Novel Fabric Made of All Elastomeric Fiber and Its Applications

a technology of elastomeric fibers and fabrics, applied in the field of elastic fabrics, can solve the problems of easy rip or burst weftwise, difficult to return to its original shape, etc., and achieve the effects of good elastic resilience, easy stretching, and little binding for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

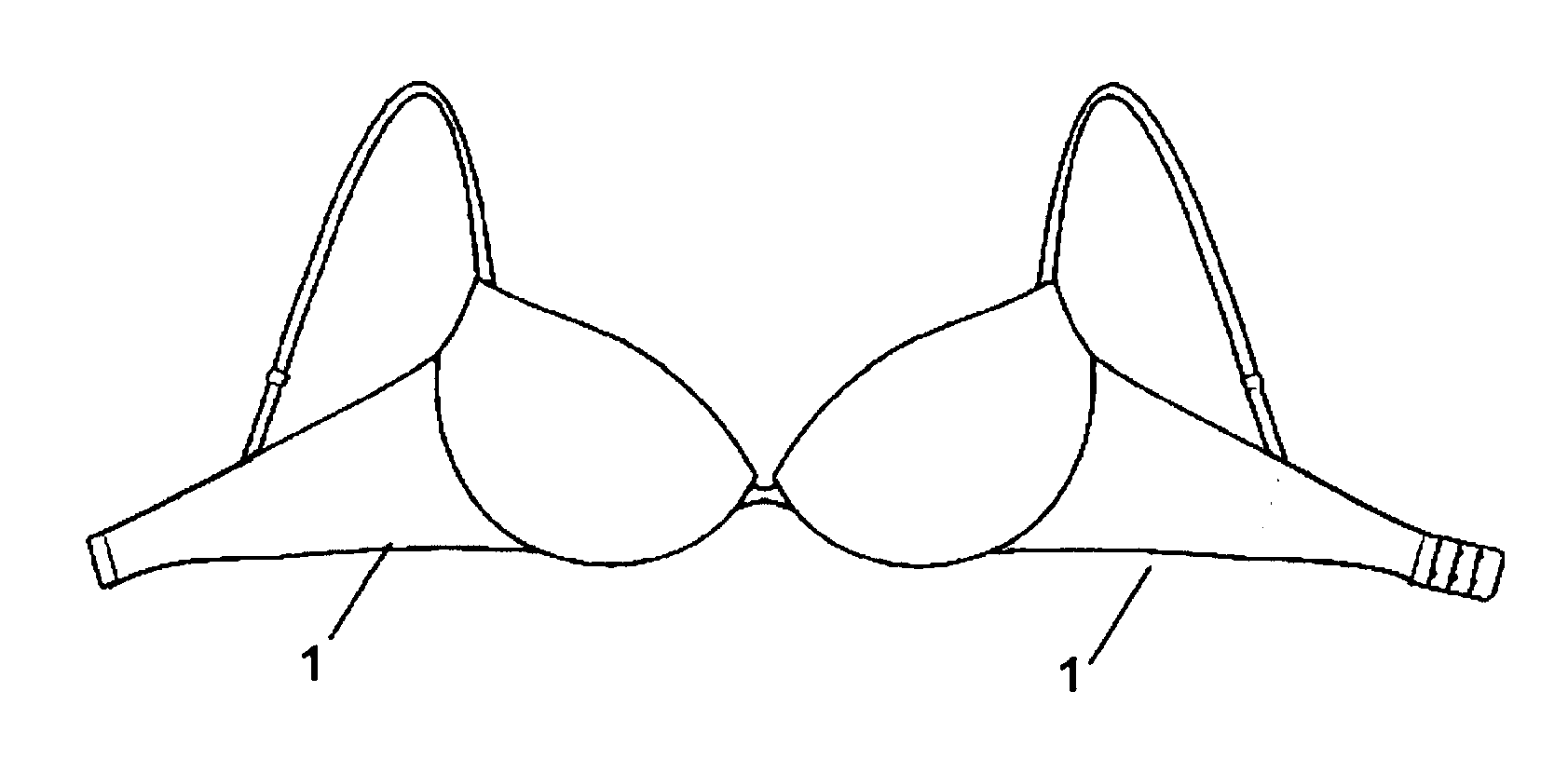

Compared with ordinary woven band, the 100% spandex fabric greatly enhances the elastic resilience and force. In addition, the fabric has high wear resistance, maintaining good elastic resilience and force after long-term wear, which can solve the difficulties that the shoulder straps easily become slide and provide a weak elastic resilience and force. Meanwhile, the 100 percent spandex fabric can meet the requirements on flatness, smoothness, close fit, sound elasticity, high level of wearing comfort, good hand feel, etc, which can be applied to brassiere (to aid the elastic supporting effect between cups and the back buckle), shoulder strap, swimwear, briefs, lingerie, etc.

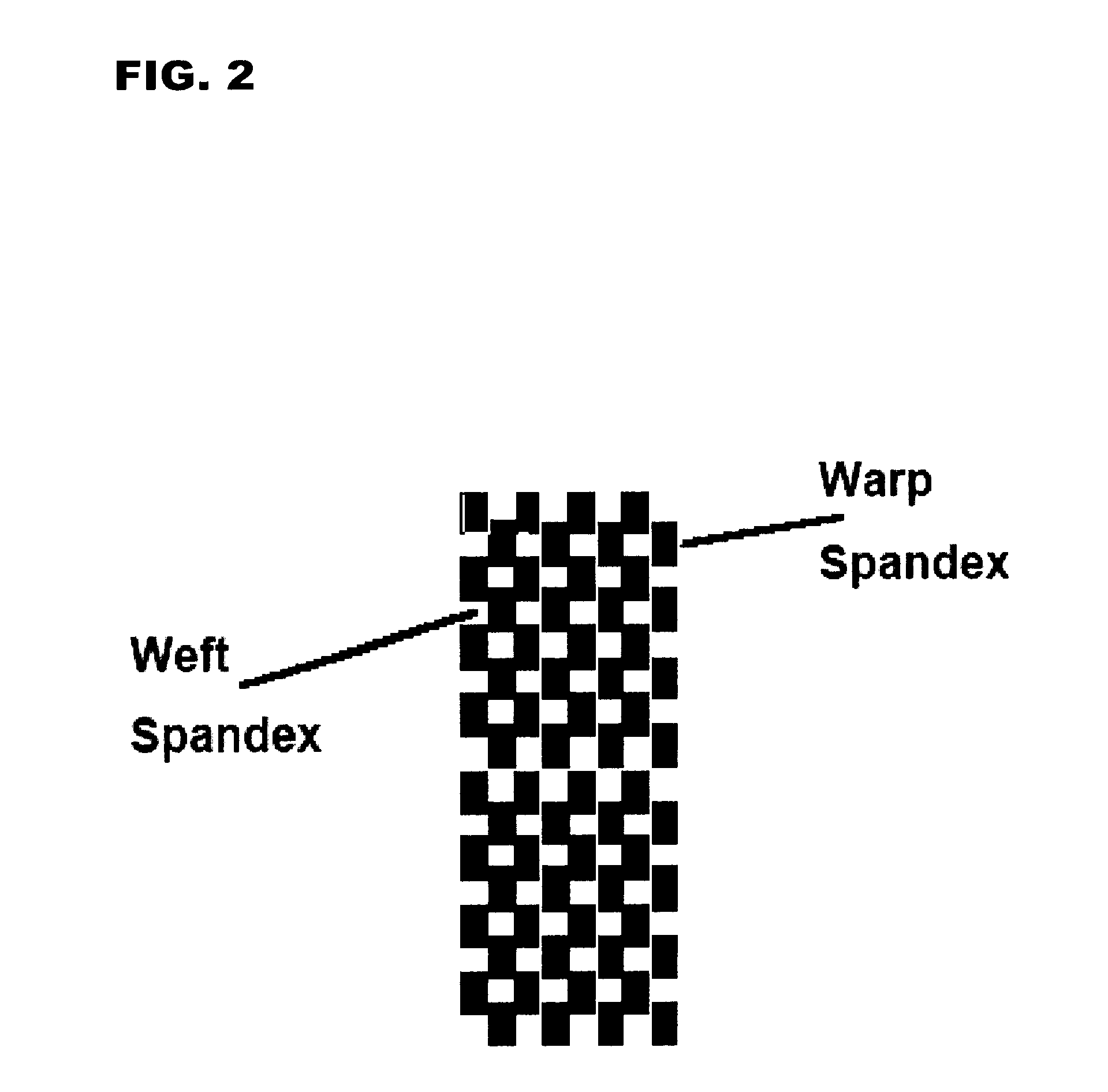

The concrete weaving process of present novel fabric is as follows:

I. Warp yarn and weft yarn which are made of 100% spandex filament material are mutually crocheted.

II. The back weft of the spandex filament is required to pass through a filament packaging frame and a weft yarn accelerating conveyer device is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| elongation property | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com