Clamps for Vacuum Piping

A fixture and vacuum technology, applied in the direction of manufacturing tools, workpiece clamping devices, pipes/pipe joints/fittings, etc., can solve problems such as loosening of fixtures, release of airtight connection status of vacuum piping, and loosening of fastening nuts. achieve a firm bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, with reference to the accompanying drawings, the content of the present invention will be described in detail through embodiments. The following embodiments are merely illustrative, and it is a matter of course that the scope of rights of the present invention is not limited thereto.

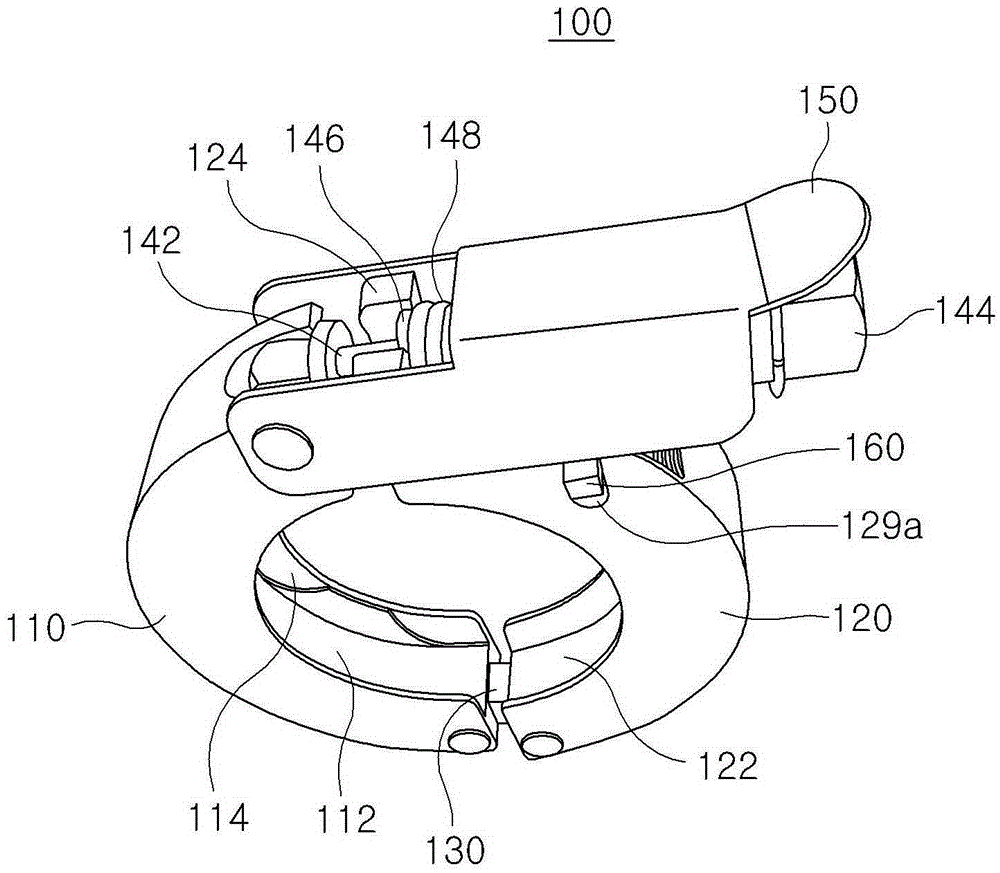

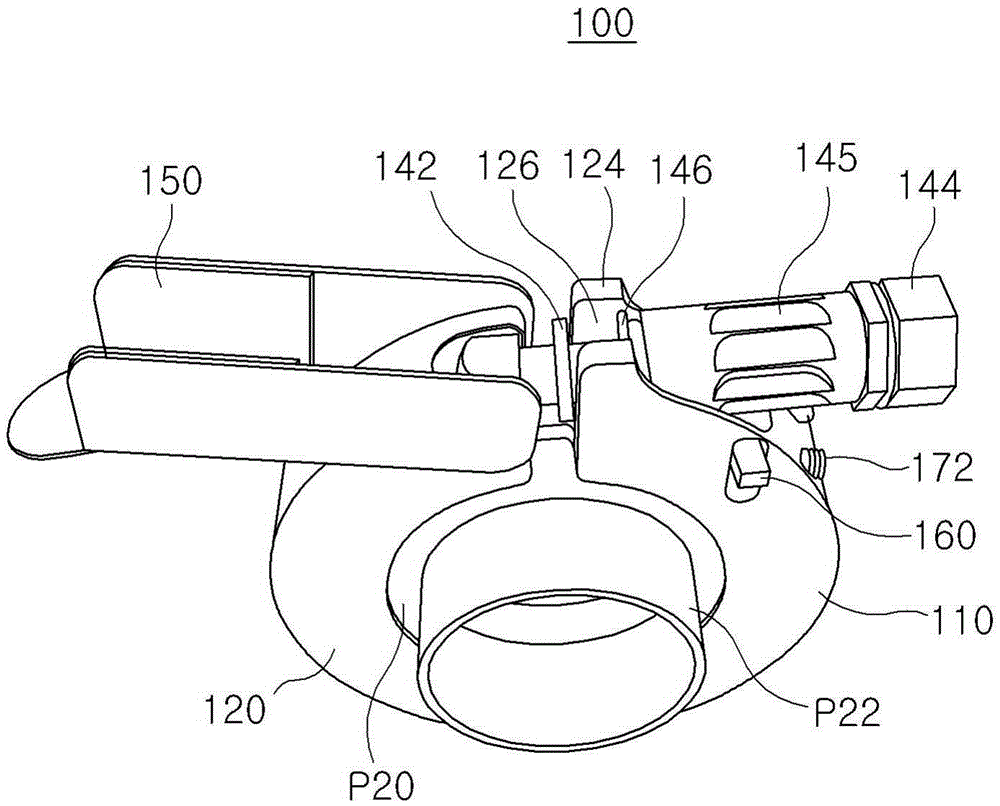

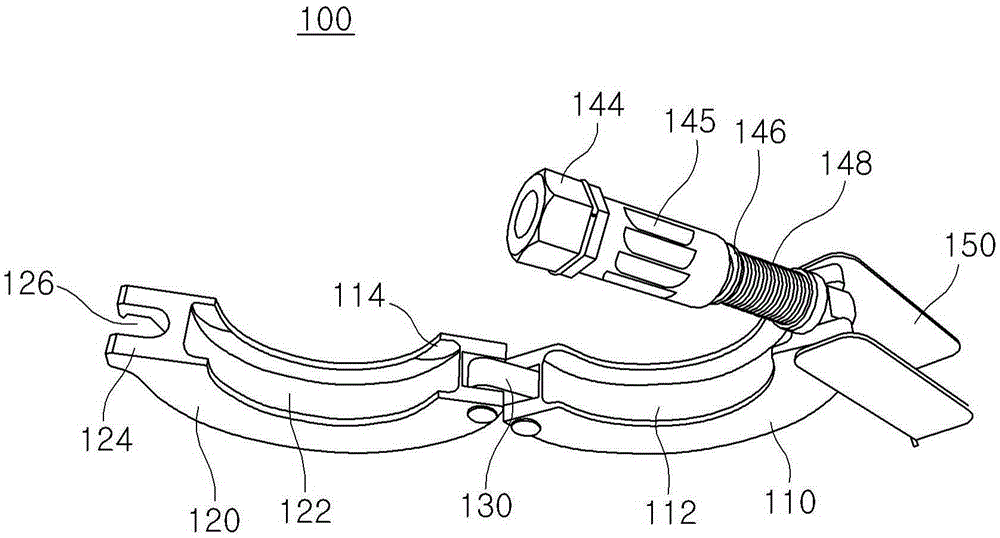

[0036] refer to Figure 1 to Figure 8 , the present invention is a jig 100 for vacuum piping, which can separate the first flange P12 of the first piping P10 and the second flange P22 of the second piping P20 in a state of being in contact with each other via the central ring CR. be fixed. The center ring CR has a portion formed of a metal material and a portion formed of a rubber material outside the portion. The above-mentioned portion made of a rubber material is used to ensure airtightness at the contact surface between the first flange P12 and the second flange P22.

[0037] The jig 100 for vacuum piping includes a first jig 110 and a second jig 120 . The first insertion g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com