Stepless speed regulation hydraulic drive system of screw conveyor for super large diameter shield tunneling machine

A screw conveyor, super-large diameter technology, applied in the field of stepless speed regulation hydraulic drive system for super-large diameter shield screw conveyor, can solve the problems of insufficient muck conveying capacity, insufficient rescue torque, small driving torque, etc. The effect of wide range, novel design and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

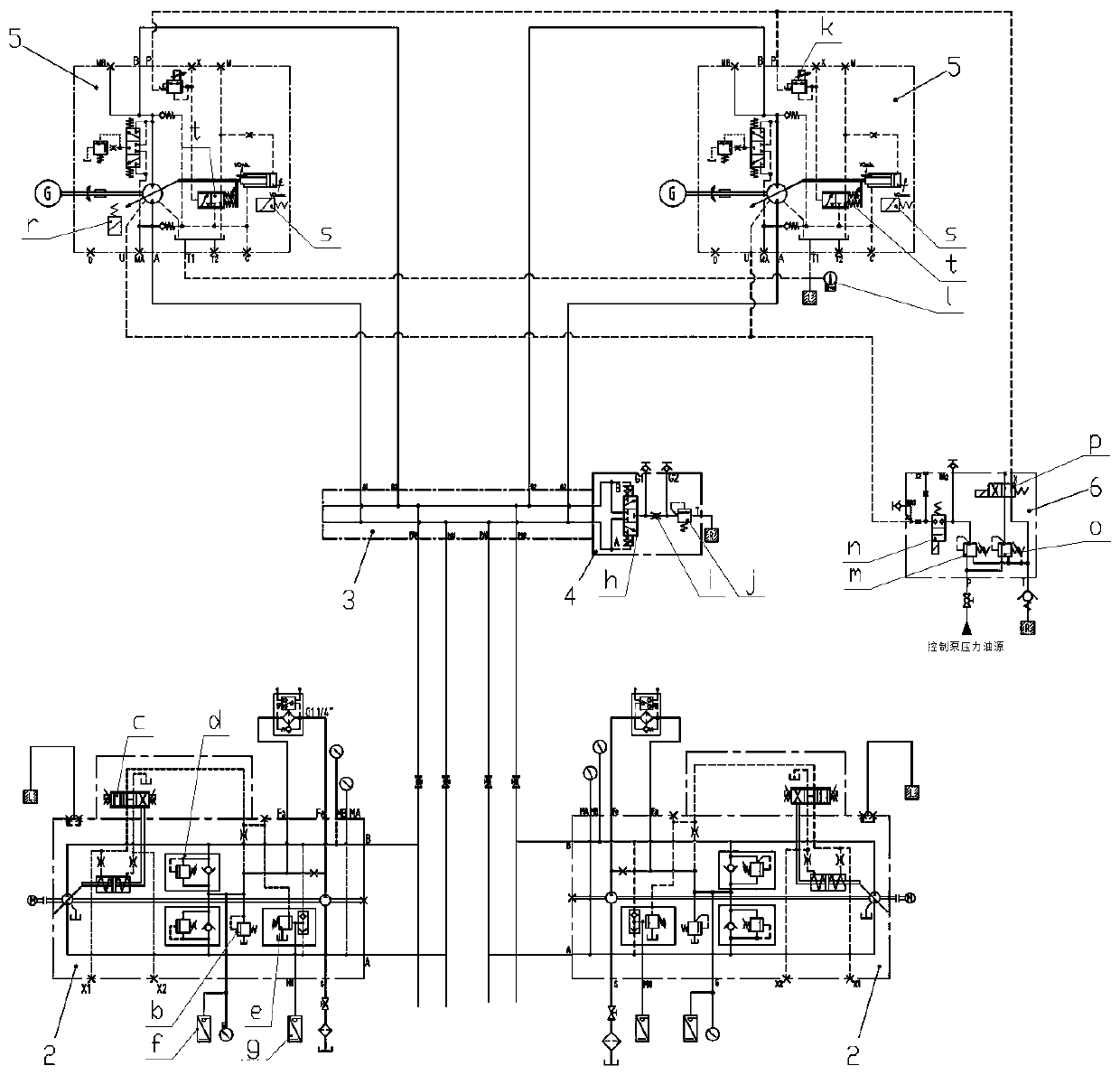

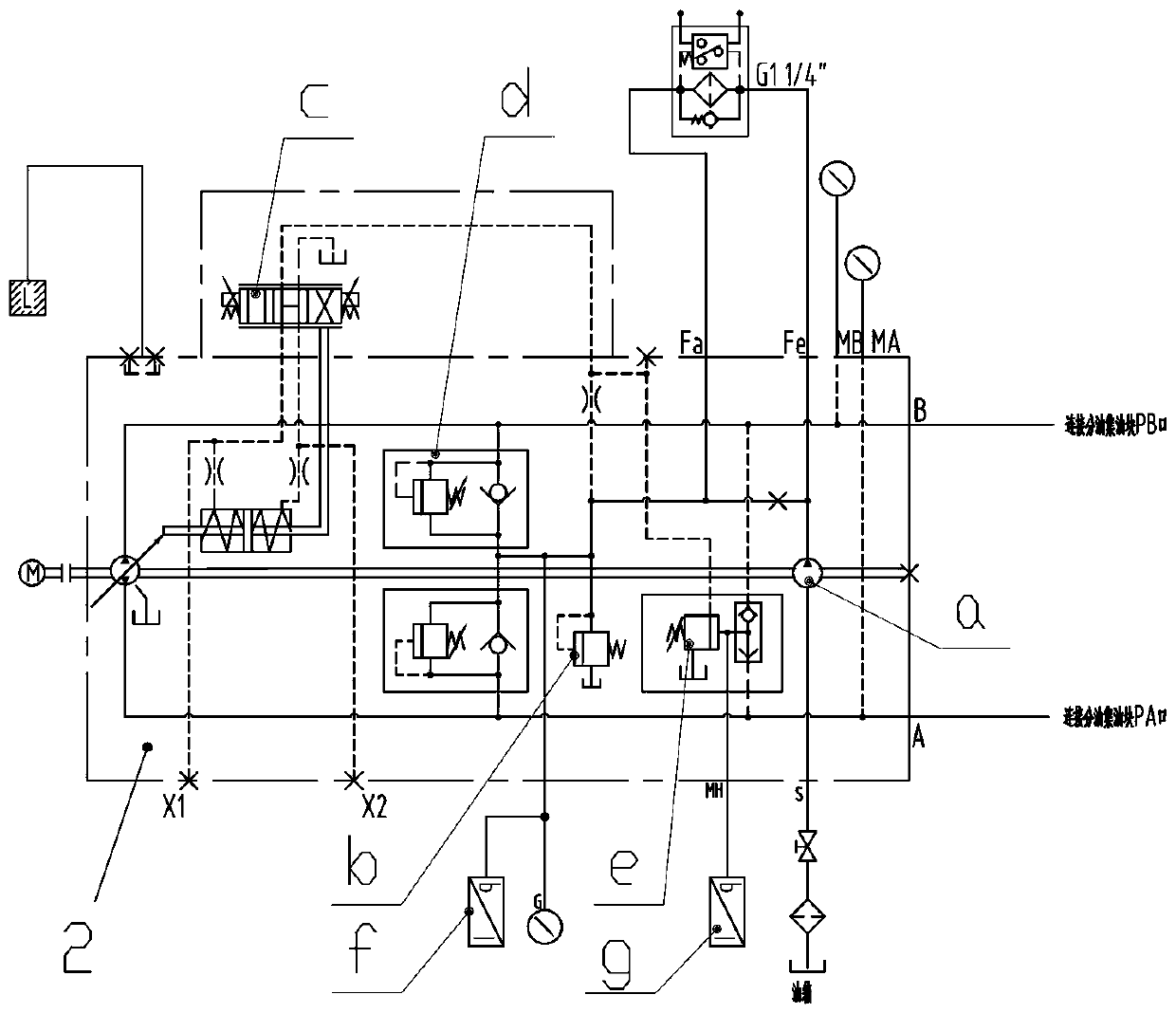

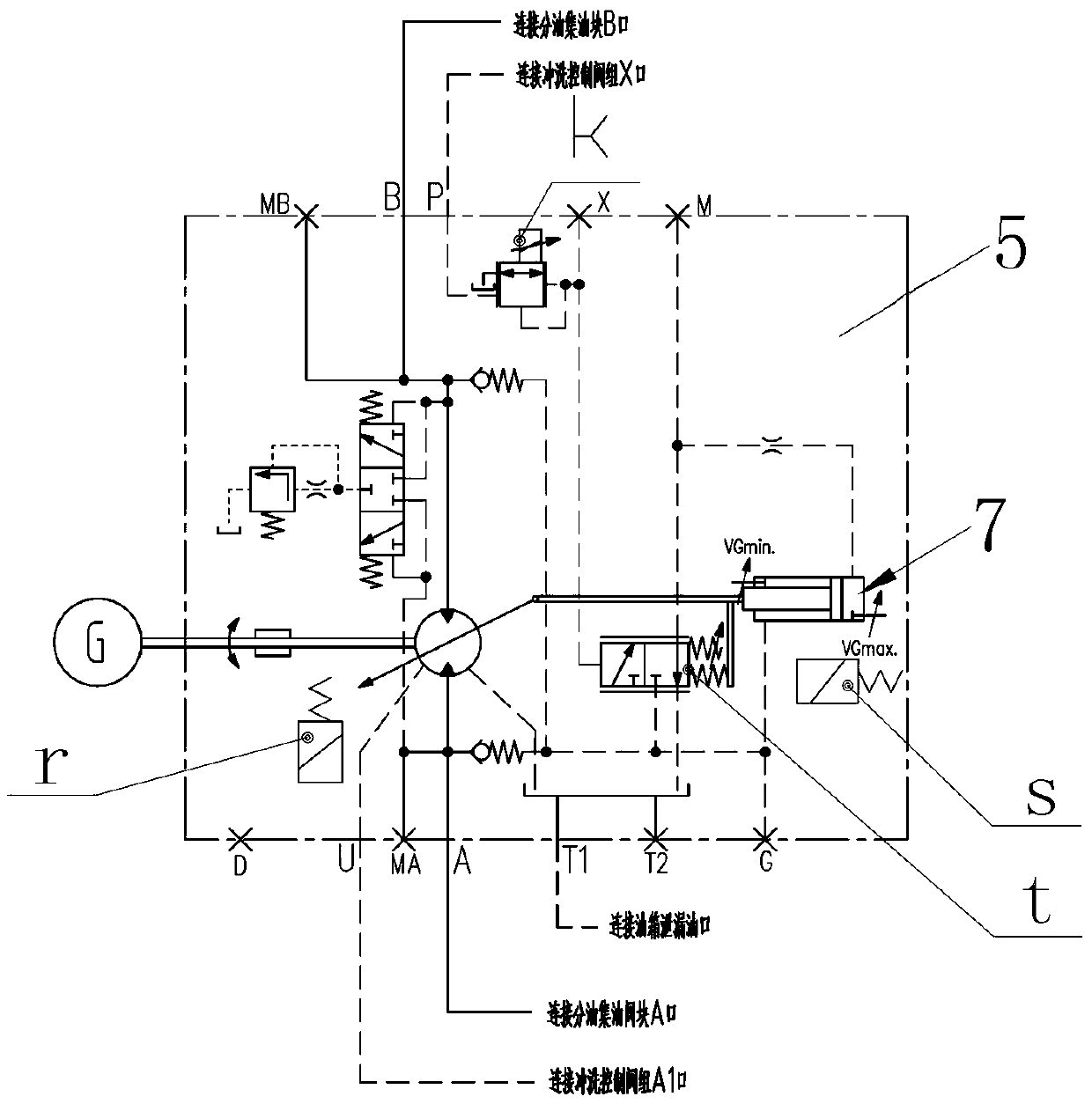

[0024] Embodiment one, see figure 1 As shown, a stepless speed-regulating hydraulic drive system for a screw conveyor for super-large-diameter shield tunneling, including a fuel tank, a hydraulic pump set, a speed-regulating hydraulic circuit, a reducer, a hydraulic motor set, and a control unit. The hydraulic circuit is connected with the hydraulic motor group. The speed regulating hydraulic circuit is equipped with an oil separation and collection valve module, a flushing control valve module, a control pump, and a sensor module. The oil separation and collection valve module, the flushing control valve module and the sensor module are all connected to the The control unit is connected by communication. The hydraulic pump group includes hydraulic pump 1 and hydraulic pump 2. The hydraulic pump 1 and hydraulic pump 2 are connected to the hydraulic motor group through the oil separation and oil collection valve module. The hydraulic pump 1, hydraulic pump Pump 2 is provided wi...

Embodiment 2

[0026] Embodiment two, see Figure 1~5 As shown, it is basically the same as Embodiment 1, except that the oil separation and collection valve module also includes a hot oil valve group, and the hot oil valve group is connected to the oil tank.

[0027] Preferably, the hot oil valve group includes hot oil valve 1 and hot oil valve 2; said hot oil valve 1 and hot oil valve 2 both include: hydraulic control valve, back pressure valve, hydraulic control valve control end and hydraulic motor group The other end of the hydraulic control valve is connected to the back pressure valve, and a damping hole is also arranged on the connecting pipeline between the hydraulic control valve and the back pressure valve, and the outlet end of the back pressure valve is connected to the fuel tank through the oil return pipeline.

[0028] Above, hydraulic pump 1 and hydraulic pump 2 are both swash plate axial piston pumps. see figure 1 As shown in , the oil separation and collection valve modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com