Metal lead powder production method

A production method and metal lead technology are applied in the production of metal powder and the atomization production of metal lead powder, which can solve the problems of lead powder and tin powder being easy to agglomerate, poisoning by heavy metals, easy to oxidize and deteriorate, etc., and improve the working environment. , The production cost is reduced, and the economic benefit is remarkable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of production method of metallic lead powder, carry out according to the following steps:

[0018] a. Dissolving in a metal melting furnace to obtain a metal lead liquid flow, the temperature of the molten lead liquid is controlled at 430-436°C;

[0019] b. The diameter of the metal lead liquid added in the atomization process is 5-5.5mm; the pressure is 0.3-0.5Mpa, and the air flow is 6-6.5m 3 The high-pressure air of / min is fed into the atomizing equipment to atomize the metal lead liquid flow, and simultaneously feeds the benzotriazole additive, and the added amount of the benzotriazole additive accounts for 10% of the metal liquid flow weight entering the atomizing equipment 0.002% to 0.004%, the addition temperature of the benzotriazole additive is 264 to 275°C and the pressure is 0.8 to 0.95 standard atmospheres;

[0020] c. Cool to normal temperature and collect powder;

[0021] d. Sieved, packaged into bags for standby or for sale.

[0022] The above ...

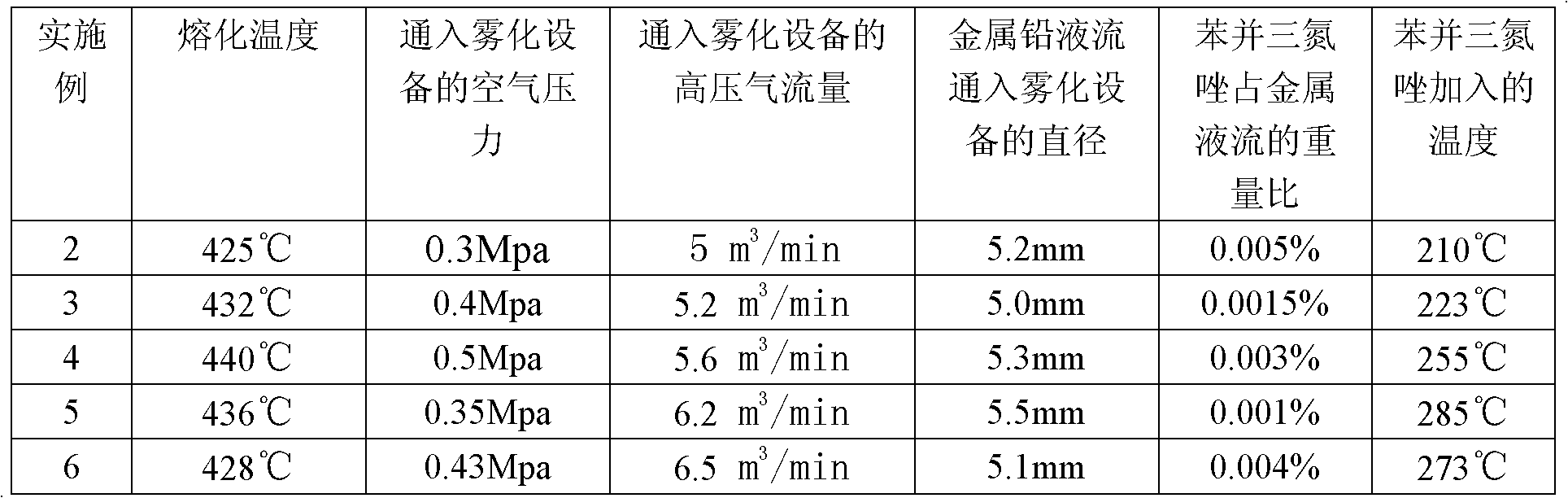

Embodiment 2~6

[0023] Embodiment 2~6: Produce metal powder according to following steps and process, all the other are the same as embodiment 1.

[0024]

[0025] The oxidative deterioration rate of the 0.1-4mm grade metal lead powder prepared by the above method is only 1.2-3%, and it is conventionally packaged, and the economic benefit is remarkable; the safety is good in the preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com