Anion-cation co-doped bismuth silicate scintillation crystal and preparation method thereof

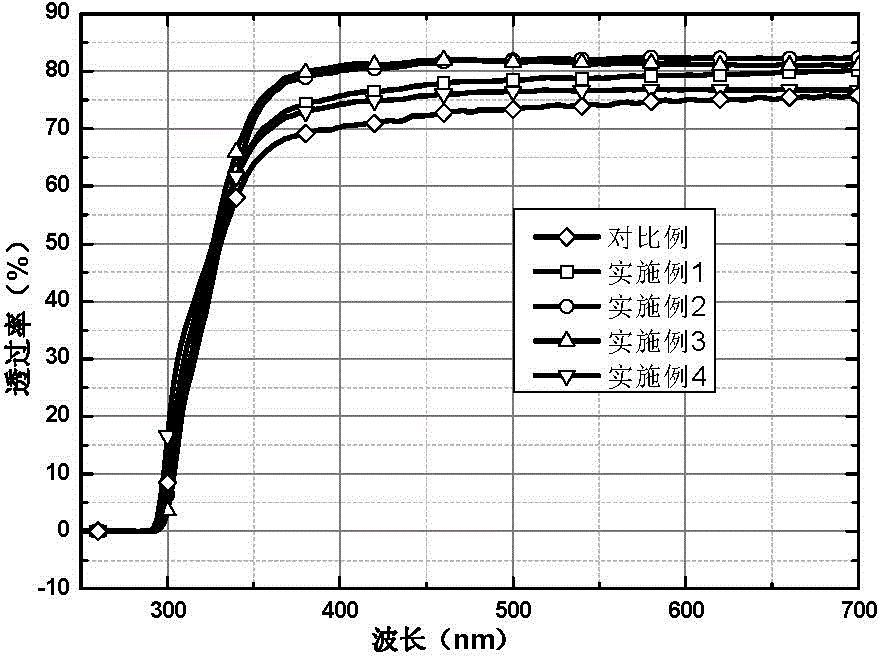

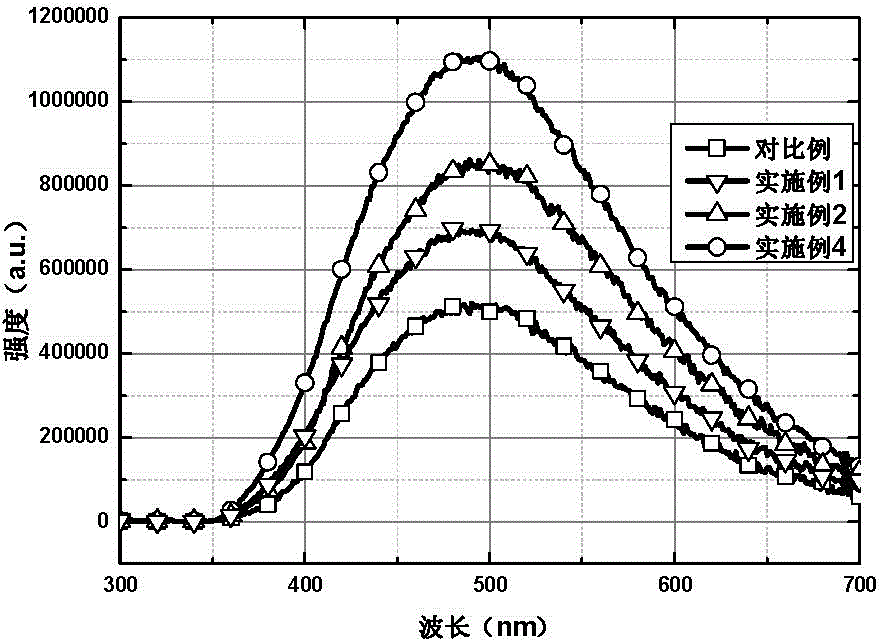

A scintillation crystal, anion and cation technology, applied in the direction of crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of low absorption and emission spectrum intensity, and achieve the goal of reducing binding force, increasing luminous intensity, and improving absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The Bi with a purity of not less than 99.99% 2 O 3 , SiO 2 And BaF 2 The solid powder is dried at about 200℃ for 20 hours for dehydration; the Bi 2 O 3 , SiO 2 Weigh accurately according to the molar ratio of 2:3, mix well, press into a block, and then sinter it at 880°C for 5 hours by the high-temperature solid phase method to obtain the BSO polycrystalline material;

[0050] Take the BSO single crystal as the seed crystal, and use the dopant BaF 2 (200ppm) Fully mix with BSO polycrystalline material by means of mechanical mixing, and then will be doped with BaF 2 The BSO polycrystalline material and seed crystals are put into a platinum crucible with a thickness of 0.14mm and sealed. Then use the crucible descending method for crystal growth: first raise the furnace temperature to 1130°C for 15 hours and keep it for 6 hours; gradually raise the down tube until all the raw materials in the crucible are melted, and then keep it for 1.5 hours; Lower the speed and lead down t...

Embodiment 2

[0053] The Bi with a purity of not less than 99.99% 2 O 3 , SiO 2 And BaF 2 The solid powder is dried at about 200℃ for 20 hours for dehydration; the Bi 2 O 3 , SiO 2 Accurately weigh it according to the molar ratio of 2:3 and mix it evenly, press it into a block, and then use the high-temperature solid phase method to sinter it at 900°C for 3 hours to obtain the BSO polycrystalline material;

[0054] Take the BSO single crystal as the seed crystal, and use the dopant BaF 2 (500ppm) Fully mix with BSO polycrystalline material by means of mechanical mixing, and then will be doped with BaF 2 The BSO polycrystalline material and seed crystals are put into a platinum crucible with a thickness of 0.14mm and sealed. Then use the crucible descending method for crystal growth: first raise the furnace temperature to 1140°C for 15 hours and keep it for 6 hours; gradually raise the down tube until the raw materials in the crucible are all melted, and then keep it for 1.5 hours; Lower the spe...

Embodiment 3

[0057] The Bi with a purity of not less than 99.99% 2 O 3 , SiO 2 And BaF 2 The solid powder is dried at about 200℃ for 20 hours for dehydration; the Bi 2 O 3 , SiO 2 Weigh accurately according to the molar ratio of 2:3, mix well, press into a block, and then sinter it at 880°C for 5 hours by the high-temperature solid phase method to obtain the BSO polycrystalline material;

[0058] Take the BSO single crystal as the seed crystal, and use the dopant BaF 2 (1000ppm) Fully mix with BSO polycrystalline material by means of mechanical mixing, and then will be doped with BaF 2 The BSO polycrystalline material and seed crystals are put into a platinum crucible with a thickness of 0.14mm and sealed. Then use the crucible descending method for crystal growth: first raise the furnace temperature to 1120°C for 12 hours and keep it warm for 5 hours; gradually raise the down tube until all the raw materials in the crucible are melted, and then keep it warm for 1 hour; Lower the speed and lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com