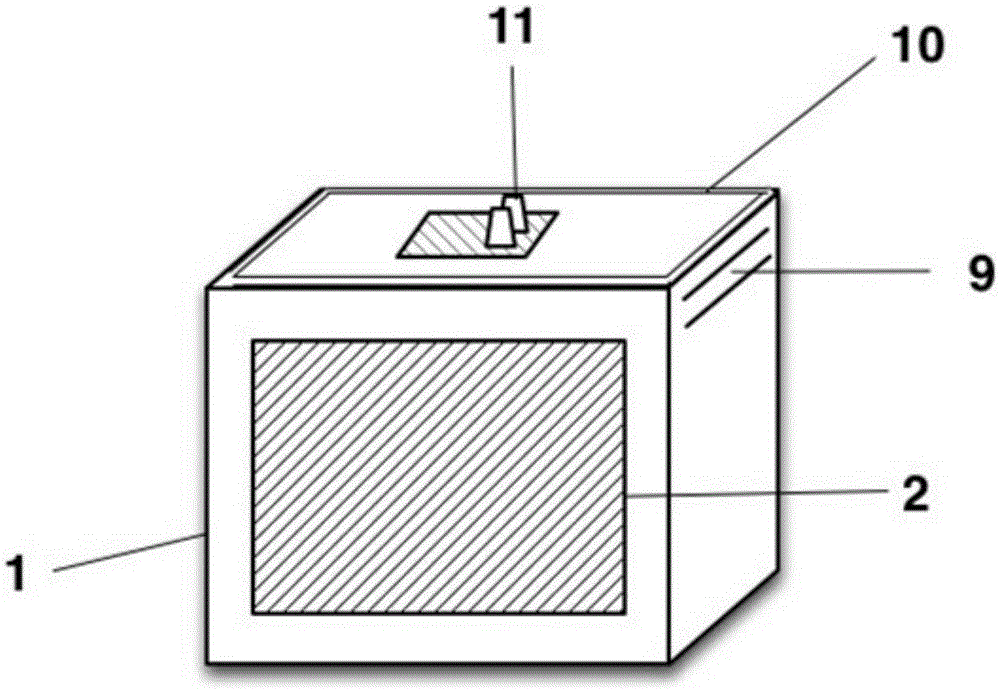

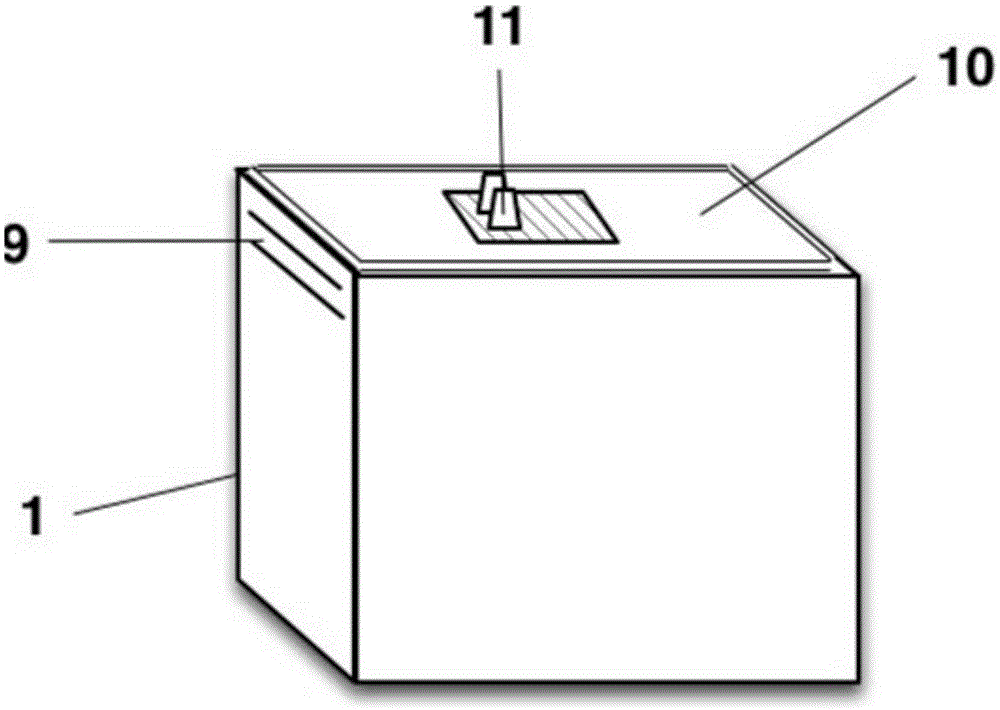

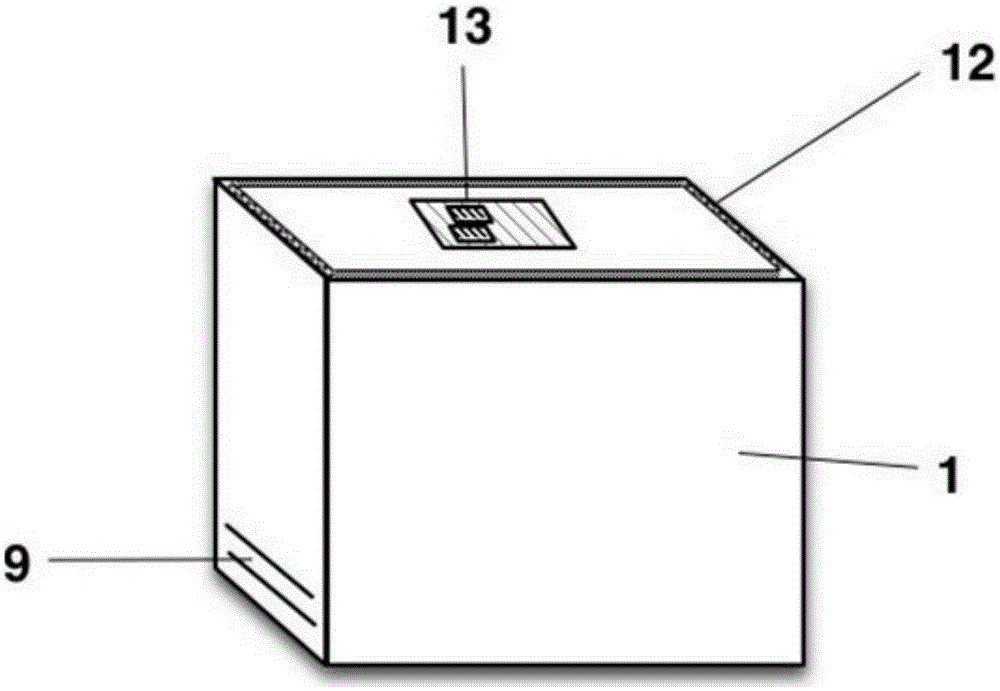

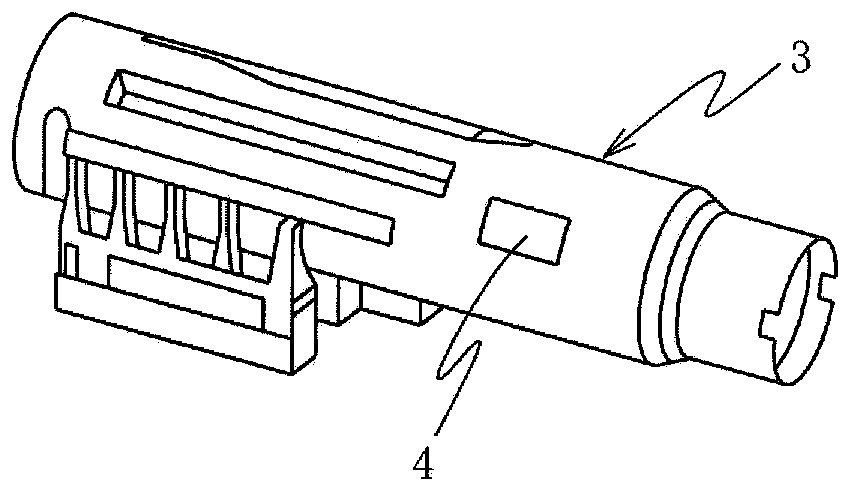

Intelligent interaction turnover box

InactiveCN105383774AReduce loss rateImprove qualityInternal fittingsLocking devicesLogistics managementDeterioration rate

The invention provides an intelligent interaction turnover box. A box body is divided into a box body cover and a box body container. One ends of the box body cover and the box body container are connection ends. The other ends of the box body cover and the box body container are free ends. The box body cover and the box body container are connected through pin shafts at the connection ends to open and close the box body. The free ends of the box body cover and the box body container are provided with a two-dimension code lock and a sealing line. The box body cover and the box body container of the box body are locked through the two-dimension code lock. An internal support is fixed to the middle of the box body container of the box body. A commodity fixing and adjusting support is connected with the internal support through a spring. By means of the intelligent interaction turnover box, the deterioration rate of goods in the transport process can be lowered effectively, and logistics transport service quality is improved; and a vibration inductor induces the vibration magnitude of the goods in the logistics process to confirm whether the commodities are stressed or not.

Owner:张盛毅

Battery pack, electronic device and method for detecting remaining quantity in battery

InactiveCN101322280AAccurate detectionCircuit monitoring/indicationCurrent/voltage measurementDeterioration rateCharge current

A battery pack is provided with a charging / discharging count measuring section (131) for measuring the charging / discharging count of a secondary battery, based on an integration value of a charging current to the secondary battery; and a deterioration rate outputting section (132) for calculating a deterioration rate indicating the degree of deterioration of the secondary battery, based on the charging / discharging count measured by the charging / discharging count measuring section (131), and outputs the results to a discharge load device. The charging / discharging count measuring section (131) repeatedly integrates the detection value of the charging current up to a prescribed threshold value, for instance, and counts up the charging / discharging count each time the integration value reachesthe threshold value. Thus, even when charging and discharging are repeated many times within a relatively small voltage range, the number of charging / discharging can be accurately counted, and calculation accuracy of the deterioration rate is improved. In the battery pack containing the secondary battery, parameters for detecting the remaining quantity in the battery are accurately detected.

Owner:SONY GROUP CORP

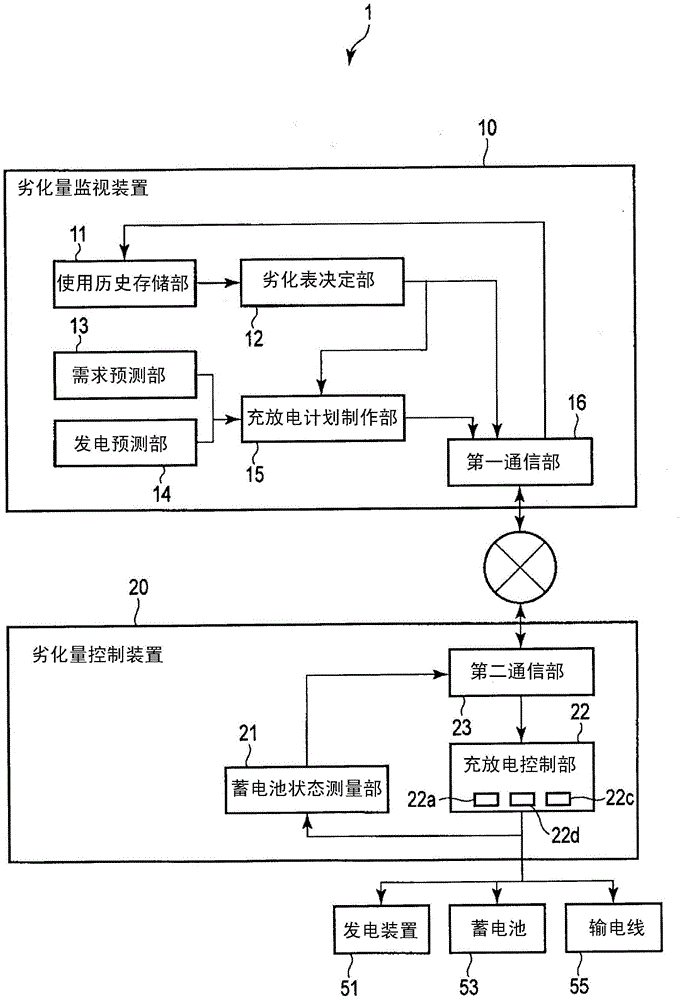

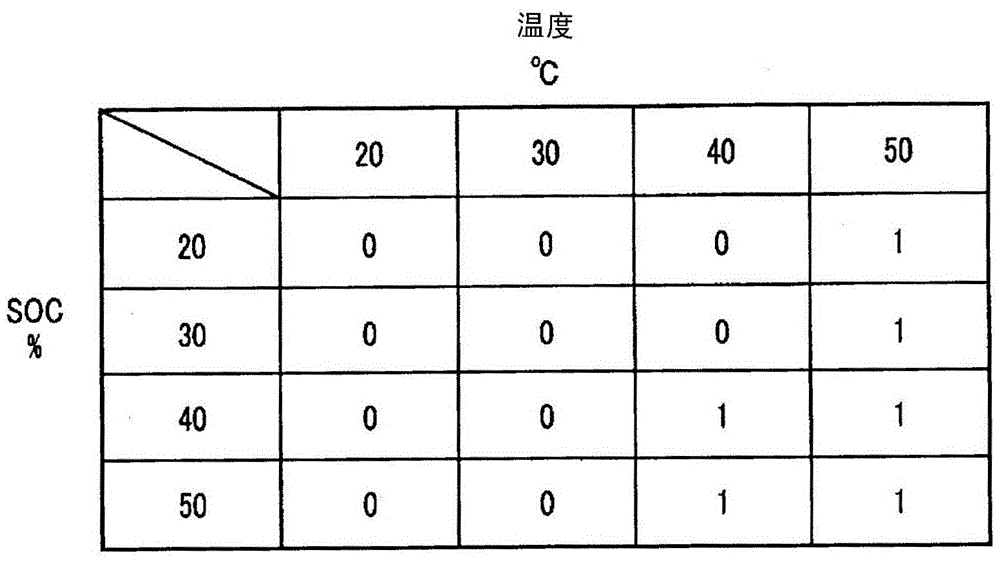

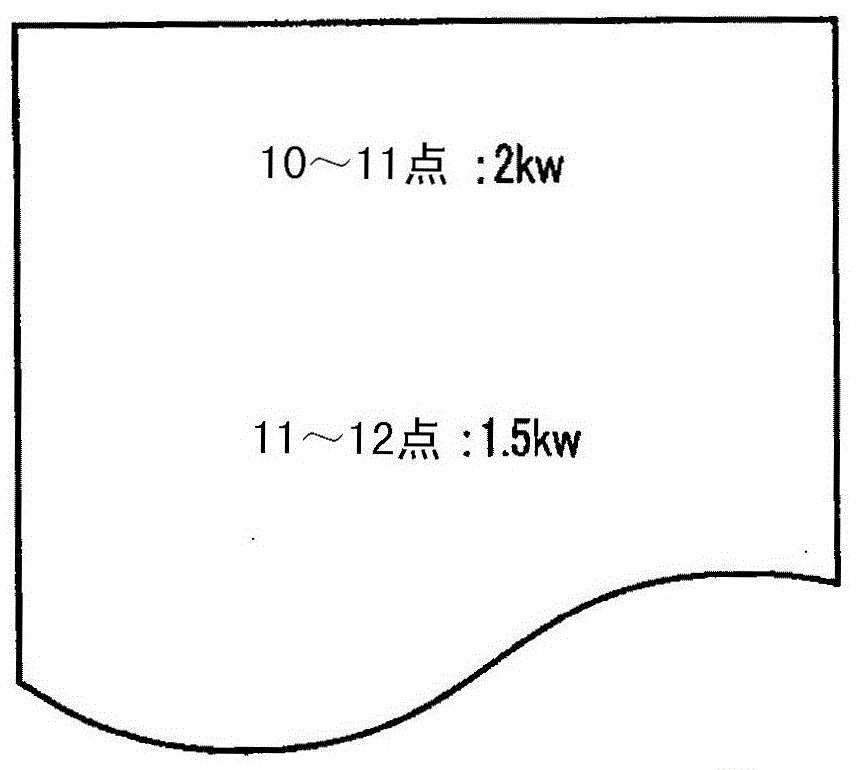

Monitoring device, control device and control system

Provided are a monitoring device, a control device and a control system with which charging / discharging of a storage battery can be effectively controlled. A monitoring device according to an embodiment of the present invention includes a use history accumulation unit, a demand prediction generation unit, a power generation prediction unit, a deterioration table determination unit, a charging / discharging plan creation unit and a transmission unit. The use history accumulation unit receives at least storage battery state information from the control device that controls a power generation device and a storage battery, and generates and then stores the use history of the storage battery. The demand prediction generation unit generates a demand prediction for power consumption of a power consumption unit to which supply of power is controlled by the control device. The power generation prediction unit generates a power generation prediction for the power generation device. The deterioration table determination unit determines a deterioration table that indicates a deterioration rate of the storage battery from the use history. The charging / discharging plan creation unit creates a charging / discharging plan for the storage battery on the basis of the deterioration table, the demand prediction and the power generation prediction. The transmission unit transmits to the control device the demand prediction, the power generation prediction, the charging / discharging plan and the deterioration table which is for controlling charging / discharging of the storage battery.

Owner:KK TOSHIBA

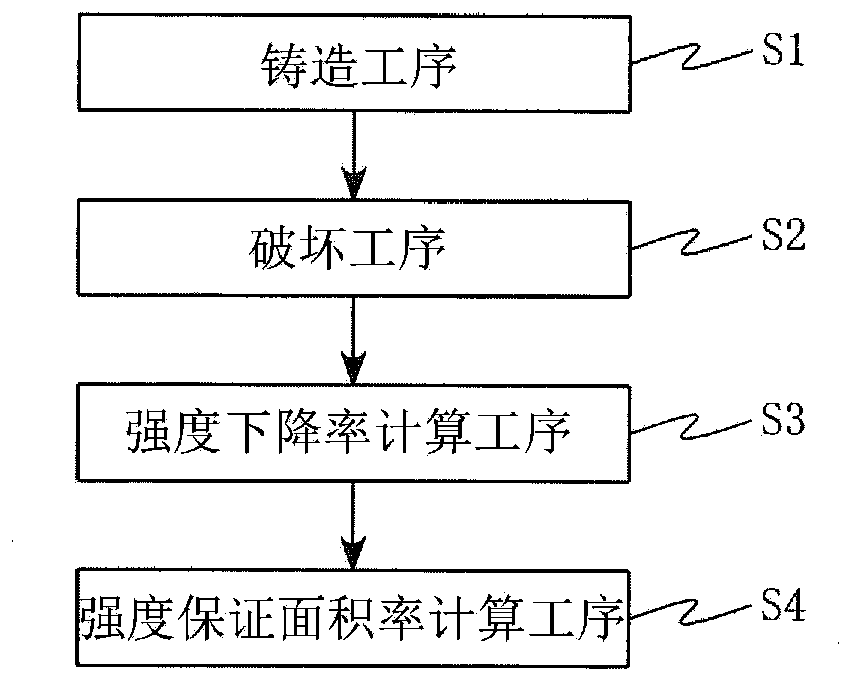

Die-cast product rigidity evaluation method and die-cast product

InactiveCN103635787AShorten working timeAccurate evaluationAnalysing solids using sonic/ultrasonic/infrasonic wavesBuilding locksDeterioration rateDie casting

Provided are a die-cast product rigidity evaluation method and a die-cast product, the rigidity whereof is evaluated by the rigidity evaluation method, with which it is possible to appropriately evaluate the rigidity of a die-cast product. To this end, after carrying out a post-casting fracture test with a simple rigidity testing device, a rigidity deterioration rate is estimated on the basis of the proportion at which cold flakes are present on the fracture surface, which is obtained by observing a breakage surface. An internal defect of a prescribed range of a high-stress part of a die-cast product which is pre-derived with a stress analysis is detected with ultrasound, and when a defect rate which is the quotient of the total surface area of the internal defects of the prescribed range divided by the total defect detection surface area is less than or equal to a prescribed value, the die-cast product is evaluated as having a prescribed rigidity.

Owner:NSK LTD

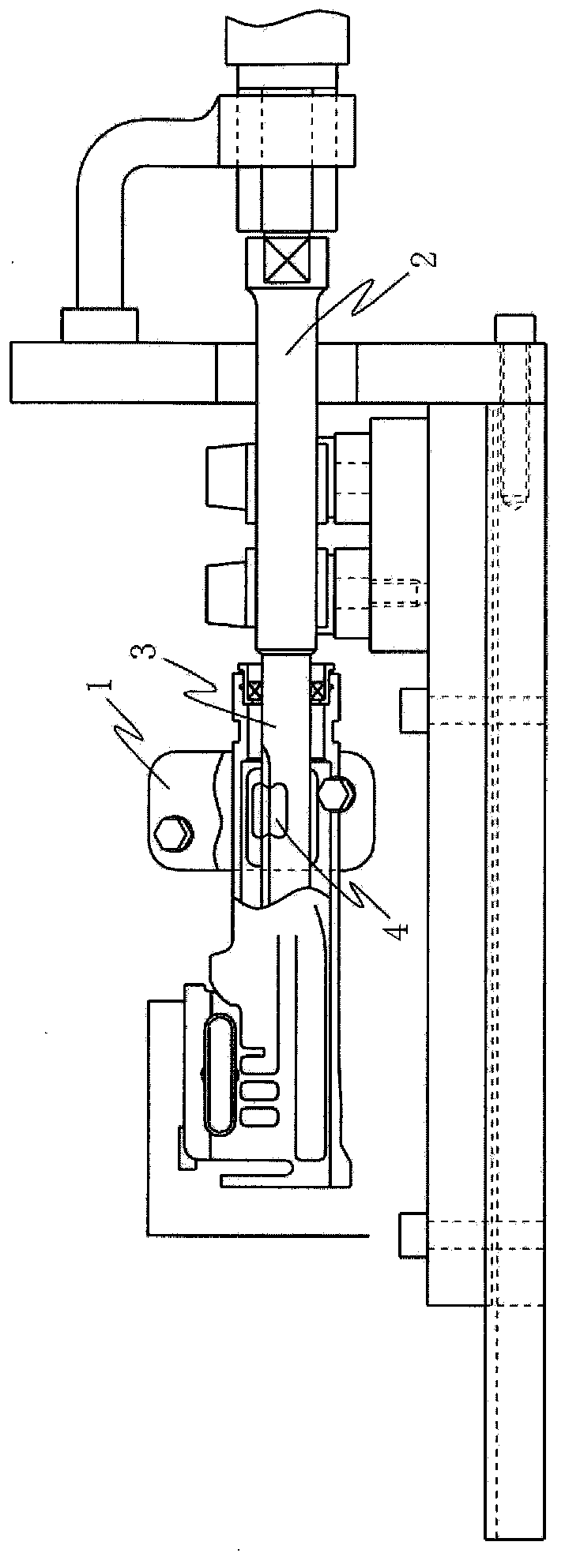

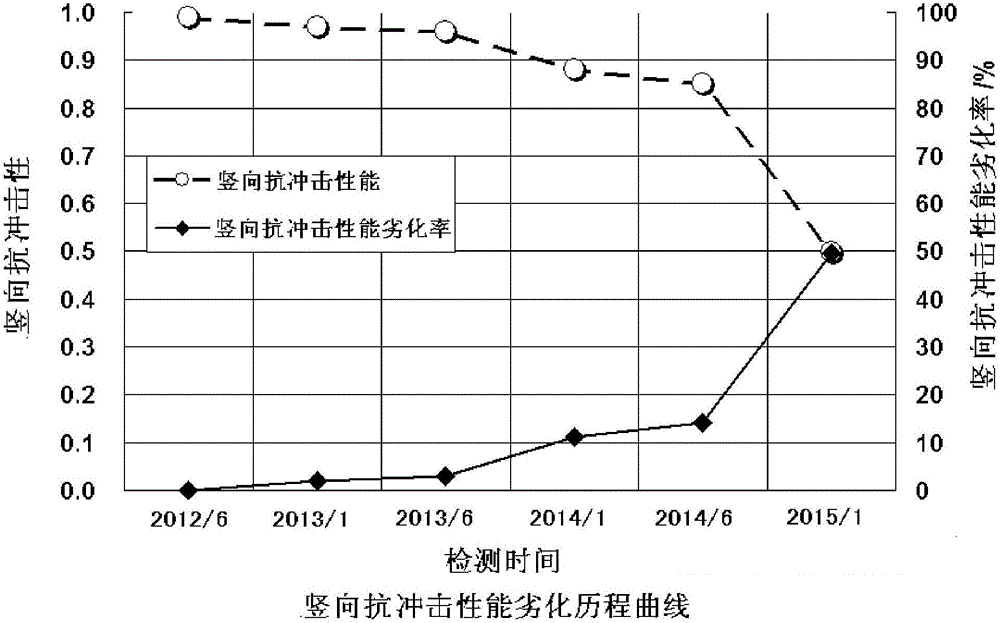

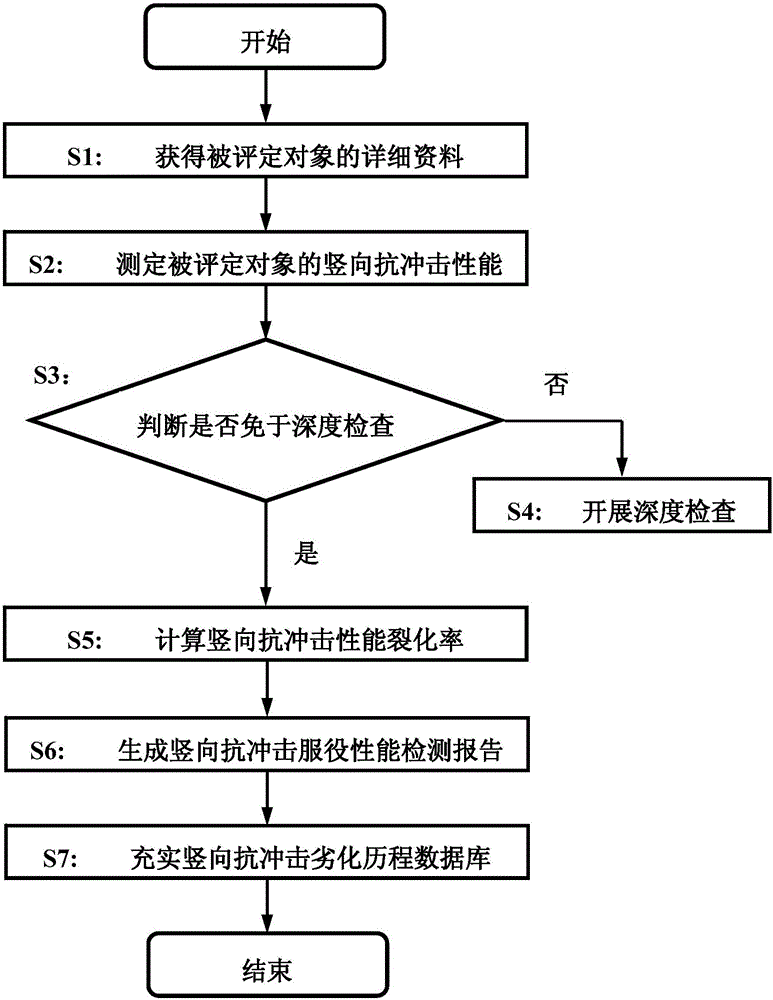

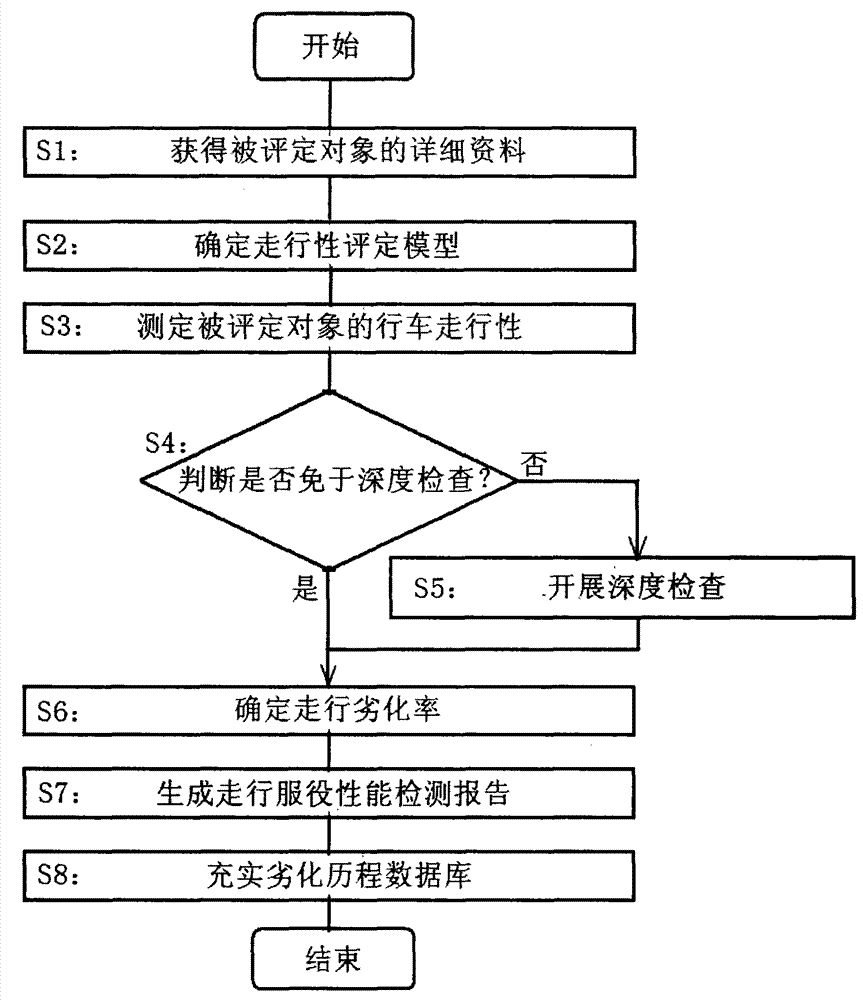

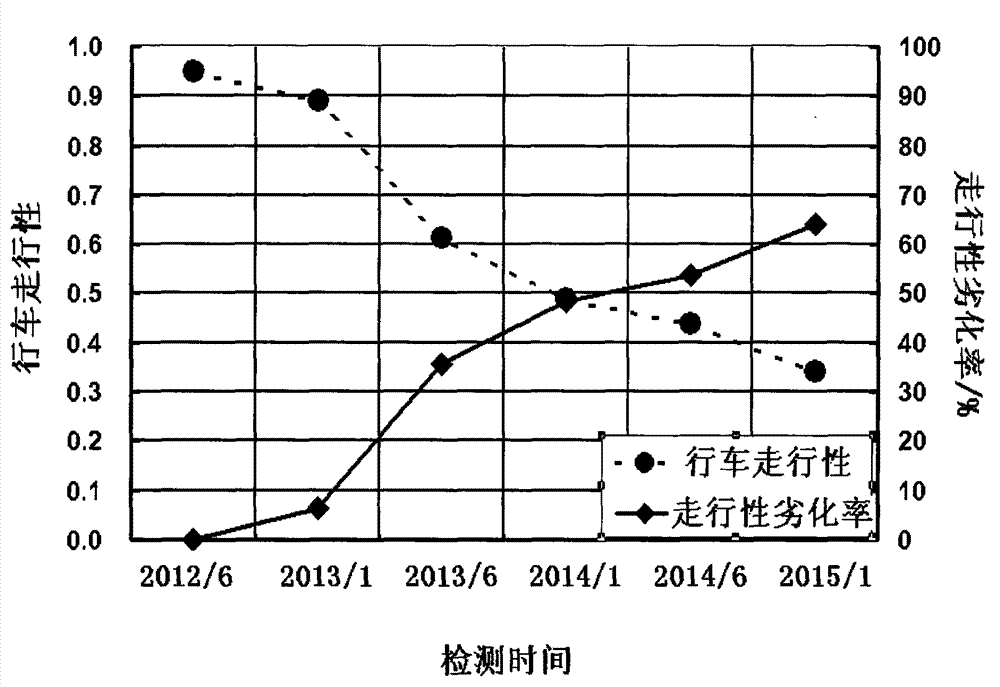

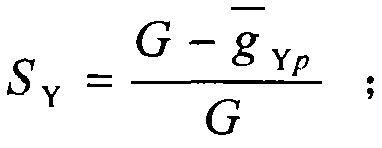

Method for evaluating longitudinal shock resistance of highway bridge support and stretching device

ActiveCN104991986AEasy to identifyImprove reliabilityBridge structural detailsSpecial data processing applicationsDeterioration rateData acquisition

The invention is suitable for the field of highway bridge detection. If a bridge support or a stretching device is damaged, under the excitation action of dynamic loads, the stretching device or a beam body can generate longitudinal shock vibrations. The invention discloses a method for evaluating the longitudinal shock resistance of a highway bridge support and a stretching device quickly. According to the method, a vibration data acquisition module for acquiring a longitudinal acceleration response signal of an object to be evaluated, a longitudinal shock resistance evaluation model which defines calculating and grading methods of the longitudinal shock resistance and the shock resistance deterioration rate, and a deterioration process database for storing the evaluation results of the longitudinal shock resistance and the shock resistance deterioration rate in all detection periods, tracking and monitoring the change of the shock resistance deterioration rate, and diagnosing and identifying the early deterioration and damage of the shock resistance are included. According to the method, the detection efficiency is improved, and the reliability of checking and evaluation is improved.

Owner:SOUTHEAST UNIV

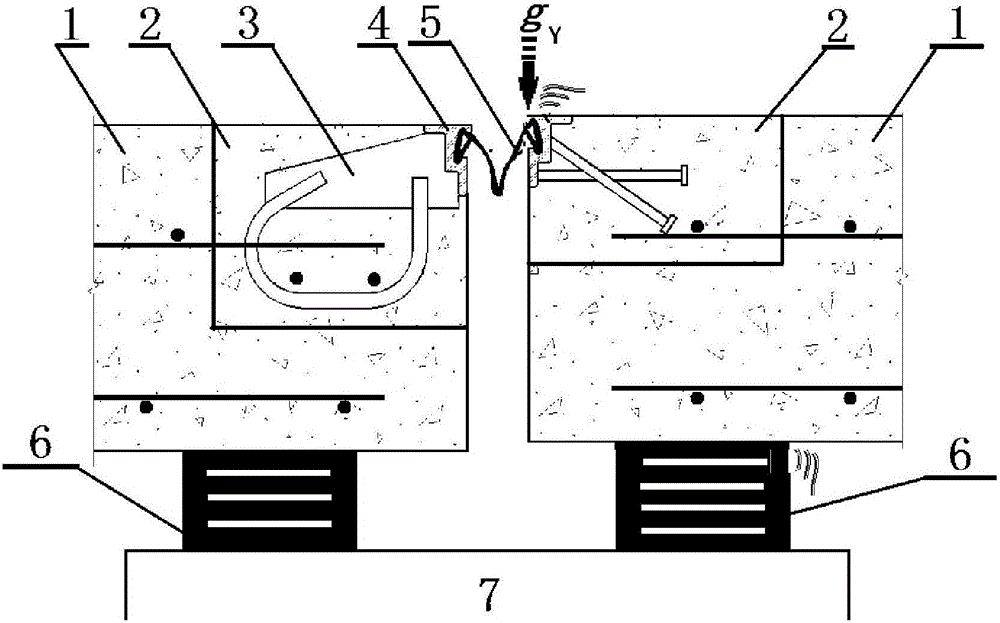

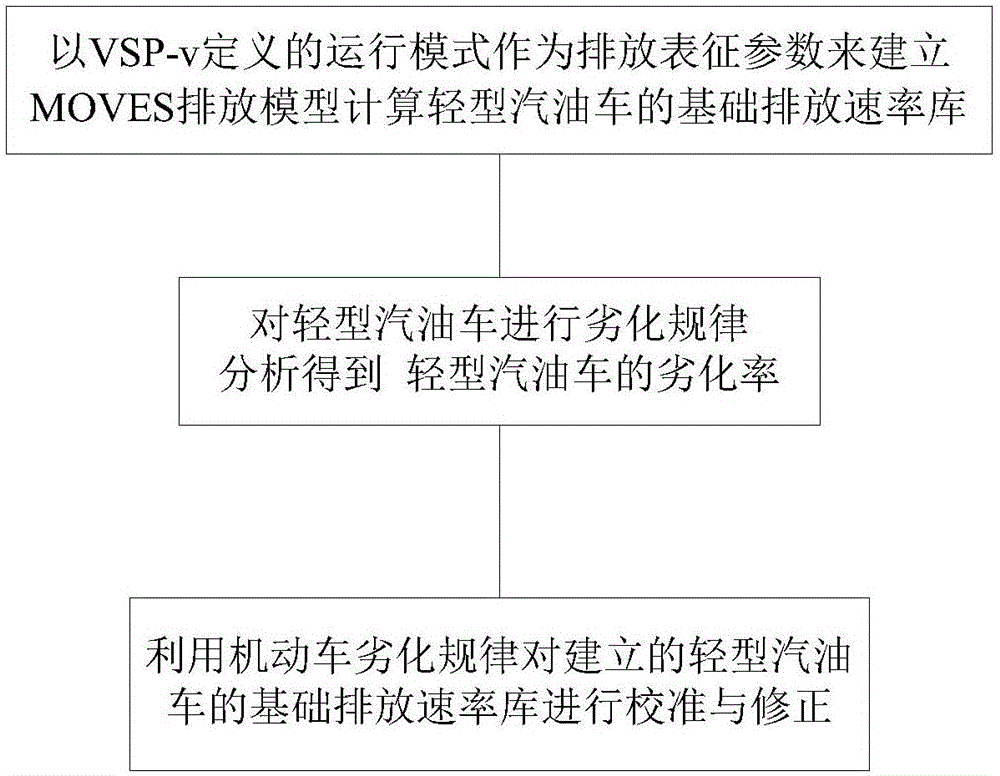

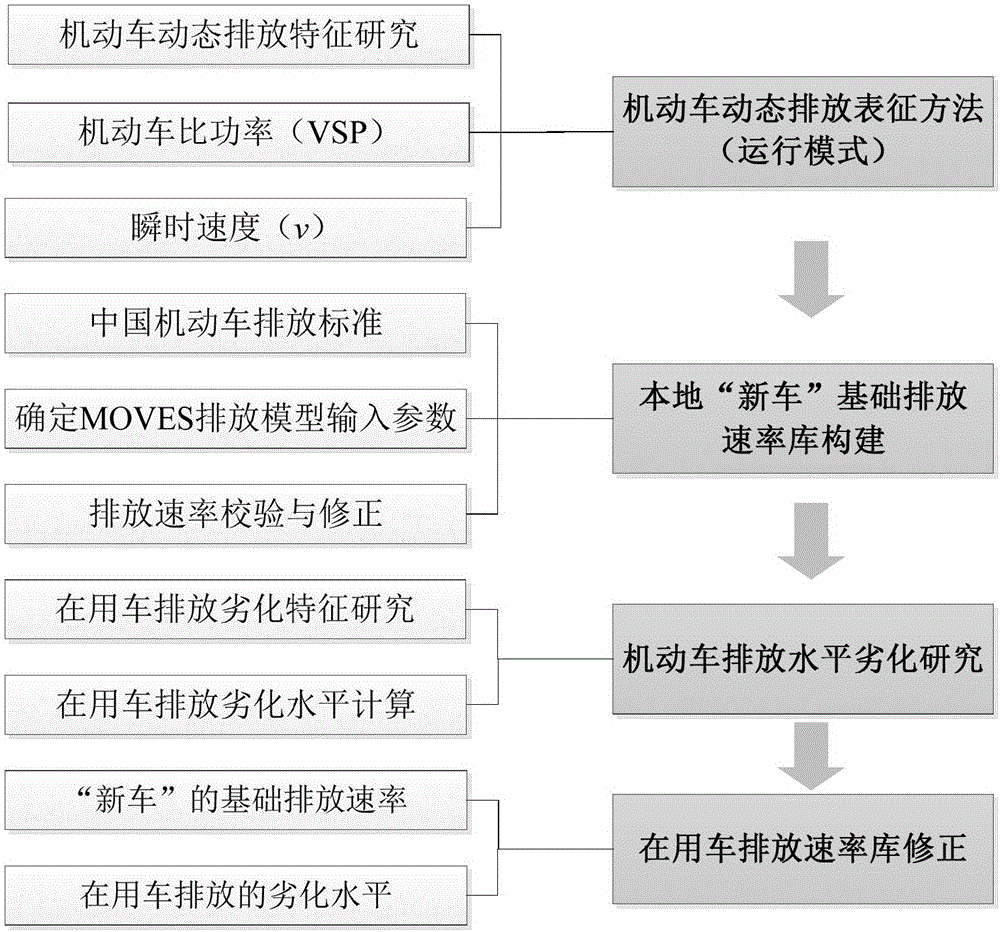

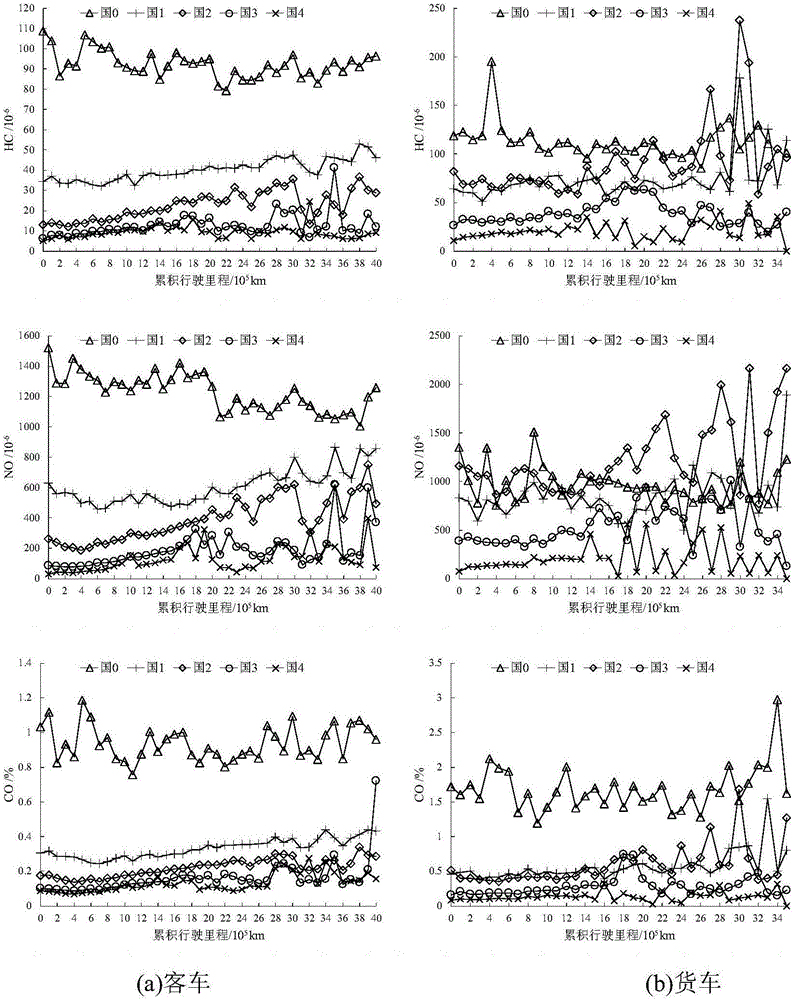

Light vehicle emission speed calculation method based on traffic operation data and deterioration rate

ActiveCN106446398AEmission reductionImprove air qualityDesign optimisation/simulationSpecial data processing applicationsDeterioration rateGasoline

The invention provides a light vehicle emission speed calculation method based on traffic operation data and a deterioration rate. The method comprises the steps that a motor vehicle MOVES emission model is built by adopting an operation mode defined by VSP-v as emission characterization parameters, and then, repeated input and output testing is performed on the MOVES emission model to obtain a basic emission speed library of a light gasoline motor vehicle in China; then, deterioration rule analysis is performed on the light gasoline motor vehicle, a fitting equation of ages and pollutant concentrations is built, and the deterioration rate of the light gasoline motor vehicle is calculated; finally, by means of the conclusion obtained in the motor vehicle deterioration rules, the built basic emission speed library of the light gasoline motor vehicle is calibrated and corrected to obtain the corrected emission speed, and the method is of great significance in optimizing road operation working conditions, lowering the motor vehicle emission amount and improving the urban air quality, and has the certain referential significance in formulation and implementation of China motor vehicle pollution control measures.

Owner:SUN YAT SEN UNIV

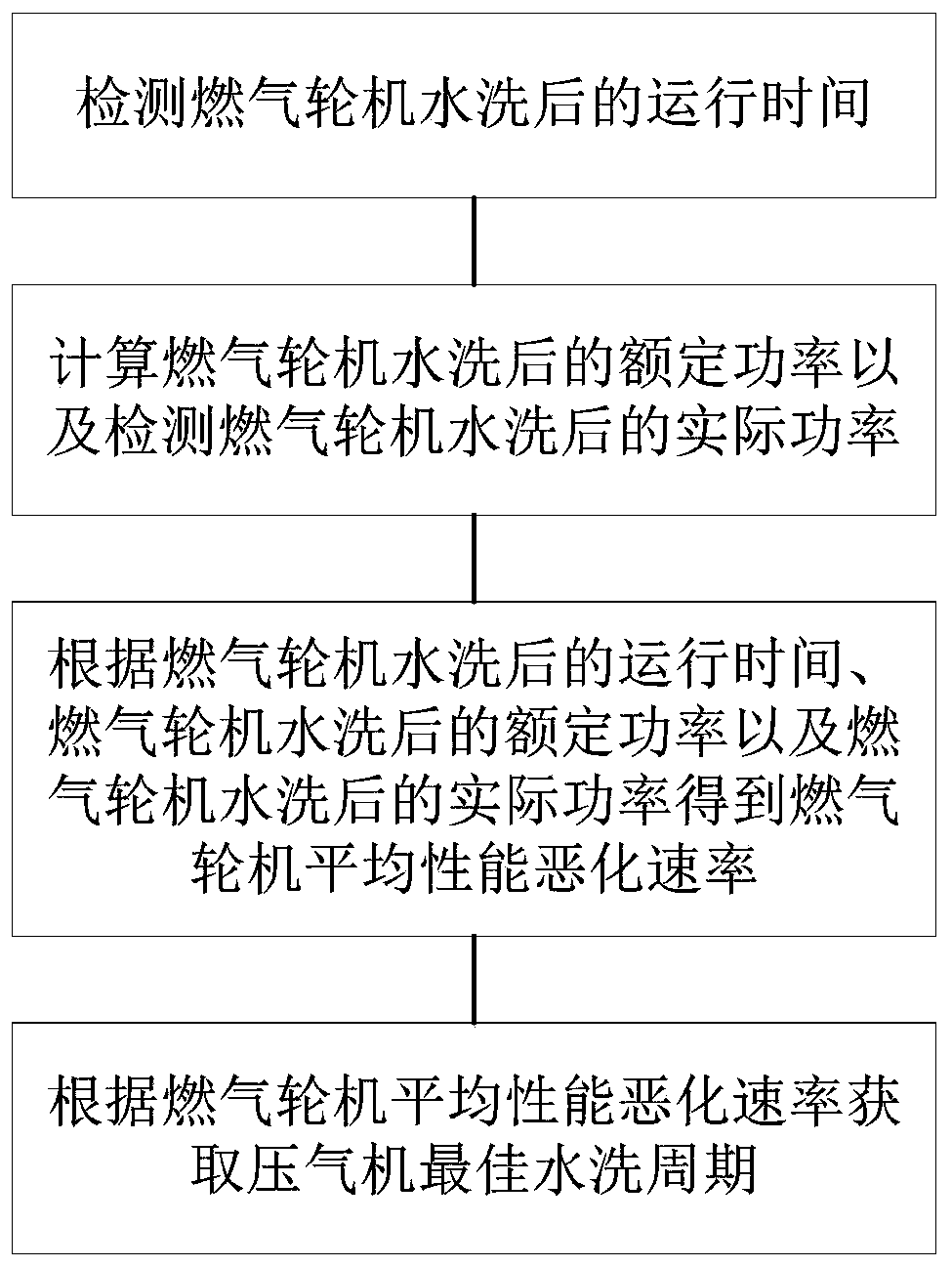

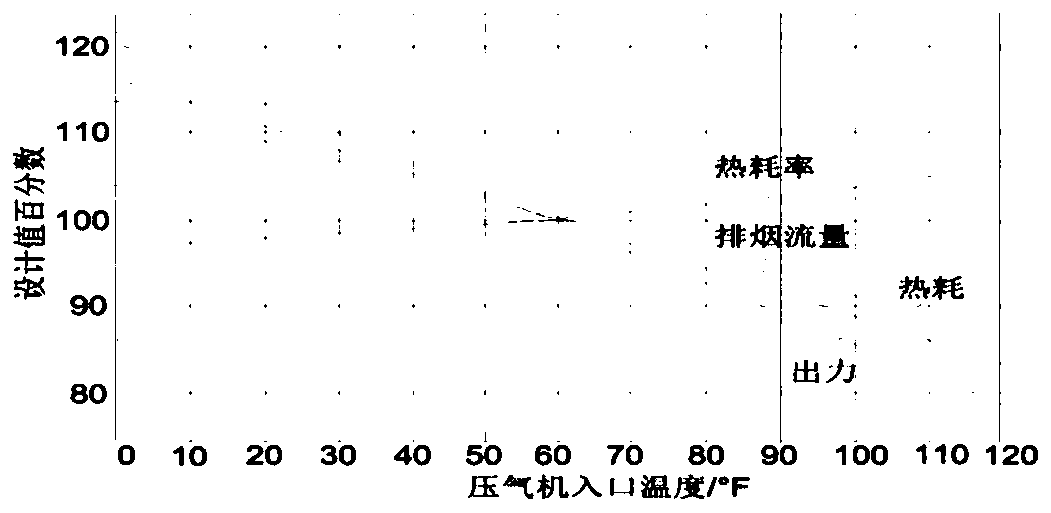

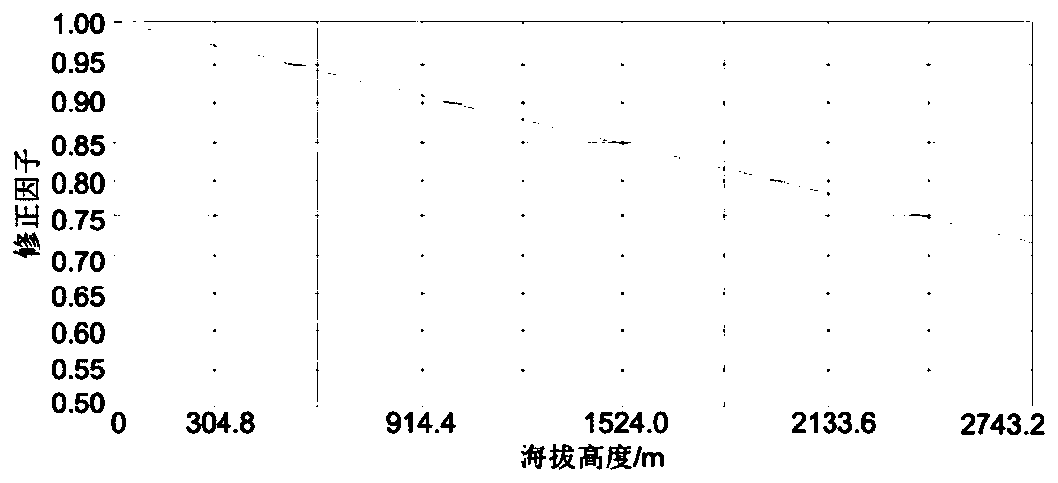

Acquisition method for optimum washing period of compressor

ActiveCN110056544ALow running costThe principle is clearPump componentsPumpsDeterioration rateEngineering

The invention discloses an acquisition method for an optimum washing period of a compressor. The method comprises the following steps: detecting the operating time of a gas turbine after washing; calculating the rated power of the gas turbine after washing and detecting the actual power of the gas turbine after washing; acquiring the average performance deterioration rate of the gas turbine according to the operating time of the operating time of the gas turbine after washing, the rated power of the gas turbine after washing and the actual power of the gas turbine after washing; and acquiringthe optimum washing period of the compressor according to the average performance deterioration rate of the gas turbine. The acquisition method can acquire the optimum washing period of the compressorby calculating the average performance deterioration rate of the gas turbine, and washing is carried out from the economical aspect, so that the operating cost of a power plant is saved.

Owner:马文德

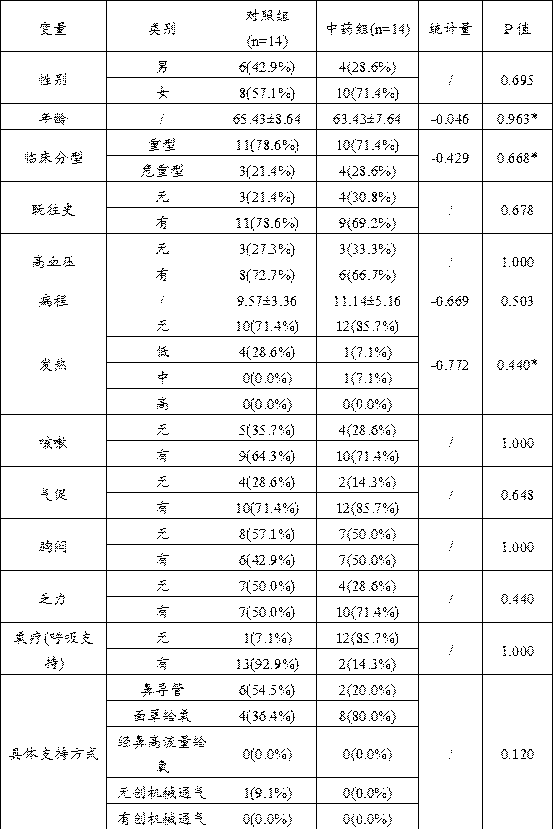

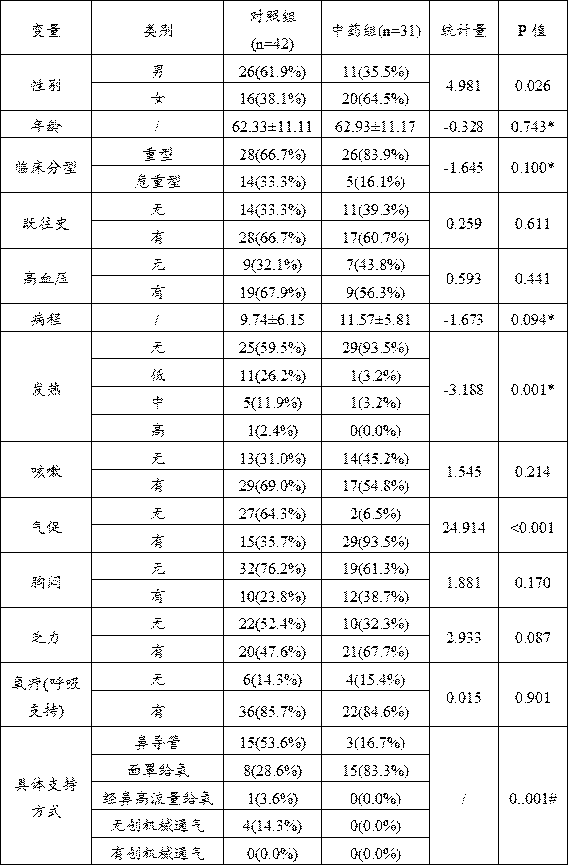

Pharmaceutical composition for strengthening body resistance and rescuing lung and application thereof

The invention belongs to the technical field of traditional Chinese medicines and relates to a pharmaceutical composition for strengthening body resistance and rescuing the lung. The composition is prepared from the following components in parts by mass: 10 to 30 parts of cooked common monkshood branched roots, 5 to 15 parts of dried ginger, 20 to 30 parts of prepared radix licorice, 10 to 20 parts of honeysuckles, 10 to 30 parts of spina gleditsiae, 20 to 45 parts of ficus hirta roots or twigs, 10 to 15 parts of herba pogostemonis and 5 to 15 parts of dried tangerine peel. The invention further provides an application of the body resistance-strengthening and lung-rescuing pharmaceutical composition in preparation of a medicine for treating COVID-19. The pharmaceutical composition for strengthening body resistance and rescuing the lung possibly has a certain effect on reversing the progress of severe and critical COVID-19 and reducing the deterioration rate.

Owner:JIANGSU KANION PHARMA CO LTD

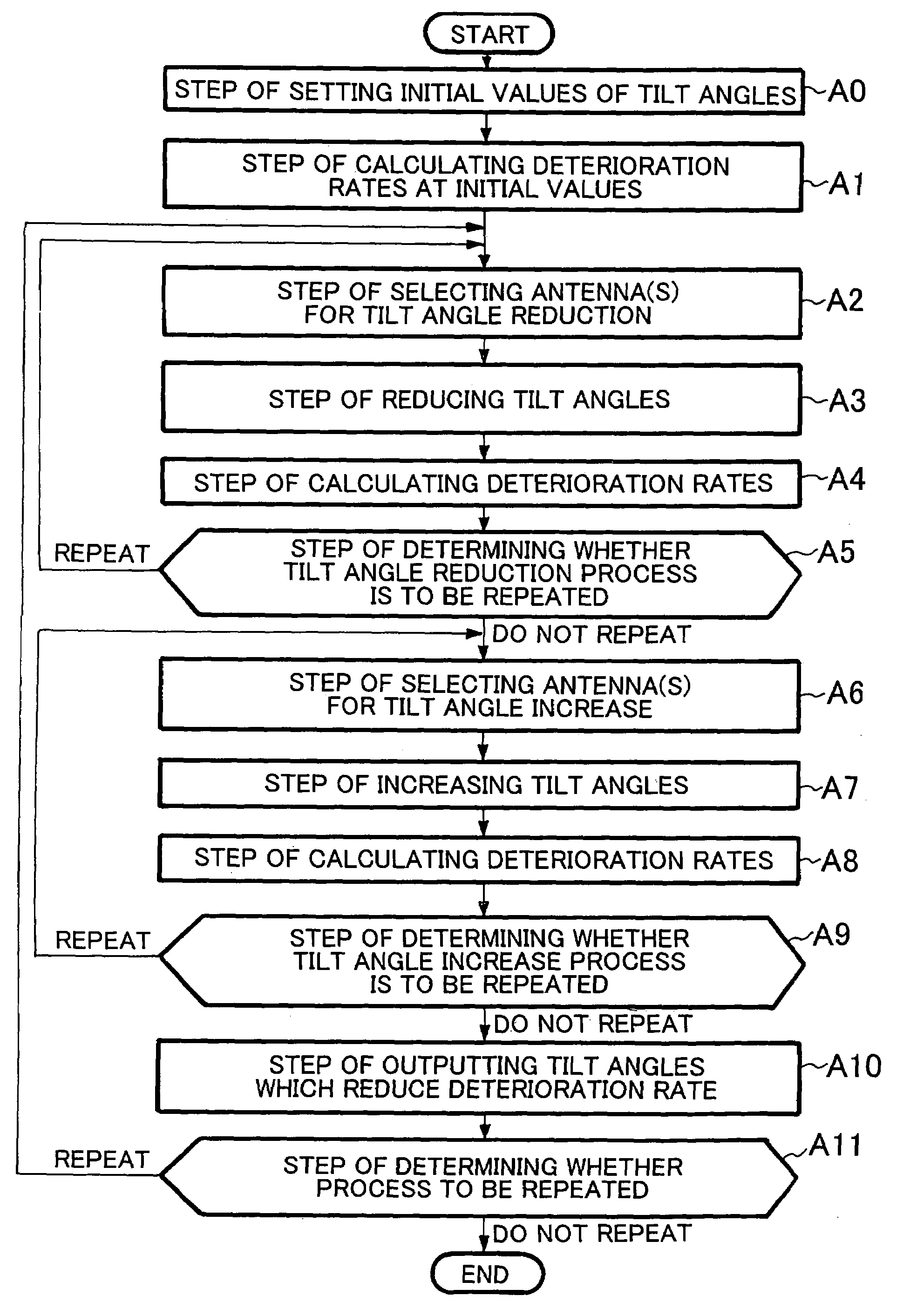

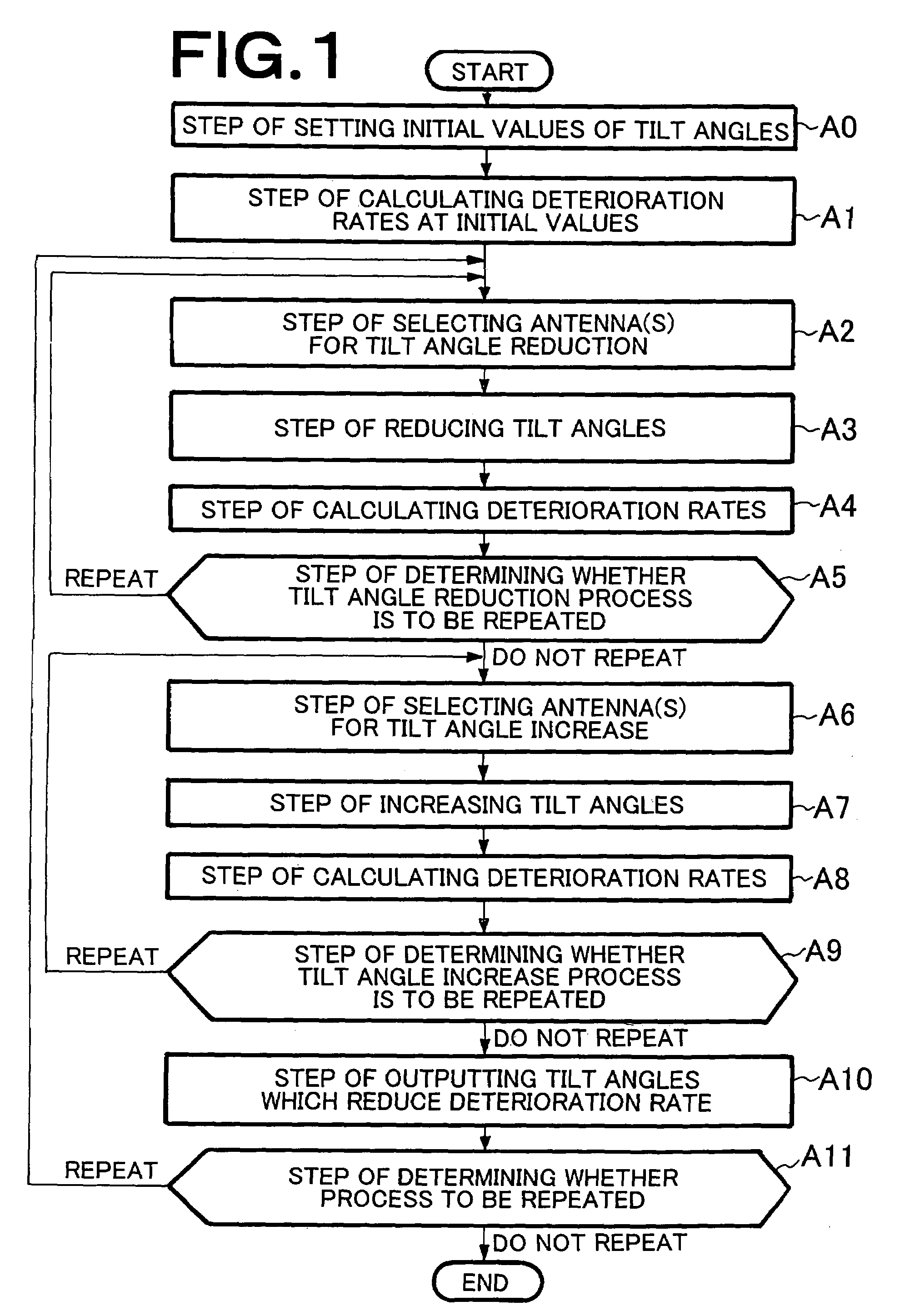

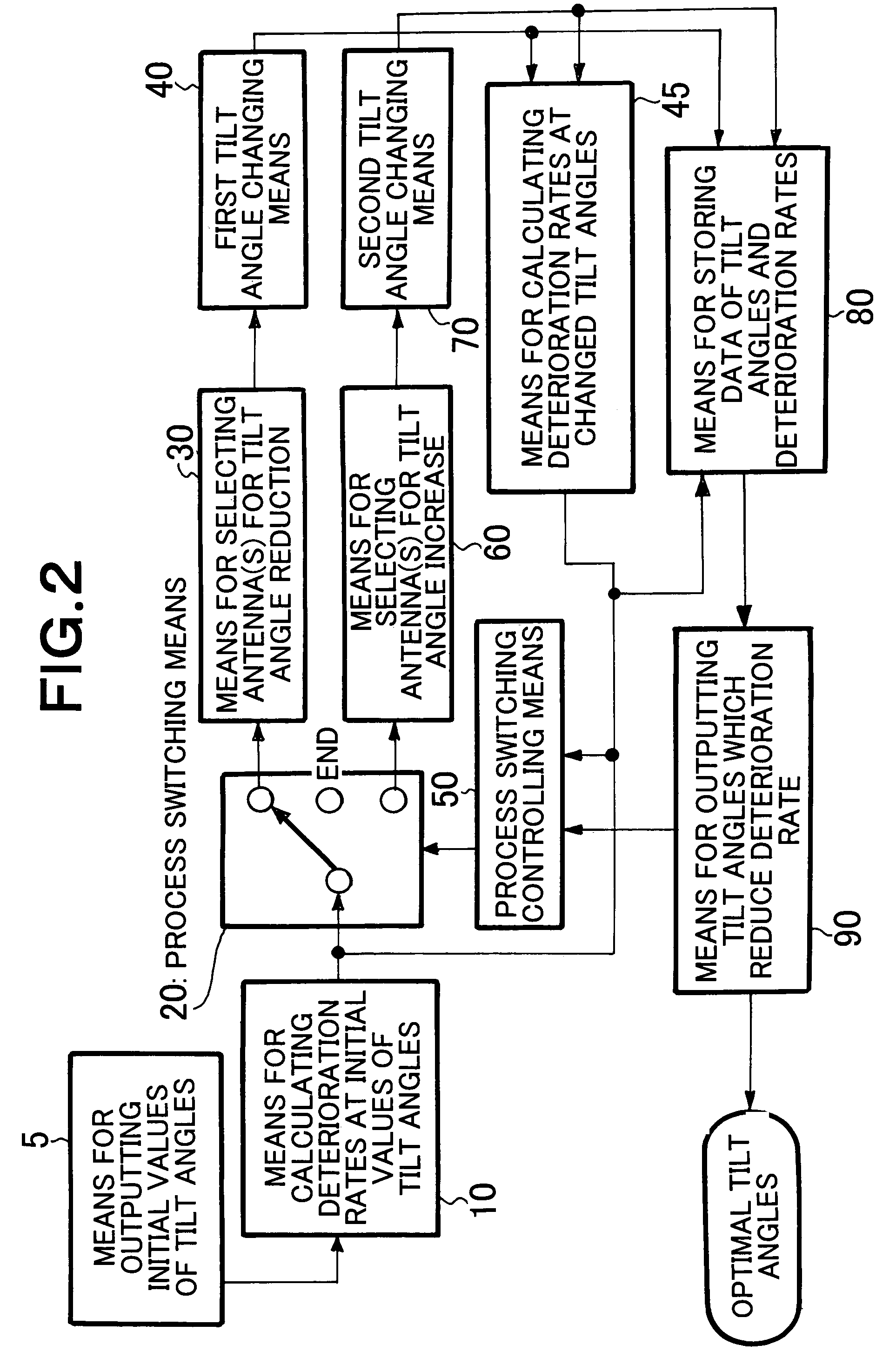

Method for deciding tilt angle of antenna in radio communication system and apparatus for deciding the same

InactiveUS7218955B2Small deterioration rateDeterioration of rateAntenna supports/mountingsSubstation equipmentCommunications systemDeterioration rate

The purpose of the present invention is to provide a tilt angle deciding method and a system wherein tilt angles to diminish the deterioration rate of the entire system can be obtained in the radio communication system. The method comprises the steps of setting initial values of tilt angles; calculating the deterioration rate at the initial values of tilt angles; selecting an antenna for reducing a tilt angle; reducing the tilt angle of the selected antenna; calculating a deterioration rate at the time when the tilt angle is reduced; determining the continuity of repeating the processes, after repeating the series of processes for reducing these tilt angles, and increasing tilt angles repeatedly in the similar way. In addition, the method comprises the steps of outputting tilt angles for diminishing a small deterioration rate, and determining whether the processes of repeating the whole steps finish. With the above-specified processes, it becomes possible to obtain tilt angles for diminishing the deterioration rate of the entire system in comparison with that obtained at initial values of tilt angles.

Owner:NEC CORP

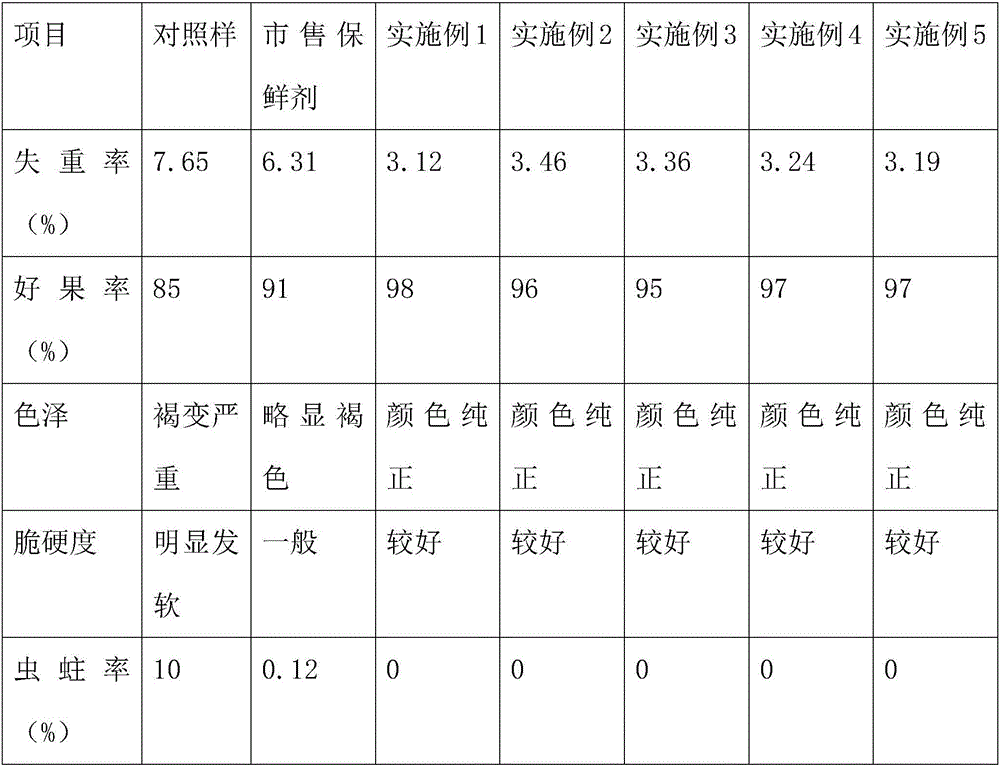

Chili preservation method

ActiveCN103518834AReduce lossesEasy to eatFruit and vegetables preservationDeterioration rateAdditive ingredient

The invention relates to a chili preservation method which comprises the steps of picking, selecting, pre-cooling, fumigation, fresh-keeping film sub-packaging and warehousing. The chili preservation method is simple and low in cost; the nutritional ingredient loss of the preserved chili is low; the shelf life is prolonged from 20 to 30 days in a normal state to 60 to 90 days, so that the problems of high spoilage and deterioration rate caused by long-distance transportation is greatly solved, and a convenient chili preservation method is provided so that anti-season vegetables are available for southerners and northerners.

Owner:青海兴农实业有限公司

Preservative for fruits and preparation method thereof

InactiveCN107173431AInhibition of respirationImprove the preservation effectFruits/vegetable preservation by coatingCalcium silicateDeterioration rate

The present invention discloses a preservative for fruits. The preservative comprises the following raw materials: water, citric acids, ferrous sulfate, phytic acid, vitamin C, potassium myristate, lignin, glutamic acid, calcium silicate, sepiolite, chitin, sodium carbonate, starch, activated carbon, silica gel, sucrose, sodium lactate, carboxymethyl chitosan, potassium chloride, tea polyphenols, honey, a traditional Chinese medicinal preservative extractant and a preservative slow release agent. The present invention also provides a preparation method of the preservative for the fruits. A prepared water-retaining agent for the fruits can form a layer of thin film on surfaces of the fruits, can realize micro-organism and oxidation preventing on surfaces of the fruits, can also seal pores of surface skins of the fruits, inhibits respiration of the fruits, reduces water content loss of the fruits, effectively delays quality of fruit fleshes and deterioration rates of flavors, and extends a storage period of the fruits.

Owner:安徽恒海生态农业观光园有限公司

Vehicle travelling performance-based method for evaluating travelling service performance of highway bridge expansion device

InactiveCN104850678ARealize automatic identification and diagnosisImprove detection efficiencyBridge structural detailsSpecial data processing applicationsObject basedDeterioration rate

The invention is applied to the field of highway bridge detection. If a bridge support or an expansion device is damaged, an expansion joint could be misplaced, and travelling vibration response may be caused under the stimulation of the concave-convex expansion joint. The invention discloses a vehicle travelling performance-based method for evaluating travelling service performance of a highway bridge expansion device. The method comprises the steps as follows: defining a travelling performance grading evaluation method and a travelling performance deterioration rate computing method; determining vehicle travelling performance according to a vehicle acceleration response signal, and determining a travelling deterioration rate according to an actual measured current value and a detection initial value of travelling performance; outputting an inspection and evaluation report according to a result of grading evaluation. By using the method for regularly tracking and monitoring vehicle travelling performance deterioration rate, the method of the invention can be used for diagnosing early damage of the evaluated object based on the travelling service performance. The method of the invention improves the recognizability of early damage of the highway bridge expansion device and support service and the quality of inspection and evaluation while improving detection efficiency.

Owner:黄跃平 +2

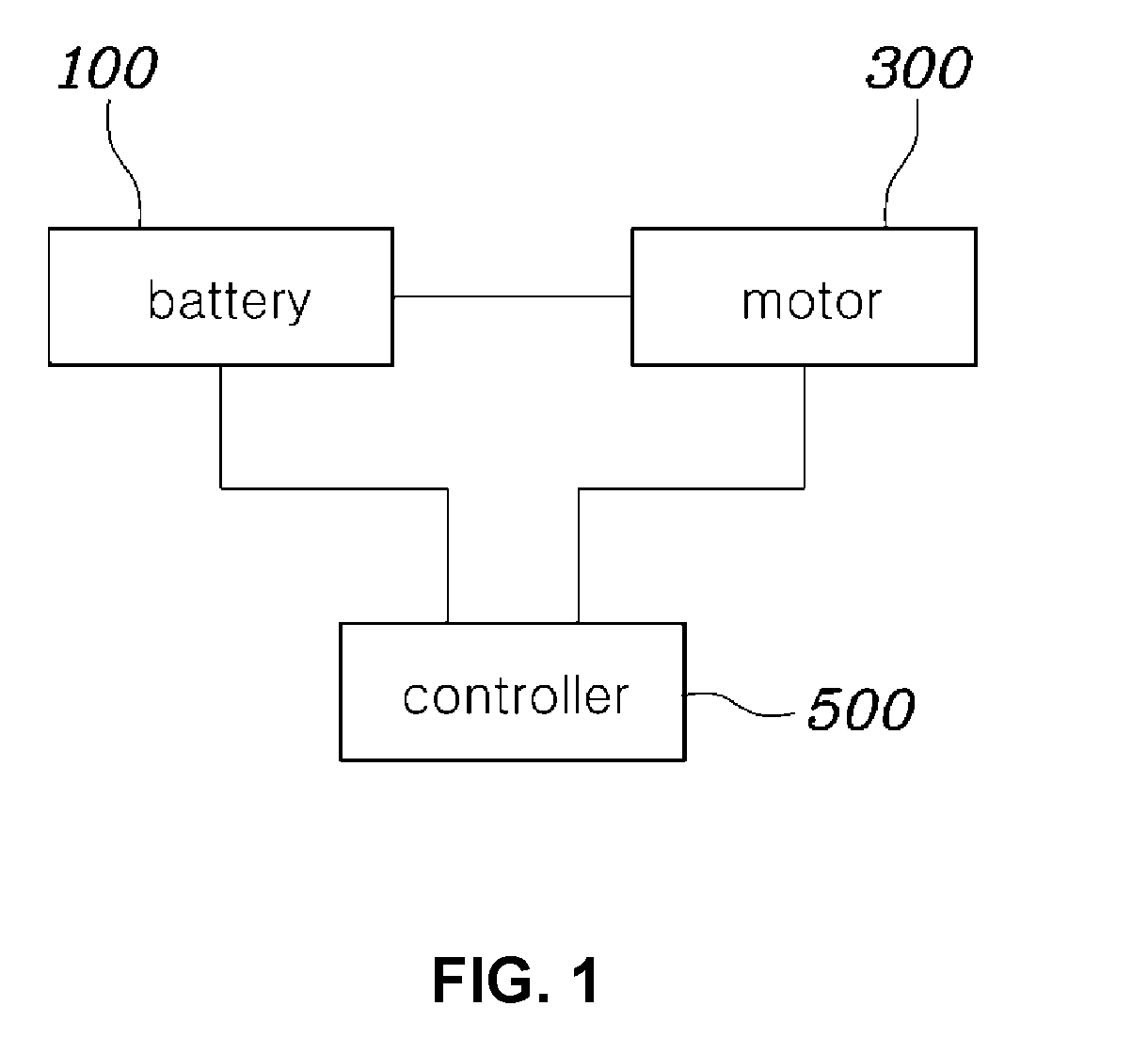

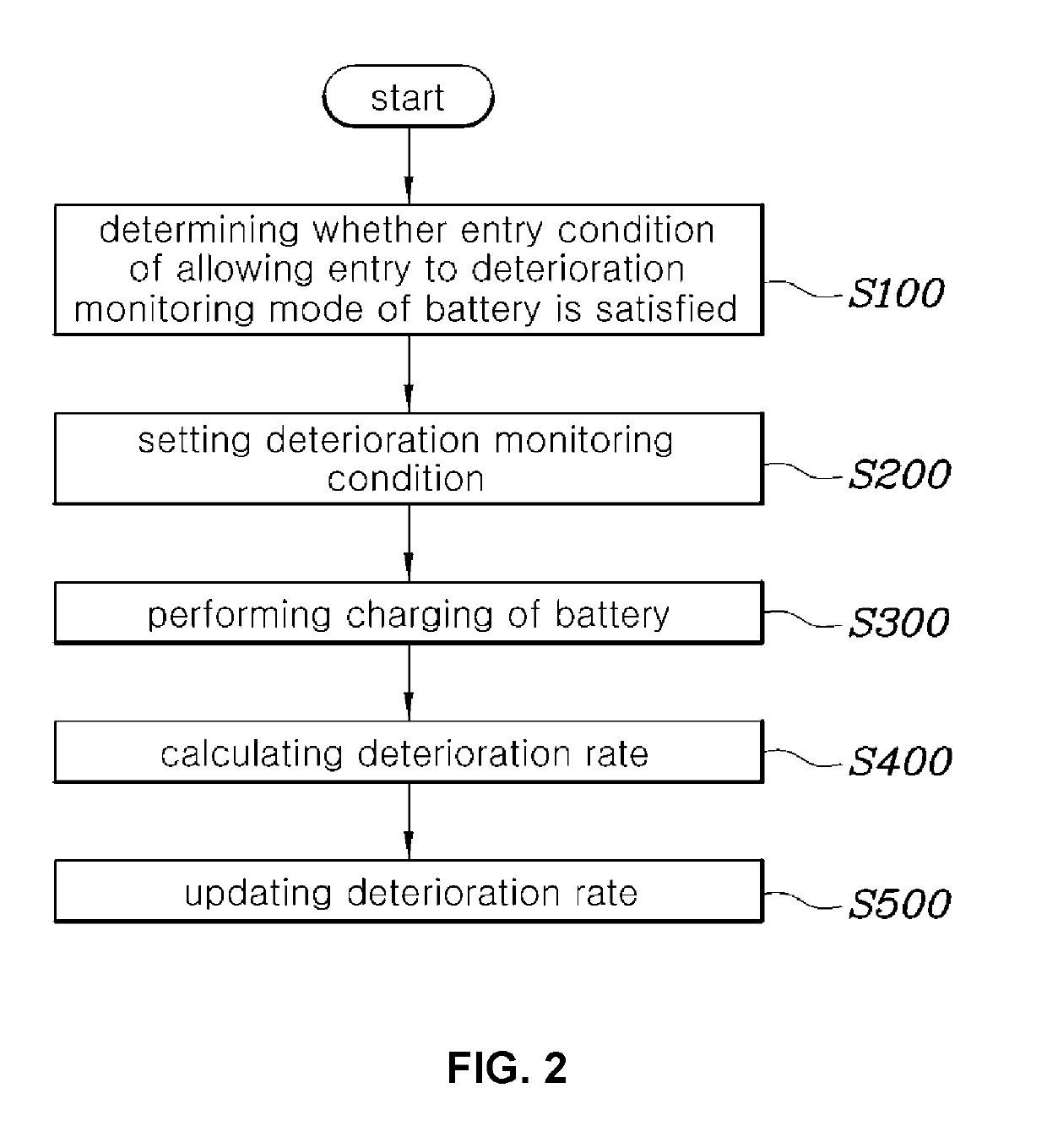

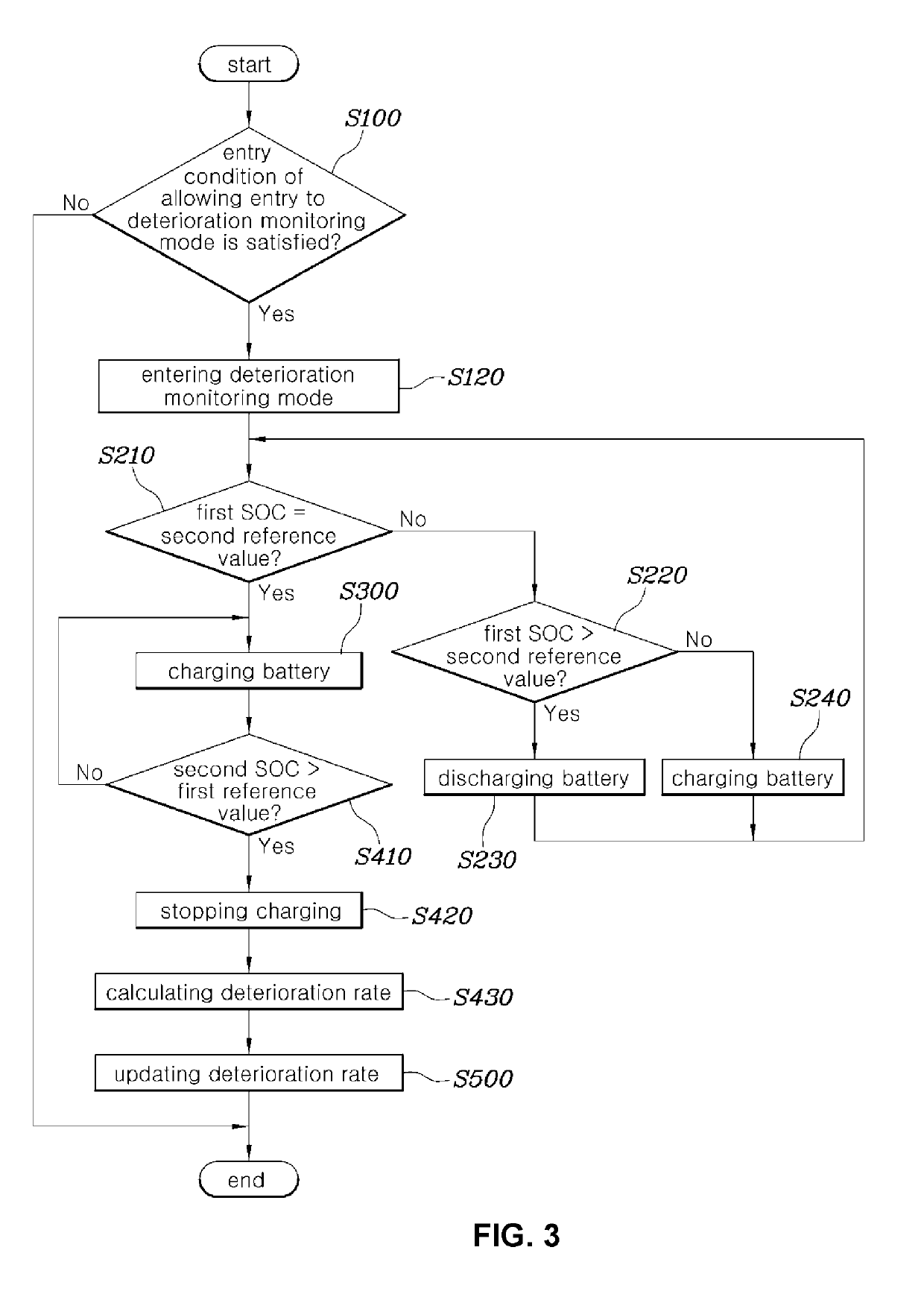

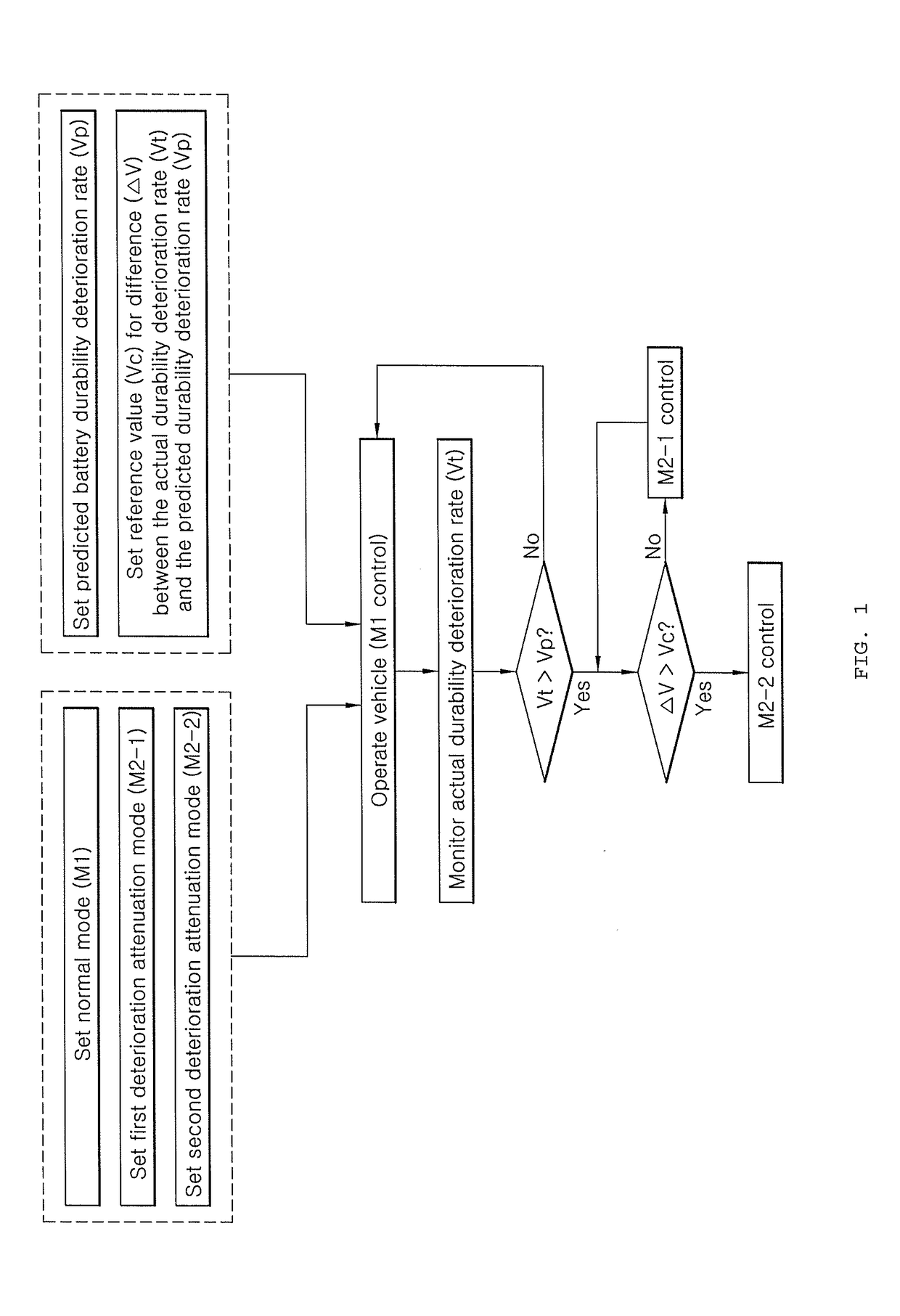

Control method and system for monitoring deterioration of battery of vehicle

ActiveUS20190178949A1Increase freedomUpdate deterioration rateCircuit monitoring/indicationDifferent batteries chargingDeterioration rateState of charge

A control method of monitoring deterioration of a battery of a vehicle, may include determining, by a controller, whether an entry condition of allowing an entry to a deterioration monitoring mode of the battery is satisfied; setting, by the controller, a deterioration monitoring condition when the entry condition of allowing the entry to the deterioration monitoring mode of the battery is satisfied; performing, by the controller, charging of the battery after the setting of the deterioration monitoring condition is completed; and stopping, by the controller, the charging and determining a deterioration rate of the battery when a first state of charge (SOC) value of the battery is greater than a predetermined first reference value as a result of the performing the charging.

Owner:HYUNDAI MOTOR CO LTD +1

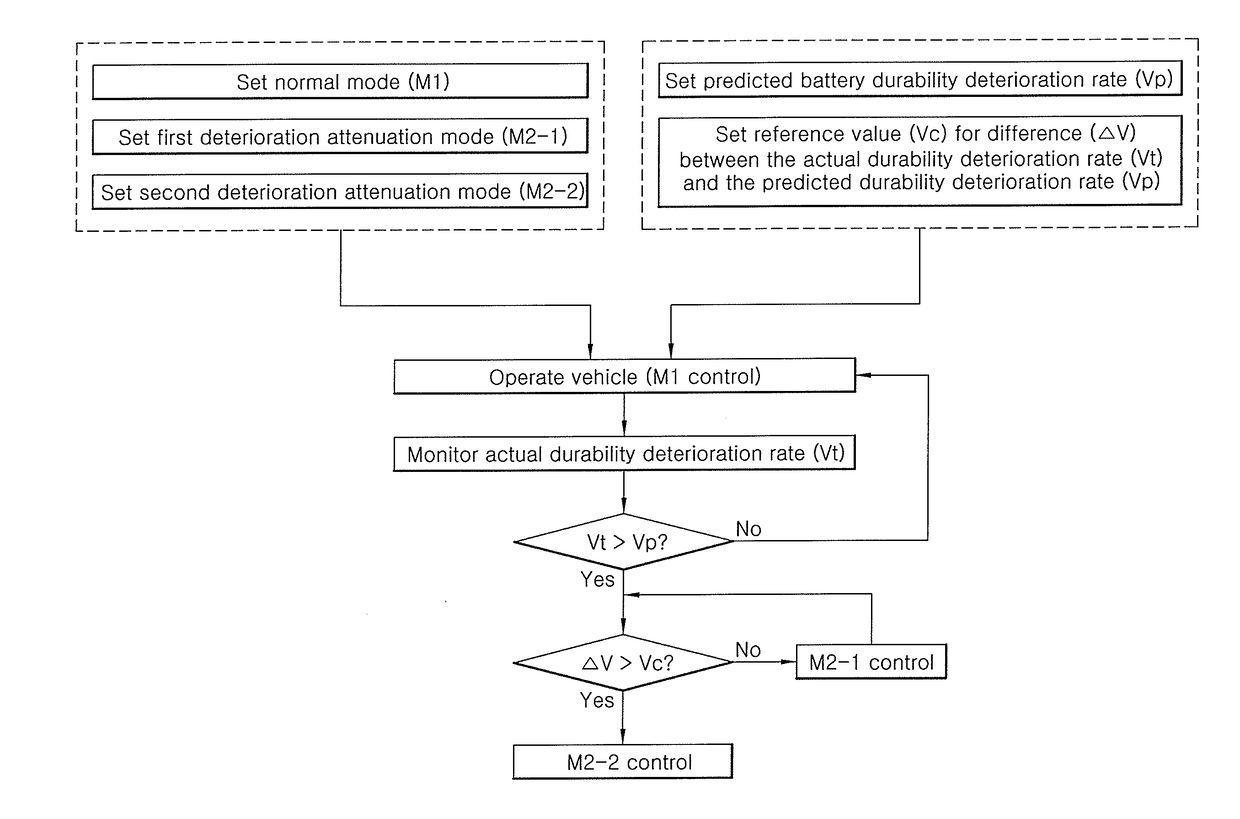

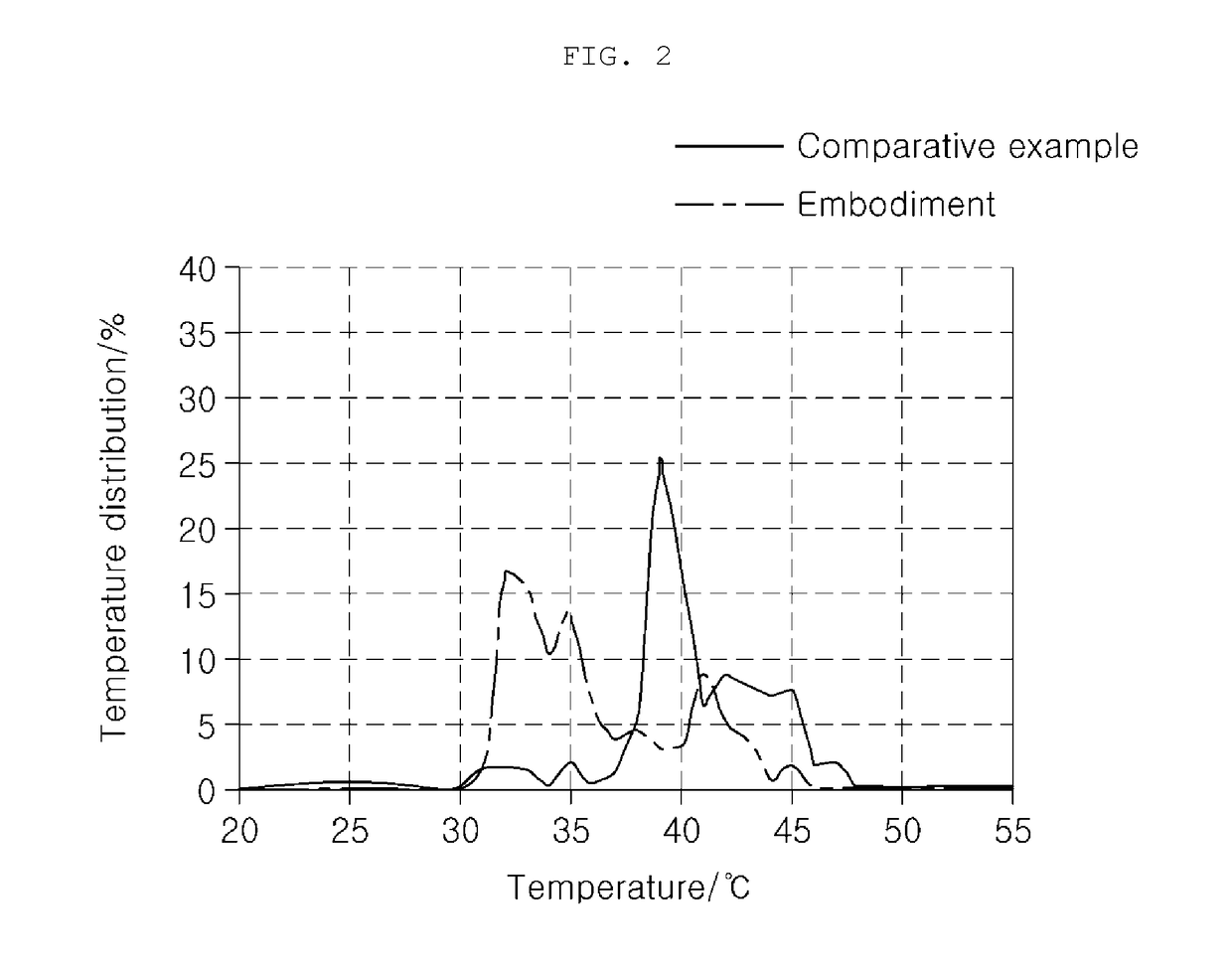

Cooling control method for battery management system in electric vehicle

ActiveUS20180326862A1High degreeAir-treating devicesCell temperature controlDeterioration rateAutomotive battery

Disclosed herein is a cooling control method for a battery management system in a vehicle in which battery cooling is controlled by according to the degree of battery durability deterioration.Specifically, the method of controlling battery cooling using a battery management system (BMS) configured to control a degree of cooling fan operation based on a battery temperature in the vehicle equipped with the battery and the cooling fan, includes the steps of increasing the degree of cooling fan operation compared normal conditions when an actual battery durability deterioration rate (Vt) measured using battery durability deterioration degree information during vehicle operation is higher than a predicted battery durability deterioration rate.

Owner:HYUNDAI MOTOR CO LTD +1

Ham Zongzi and processing technology thereof

InactiveCN107095157AUnique fragranceDispelling exterior and dispelling coldFood freezingFood thermal treatmentFlavorMonosodium glutamate

The invention relates to a ham Zongzi and a processing technology thereof. The ham Zongzi is prepared from the following raw materials by weight: 100 to 300 parts of glutinous rice, 7 to 21 parts of ham, 10 to 30 parts of oil, 0.5 to 1.5 parts of monosodium glutamate, 0.2 to 0.6 part of salt, 1 to 3 parts of white sugar, 4 to 12 parts of Micong (a kind of chive) and 8 to 24 parts of carrots. The processing technology for the ham Zongzi comprises the following successive steps: pretreatment of bamboo leaves; pretreatment of Micong (a kind of chive) and carrots; pretreatment of glutinous rice; mixing of rice materials; preparation of a raw Zongzi; preparation of a cooked Zongzi; precooling; quick-freezing; and warehousing and refrigeration. The invention has the following advantages: with the processing technology in the invention, the cooking time for the raw Zongzi can be shortened, so the sensory and flavor quality of the ham Zongzi can be improved, the phenomenon of retrogradation of the ham Zongzi can be alleviated, and the viscosity and gelling properties of the Zongzi can be enhanced; meanwhile, the processing technology substantially reduces the deterioration rate of the ham Zongzi, so economic benefits are increased.

Owner:JIANGSU CHANGSHOU GRP CO LTD

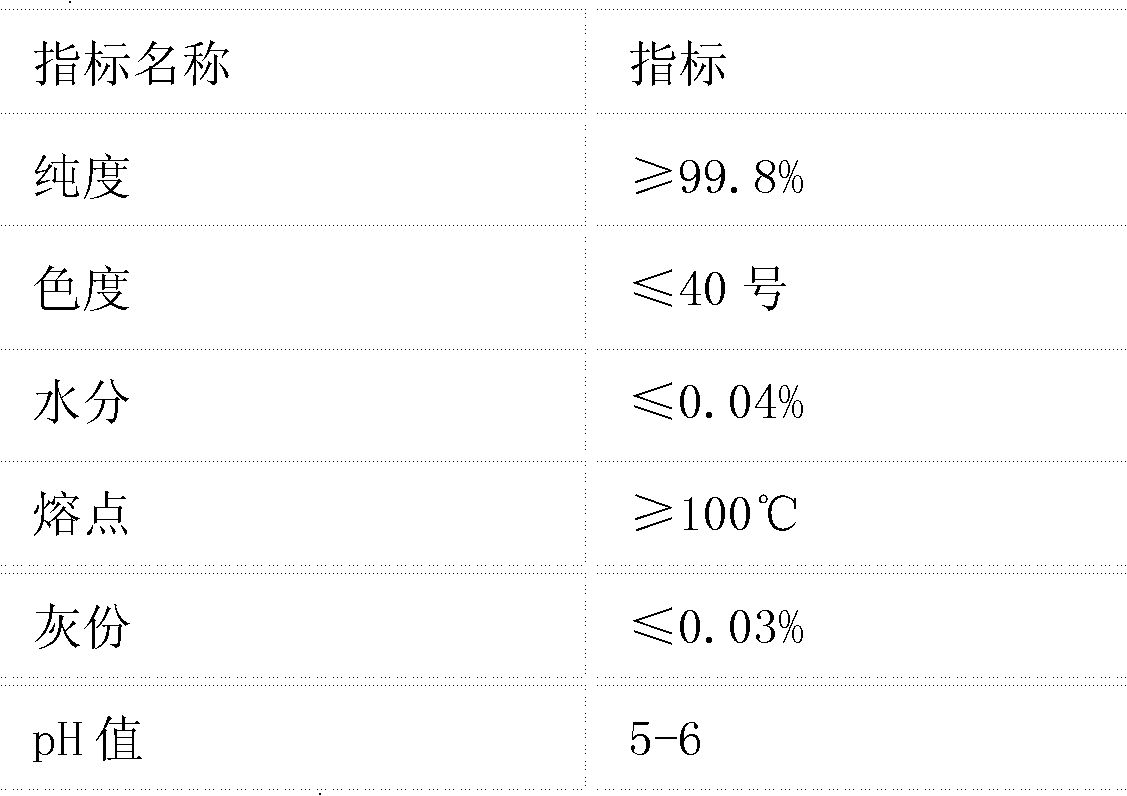

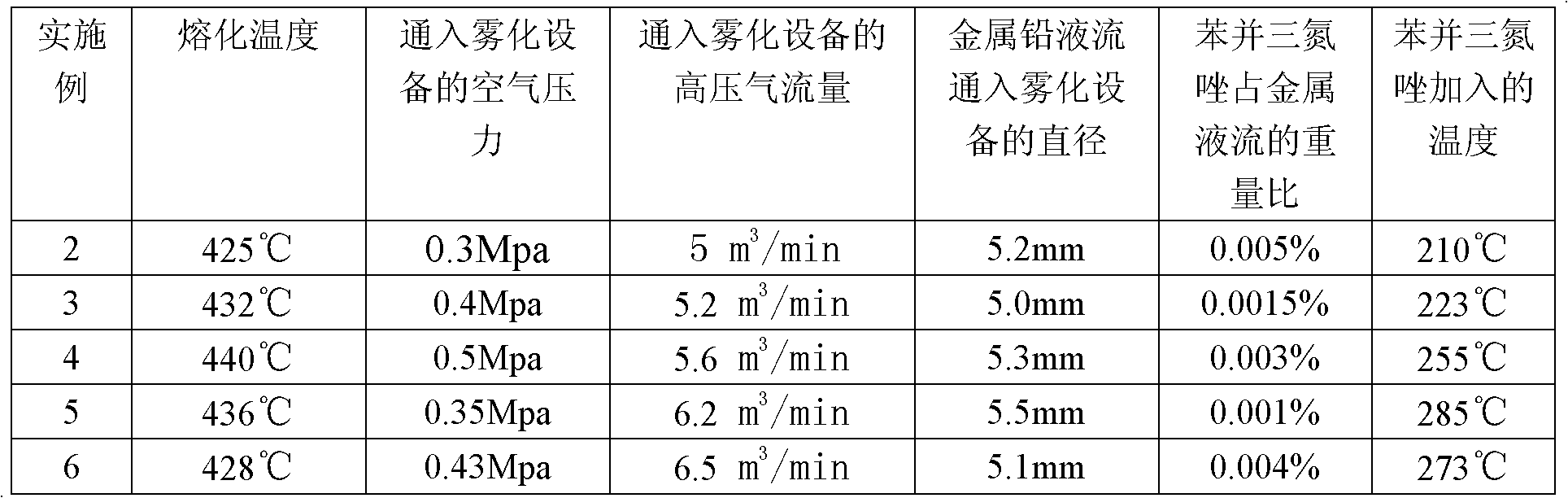

Metal lead powder production method

ActiveCN103128297AEffective control of oxidative deterioration rateImprove securityTemperature controlDeterioration rate

A metal lead powder production method comprises the steps of melting metal, atomizing and the like, wherein the temperature of fusing lead liquid in a metal melting process is controlled at around 425-440 DEG C, a benzotriazole additive is added in the process of atomization, the benzotriazole additive accounts for 0.001%-0.005% of the melted metal lead liquid in weight, and high pressure air flow which is added in the process of the atomization is controlled at about 5-6.5 m <3> / minute (min). According to the metal lead powder production method, an additive is selected in the process of metal lead power production in an atomization method, the properties of the addictive, the interaction between the additive and the metal and the favorable environment of atomization are used, and therefore the additive is atomized to form a protective layer which can avoid oxidation and caking on the surface of the metal lead powder. Metal lead powder products which are produced through the metal lead powder production method are packed with normal packaging, and the oxidative deterioration rate of the metal lead powder products can be controlled within the range of 0.5%-3.5%. Due to the fact that the normal packaging is used, the production cost is reduced effectively, the safety of a production system is good, returned goods rate is reduced greatly, and economic benefit is remarkable.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com