High-frequency quenching machine for shaft parts

A technology for high-frequency quenching and shaft parts, applied in the field of parts processing, can solve the problems of inability to guarantee the safety of workers, high labor intensity of workers, etc., to reduce the possibility of scalding the operator's hand, reduce the possibility of taking workpieces, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

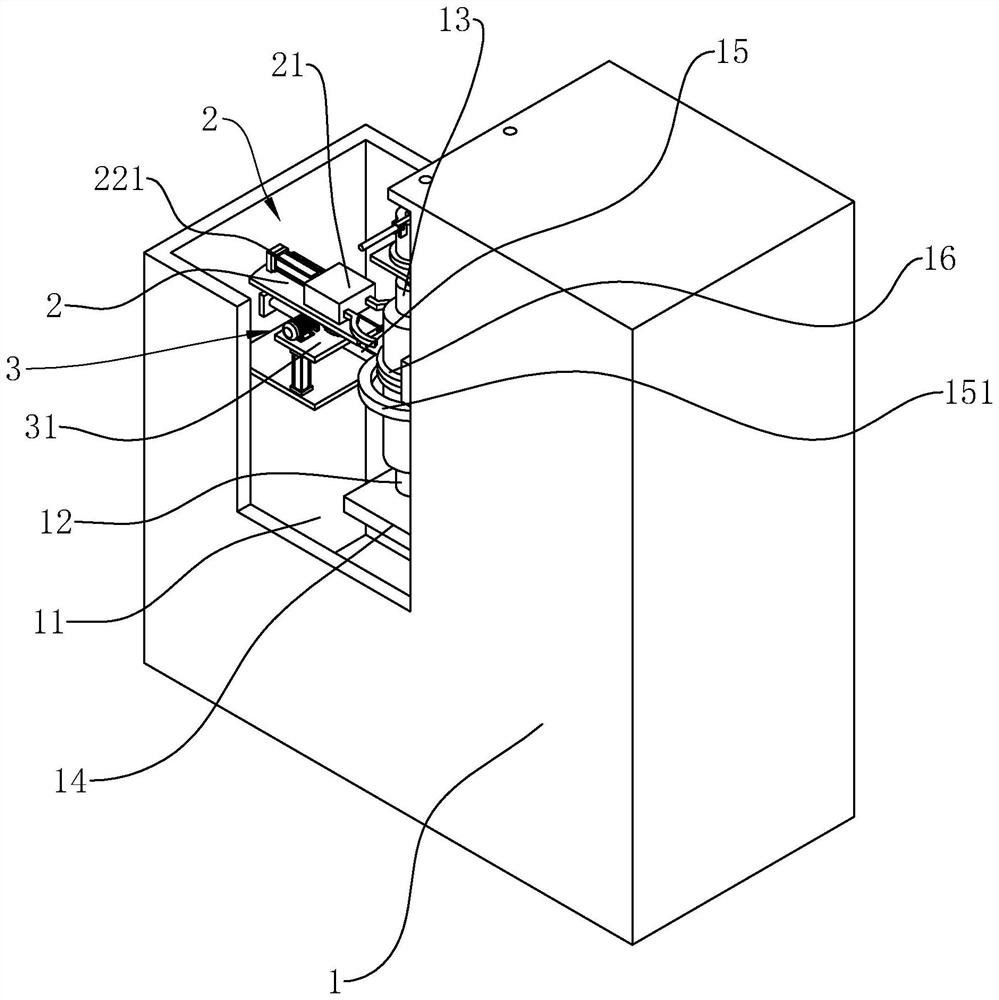

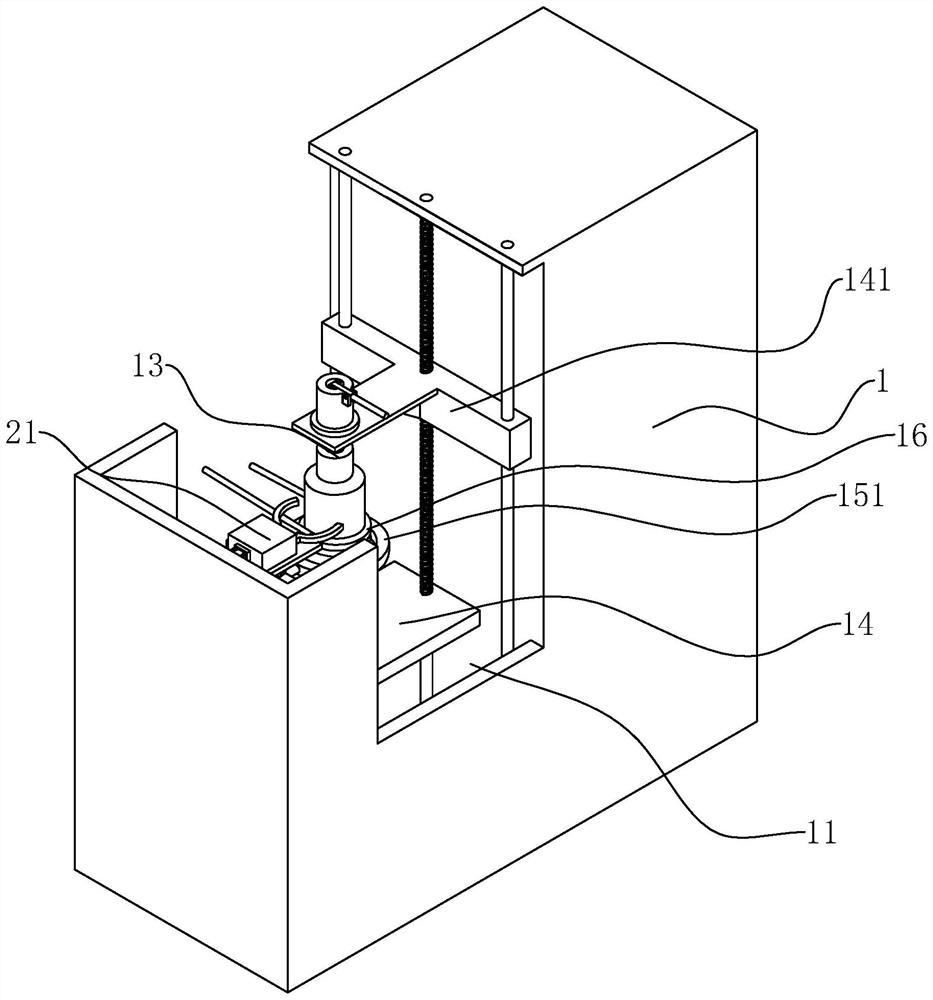

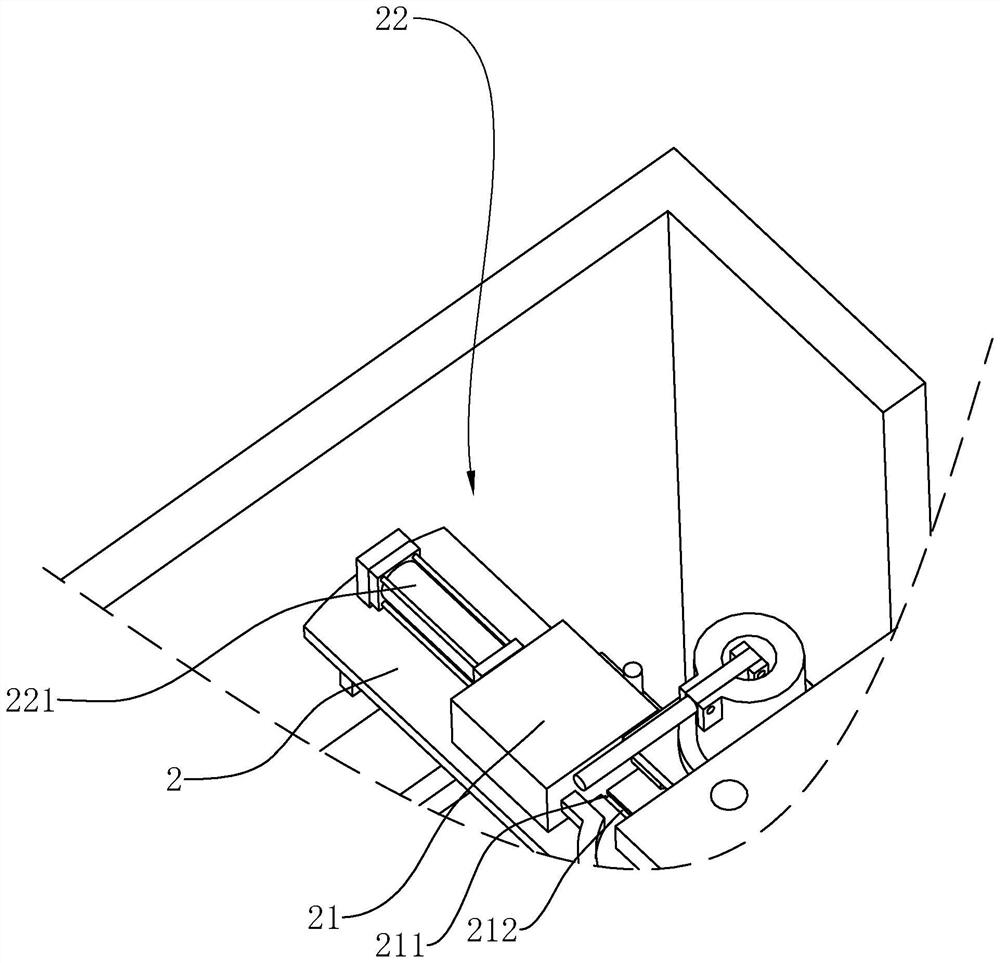

[0035] refer to figure 1 and figure 2 , a high-frequency quenching machine for shaft parts, including a body 1, the body 1 is provided with a cooling pool 11, the cooling pool 11 is filled with cooling liquid, so as to cool the workpiece after processing, the body 1 is provided with a sliding table 14 , the sliding table 14 is slidably connected with the body 1 in the vertical direction, the sliding table 14 is located in the cooling pool 11, and the cooling purpose of the workpiece can be achieved by sliding the sliding table 14 into the cooling pool 11, and the body 1 is provided with a first fixed shaft 12 and The second fixed shaft 13, the first fixed shaft 12 is located on the upper end surface of the sliding table 14, and the first fixed shaft 12 is fixedly connected with the sliding table 14, the body 1 is provided with a linkage block 141, and the second fixed shaft 13 is connected with the linkage block 141 , and the linkage block 141 and the sliding table 14 are co...

Embodiment 2

[0045] The main difference between Embodiment 2 and Embodiment 1 is that the driving manner of the worm 33 is different.

[0046] refer to Figure 5 , the support plate 31 is provided with a hand wheel 4, the hand wheel 4 is arranged vertically, the rotating shaft of the hand wheel 4 is fixedly connected to the worm 33 coaxially, when the workpiece needs to be taken, the operator turns the hand wheel 4, and when the hand wheel 4 rotates, The worm 33 can be driven to rotate, and the rotation of the worm 33 drives the worm wheel 32 to rotate, so as to realize the purpose of driving the installation table 2 to rotate, so as to facilitate the operator to take the workpiece and improve the convenience for the operator to take the workpiece.

[0047] refer to Figure 5 , the outer wall of the handwheel 4 is provided with an anti-scalding sleeve 41 , and the anti-scalding sleeve 41 is fixedly connected with the handwheel 4 . When the operator rotates the handwheel 4 , the anti-scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com