A kind of preparation method of nano-hydroxyapatite-chitosan artificial bone

A technology of nano-hydroxyapatite and chitosan, which is applied in pharmaceutical formulations, prostheses, and drug delivery, can solve problems such as processing difficulties and restrictions on popularization and application, and achieve simple preparation processes, controllable process parameters, and high dispersibility Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

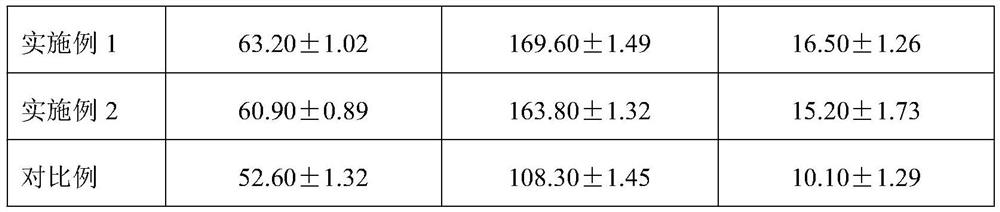

Examples

Embodiment 1

[0032] The preparation of embodiment 1 nanometer hydroxyapatite-chitosan artificial bone

[0033] 1. Preparation of surface-modified nano-hydroxyapatite. Take polyethylene glycol 600, configure it into a 5% aqueous solution, and add nano-hydroxyapatite under stirring. After the addition, keep stirring at 55°C for 6 hours, then ultrasonically disperse for 3 hours, filter, and the filter cake is washed with absolute ethanol in turn. 1. After washing with chloroform, dry the organic solvent, vacuum-dry at 100° C. for 24 hours, and grind to obtain surface-modified nano-hydroxyapatite.

[0034] 2. Preparation of butyrylated chitosan. Take chitosan powder, add methanesulfonic acid in an ice-water bath, stir to make chitosan fully swell, slowly add butyric anhydride dropwise under continuous stirring, react at room temperature for 8 hours, overnight at -20°C, take out, filter, double steam Suspended in water, adjusted to pH 7 with ammonia water, boiled for 2 hours, filtered while h...

Embodiment 2

[0037] The preparation of embodiment 2 nanometer hydroxyapatite-chitosan artificial bone

[0038] 1. Preparation of surface-modified nano-hydroxyapatite. Take polyethylene glycol 800, configure it into a 5% aqueous solution, and add nano-hydroxyapatite under stirring. After the addition, keep stirring at 60°C for 6 hours, then ultrasonically disperse for 3.5 hours, filter, and the filter cake is washed with absolute ethanol in turn. 1. After washing with chloroform, dry the organic solvent, vacuum-dry at 90° C. for 24 hours, and grind to obtain surface-modified nano-hydroxyapatite.

[0039] 2. Preparation of butyrylated chitosan. Take chitosan powder, add methanesulfonic acid in an ice-water bath, stir to make chitosan fully swell, slowly add butyric anhydride dropwise under continuous stirring, react at room temperature for 8 hours, overnight at -20°C, take out, filter, double steam Suspended in water, adjusted to pH 7 with ammonia water, boiled for 2 hours, filtered while ...

Embodiment 3

[0042] The preparation of embodiment 3 nanometer hydroxyapatite-chitosan artificial bone

[0043] 1. Preparation of surface-modified nano-hydroxyapatite. Take polyethylene glycol 1000, configure it into a 10% aqueous solution, add nano-hydroxyapatite under stirring, after the addition, keep stirring at 80°C for 10 hours, then ultrasonically disperse for 3 hours, filter, and filter the cake in turn with absolute ethanol 1. After washing with chloroform, dry the organic solvent, vacuum-dry at 140° C. for 40 hours, and grind to obtain surface-modified nano-hydroxyapatite.

[0044] 2. Preparation of butyrylated chitosan. Take chitosan powder, add methanesulfonic acid in an ice-water bath, stir to make chitosan fully swell, slowly add butyric anhydride dropwise under continuous stirring, react at room temperature for 8 hours, overnight at -20°C, take out, filter, double steam Suspended in water, adjusted to pH 7 with ammonia water, boiled for 2 hours, filtered while hot, washed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com