Assembly line for dense-type bus duct

A bus duct and assembly line technology, which is applied in the field of assembly devices for producing bus ducts, can solve problems such as insufficient pressing force, slow assembly speed, and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

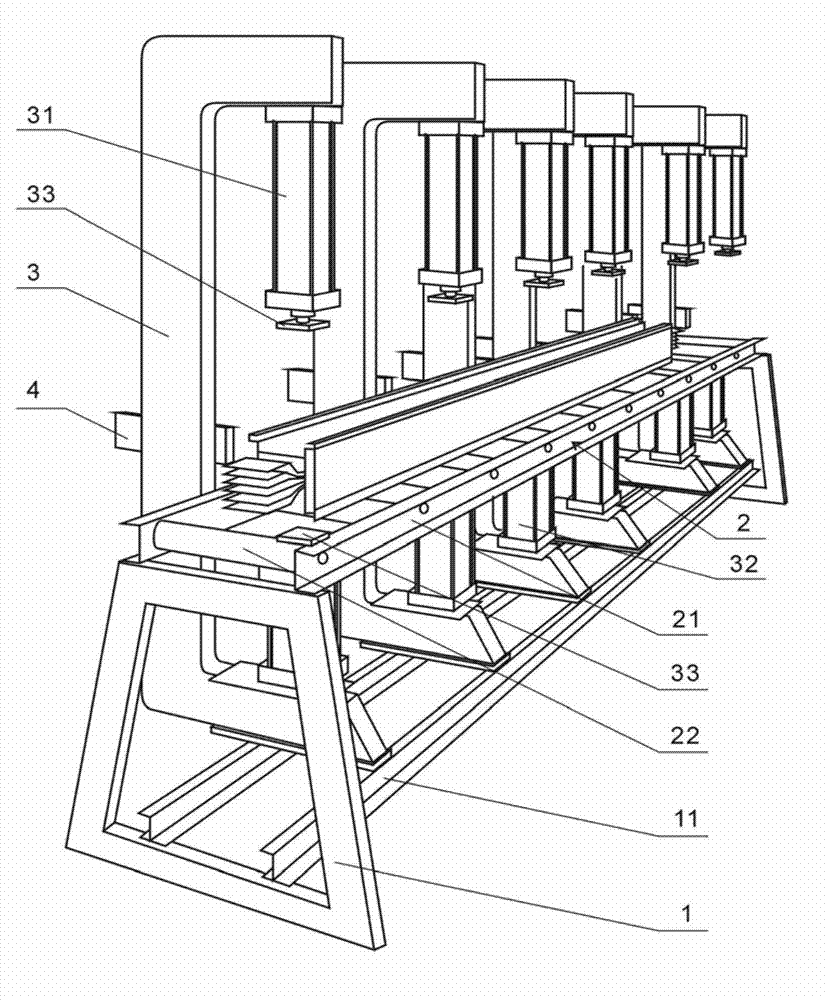

[0017] refer to figure 1 It can be seen that an intensive bus duct assembly line of the present invention includes a pressing mechanism, a tightening mechanism, a bracket 1, and a roller support 2 for placing the bus duct. The pressing mechanism includes a pressing frame 3 and an upper cylinder 31 , the lower cylinder 32, the output end of the upper cylinder 31 and the output end of the lower cylinder 32 are respectively fixed with a compression gasket 33 along with the operation of the upper and lower cylinders, and the compression frame 3 is a U-shaped compression frame. The bottom of the support 1 is provided with two moving bars 11, and the support 1 is provided with a group of six compression frames 3, and the bottoms of the compression frames 3 are fixed on the moving bars 11 side by side in parallel, forming a movable link between the compression frame 3 and the support 1. Mobile connection, the two ends of the compression frame 3 are respectively placed on the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com