Double-layer coaxial cable connector assembly line

A coaxial cable and assembly line technology, applied in the field of cable joint assembly devices, can solve the problems of low production efficiency, low degree of automation, and high labor intensity, and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

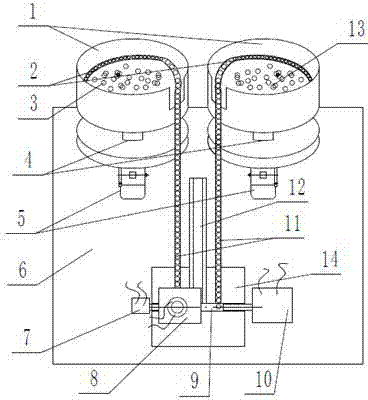

[0014] Depend on figure 1 It is known that a double-layer coaxial cable joint assembly line consists of a hopper 1, a spiral track 2, a stem 3, a central shaft 4, a motor 5, a base 6, a third cylinder 7, a second cylinder 8, a guide groove 9, a first Cylinder 10, slide rail 11, finished product groove 12, shell 13 are formed. The screw feeder consists of a motor 5, a central shaft 4 and a hopper 1. The hopper 1 is fixed above the base 6 , the motor 5 is fixed below the base 6 , and the hopper 1 is connected to the motor 5 through the central shaft 4 . A spiral track 2 is arranged on the screw feeder. One end of the slide rail 11 is connected to the spiral track 2 , and the other end is placed above the assembly plate 14 . The stem 3 and the shell 13 are placed in different screw feeder hoppers 1 . The spiral track 2 is fixed on the inner wall of the hopper 1 of the screw feeder, and has a certain angle with the inner wall. The width of the spiral track 2 can be adjusted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com