Variable-parameter crank shaft corrective polishing method and device

A crankshaft correction and polishing device technology, which is applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problem that journal rounding and journal side polishing are difficult to implement, and journal roundness error correction and roundness cannot be corrected. Errors and other problems, to achieve the effect of reducing time, high processing efficiency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

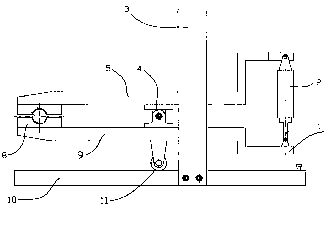

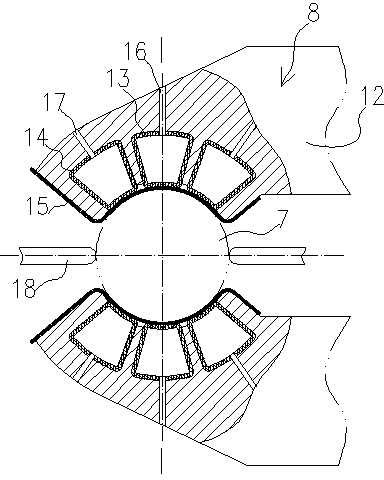

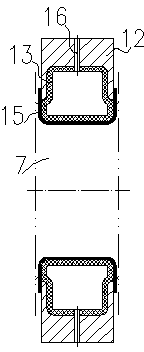

[0014] Such as Figure 1 to Figure 3 As shown, the variable parameter crankshaft correction polishing device includes a machine tool (not shown, such as a lathe) that drives the crankshaft to rotate, a follow-up clamping device 1, and two polishing heads 8 arranged on the follow-up clamping device 1, The follow-up clamping device 1 includes an upper pressing arm 5, a lower pressing arm 9, an oil cylinder 2, a guide rail 10 and a stop frame 3. The upper pressing arm 5 and the lower pressing arm 9 are hinged in the middle by a pin 4, and the two ends of the oil cylinder 2 are respectively Hinged with the rear ends of the upper pressing arm 5 and the lower pressing arm 9, the lower pressing arm 9 is equipped with a roller 11 cooperating with the guide rail 10, the stop frame 3 is in an inverted U shape, and its two ends are fixed on both sides of the guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com