Chemical recovery method for waste polycarbonate material

A polycarbonate, easy-to-recycle technology, applied in chemical recovery, chemical instruments and methods, carbonate/haloformate preparation, etc., can solve the problems of harsh high temperature and high pressure conditions, long reaction time, etc., and meet the requirements of equipment conditions low, fast reaction, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

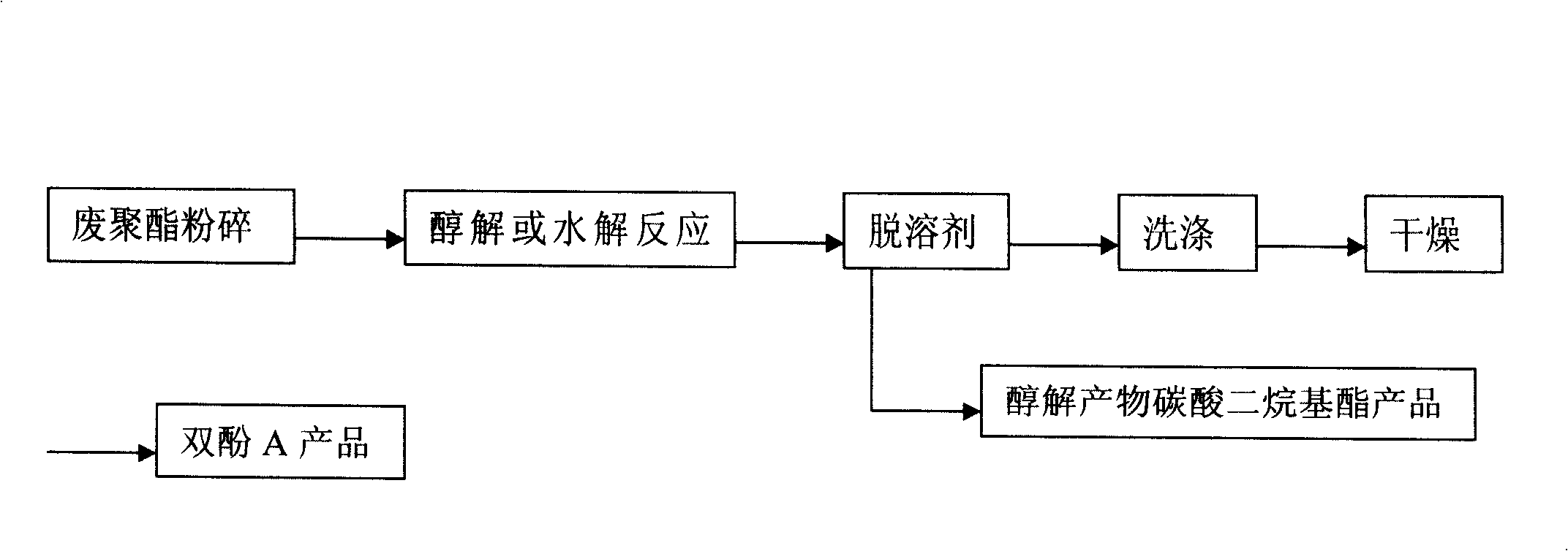

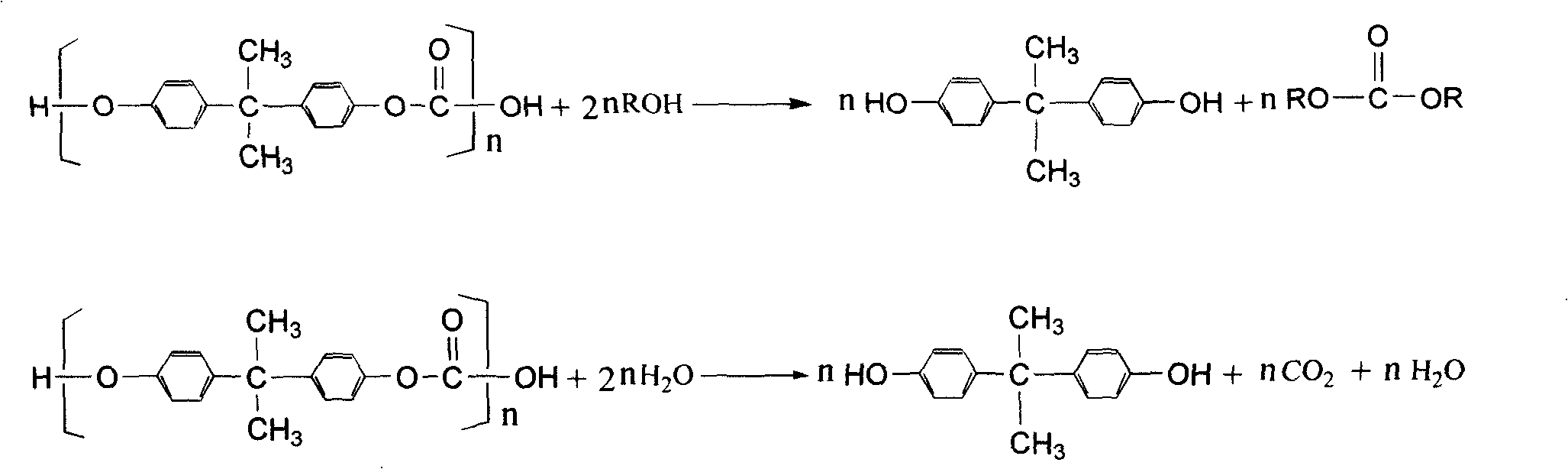

Method used

Image

Examples

Embodiment 1

[0020] Example 1: After pulverizing 50.0 g of waste polycarbonate (particle size ≤ 1 mm), put it into a 250 ml three-necked flask, add 50.0 g of methanol, 1.0 g of sodium hydroxide, and 100.0 g of tetrahydrofuran in sequence, and after the addition is completed, heat the mixture at 40° C. Stirring and reacting for 30 minutes, the reaction solution was subjected to solvent removal, washing, drying and other processes, with a degradation rate of 99%, and 41.7 g of bisphenol A product was obtained with a yield of 92.9%.

Embodiment 2

[0021] Embodiment 2: The experimental conditions and steps are the same as in Embodiment 1, except that tetrahydrofuran is changed to dichloroethane. The degradation rate was 98.6%, and 41.6 g of bisphenol A product was obtained, with a yield of 92.7%.

Embodiment 3

[0022] Embodiment 3: The experimental conditions and steps are the same as in Example 1, except that tetrahydrofuran is changed into a mixture of tetrahydrofuran and dichloroethane, and sodium hydroxide is changed into potassium hydroxide. The degradation rate was 99%, and 41.8g of bisphenol A product was obtained with a yield of 93.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com