Composite material with titanium diboride intermediate coating

A technology of titanium diboride and intermediate coating, applied in the field of composite materials, can solve the problems of large internal resistance of the coating and high voltage of the electrode tank, and achieve the effects of improving electrical conductivity, low cost and uniform electrode current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

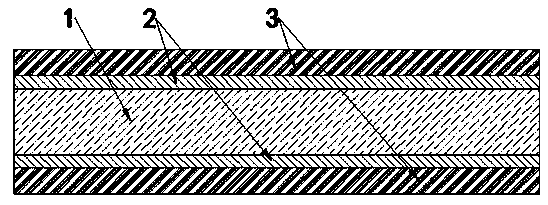

[0017] Implementation mode one: if figure 1 As shown, the structure of the composite plate of the present invention is: the outer surface of the base metal plate 1 is coated with an intermediate layer of titanium diboride 2 and a surface active coating 3 in sequence, and the thickness of the intermediate layer of titanium diboride 2 is 0.5 μm. The surface-active coating 3 has a thickness of 1 mm. The base metal sheet 1 is a pure titanium or pure aluminum sheet with a thickness of 0.5 mm. The material of the surface active coating 3 is a multi-system coating composed of lead, manganese and rare earth element oxides, and the specific components are 70wt% lead dioxide, 20wt% manganese dioxide, and 0.1wt% rare earth oxide.

[0018] Degrease and sandblast the 120×120×0.8mm aluminum plate, use H62 hot rolling mill and ZT-45-18Y vacuum hot pressing furnace, the working parameters are hot rolling temperature 400°C, sintering temperature 450°C, vacuum degree 10-2Pa, holding time 4h, ...

Embodiment approach 2

[0019] Implementation mode two: if figure 1 As shown, the structure of the composite sheet of the present invention is: the structure of the composite sheet of the present invention is: the outer surface of the base metal sheet 1 is coated with an intermediate layer titanium diboride 2 and a surface active coating 3 successively, and the intermediate layer two The titanium boride 2 has a thickness of 0.6 μm and the surface-active coating 3 has a thickness of 0.8 mm. The base metal plate 1 is a pure titanium or pure aluminum plate with a thickness of 5 mm. The material of the surface active coating 3 is a multi-system coating composed of lead, manganese and rare earth element oxides, and the specific components are 78wt% of lead dioxide, 30wt% of manganese dioxide, and 4wt% of rare earth oxide.

[0020] Degrease and sandblast the 120×120×0.8mm aluminum plate, use the working parameters of spraying voltage 38V, current 160A, air pressure 0.5MPa, spraying distance 100mm, CDM-162...

Embodiment approach 3

[0021] Implementation mode three: if figure 1 As shown, the structure of the composite sheet of the present invention is: the structure of the composite sheet of the present invention is: the outer surface of the base metal sheet 1 is coated with an intermediate layer titanium diboride 2 and a surface active coating 3 successively, and the intermediate layer two The titanium boride 2 has a thickness of 3 μm and the surface-active coating 3 has a thickness of 0.2 mm. The base metal plate 1 is a pure titanium or pure aluminum plate with a thickness of 5mm. The surface active coating 3 is made of lead and manganese, and the specific components are 90wt% lead dioxide and 10wt% manganese dioxide.

[0022] Degrease and sandblast the surface of the 120×120×0.8mm aluminum plate, use the working parameters of spraying voltage 36V, current 200A, air pressure 0.5MPa, spraying distance 180mm, CDM-1620 arc spraying machine to spray 0.5~3μm thick diboride Titanium intermediate layer, elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com