Production process and device for TPU laminating ornamental band

A production device and production process technology, applied in the production process and production device field of lamination decorative tape, can solve the problems of falling off, separation of lamination and decorative tape, poor stability of finished products, etc., and achieve the effect of improving quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

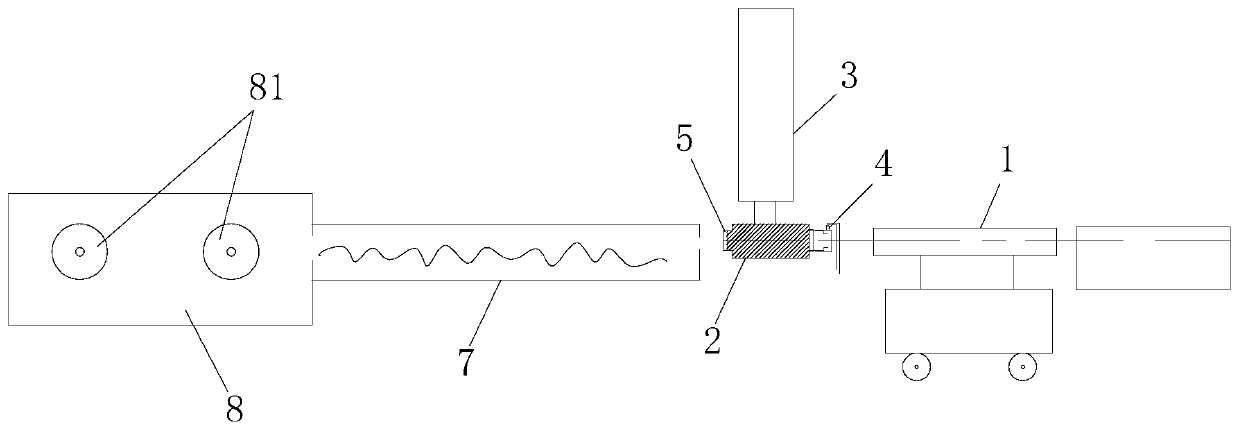

[0025] In this example, refer to figure 1 , the production process of the TPU film-coated decorative tape is carried out in the following steps,

[0026] 1) Preheat the decorative tape through the heating device 1, and the preheating temperature is 200-230°C;

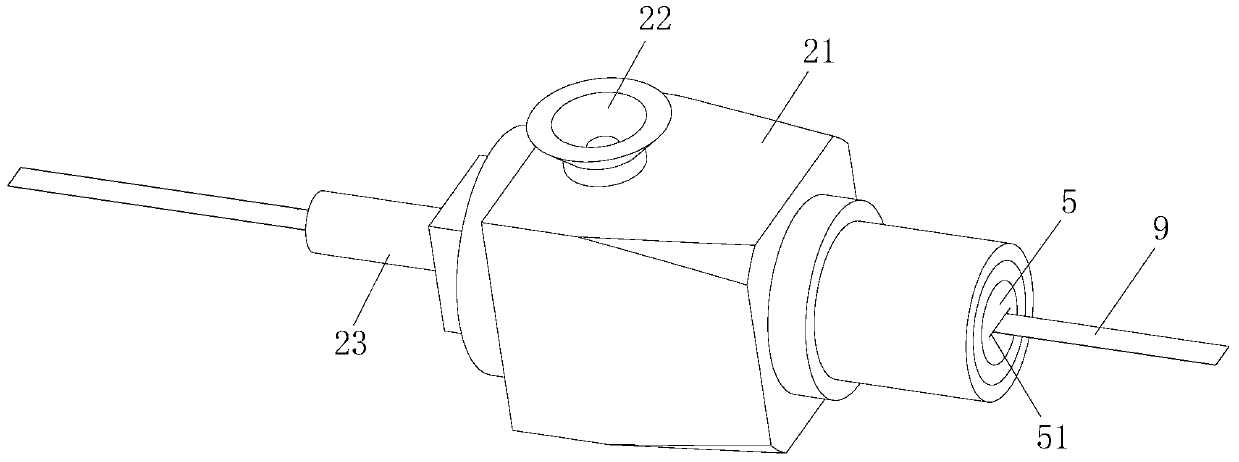

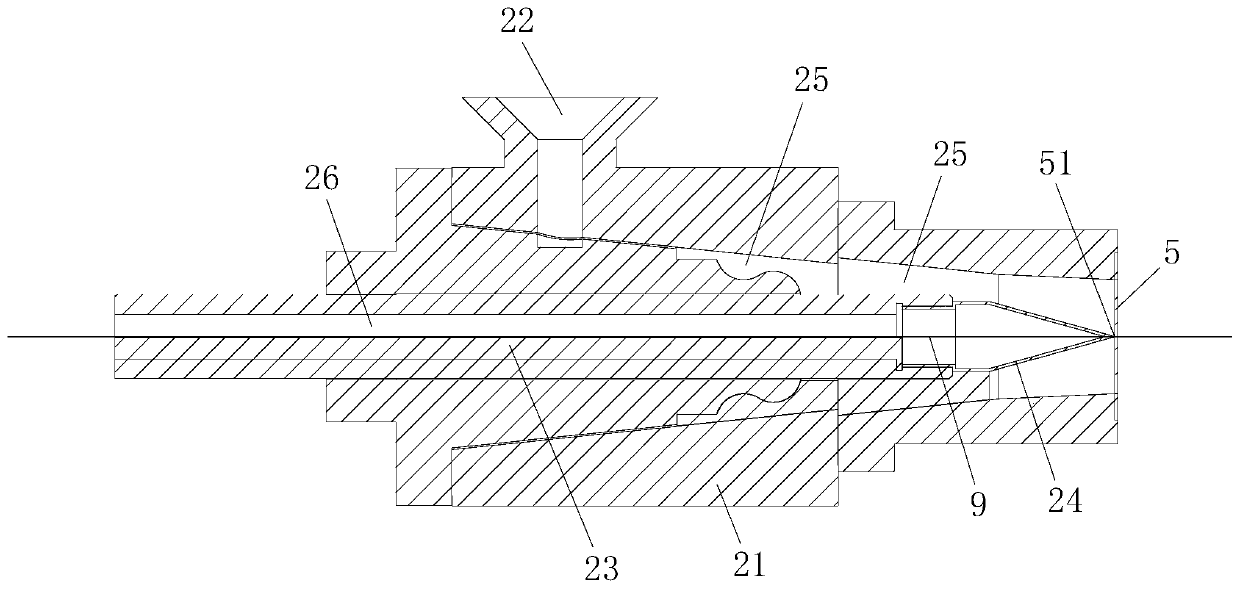

[0027] 2) Vacuum the laminating head 2 through the vacuum negative pressure device 4, then transport the preheated decorative tape to the vacuum environment in the laminating head 2, and add TPU rubber to the laminating head 2 at the same time ;

[0028] 3) Through the control of the laminating machine 3, the TPU rubber material flows along the flow channel to the mold sleeve located in the laminating head 2 after equalizing the pressure in the flow channel of the laminating head 2;

[0029] 4) After the decorative tape passes through the mold sleeve, the TPU rubber material is combined with the decorative tape through the negative pressure in the mold sleeve;

[0030] 5) After the decorative belt is combined with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com