Ultrasonic sensor

A sensor and ultrasonic technology, applied in the ultrasonic field, can solve the problems of affecting the vibration of piezoelectric ceramic sheets, complex process, decreased sensitivity, etc., to reduce the binding force, simplify the process, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

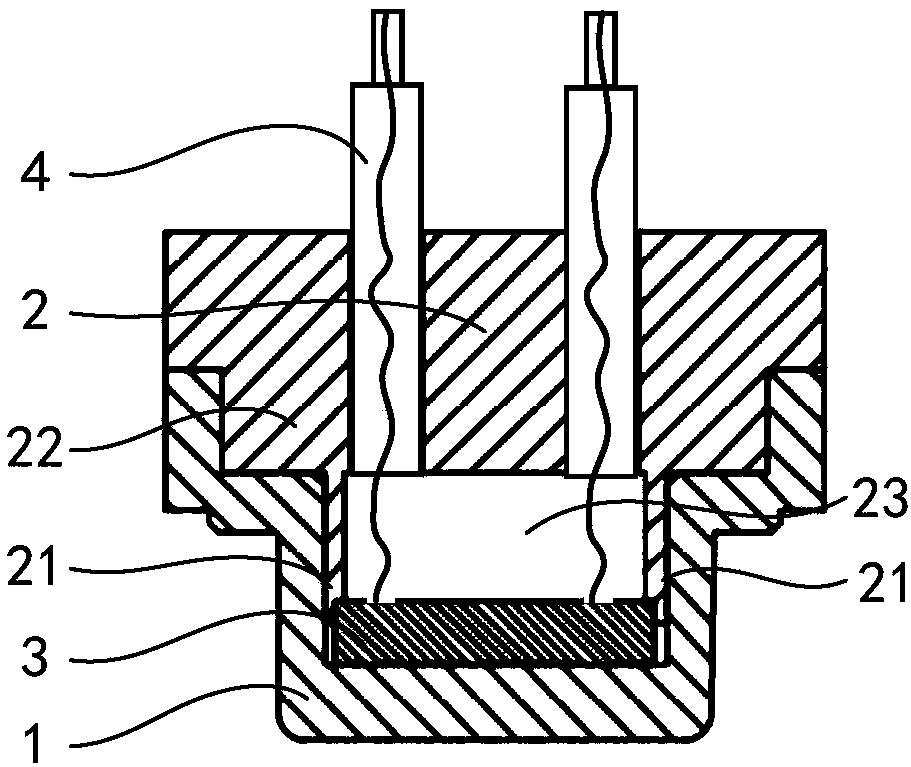

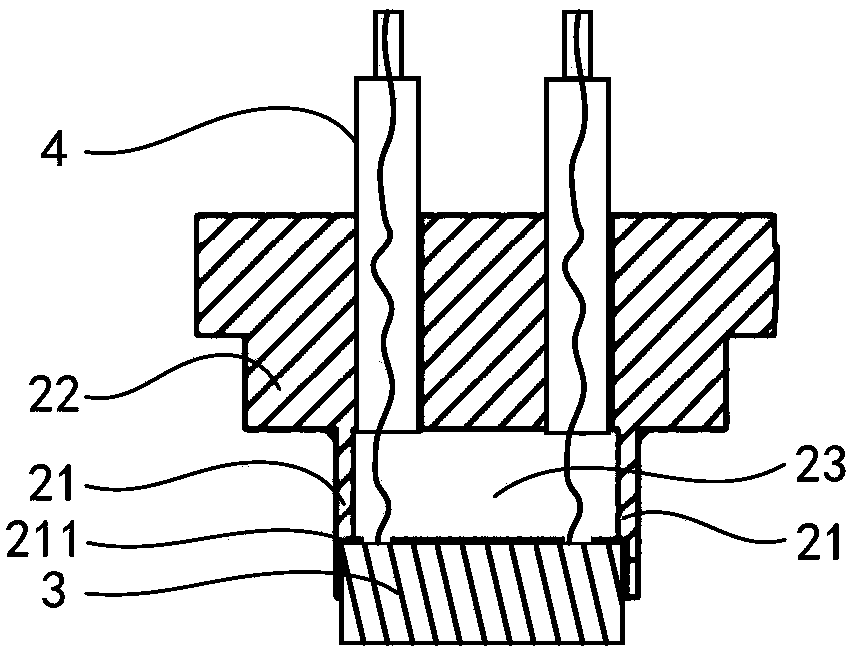

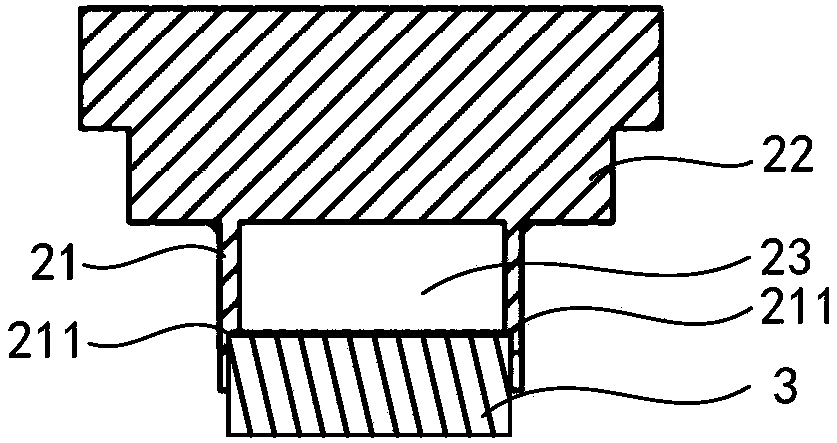

[0037] In this embodiment, the other end of the support member 21 extends along the side wall of the piezoelectric ceramic sheet 3 and forms a first installation groove, and the outer wall surface of the piezoelectric ceramic sheet 3 is against the first mounting groove. On the inner wall surface of a mounting groove; the cross-sectional area of the first mounting groove is greater than the cross-sectional area of the groove 23, and a first step portion 211 is formed before the first mounting groove and the groove 23, The top of the piezoelectric ceramic sheet 3 abuts against the first step portion 211 , and the bottom of the piezoelectric ceramic sheet 3 abuts against the bottom of the cavity of the housing 1 .

[0038] In this embodiment, the piezoelectric ceramic sheet 3 is in an annular structure, and the shape of the first mounting groove is adapted to the shape of the piezoelectric ceramic sheet 3. Therefore, the piezoelectric ceramic sheet 3 can be Partially accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com