Built-in battery pack for mobile communication terminal and method of manufacturing the same

A mobile communication terminal and built-in technology, which is applied in the field of built-in battery packs for mobile communication terminals and its manufacturing, can solve problems such as defective products, complex product structures and manufacturing processes, and increased man-hours, so as to reduce man-hours and costs, reduce Product defect rate, effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

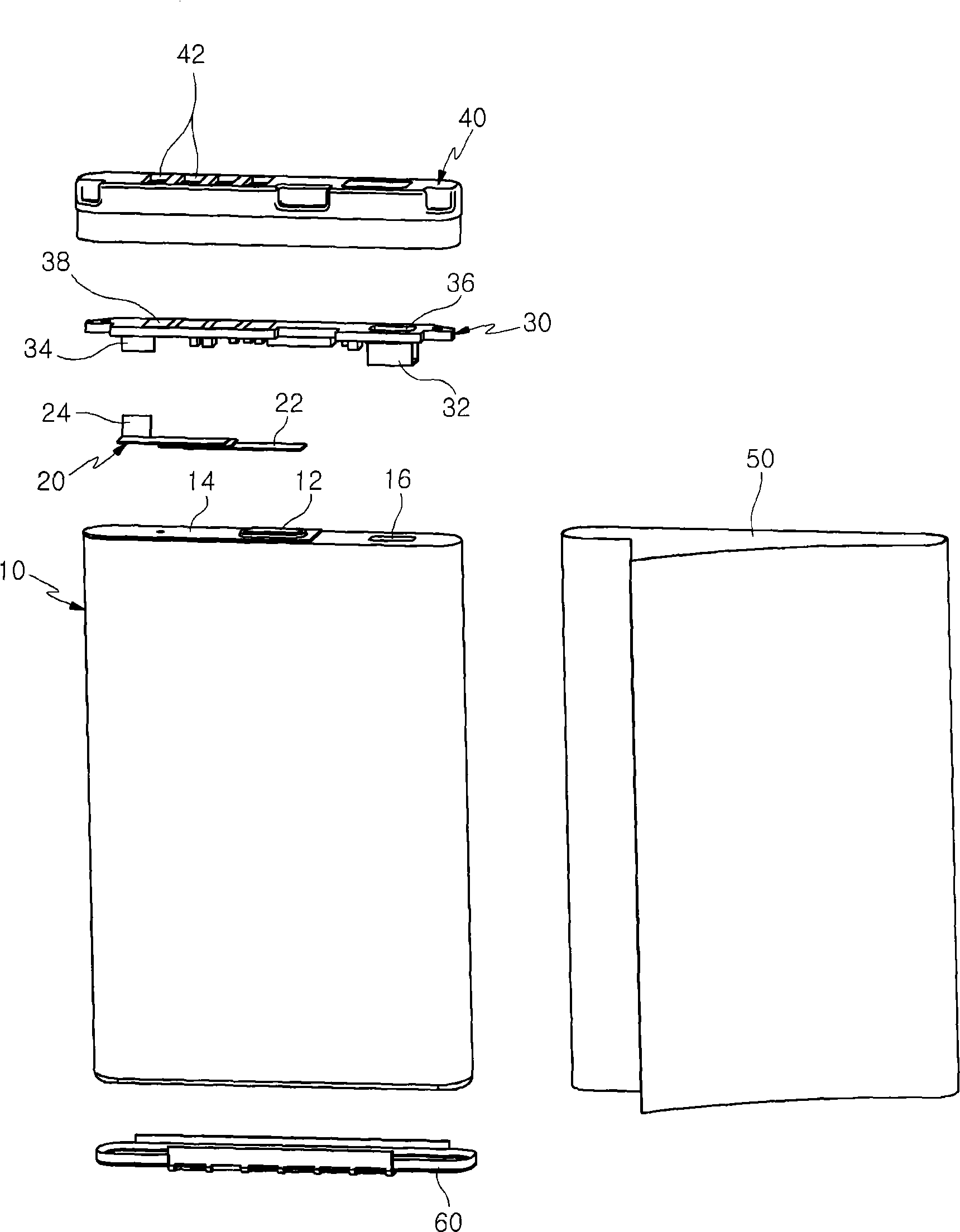

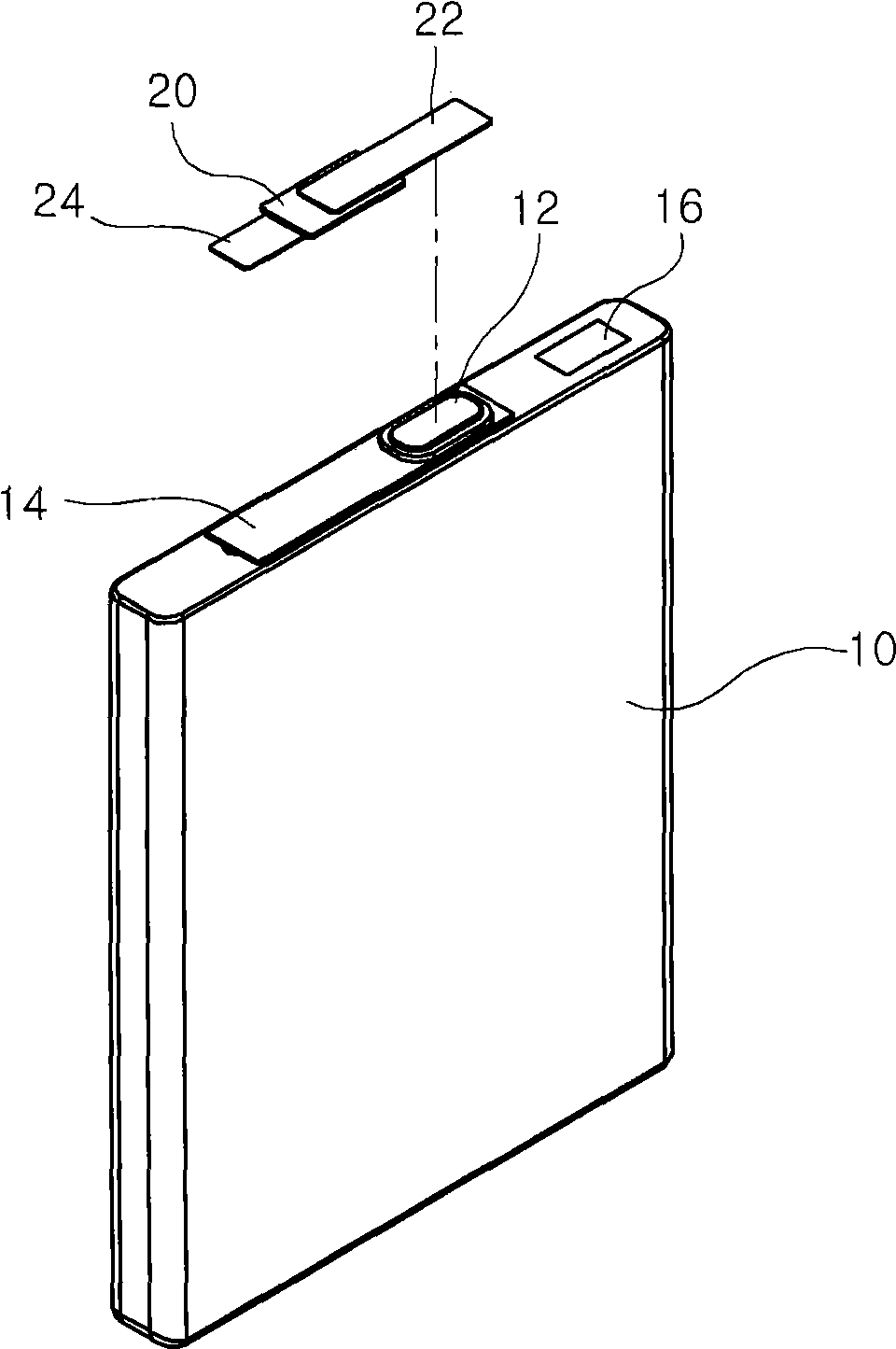

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. When describing the structure of the power supply (connection) terminal of the present invention, the anode terminal and the cathode terminal are indicated by different reference symbols, but the polarities may be reversed during design. In addition, in the description of the structure of the present invention, for the convenience of explanation, the anode and cathode terminals 16, 12 of the battery cell 10 as connection terminals, the connection parts 22, 24 of the PTC 20, and the anode and cathode nickel sheets 32, 34 of the PCM30 are sometimes They will be described together and the reference signs will be omitted.

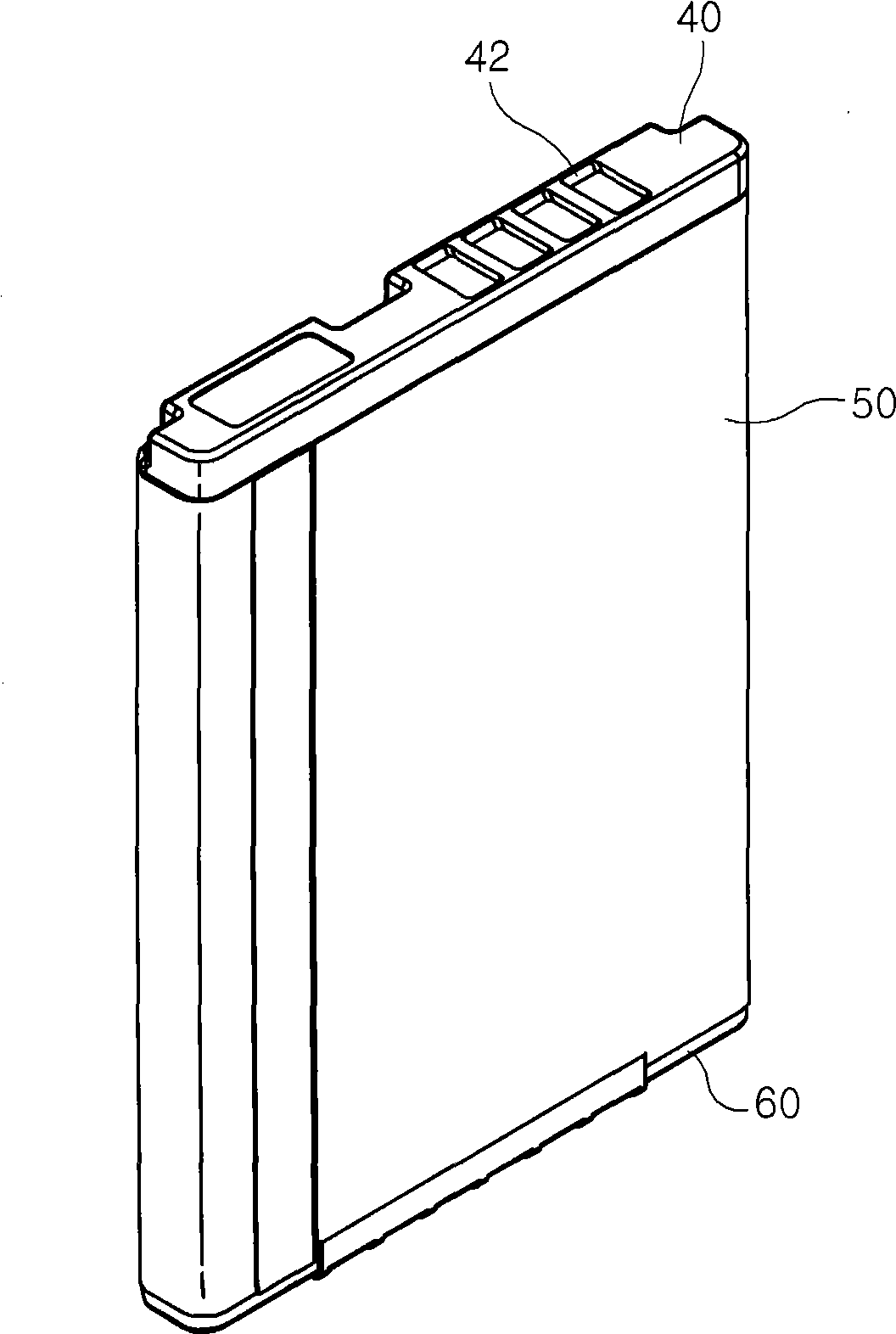

[0038] figure 1 It is a schematic diagram of the combined state of the built-in battery pack according to the manufacturing method of the present invention; figure 2 For the manufacturing method according to the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com