Patents

Literature

567 results about "Cooling pond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cooling pond is a man-made body of water primarily formed for the purpose of storing heated water and/or supplying cooling water to a nearby power plant or industrial facility such as a petroleum refinery, pulp and paper mill, chemical plant, steel mill or smelter.

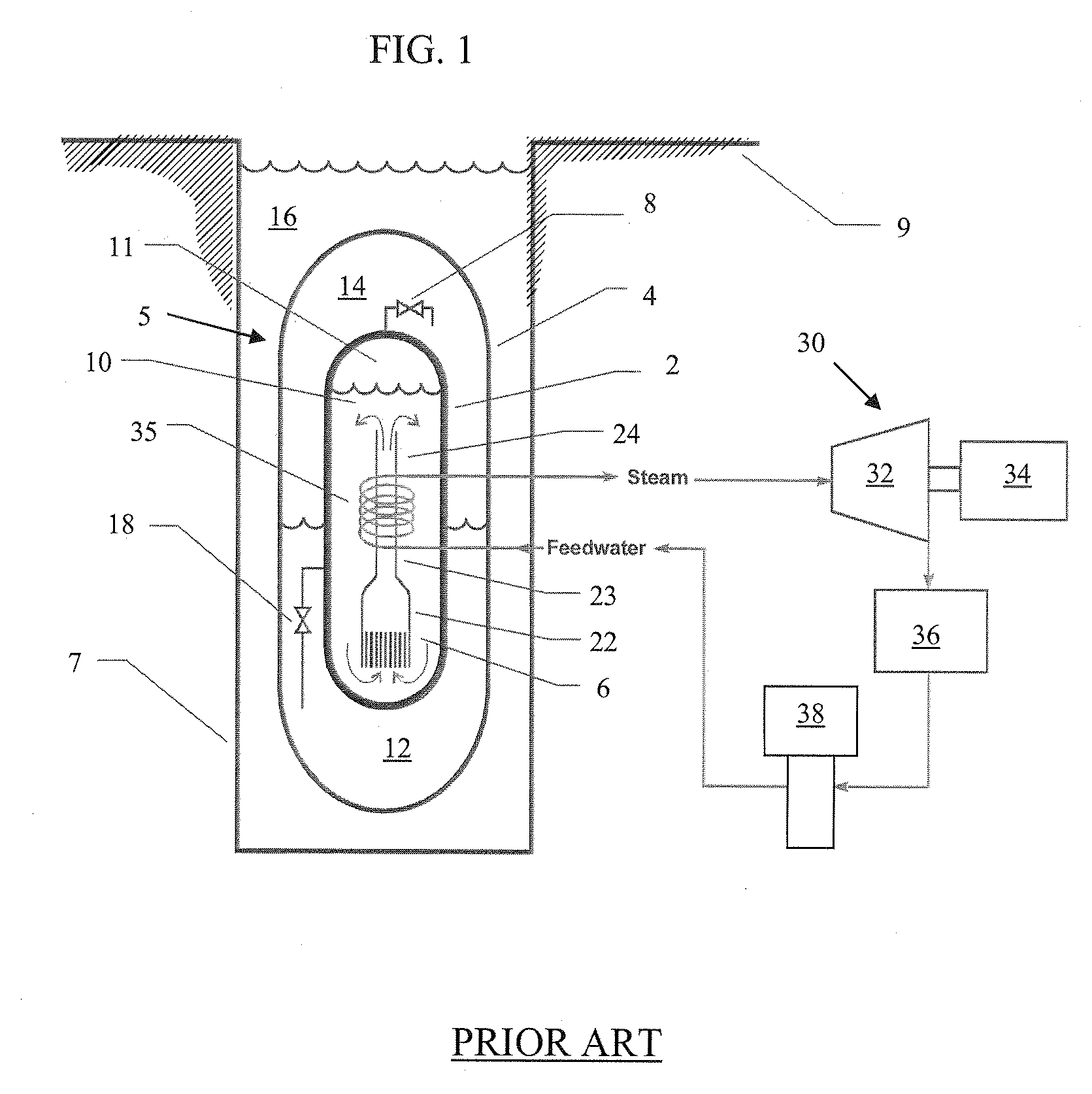

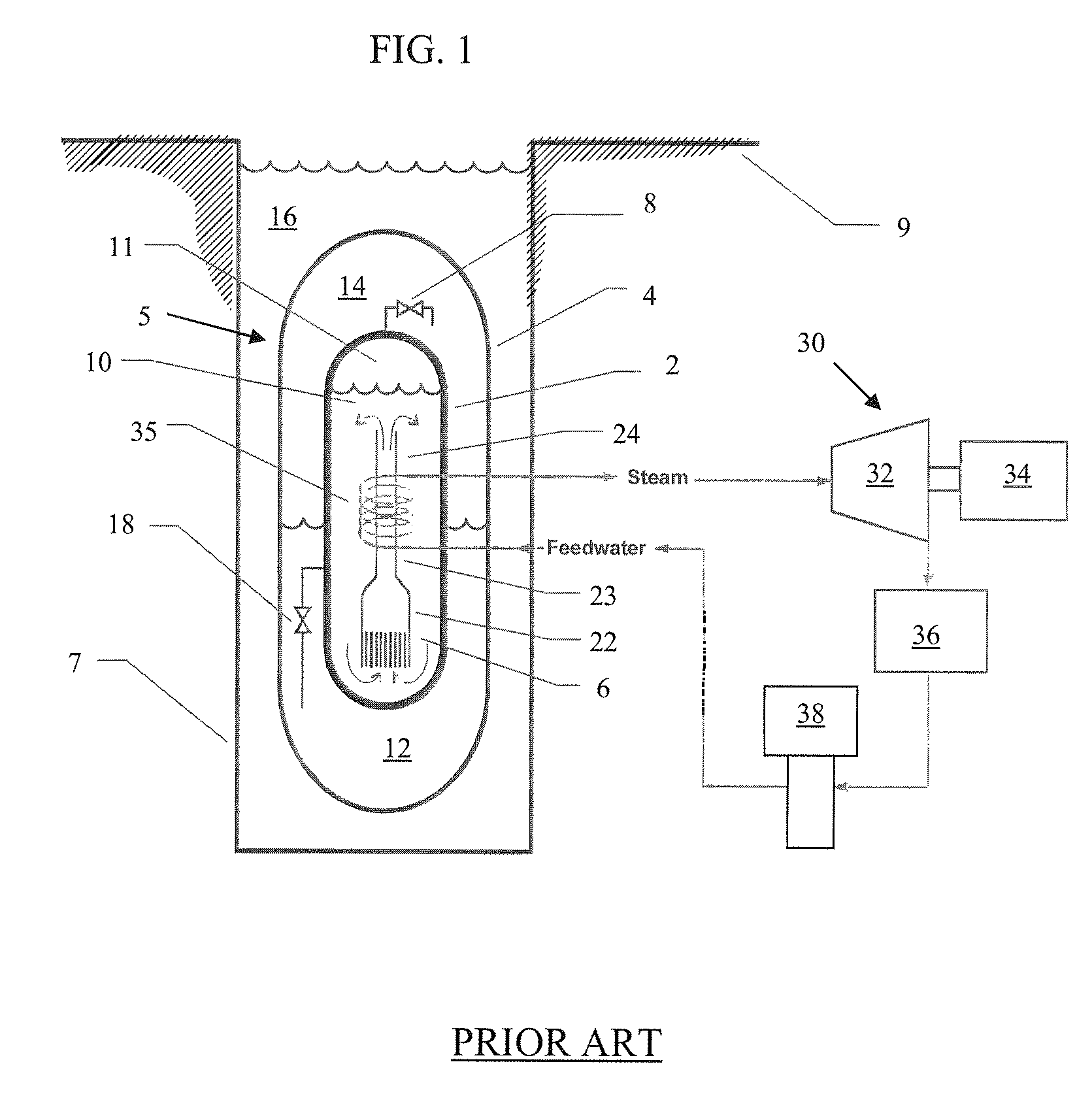

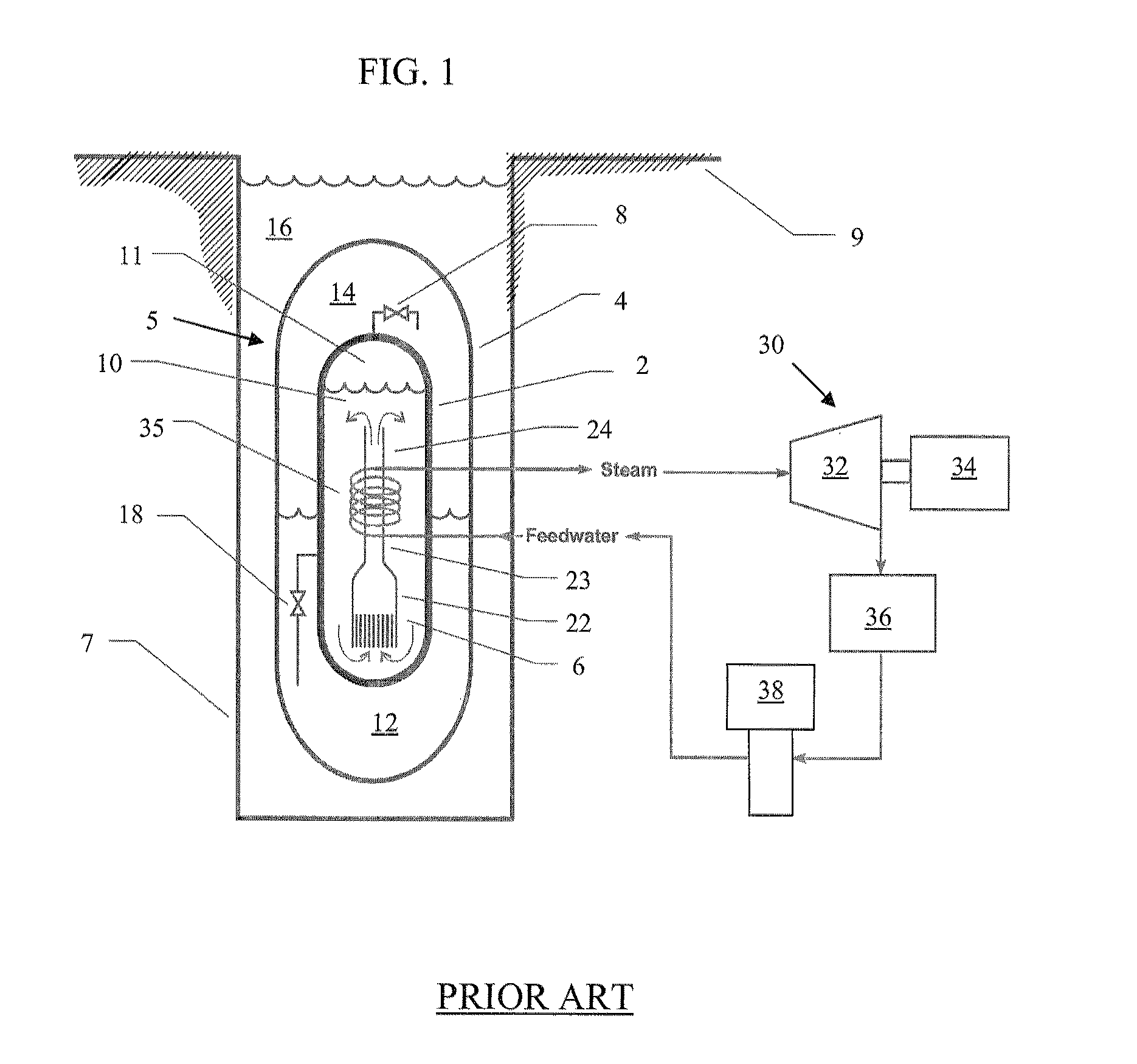

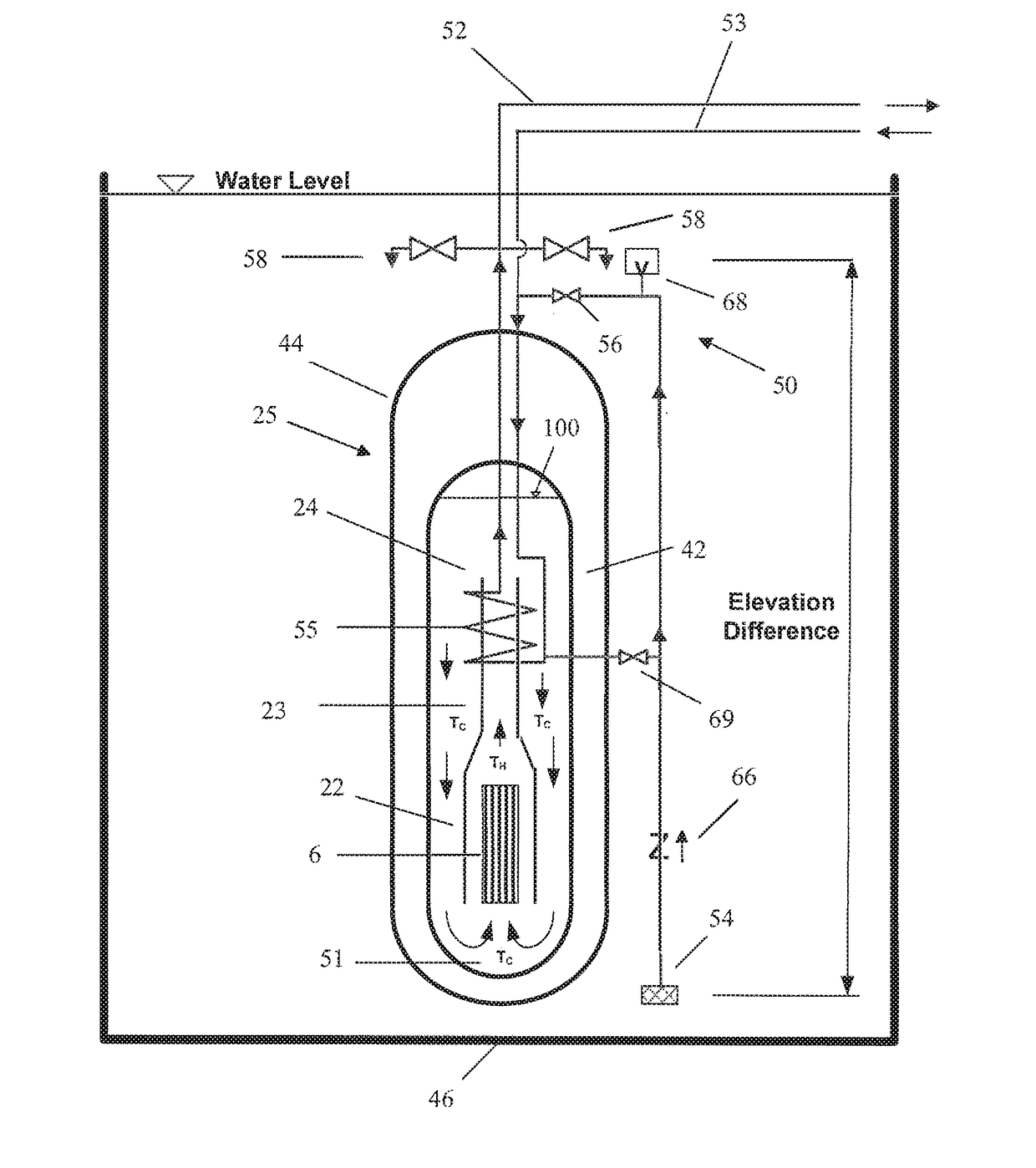

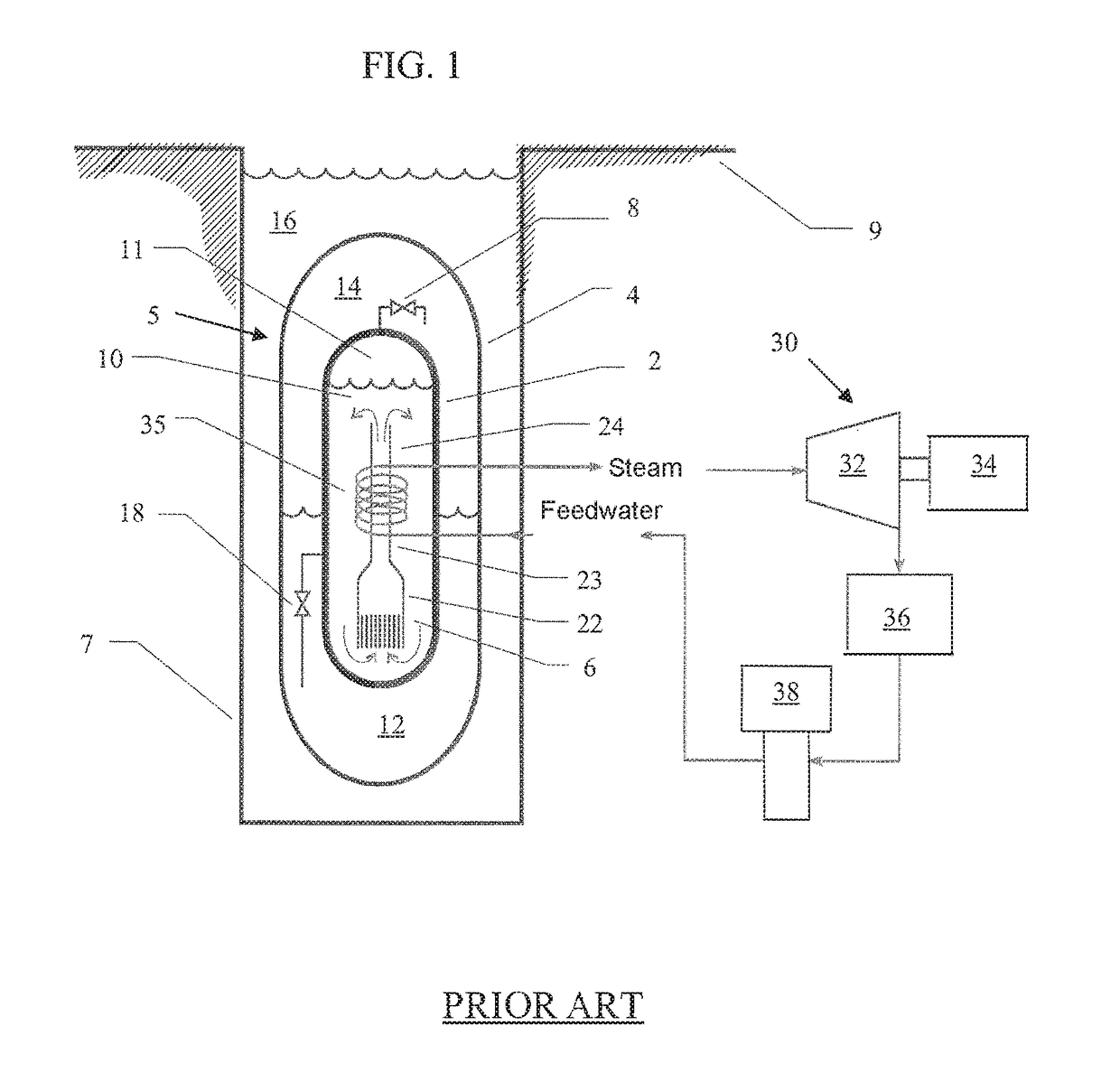

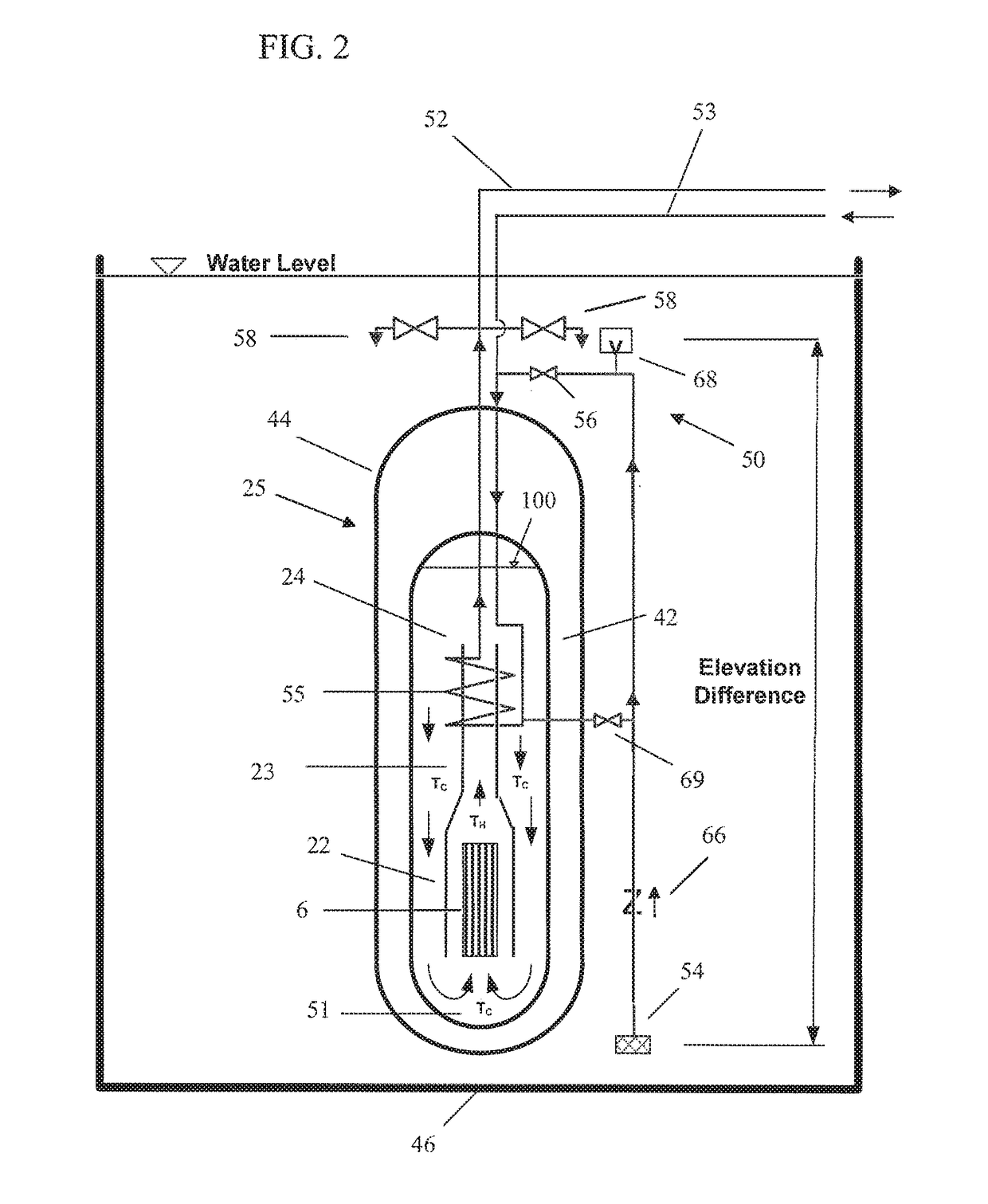

Passive emergency feedwater system

A power module assembly includes a reactor vessel containing a reactor core surrounded by a primary coolant. A containment vessel is adapted to be submerged in a containment cooling pool and to prohibit a release of the primary coolant outside of the containment vessel. A secondary cooling system is configured to remove heat generated by the reactor core. The heat is removed by circulating liquid from the containment cooling pool through the primary coolant.

Owner:NUSCALE

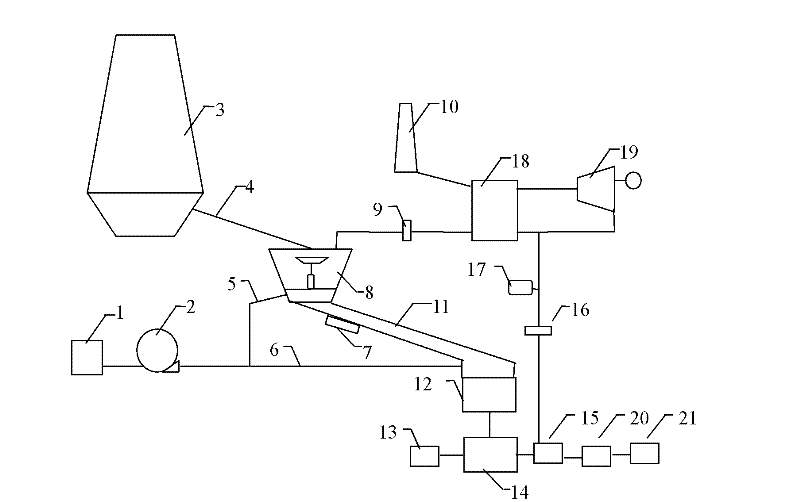

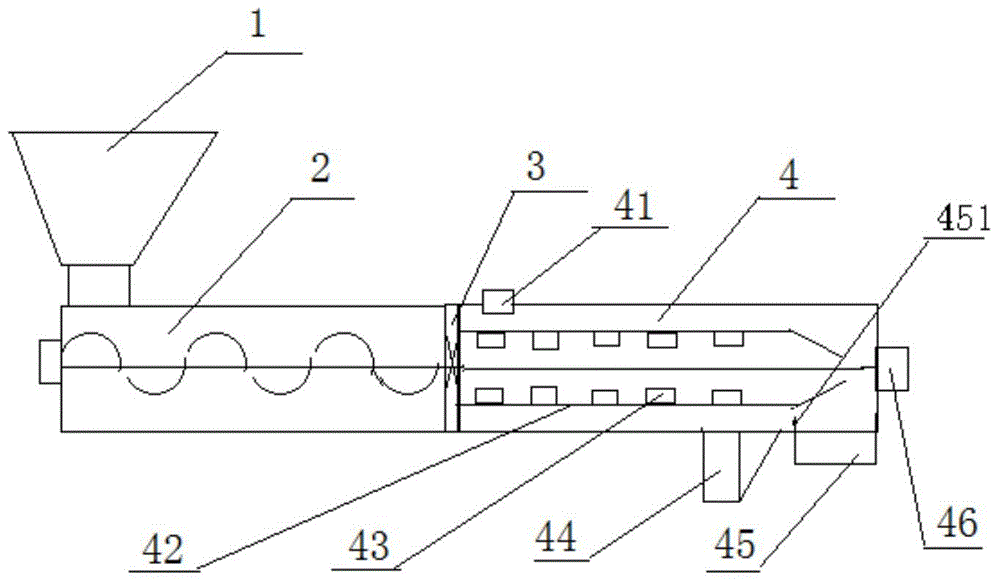

Novel method for innocent treatment and utilization of dead livestock and poultry

InactiveCN101182247ASave energyNo secondary pollutionBio-organic fraction processingInternal combustion piston enginesSlagSludge

The invention discloses a novel method of the harmless treatment and utilization of livestock and poultry which died of disease according to the steps as follows: firstly, various kinds of the animal bodies of the livestock and the poultry which died of disease are collected; secondly, the animal bodies are crushed; thirdly, the crushed animal bodies are sterilized under high temperature and highpressure and separated for filtering, the material of oil and fat flows into a cooling pool, and the material of hair and bone is dried; fourthly, the material of hair and bone after drying is carbonized; fifthly, the material of oil and fat after cooling is added with catalyst, high-efficiency compound microorganism, trash, organic wastewater and sludge; sixthly, the mixed organic material is put into an anaerobic tower to be fermented, and then biogas, biogas slurry and biogas slag are processed for three-phase separation; seventhly, the biogas is used for burning and generating electricity; eighthly, the biogas slurry inside a fertilizer storing pool is used as farmland fertilizer; ninthly, the biogas slag is added with the high-efficiency compound microorganism and the catalyst for secondary ferment; tenthly, the material after the secondary ferment is made into agricultural high-efficiency organic fertilizer. The invention solves the problem of the environmental pollution caused by the livestock and poultry which died of disease and change the waste livestock and poultry which died of disease into valuables.

Owner:浙江威尔斯生物能源开发有限公司

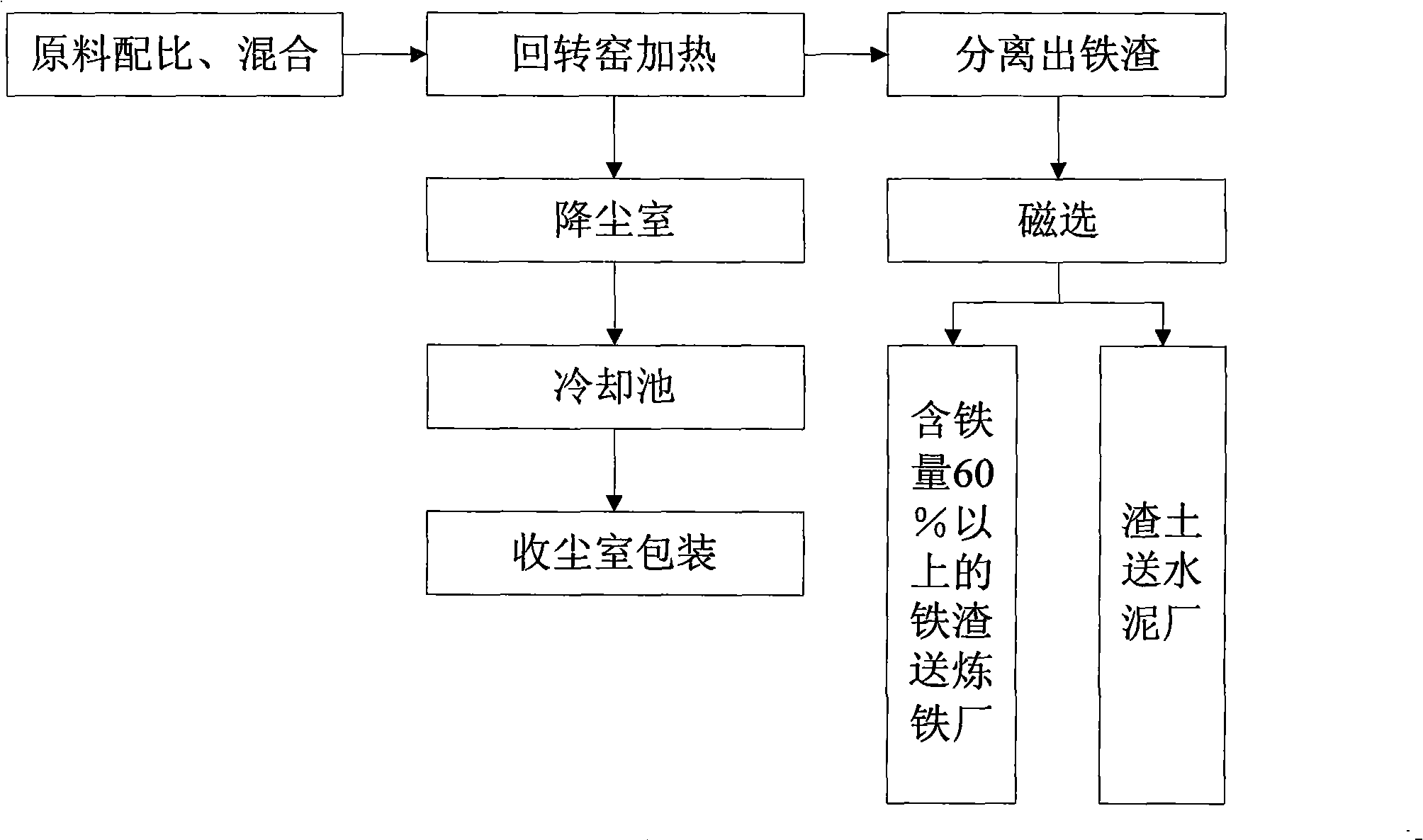

Dust-separation zinc extraction method

InactiveCN101343693ATo achieve the purpose of turning waste into treasureImprove resource utilizationSolid waste managementProcess efficiency improvementResource utilizationWaste material

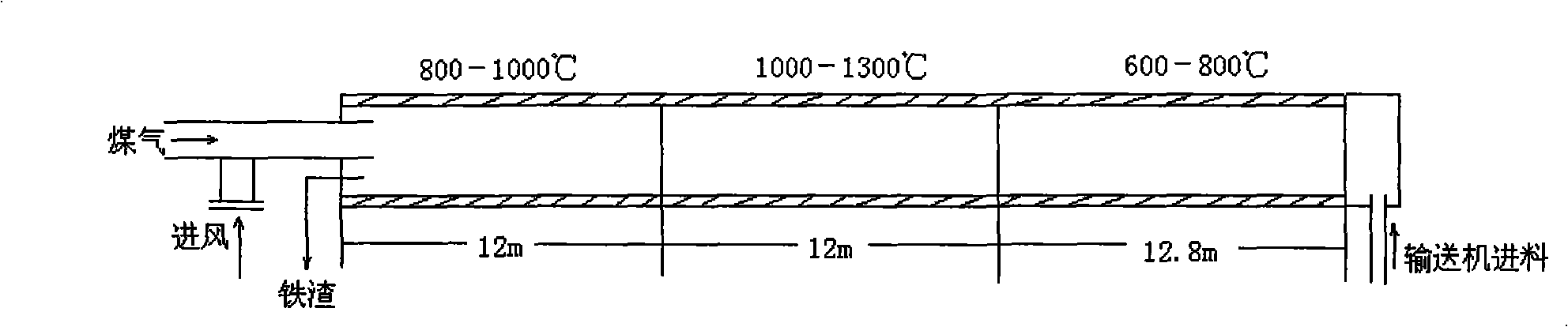

Disclosed is a dust removal and zinc extraction method. Raw materials are mixed and evenly stirred through a loader according to weight proportion, 30 percent to 40 percent of blast furnace dust removal ashes, 25 percent to 35 percent of power plant dust removal ashes, 25 percent to 35 percent of blast furnace gas slime, 5 percent to 10 percent of anthracite coal are evenly delivered to a rotary kiln to be heated for refining through a conveyor, then are delivered into a dedusting chamber to experience the atomization and separation, the raw materials are delivered into a cooling pond then and zinc oxide powder is forcedly sent into a dust collecting chamber by a suction blower, the dust is collected through a bag and is supplied to a zinc supply smeltery as the raw material. The iron residues separated in the heating and extracting process in the rotary kiln are magnetically separated through a magnet separator, the iron residues with the iron content of 60 percent are delivered to an iron smelting plant, and the residue soil is supplied to a cement plant as the raw material. The invention has the advantages that the iron residues and zinc powder are extracted and separated through adopting the processed waste material dust removal ashes in large-scale smelting enterprises, the purpose of changing wastes into valuables is realized, and the resource utilization rate is enhanced.

Owner:NANJING BANQIAO SLAG

Passive emergency feedwater system

A power module assembly includes a reactor vessel containing a reactor core surrounded by a primary coolant. A containment vessel is adapted to be submerged in a containment cooling pool and to prohibit a release of the primary coolant outside of the containment vessel. A secondary cooling system is configured to remove heat generated by the reactor core. The heat is removed by circulating liquid from the containment cooling pool through the primary coolant.

Owner:NUSCALE LLC

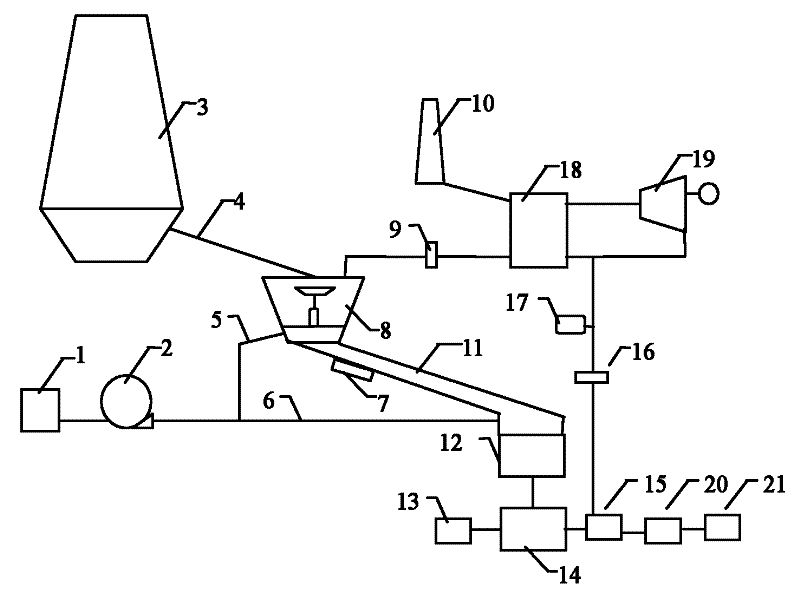

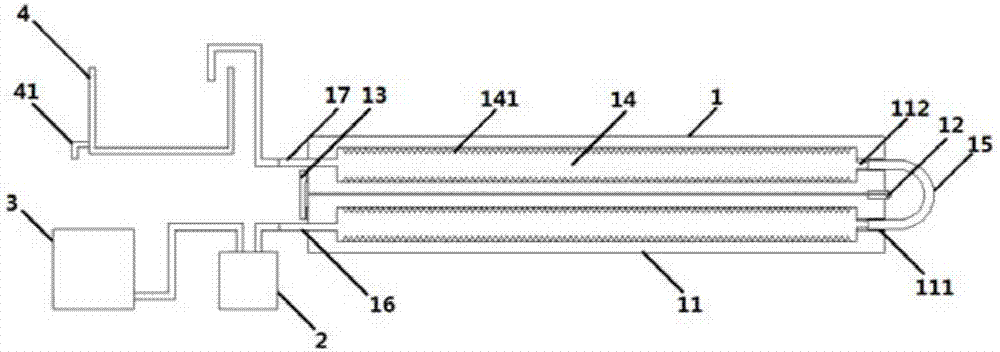

System for advanced treatment and recycle of cold rolling wastewater

ActiveCN101428939AEfficient removalAchieve the goal of energy saving and emission reductionDispersed particle separationWaste water treatment from metallurgical processCooling towerEngineering

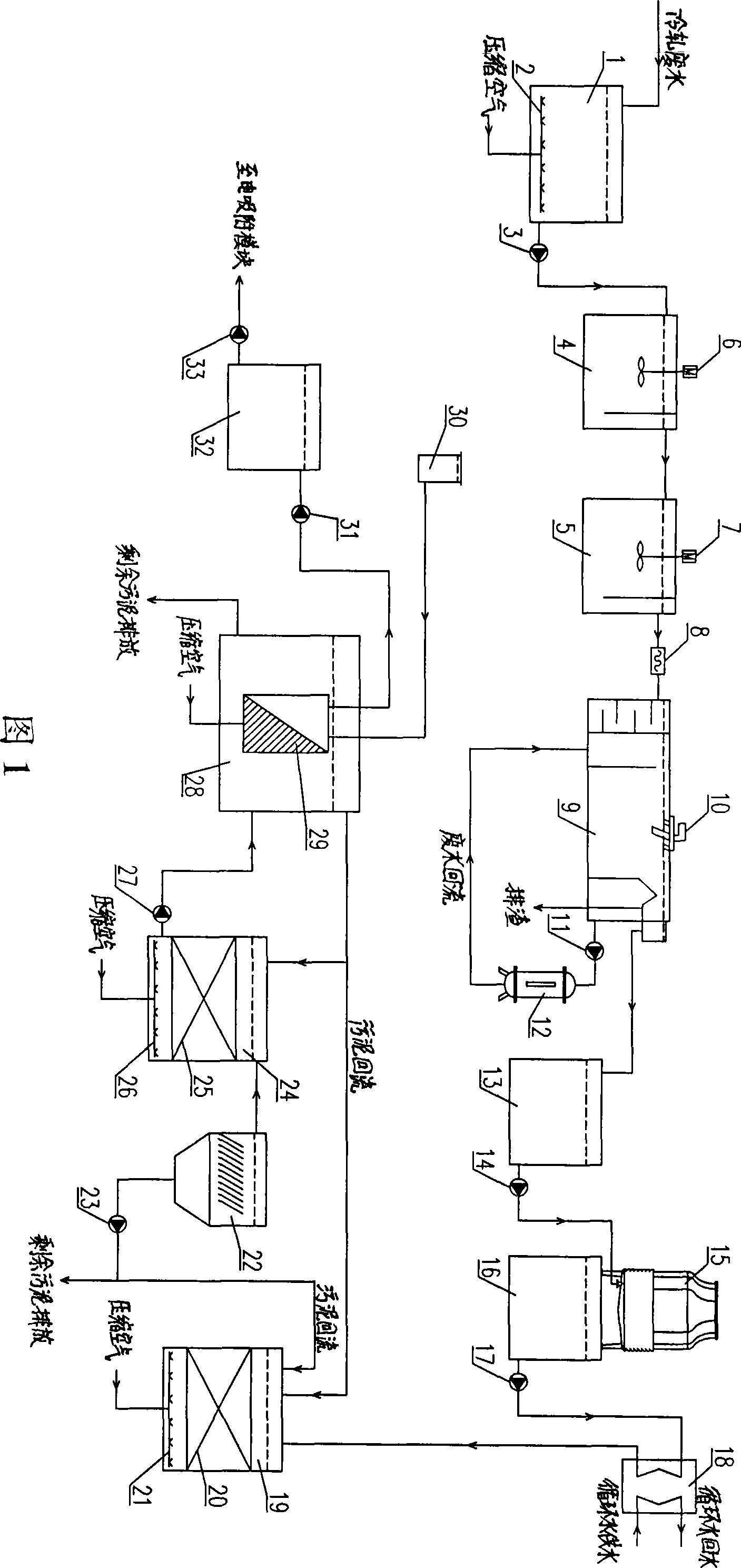

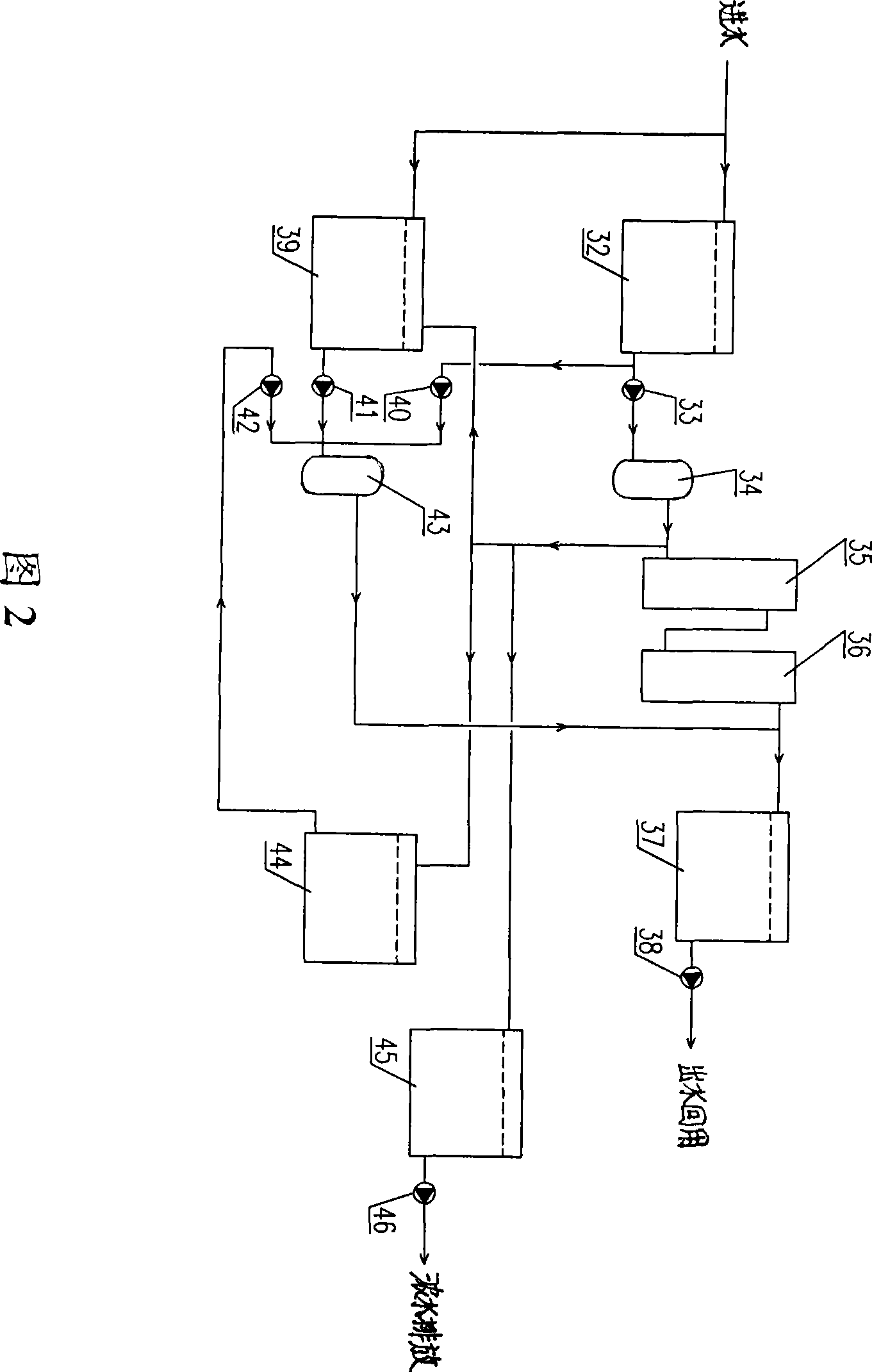

The invention relates to a cold rolling waste water advanced treatment reuse system, which comprises a pretreatment process, a biological two-stage treatment process and an electric adsorption desalting treatment process. The pretreatment process comprises a uniformly-adjusting tank, a two-stage pH adjusting groove, a dissolved-air float, a middle pond, a cooling tower, a cooling pond, a plate type heat exchanger and the like. The biological two-stage treatment process comprises a biological contact oxidation pond, an inclined plate settling tank, a membrane biological reaction tank, a reactor, a cleaning box, a suction pump and the like. The electric adsorption desalting treatment process comprises an electric adsorption raw water pool, an electric adsorption moudle, a clean water tank, a reuse water pump, a regeneration pump, a sewage drain pump, an electric adsorption enriched water tank and the like. The cold rolling waste water undergoes the pre-treatment process comprising the uniform aeration adjustment, the two-stage pH adjustment and the dissolved-air flotation, the biological two-stage treatment step provided with the membrane biological reactor for contact oxidation and the electric adsorption deep desalting treatment process, thereby effectively removing pollutants in the cold rolling waste water, reutilizing the cold rolling waste water and achieving the aim of energy conservation and emission reduction.

Owner:宝武水务科技有限公司

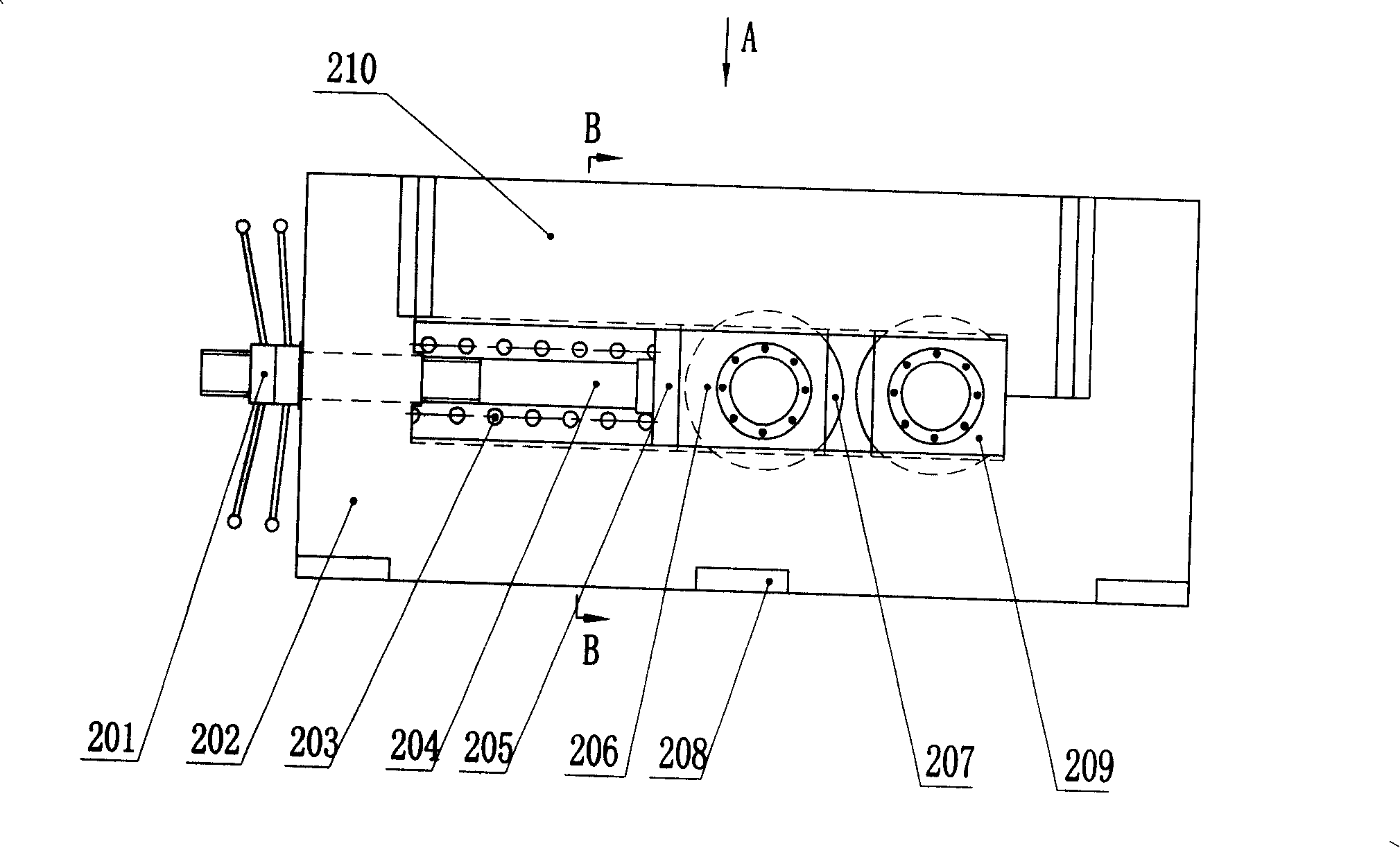

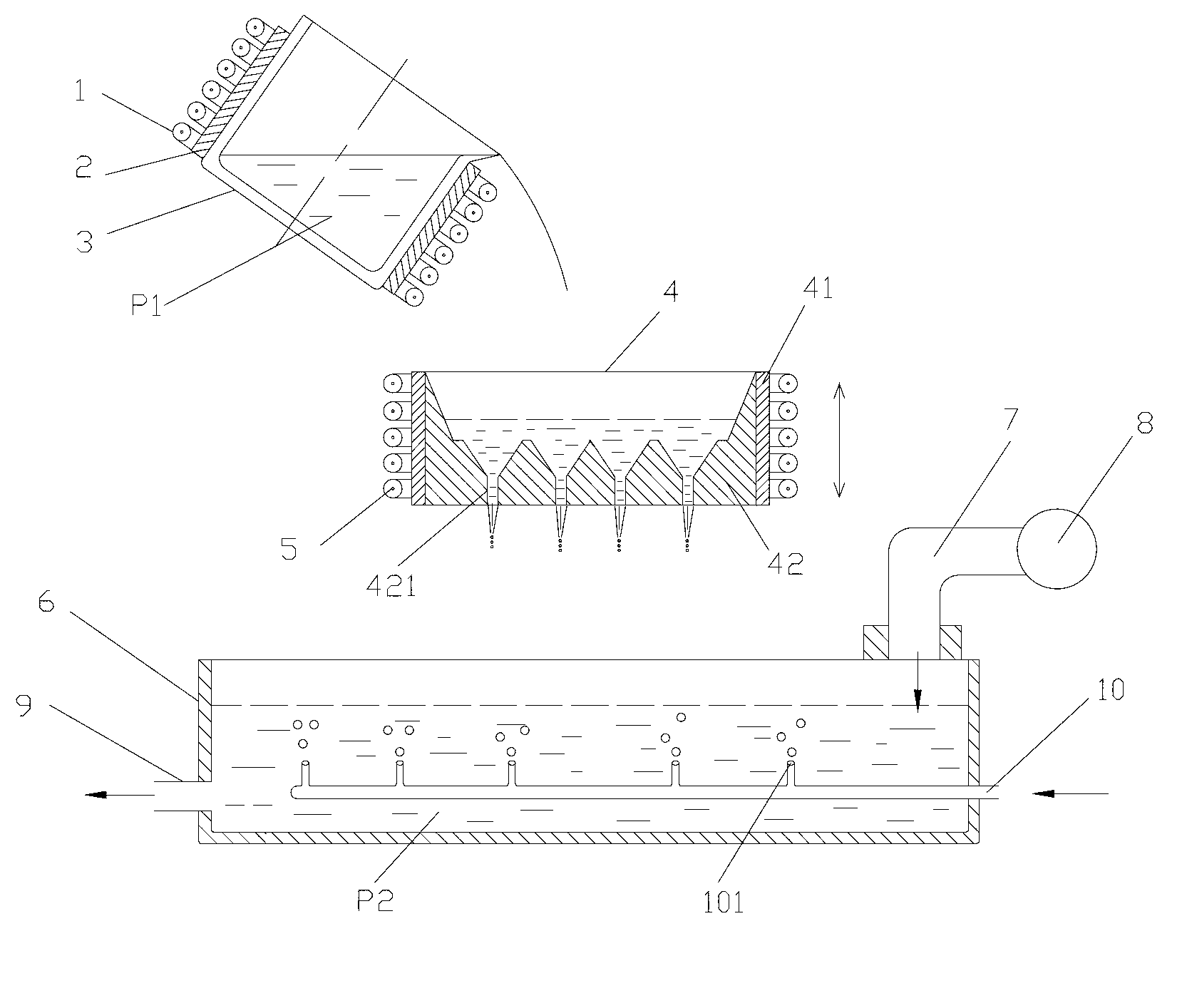

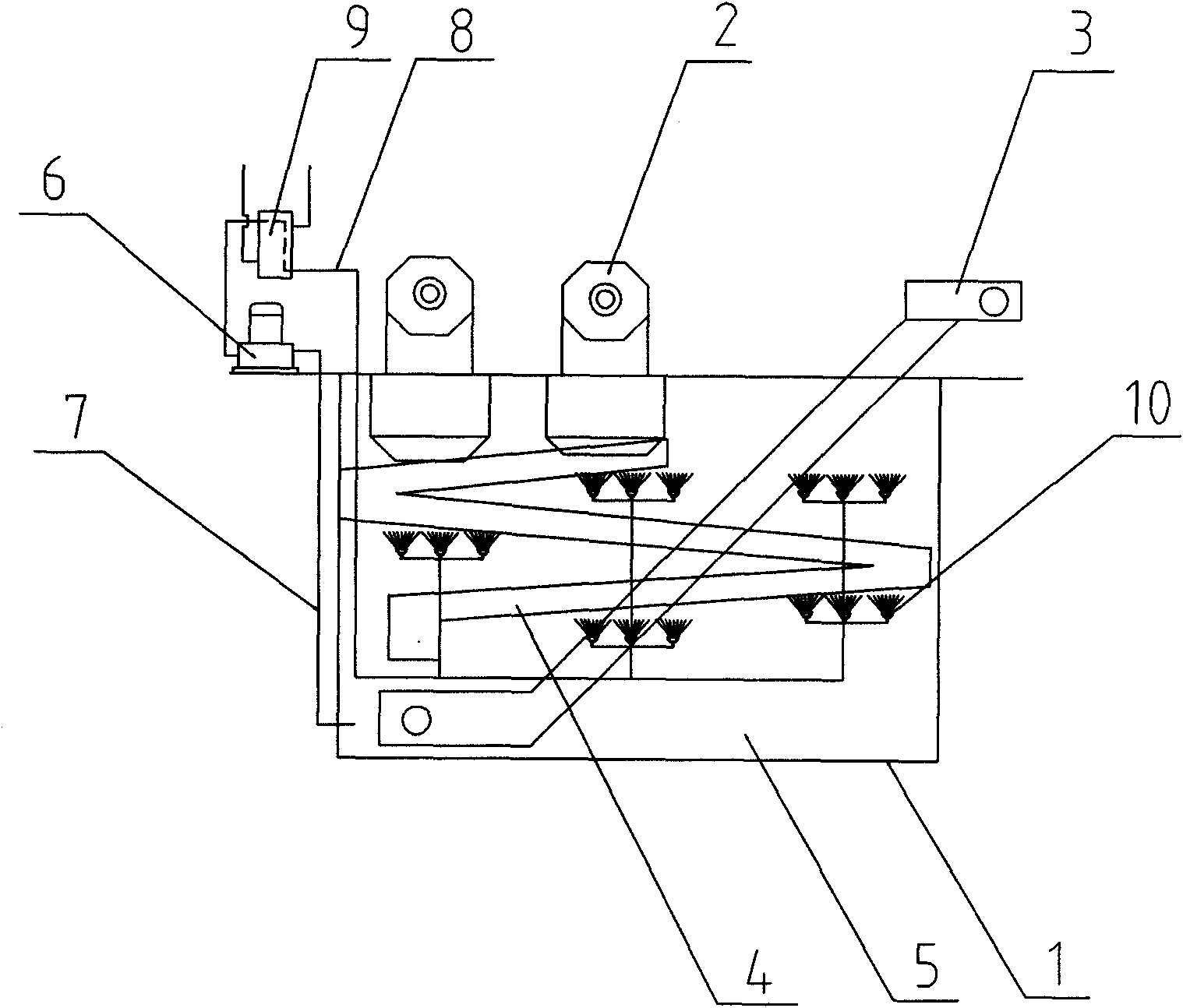

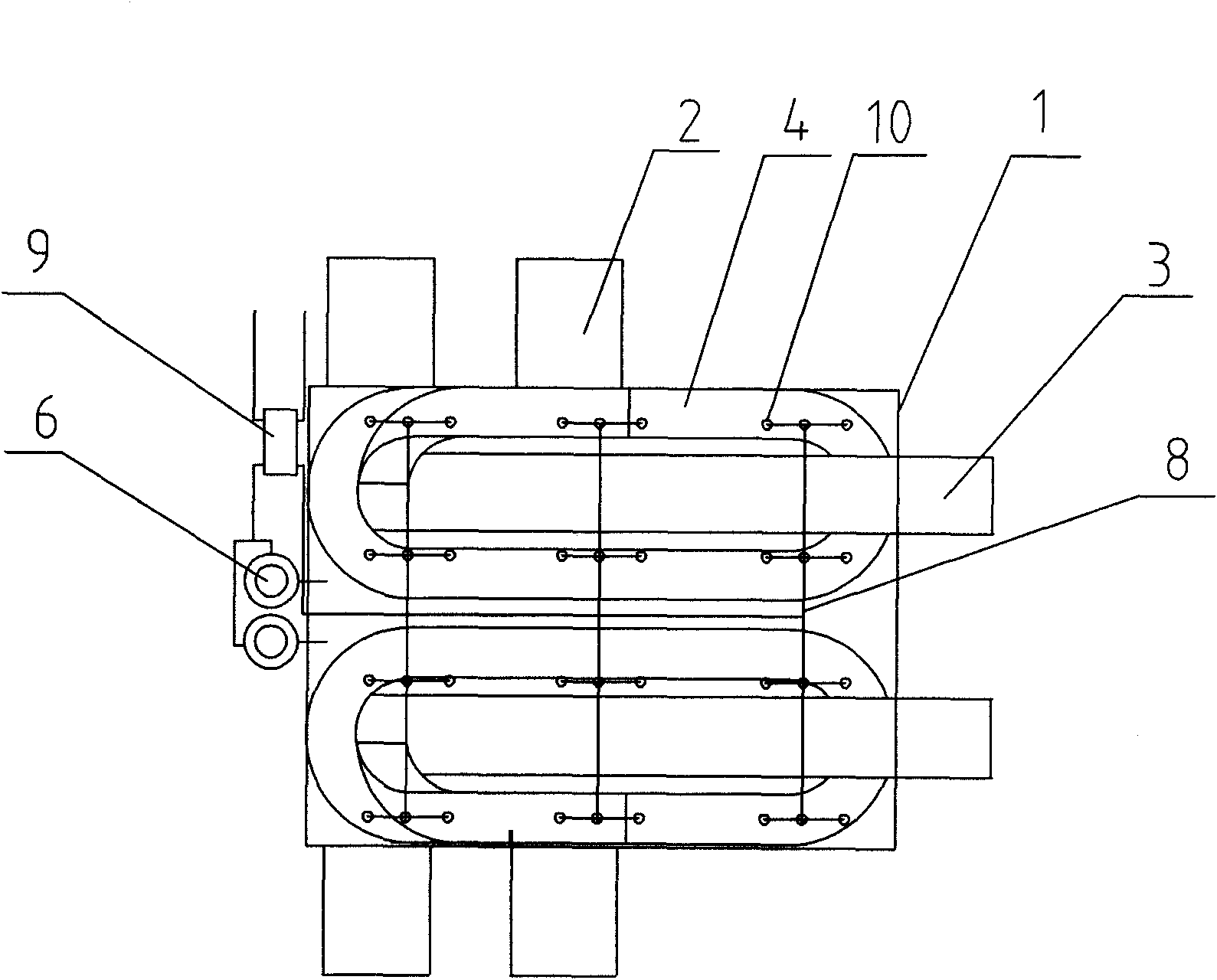

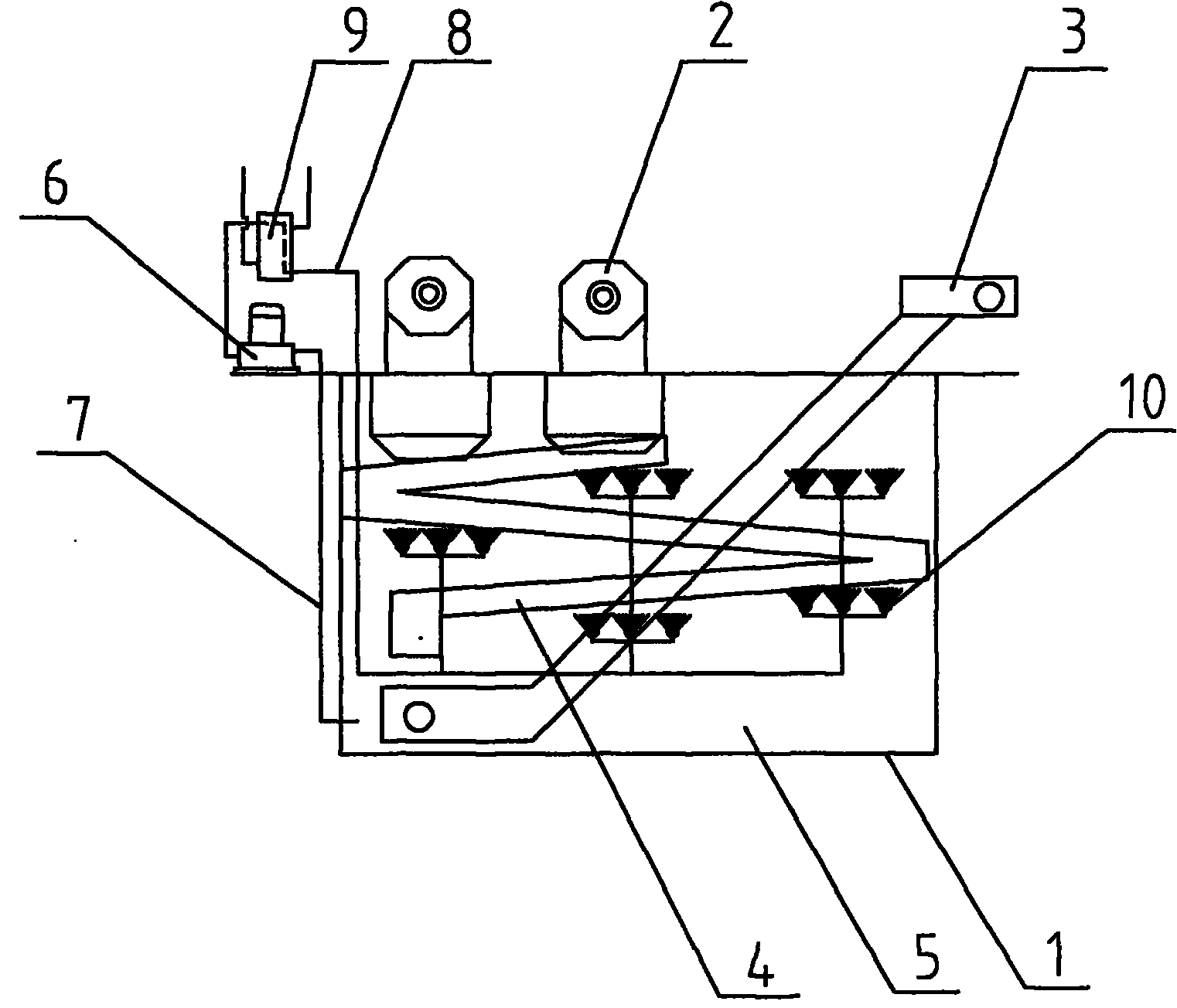

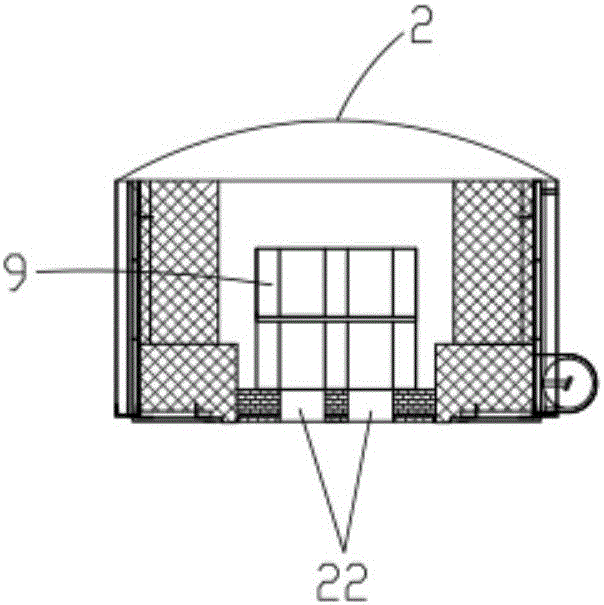

Metallurgical slag treatment method and treatment apparatus

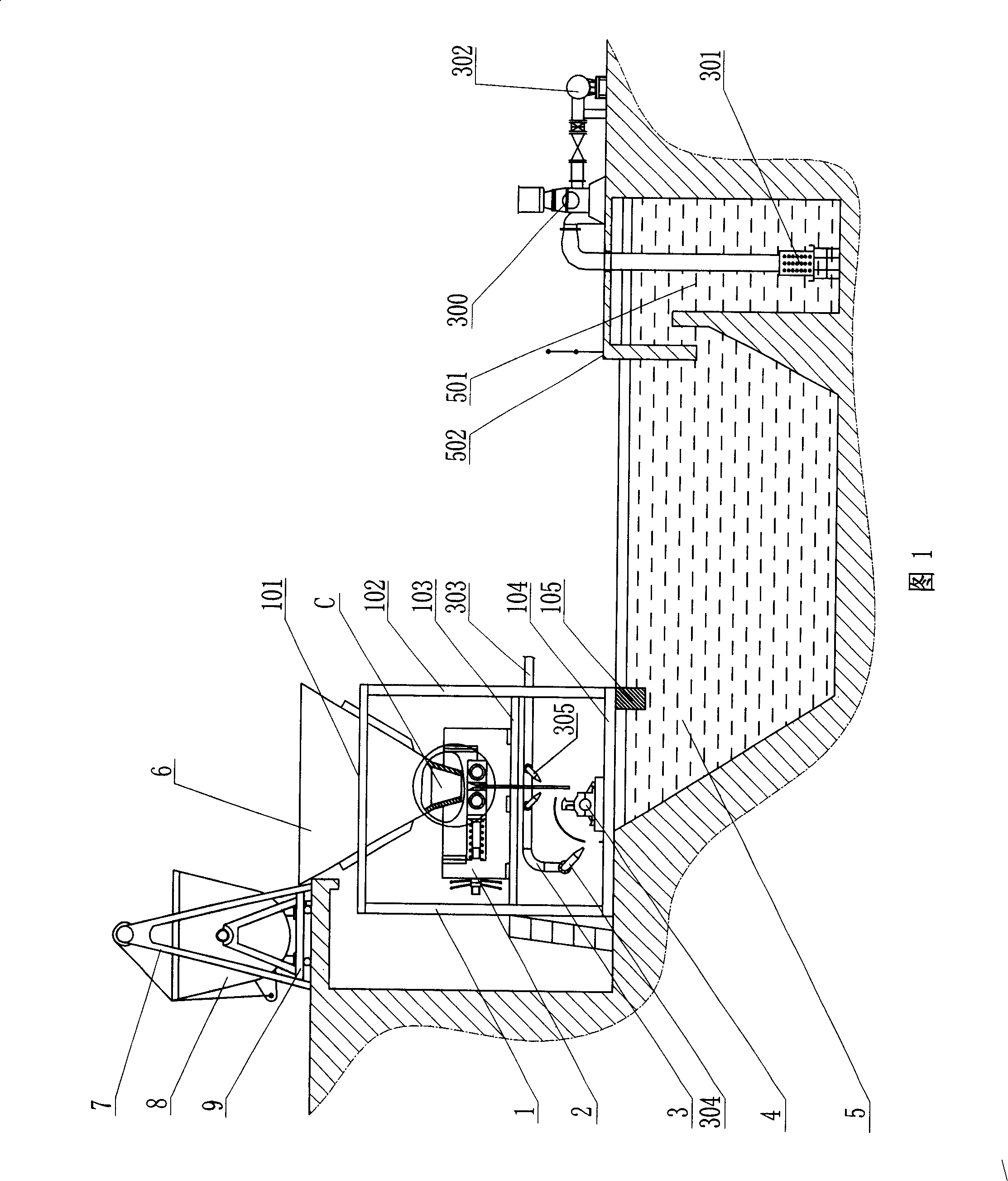

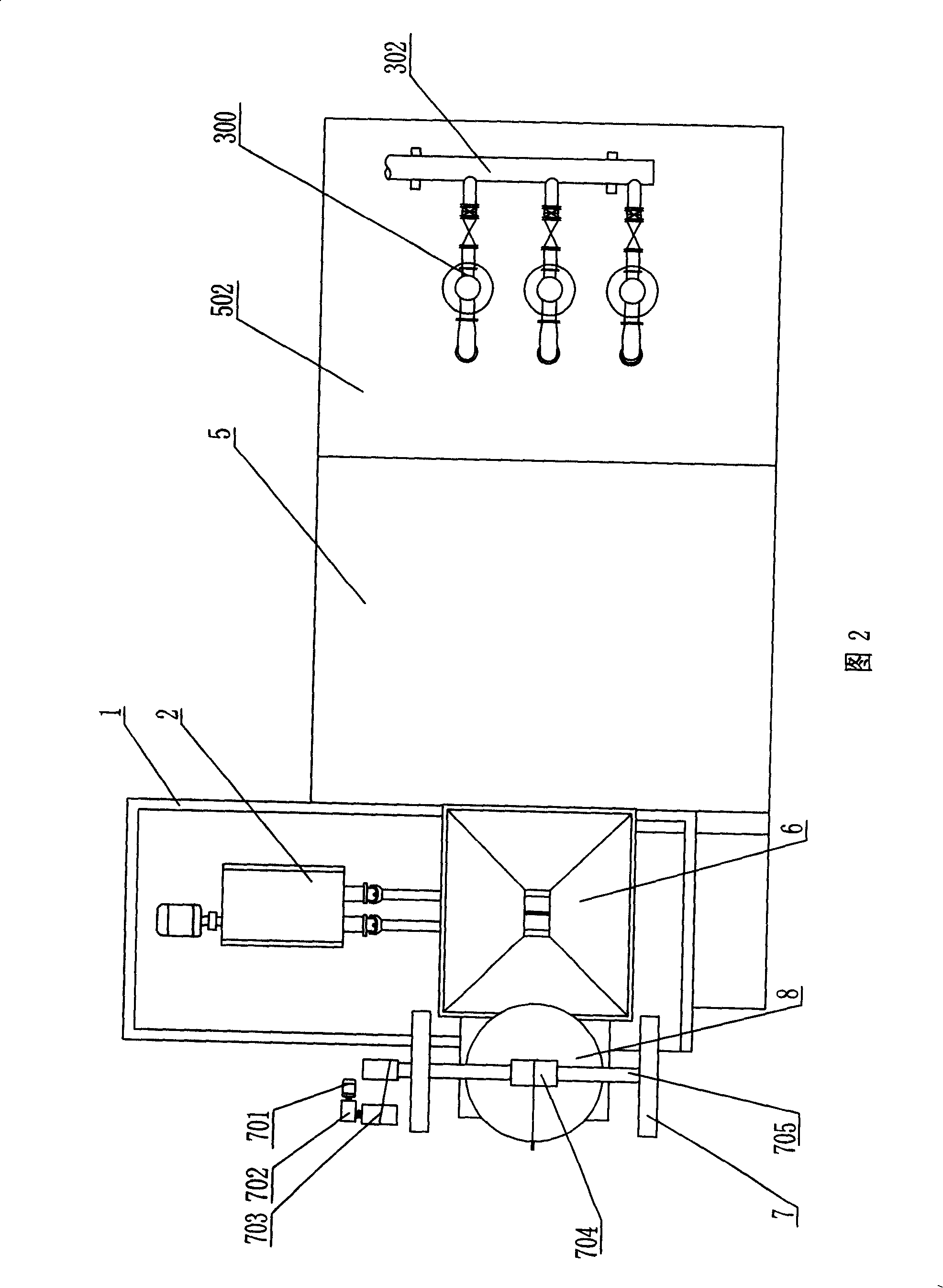

The invention relates to a metallurgical slag treatment method, wherein, the metallurgical slag in a smelting furnace is collected in a slag tank, which is delivered to a tipping device through delivery equipment; the tipping device tips the metallurgical slag into a slag rolling device which comprises a hopper, an outlet at the bottom of the hopper is provided with a pair of rotating rollers which roll the metallurgical slag into sheet shaped slag material, and continuously output outwards; the sheet shaped material continuously passes through a water spray cooling device and is made quick cooling treatment; the sheet shaped slag material enters into a crushing device and is made granulating treatment and forms slag grains by the crushing device which comprises a rotating crushing roller which is provided with a plurality of crushing teeth; the slag grains are thrown into a cooling bay for completely cooling.

Owner:张维田

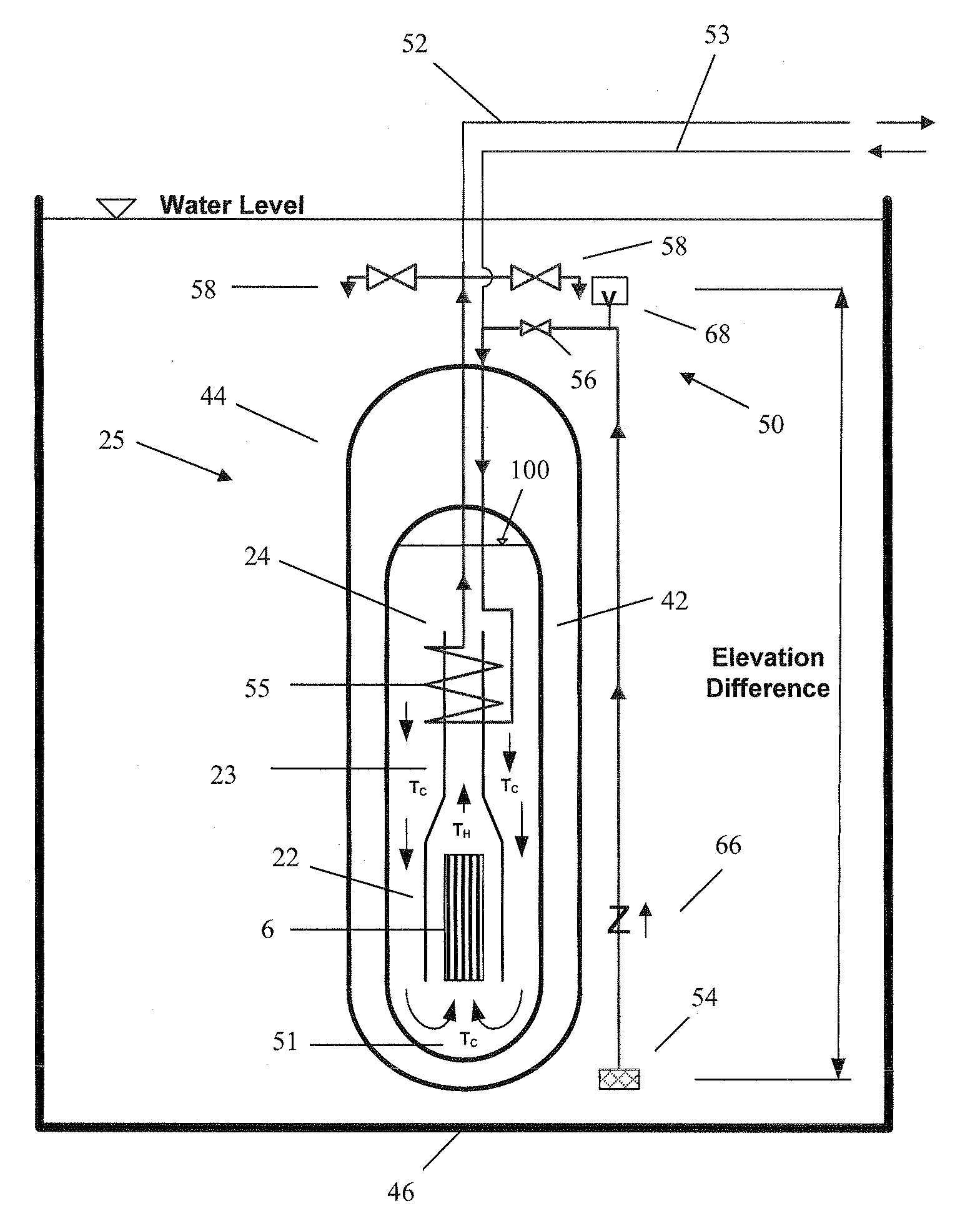

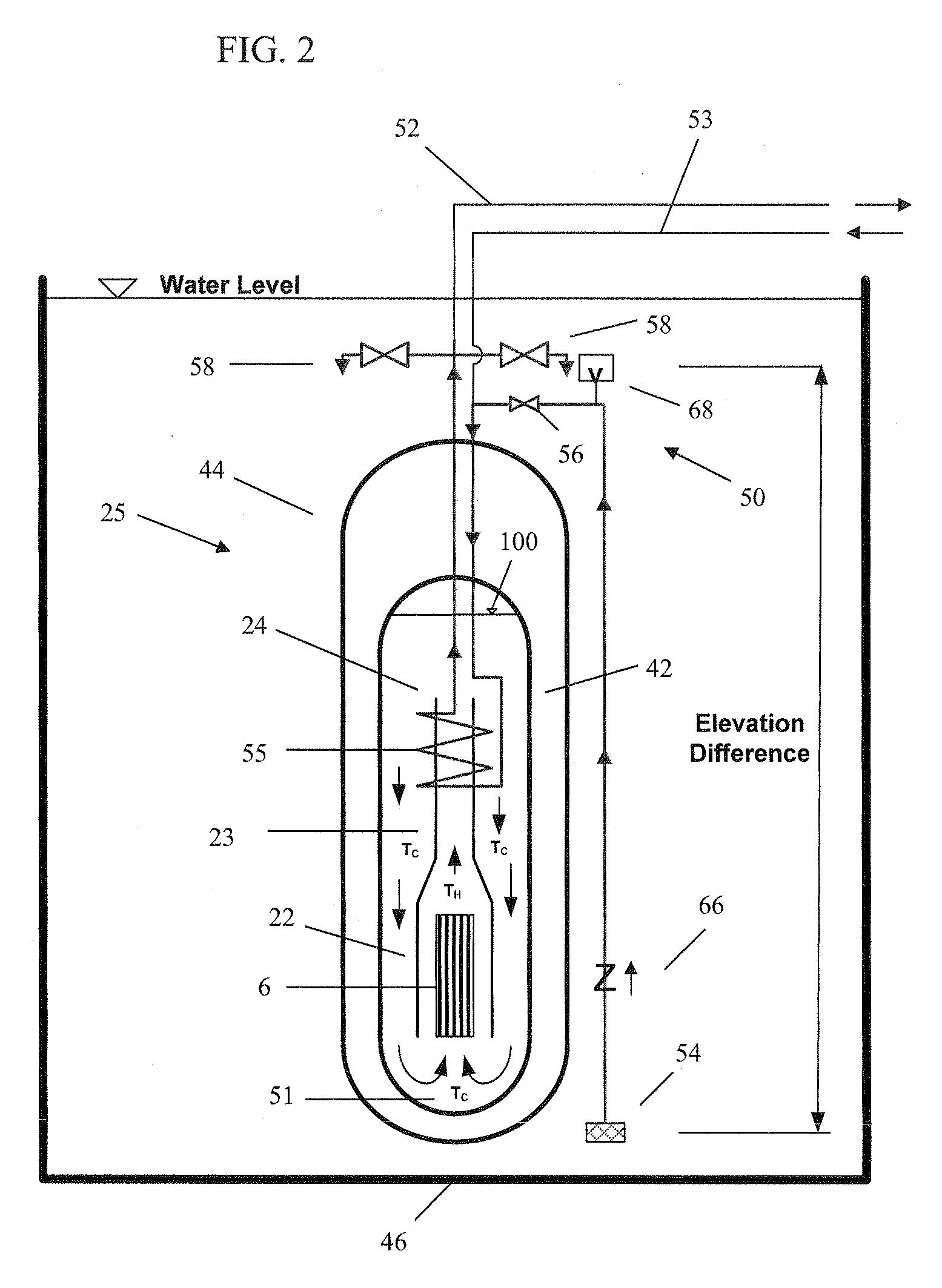

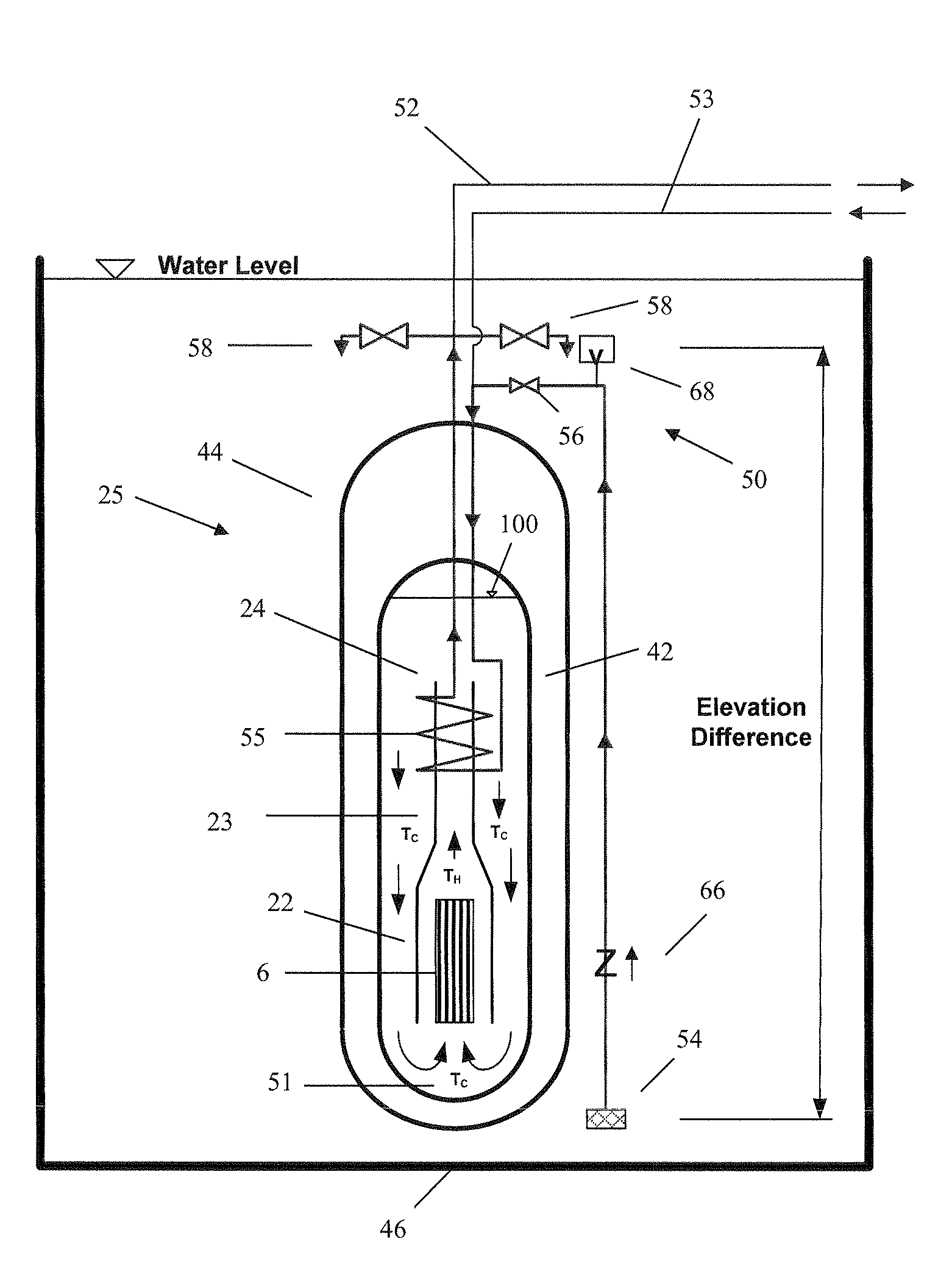

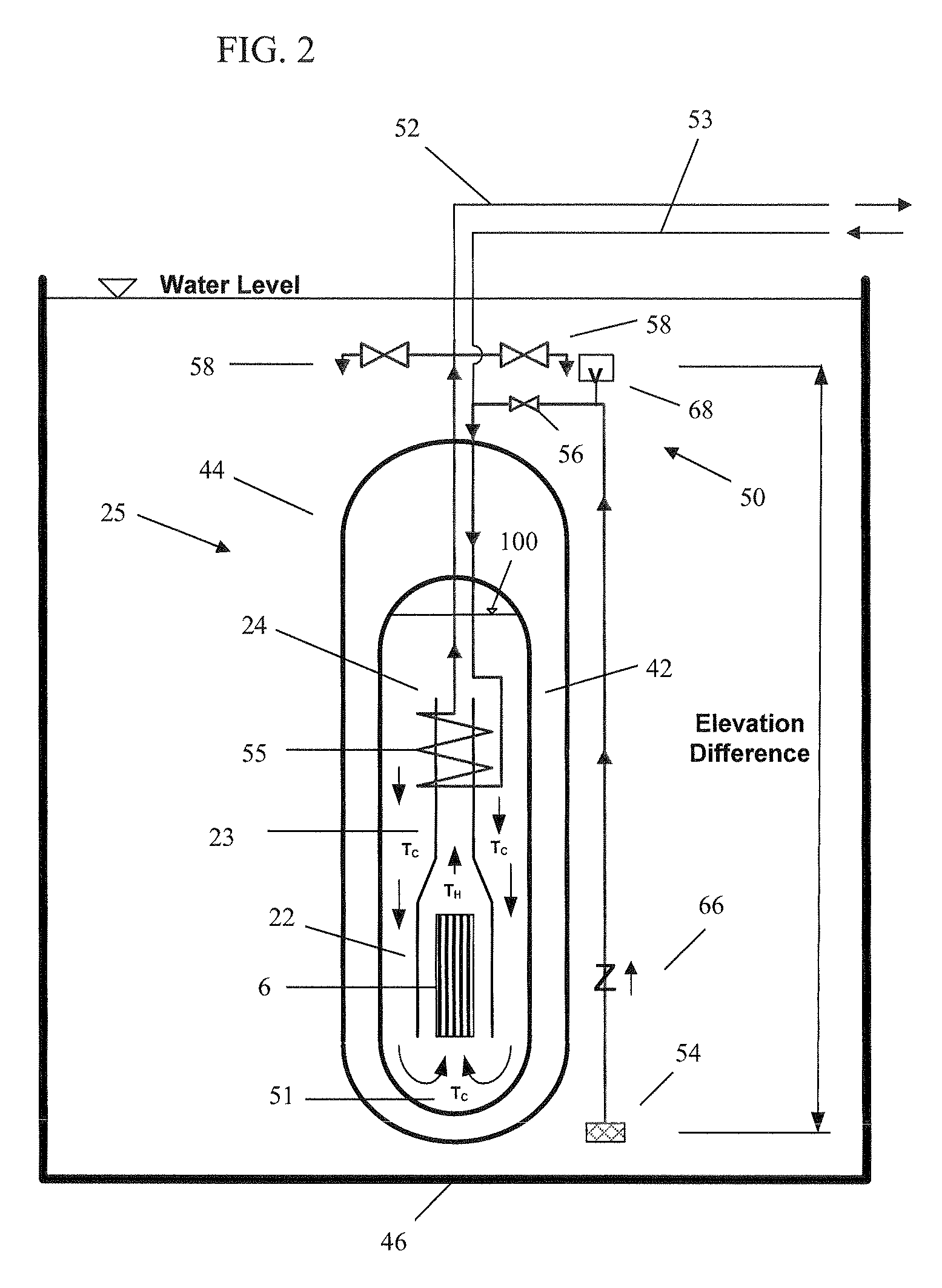

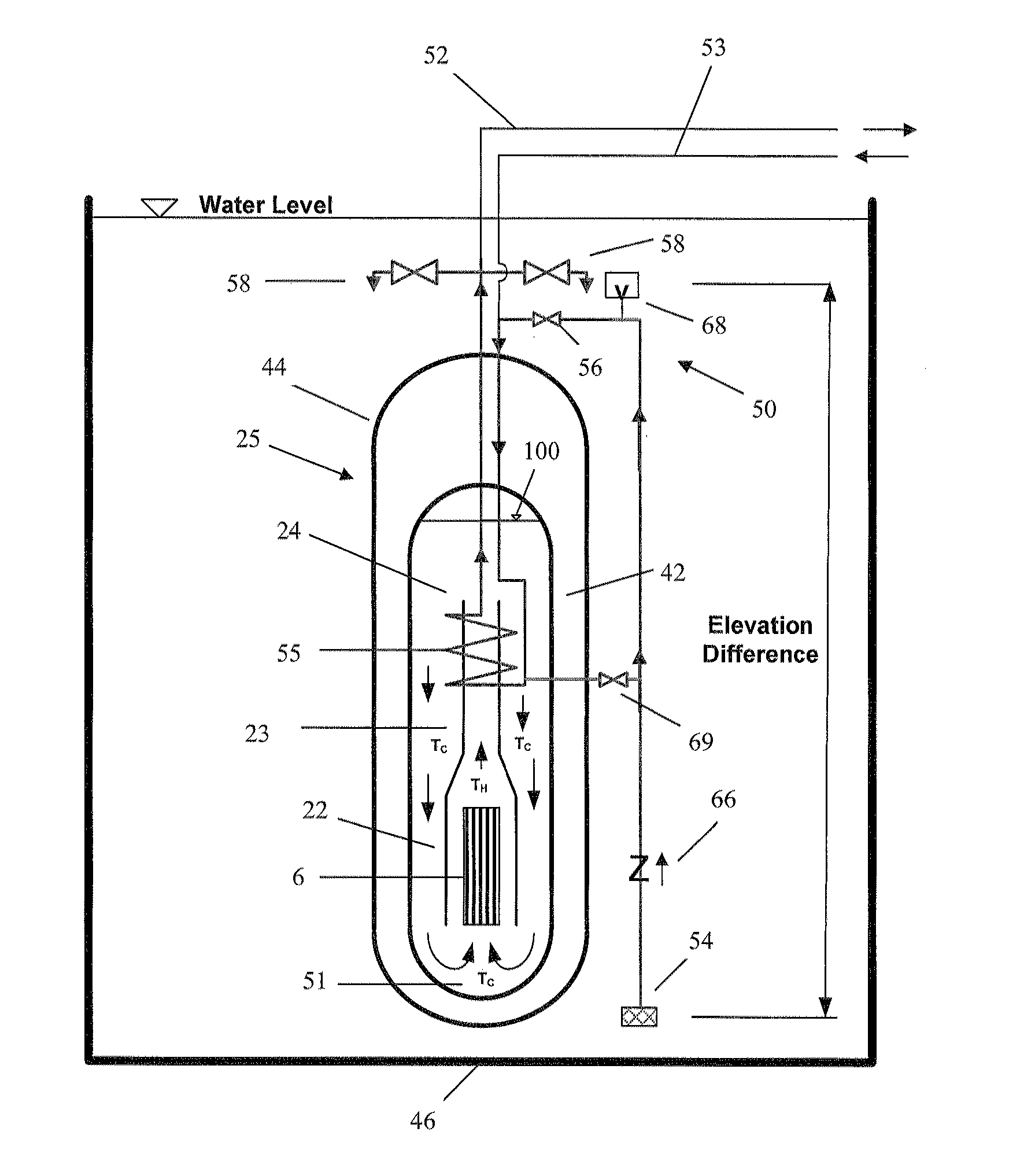

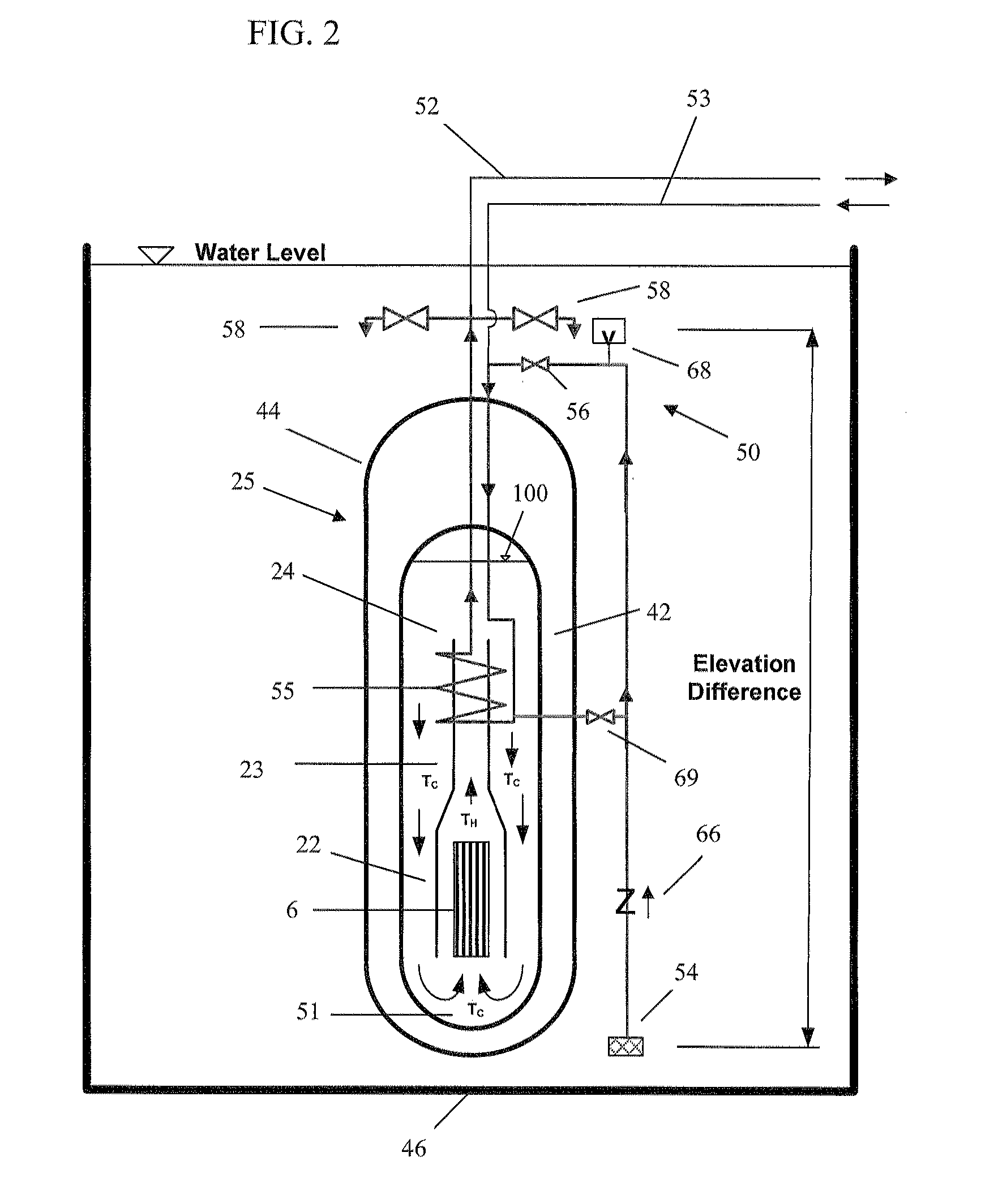

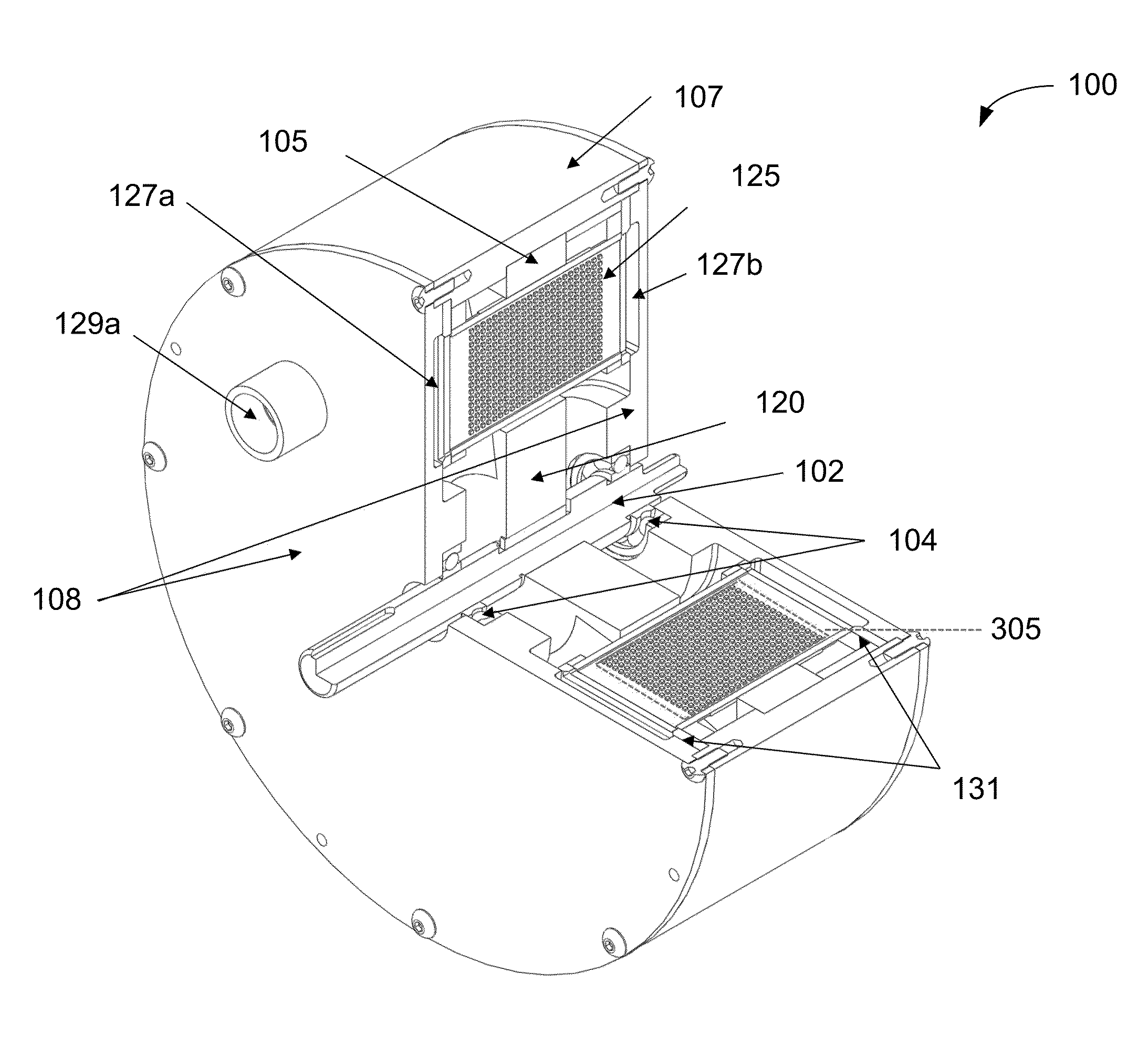

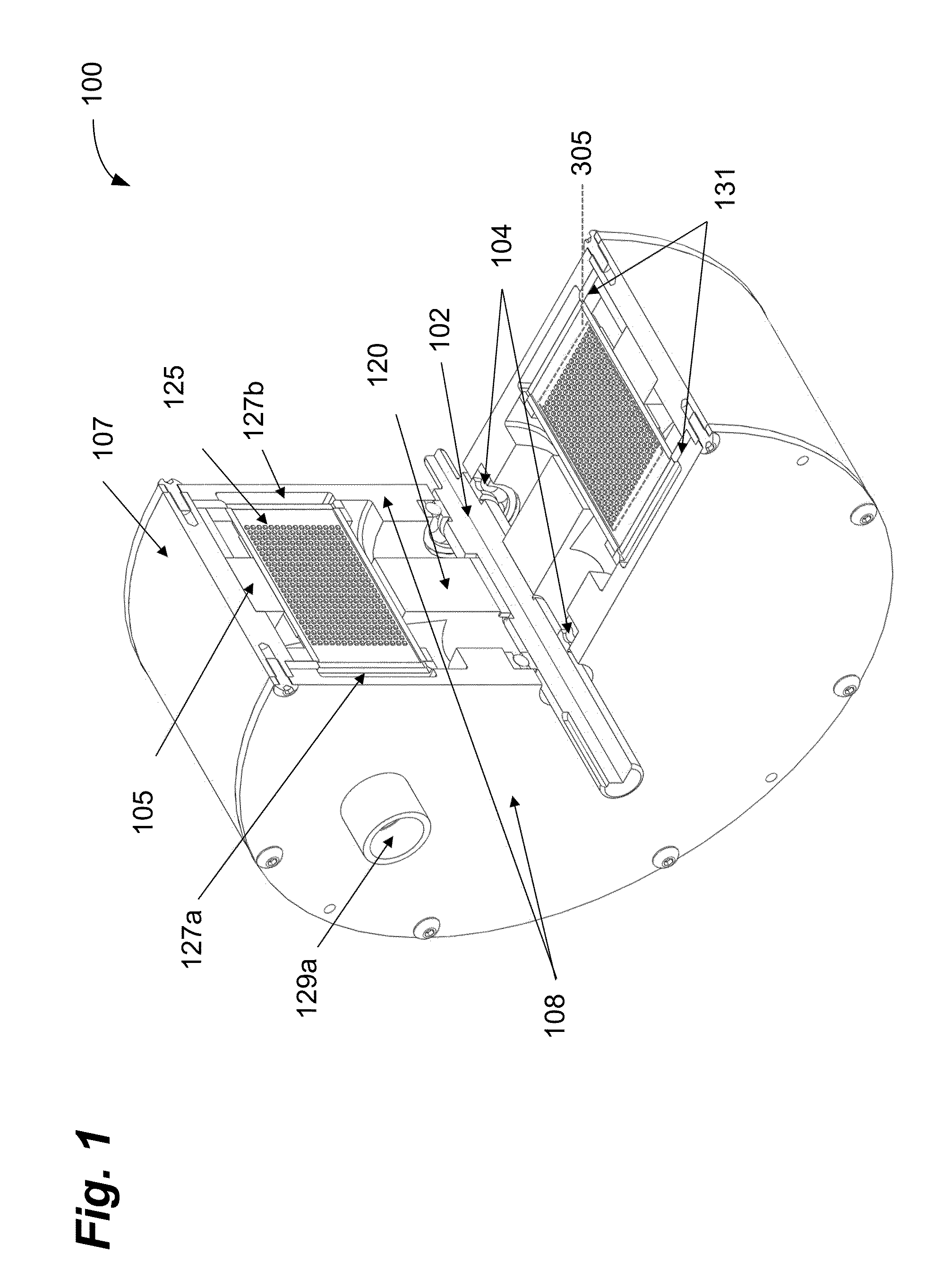

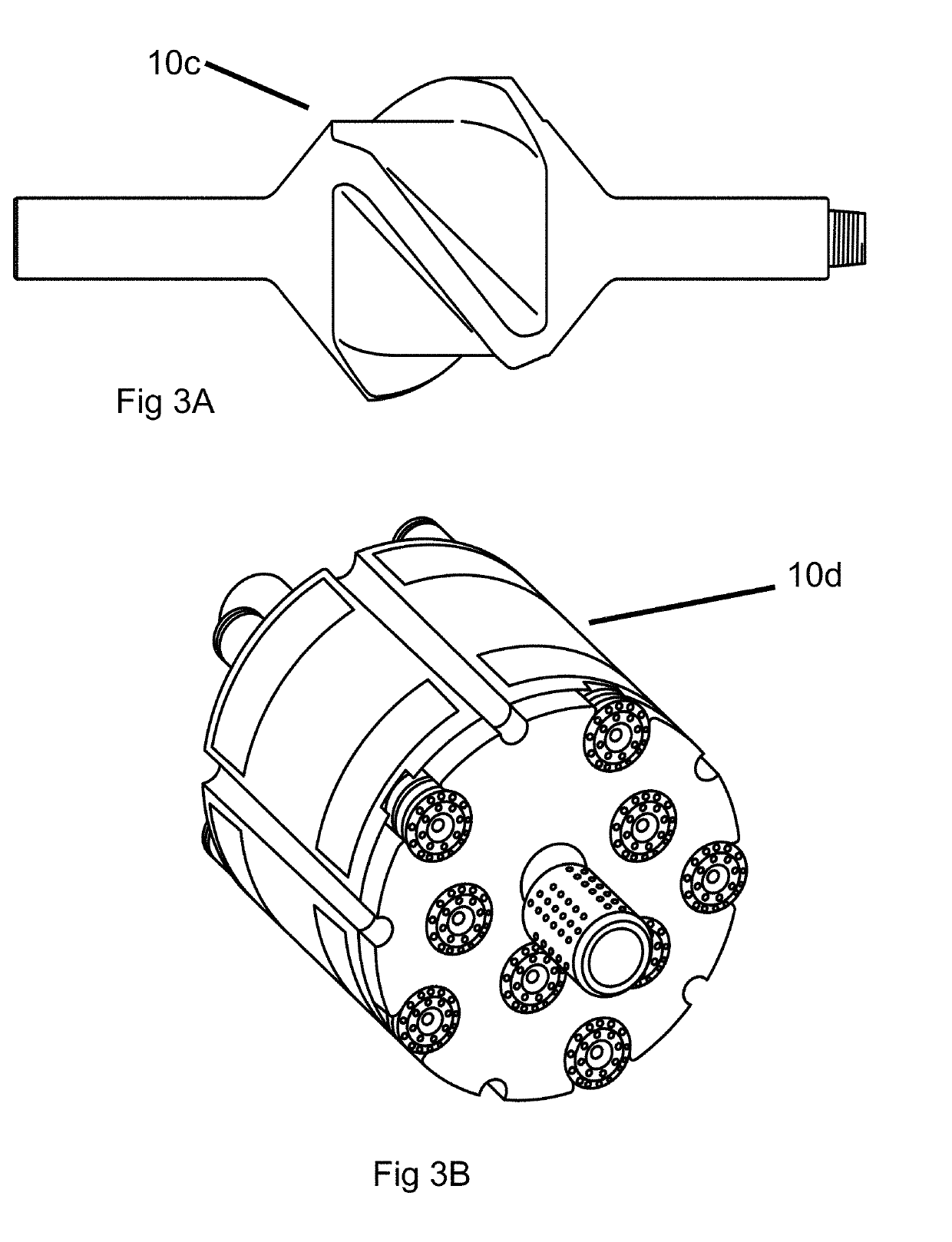

Passive emergency feedwater system

ActiveUS20120177168A1Remove heatIntegral reactorsNuclear energy generationNuclear engineeringCooling pond

A power module assembly may include a reactor vessel containing a primary coolant and one or more inlets configured to draw a secondary coolant from the containment cooling pool in response to a loss of power and / or a loss of coolant. One or more outlets may be submerged in the containment cooling pool and may be configured to vent the secondary coolant into the containment cooling pool. A heat exchanger may be configured to remove heat from the primary coolant, wherein the heat may be removed by circulating the secondary coolant from the containment cooling pool through the heat exchanger via natural circulation.

Owner:NUSCALE

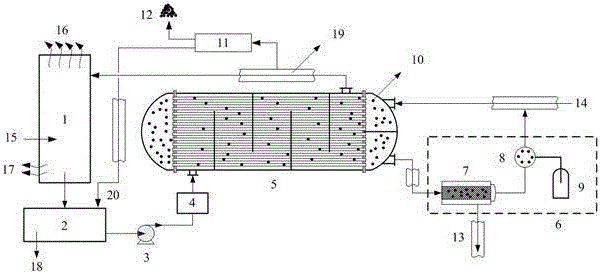

Method and device for sensible heat reclaiming of blast furnace slag and desulfurization of sintering flue gas

ActiveCN102228774ASensible heat effectiveSensible heat recovery is effectiveDispersed particle separationIncreasing energy efficiencySlagFlue gas

The invention relates to a method and a device for sensible heat reclaiming of blast furnace slag and desulfurization of sintering flue gas, which is characterized by that: by introducing sintering flue gas to the technology process of sensible heat reclaiming of blast furnace slag, the environmental pollution of the sintering flue gas is reduced, and the processed blast furnace slag and desulphurization by-products are used for producing cement and gypsum respectively. The device comprises a granulation reactor, a vibration bed, a cooling pond, an exhaust-heat boiler, a generator and a filter No.1, wherein, the feed inlet of the granulation reactor is connected with the slag runner of the blast furnace, and the granulation reactor is connected with the vibration bed and cooling pond in order. Compared with the prior art, the invention has the beneficial effects that: according to a theory of using waste treat waste, by the three processes of desulphurization, sensible heat reclaimingand energy conversion, the purpose of using waste heat steam to generating power and removing SO2 from the sintering flue gas at the same time is realized, the prepared blast furnace slag and desulphurization by-products can be used for producing cement and gypsum respectively, the sensible heat of blast furnace slag is recovered effectively, and the sulfide is removed from sintering flue gas. The invention has a great social meaning.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

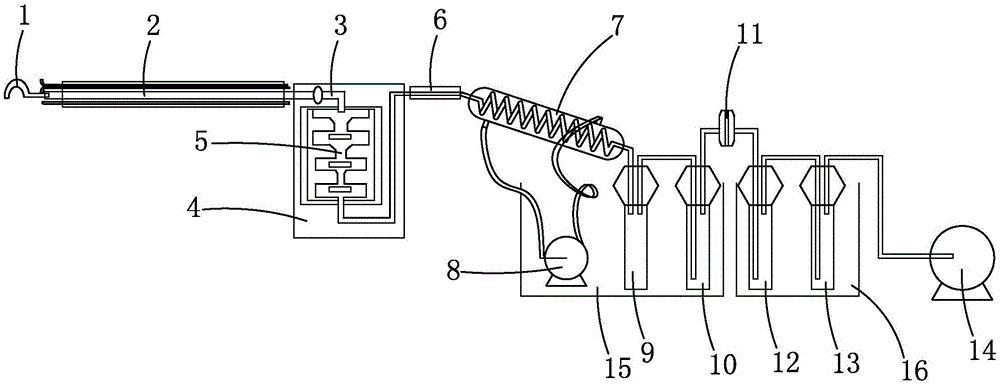

Device and method for simultaneously testing PM2.5 and coagulated particulate matters discharged by fixing source

InactiveCN105588777ARealize data collectionImprove protectionWeighing by absorbing componentParticulatesEngineering

The invention relates to a device and a method for simultaneously testing PM2.5 and coagulated particulate matters discharged by a fixing source. The prior art is short of the device and the method for simultaneously testing PM2.5 and coagulated particulate matters in the smoke discharged by the fixing source. The device comprises a smoke sampling part, a PM2.5 collecting part and a coagulated particulate matter collecting part, wherein a sampling head, a sampling gun, a multi-level striker, a condenser pipe, a first surge flask, a second surge flask, a filter, a third surge flask, a fourth surge flask and a sampling pump are serially connected and formed into a detecting pipeline; the multi-level striker is arranged in a heating chamber; a circulating water pump, the first surge flask and the second surge flask are arranged in a first cooling pond; the third surge flask and the fourth surge flask are arranged in a second cooling pond. The pollutant discharging state of the fixing source is judged by analyzing the smoke component, so that the basis is supplied for the discharging control of the fixing source, the discharging of the fixing source is kept at lower level and the device is beneficial to environmental protection.

Owner:ZHEJIANG ZHENENG TECHN RES INST

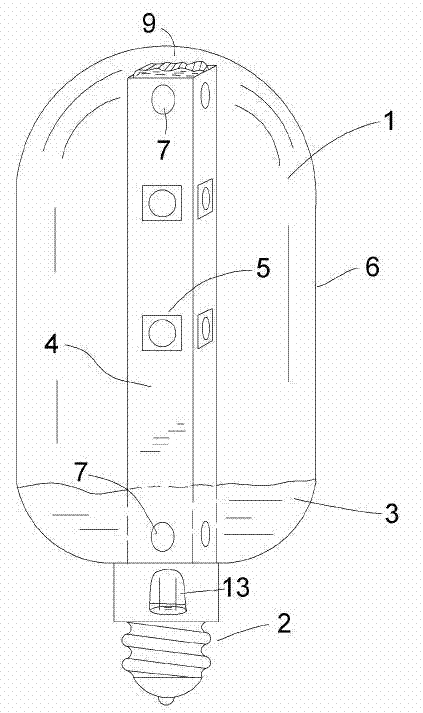

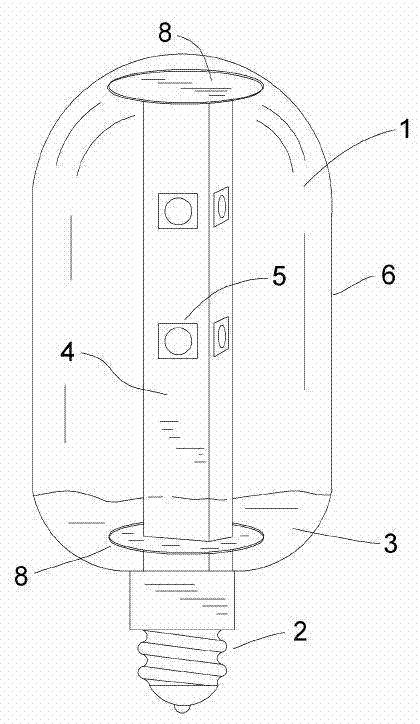

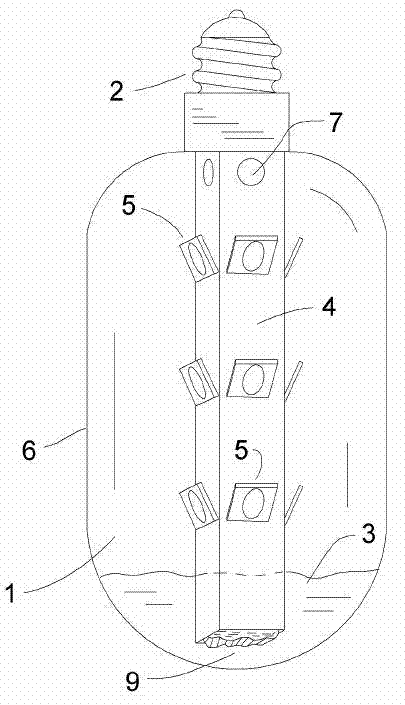

Evaporation cooled lamp

InactiveCN102792096ALow boiling pointHigh boiling pointPoint-like light sourceElectric circuit arrangementsBoiling pointEvaporation

LED or other lamps that remove heat using evaporation of water or other coolant inside a lamp enclosure structure such as a glass bulb typically without the use of external heat sinks or fins. Optionally, the pressure inside the enclosure can be reduced to lower the boiling point of the coolant. One or more LEDs or other light source can be mounted on a support structure that conducts heat to an evaporation surface. A coolant, preferably water or alcohol (or a water / alcohol mixture), is included inside the structure and can be optionally wicked to the evaporation surface. Vaporized coolant condenses on the inside surface of the enclosure or bulb transferring heat to the ambient through the enclosure. The condensed liquid coolant can return to a pool in the bottom of the enclosure.

Owner:欧勒・K・尼尔森

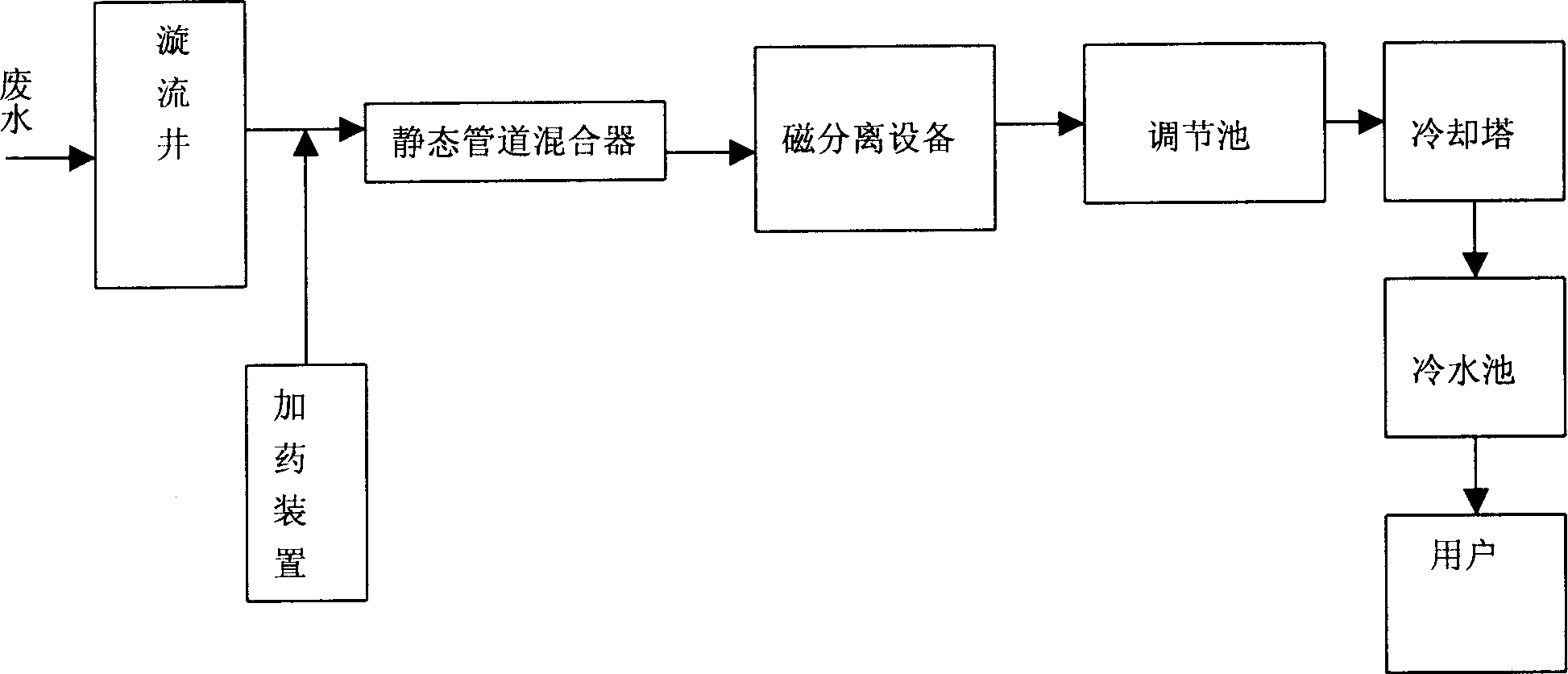

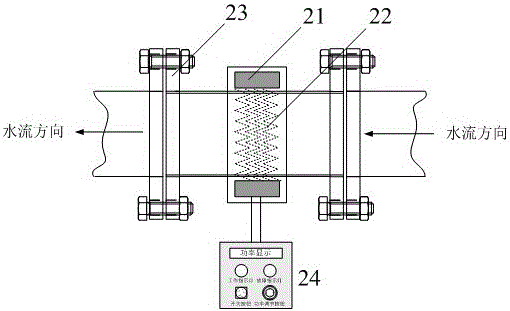

Magnetic flocculation separation waste water treatment technology

ActiveCN1911823ALess investmentSmall footprintWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationFlocculationCooling tower

The magnetically flocculating and separating waste water treating apparatus consists of mainly eddy flow well, static tubular mixer, magnetic separator, regulating pond, cooling tower, cooling pond and other parts. It has also chemical adding device before the magnetic separator for throwing flocculant and flocculant aid or complex flocculant, which is mixed into the waste water so as to demulsify oil in the waste water, combine oil and fine non-magnetic matter with flocculant. Through further magnetic separation, the purified water can reach SS less than 20 mg / l and oil less than 5mg / l, is colorless and transparent, and may be reused.

Owner:SCIMEE TECH & SCI CO LTD

Dissolution processing method for CTA draff in PTA production

ActiveCN101402564ASolve processing problemsCarboxylic compound separation/purificationBenzoic acidDistillation

The invention relates to a solvent processing method for CTA residue during the PTA production. The method comprises the following steps: mixing the CTA residue and water into slurry which is dissolved and filtrated to obtain mixed acid filter cake and hot crude benzoic acid filtrate; injecting the obtained hot crude benzoic acid filtrate into a cooling pond for natural cooling and crystallization, and obtaining crude benzoic acid filter residue and aqueous solution after filtration; injecting the obtained crude benzoic acid filter residue into a sintering kettle for heating and melting, and obtaining a big block of crude benzoic acid after cooling and recrystallization in a reception tray; and adding the obtained big block of the crude benzoic acid into a distillation tower for benzoic acid distillation, and obtaining the industrial-grade benzoic acid from the top of the tower through the heat exchange and separation of filler gas liquid in the distillation tower. The method which carries out the synthesized processing of the CTA residue in the PTA production through the solvent processing method can sufficiently extract various valuable constituents in the CTA residue, thereby not only solving the problem of processing the CTA residue during the PTA production, but also creating great economic benefits. Therefore, the method has high promotion and application values.

Owner:XIAMEN HAIWAN CHEM

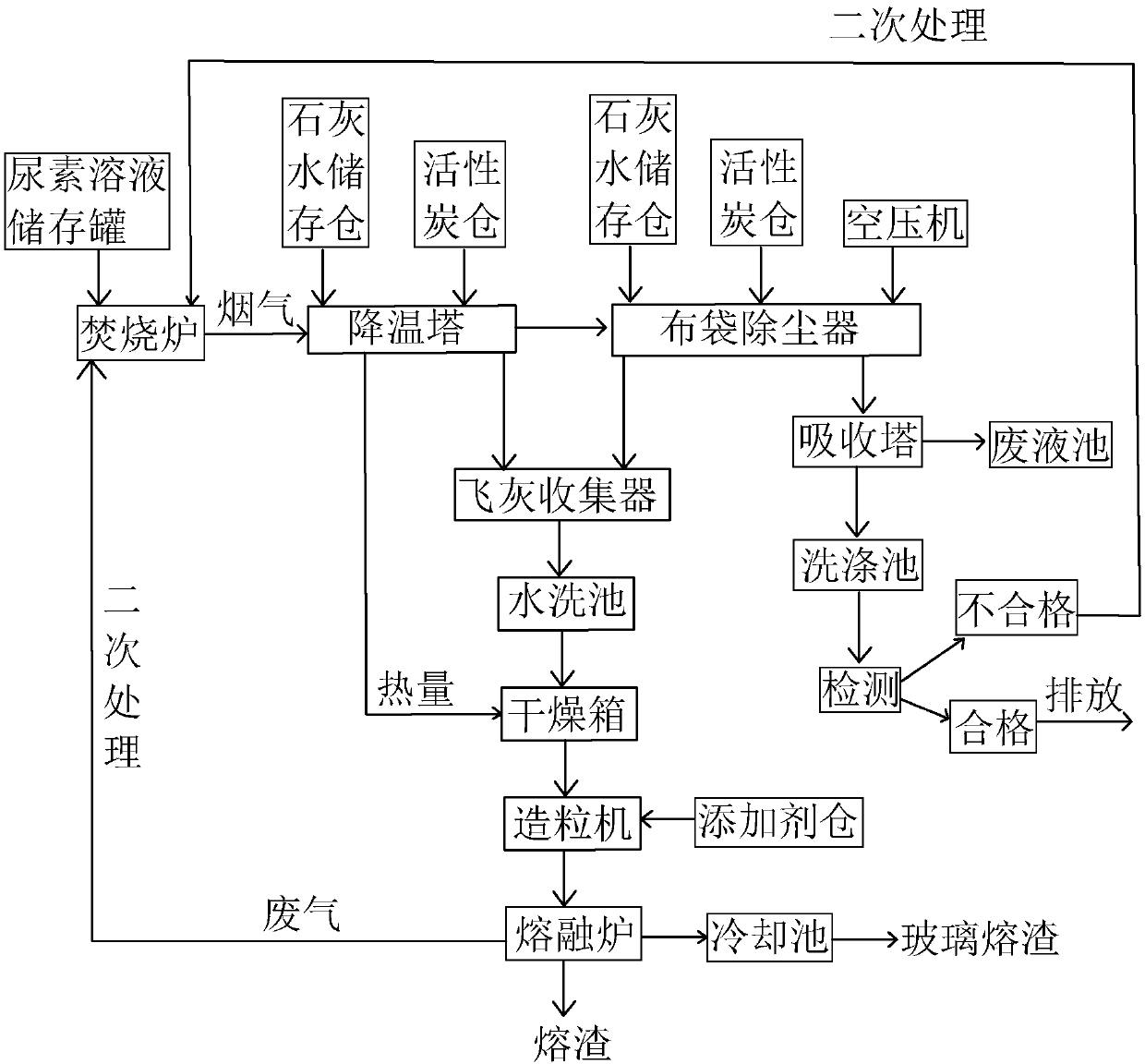

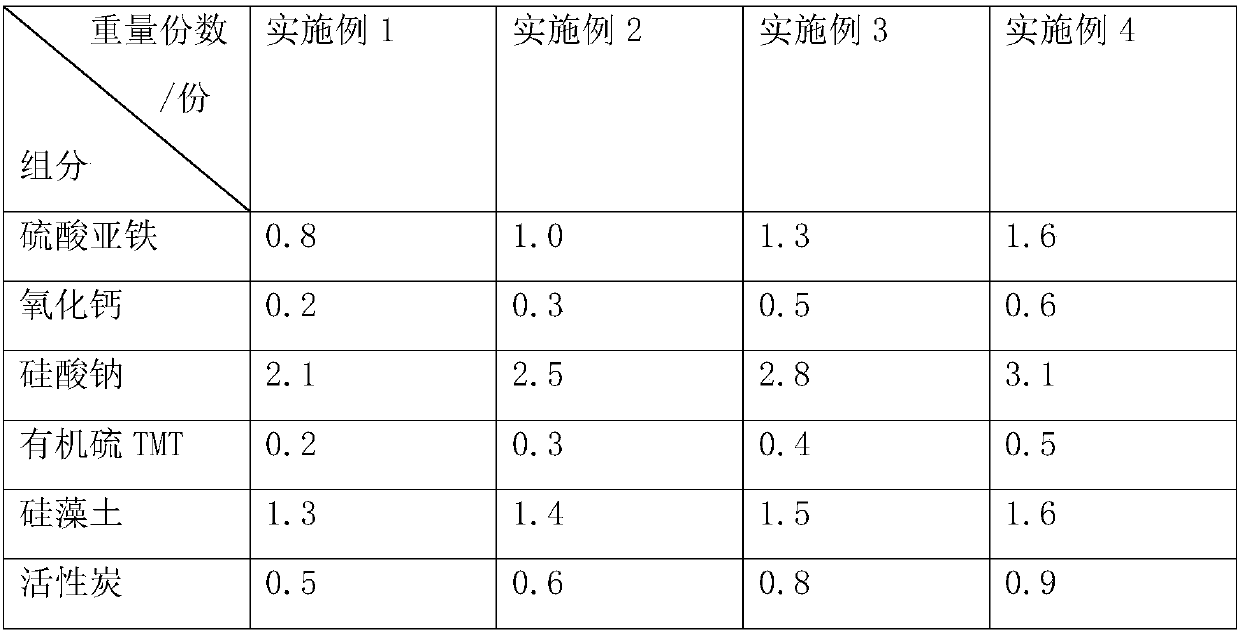

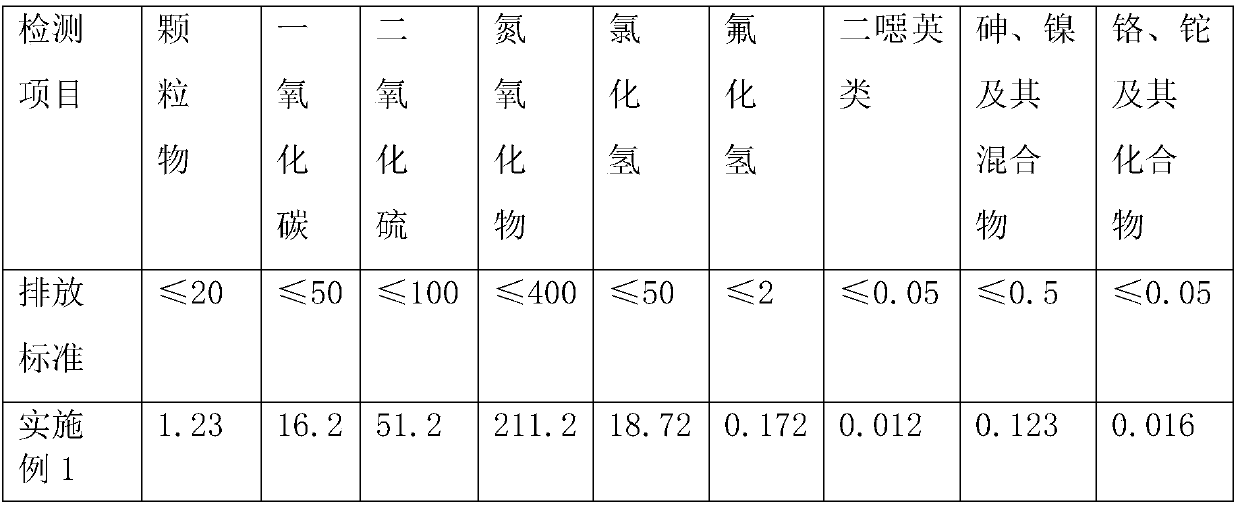

Garbage incineration waste gas and flying ash co-processing system

ActiveCN109647849AAvoid secondary pollutionGood processing effectSolid waste disposalTransportation and packagingMelting tankCooling tower

The invention discloses a garbage incineration waste gas and flying ash co-processing system. The garbage incineration waste gas and flying ash co-processing system comprises a cooling tower, a clothbag dust collector, an absorption tower, a washing tank, a flying ash collector, a water washing tank, a drying box, a granulator, a melting tank and a cooling tank, wherein the cooling tower, the cloth bag dust collector, the absorption tower and the washing tank are sequentially connected with a smoke exhausting cylinder of an incinerator; the flying ash collector is connected with the cooling tower and the cloth bag dust collector; the water washing tank, the drying box, the granulator, the melting tank and the cooling tank are sequentially connected with the flying ash collector; smoke generated in the melting tank is charged into the incinerator and is subjected to secondary treatment; flying ash generated in the melting tank enters the cooling tank which is connected with the meltingtank; the granulator is connected with an additive bin used for adding an additive into the granulator; the cooling tower and the cloth bag dust collector are each connected with a whitewash storagebin and an active carbon bin; the cloth bag dust collector is connected with an air compressor; washing liquid is placed inside the washing tank, wherein the volume ratio of the washing liquid to thesmoke is 1:(2-2.5). The garbage incineration waste gas and flying ash co-processing system disclosed by the invention has the advantages of realizing co-processing of waste gas and the flying ash andbeing low in cost and good in processing effect.

Owner:上海金山环境再生能源有限公司

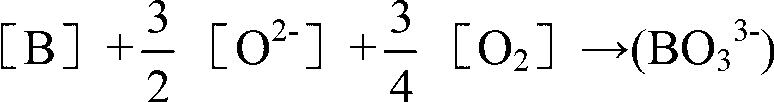

Preparation device and preparation method for silicon ball

The invention discloses a preparation device and a preparation method for a silicon ball and relates to a silicon ball. The preparation device for the silicon ball comprises an induction coil, a graphite insulation board, a graphite crucible, a flow divider, a cooling tank, a water inlet pipe, a water outlet pipe, a gas inlet pipe and an electric pump. The preparation method for the silicon ball comprises the following steps of: using a metallurgical-grade silicon material as the raw material and placing the silicon material into the crucible of an induction furnace; starting an induction furnace power supply to heat and after totally melting the silicon material, adding a slag forming constituent; after completing slag forming, switching off the induction furnace power supply; standing and removing waste residues floating at the upper part of the crucible to obtain silicon liquid; starting the flow divider to carry out preheating and when the temperature in the flow divider reaches the range of 1,450 to 1,650 DEG C, pouring the silicon liquid into the flow divider; regulating the heights of a liquid outlet at the bottom of the flow divider and the cooling tank to enable the silicon liquid to fall into the cooling tank in a droplet shape to be quenched; and filling gas into the cooling tank and after completing quenching, and obtaining the silicon ball. Boron content can be obviously reduced; the obtained silicon ball comprises small crystal grains and is easy to crush and process; and an ideal low-boron raw material can be provided for an acid pickling process.

Owner:XIAMEN UNIV +1

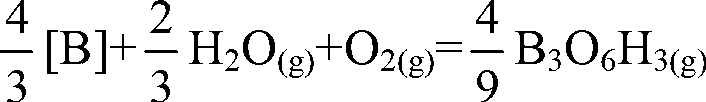

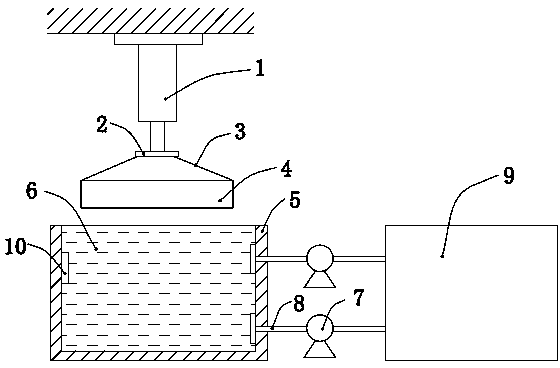

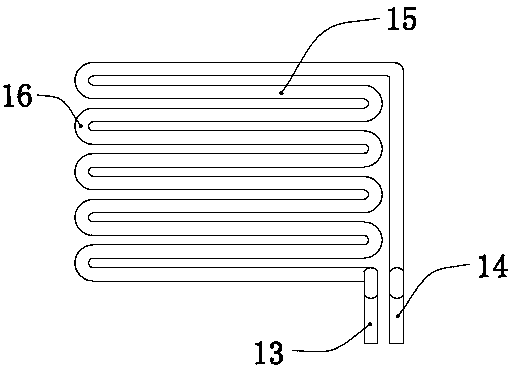

Temperature control coolant oil cycle apparatus used for quenching

InactiveCN103589834AQuickly dropped toImprove cooling efficiencyFurnace typesHeat treatment furnacesTemperature controlCooling tower

The invention relates to a temperature control coolant oil cycle apparatus used for quenching, which comprises cooling pipelines, a water pump and a cooling tower, and is characterized in that at least one cooling pipeline immersed in the coolant oil is paved at the bottom of an inner cavity of a quenching oil pond, and two ends of the cooling pipeline, the water pump and the cooling tower are communicated through the pipelines and form a loop for conveying cooling water. The coolant oil cycle apparatus is capable of cooling the coolant oil through circular flow of water, which can substitute the process that the coolant oil is directly placed in the cooling pond for air-cooled cooling in the prior art, the coolant oil can be rapidly decreased to the required temperature, the cooling efficiency is increased; the circular flow of water cools the coolant oil in real time without transfer of the coolant oil in the cooling pond for cooling, quenching work can be continuously carried out, so that the resource waste caused by continuous heating of fire temperature in cooling time of the coolant oil can be avoided.

Owner:JINAN HUIXIN IND

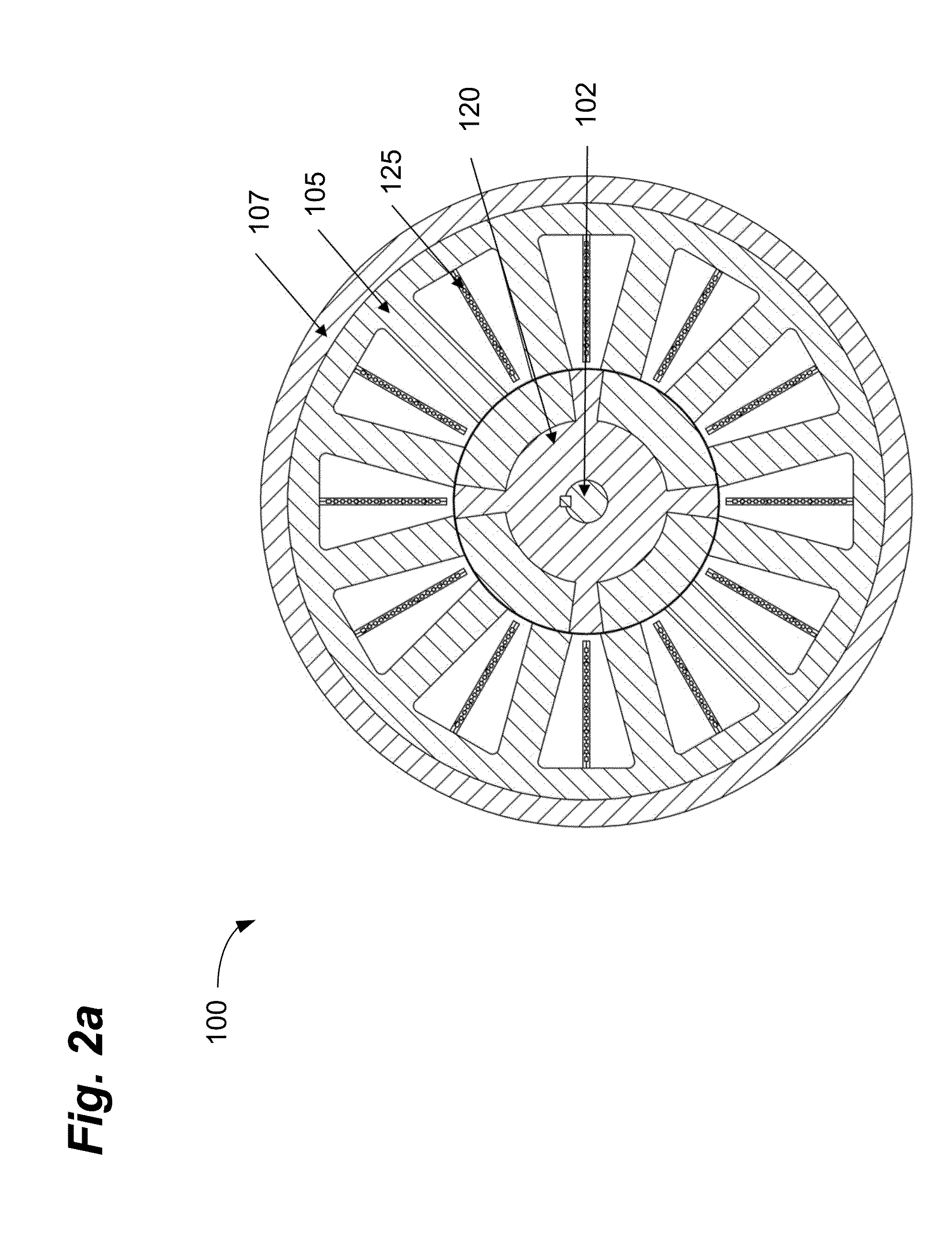

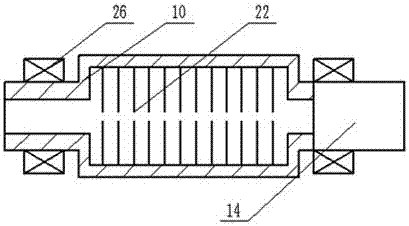

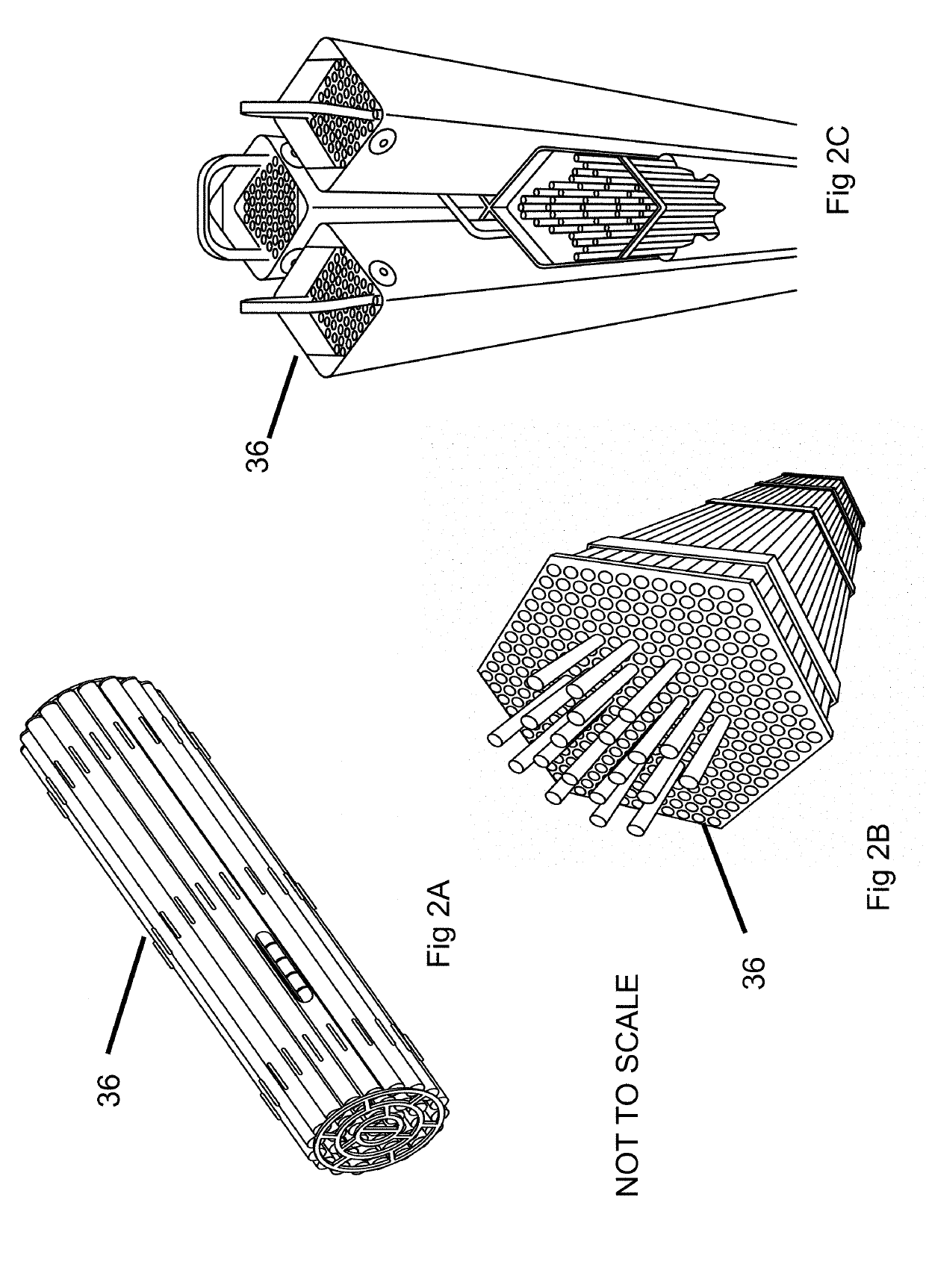

Systems and methods for direct winding cooling of electric machines

ActiveUS20130270936A1Optimize design parametersHigh densityCooling/ventillation arrangementElectric machineEngineering

A system and method for cooling electric machines using direct winding heat exchangers (DWHX) is disclosed. The system can comprise a plurality of DWHXs disposed in thermal communication with a plurality of copper windings in the stator of an electric machine for cooling the plurality of copper windings. The plurality of DWHXs can also be in fluid communication with one or more fluid manifolds for providing coolant to the plurality of DWHXs. The one or more manifolds can be in fluid communication with one or more heat reservoirs for rejecting the heat absorbed by the plurality of DWHXs. The heat reservoir can be an internal system radiator or an infinite reservoir such as a cooling pond. The method can comprise a design tool for optimizing a DWHX cooling system utilizing the internal system radiator or an infinite reservoir, among other things.

Owner:GEORGIA TECH RES CORP

Ferrotitanium alloy electric furnace smelting method

The invention relates to a smelting method for a ferrotitanium alloy electric induction furnace, which comprises following steps: adding titanium concentrate, rutile, lime, ferrosilicon and other ore charges in a smelting furnace which is resistant to high temperature of over 3000 DEG C according to proportion; heating to 1800 to 2200 DEG C; completely melting the ore charges in the furnace; adding the reducing agent of 0.5 to 1.0mm metallic aluminum particles and heat enhancer potassium chlorate in the completely melted ore charges; increasing the temperature in the furnace to over 3000 DEG C by means of reduction heat released by metallic aluminum, so as to reduce the titanium dioxide in the ore charges into titanium metal which is aggregated into ferrotitanium alloy with iron; cooling the aggregated ferrotitanium alloy with the high temperature resistant smelting furnace or crucible to below 500 DEG C; taking the solidified ferrotitanium alloy integrally from the high temperature resistant smelting furnace or crucible and putting into cooling pond for cooling. The smelting method for the ferrotitanium alloy electric induction furnace has the advantages of convenient process, convenient operation, low cost, high yield, stable product quality and applicability to ferrotitanium production of small and medium sized smelting furnace with different capacities.

Owner:苏永山 +2

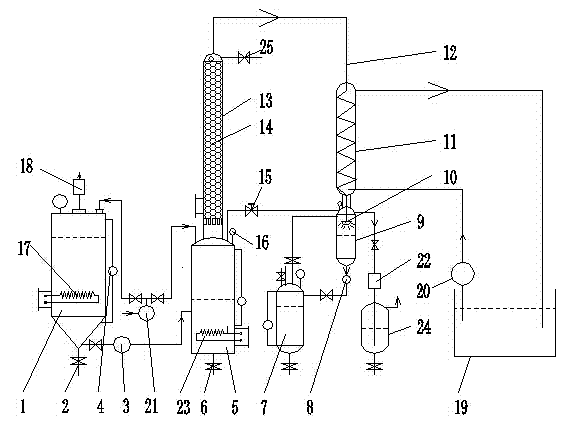

Waste oil cracking, rectifying and regenerating system

InactiveCN104845666ADehydration fastImprove decolorizationTreatment with plural serial stages onlyCooling towerDistillation

The invention discloses a waste oil cracking, rectifying and regenerating system, and relates to an oil purifier. The system is characterized by mainly comprising a dewatering tank, a reaction kettle, a cooling tower, a rectifying tower, a gas-liquid separation tower, an oil storage tank, a waste gas separation tank, a cooling pond and a gas-liquid separation tower vacuum pump, wherein external waste oil is pumped into the dewatering tank or the reaction kettle from an oil inlet pump; the oil of the dewatering tank enters the reaction kettle from an oil well pump; liquid oil is cracked in the reaction kettle to generate gas oil; the gas oil is rectified in the rectifying tower; the rectified gas oil enters the cooling tower to be cooled into the liquid oil through an oil-gas pipe; and the liquid oil and a few of miscellaneous gases are separated in the gas-liquid separation tower. According to the system, a gasification separation process and a distillation process are integrated into a whole; cracking equipment and rectifying equipment for the waste oil are merged into a whole; the system is reasonable in structure; the dewatering, degassing, decolorizing, desulfuration, cracking and rectifying effects of the waste oil are significantly improved; the oil yield and the quality are improved; the production cost for waste oil regeneration is reduced; and the waste oil cracking, rectifying and regenerating system has popularization value.

Owner:CHONGQING FANGSHENG CLEANING EQUIP CO LTD

Ferrotitanium alloy electric induction furnace smelting method

The invention relates to a smelting method for a ferrotitanium alloy electric induction furnace, which comprises following steps: adding titanium concentrate, rutile, lime, steel and other ore charges in a crucible of an ordinary electric induction furnace according to proportion; heating to 1800 to 2200 DEG C; pouring the ore charges in the crucible into a smelting furnace or a crucible which is resistant to high temperature of over 3000 DEG C after being completely melted; adding the reducing agent metallic aluminum particles and heat enhancer potassium chlorate in the completely melted ore charges; increasing the temperature in the furnace to over 3000 DEG C by means of reduction heat released by metallic aluminum, so as to reduce the titanium dioxide in the ore charges into titanium metal which is aggregated into ferrotitanium alloy with iron; cooling the aggregated ferrotitanium alloy with the high temperature resistant smelting furnace or crucible to below 500 DEG C; taking the solidified ferrotitanium alloy integrally from the high temperature resistant smelting furnace or crucible and putting into cooling pond for cooling. The smelting method for the ferrotitanium alloy electric induction furnace has the advantages of advanced process, convenient working procedure, easy operation, low cost, low energy consumption, high yield and stable product quality.

Owner:苏永山 +2

Quenching device of shaft lever

InactiveCN106086336AHigh precisionGood effectFurnace typesHeat treatment furnacesEngineeringManipulator

The invention discloses a quenching device of a shaft lever. The quenching device comprises a conveying belt and a cooling pond, wherein the conveying belt is used for conveying the shaft lever, the cooling pond is installed on one side of the conveying belt, a manipulator is arranged between the cooling pond and the conveying belt, a fixture which is used for grabbing the shaft lever is arranged on the manipulator, a quenching furnace is further arranged on one side of the cooling pond, a tooling plate is arranged in the quenching furnace, and a position sensor is arranged on the fixture. The manipulator is arranged to transfer the shaft lever, so that the quenching efficiency of the shaft lever is improved. The quenching device has the advantages of simple structure and convenience in operation, the quenching effect is greatly increased, and the input cost is reduced.

Owner:NEXTEER LINGYUN DRIVELINE WUHU

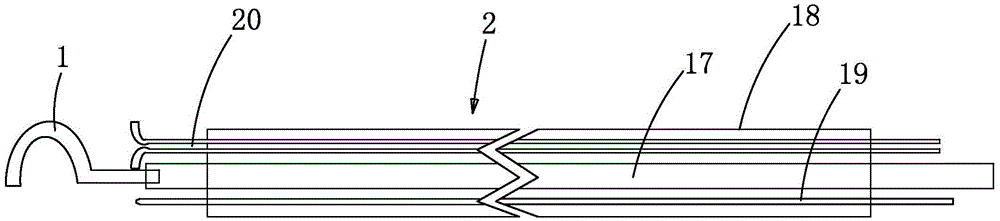

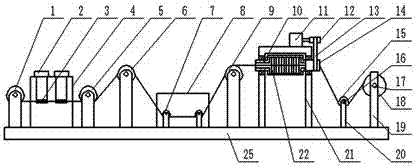

Abrasion preventing copper wire annealing machine

InactiveCN107034343AReduce wearQuality assuranceFurnace typesHeat treatment furnacesCopper wireWater source

The invention discloses an abrasion preventing copper wire annealing machine which comprises a base. A first guide wheel is arranged at the upper end of the left side of the base. A second guide wheel is arranged on the right side of the first guide wheel. A heating box is arranged between the first guide wheel and the second guide wheel. A third guide wheel is arranged on the right side of the second guide wheel. A cooling pond is arranged on the right side of the third guide wheel. Two fourth guide wheels are arranged on the inner side of the bottom end of the cooling pond. A fifth guide wheel is arranged on the right side of the cooling pond. A mounting rack is arranged on the right side of the fifth guide wheel. A cleaning roller is arranged in the mounting rack. A sixth guide wheel is arranged on the right side of the mounting rack. A wire take-up roll is arranged on the right side of the sixth guide wheel. The abrasion preventing copper wire annealing machine is simple in structure and reasonable in design, and abrasion caused by wiring to copper wires and the guide wheels can be effectively reduced. Emulsified liquid generated after annealing can be removed, the surfaces of the copper wires are prevented from being abraded, and the function of saving water sources is achieved.

Owner:JIANGSU SUFENG MECHANICAL DEV CO LTD

Injection molding machine mould cooled by circulating water

The invention discloses an injection molding machine mould cooled by circulating water. The mould is formed by splicing and combining two or more modules, and all the modules are connected in series through hinges and fixed through fasteners; each module is internally provided with a hollow water chamber, and the water chambers of every two modules connected by the corresponding hinge communicate with each other through a hose; the module located at the head end is provided with a water inlet, the module located at the tail end is provided with a water outlet, the water inlet is connected with a water pump, the water pump is connected with a cold water tank, and the water outlet is connected with a cooling pool. The injection molding machine mould is simple in structure and convenient to operate, the mould is cooled rapidly, cooling is uniform, product quality and production efficiency are greatly improved, and the production cost of enterprises is reduced.

Owner:安徽鹭江电子工业制造有限公司

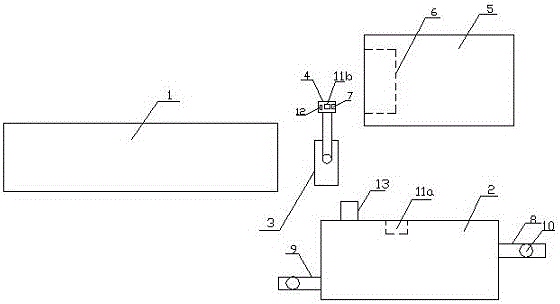

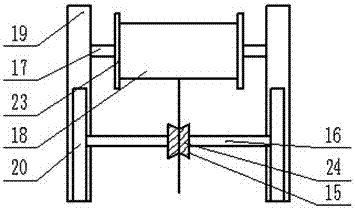

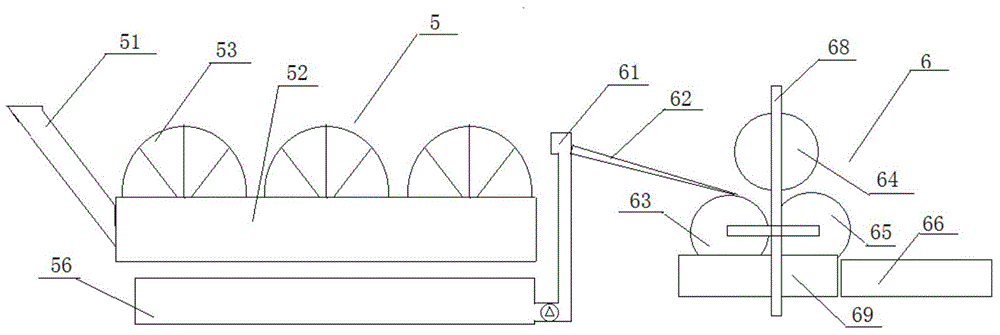

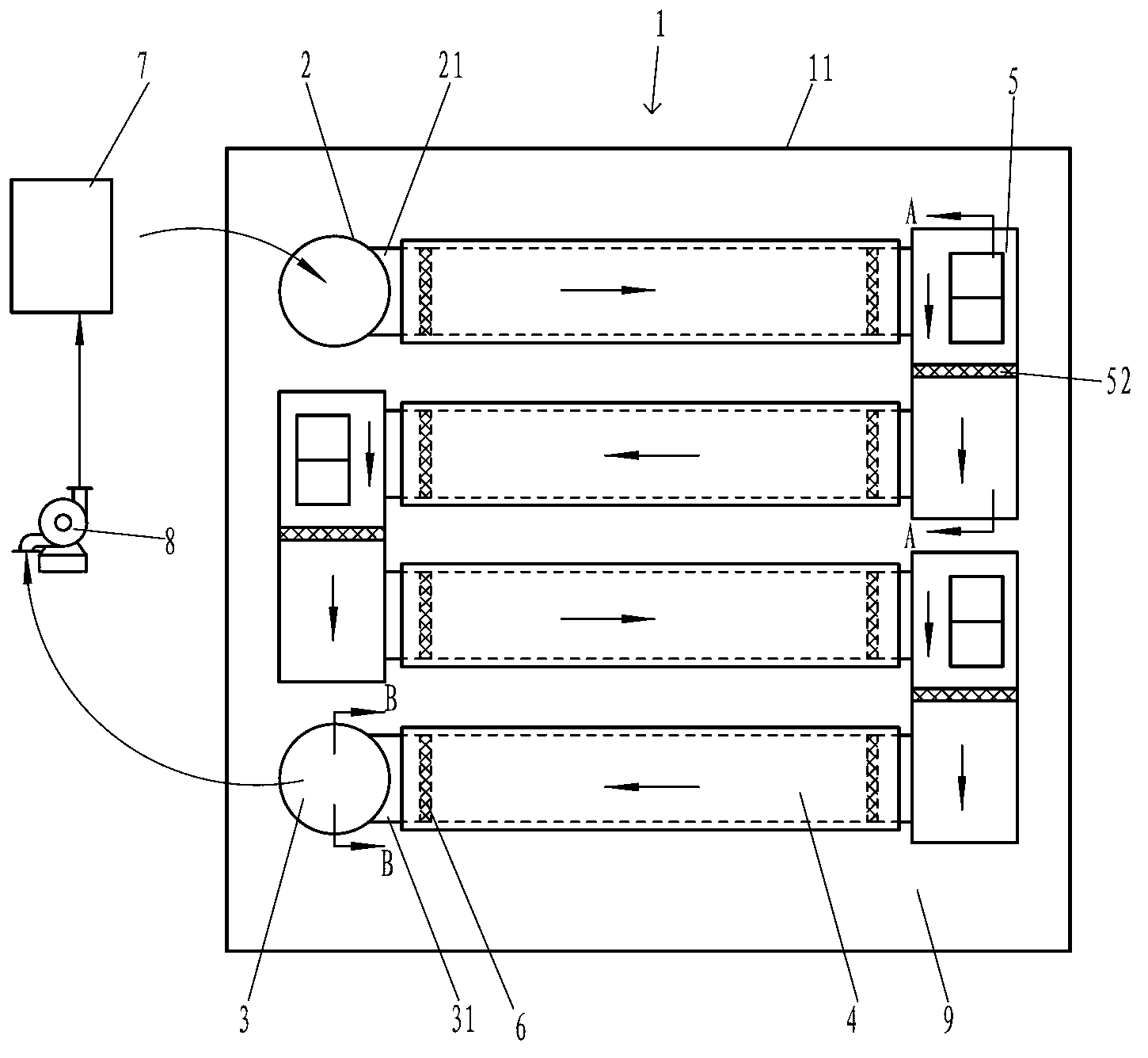

Comprehensive treatment apparatus and method for non-dosage form circulating cooling water

InactiveCN105110546ASolve the blockageImprove stabilityMultistage water/sewage treatmentNon-rotary device cleaningCyclic processCooling tower

The present invention relates to a comprehensive treatment apparatus and method for circulating cooling water. The apparatus comprises a cooling water magnetizing apparatus (4), an electrochemical water treatment apparatus (11) and a rubber ball cleaning apparatus (6). Water in a cooling pond (2) is extracted by a cooling water circulation pump (3) to be delivered into a shell-and-tube heat exchanger (5) to be carried on a heat exchange with a process medium from a process medium inlet line (14), then come into a cooling tower (1), and fall into the cooling pond after cooling. A cycle of cooling water is finished. The present invention provides a comprehensive treatment apparatus and method for non-dosage form circulating cooling water, thereby significantly reducing pollution discharge or even achieving zero pollution discharge. Problems existing in a circulating cooling water system such as corrosion, fouling, bio-erosion, and the like are solved from a comprehensive angle of ''removing'', ''cleaning'', and ''preventing''. The cooling water magnetizing apparatus (4), the electrochemical water treatment apparatus (11) and the rubber ball cleaning apparatus (6) can comprehensively protect the circulating cooling water system, so as to reduce pollution discharge, avoid secondary pollution of chemicals, and decrease an operation cost of the circulating cooling water system.

Owner:卫士循环水处理(北京)有限公司

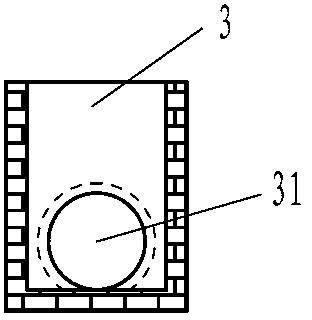

Wind power generation steel ball thermal treatment and quenching combined device

ActiveCN101928820AAvoid collision damageImprove quenching effectFurnace typesHeat treatment furnacesContact timeSteel ball

The invention relates to a wind power generation steel ball thermal treatment and quenching combined device which comprises a cooling pool, a feeding hole and a lifting mechanism, wherein the top side of the cooling pool is connected with the feeding hole, the bottom is provided with the lifting mechanism, cooling liquid is filled in the cooling pool; the cooling pool is internally provided with a spiral rail connected with the feeding hole and the lifting mechanism; and one side of the cooling pool is provided with a cooling liquid cooling and circulating device. The invention has the advantages of having large heat radiation area and little impaction because a steel ball slides along the spiral rail, avoiding the collision damage of the steel ball during the falling, and prolonging the contact time of the steel ball and the cooling liquid. One side of the cooling pool is connected with the cooling liquid cooling and circulating device, and spraying holes are uniformly arranged under the spiral rail to ensure that the cooled cooling liquid is uniformly distributed in the cooling pool, therefore, the quenching effect of the steel ball is improved.

Owner:JIANGSU LIXING GENERAL STEEL BALL

Passive emergency feedwater system

ActiveUS20180261343A1Integral reactorsNuclear energy generationNuclear engineeringProcess engineering

A power module assembly may include a reactor vessel containing a primary coolant and one or more inlets configured to draw a secondary coolant from the containment cooling pool in response to a loss of power and / or a loss of coolant. One or more outlets may be submerged in the containment cooling pool and may be configured to vent the secondary coolant into the containment cooling pool. A heat exchanger may be configured to remove heat from the primary coolant, wherein the heat may be removed by circulating the secondary coolant from the containment cooling pool through the heat exchanger via natural circulation.

Owner:NUSCALE LLC

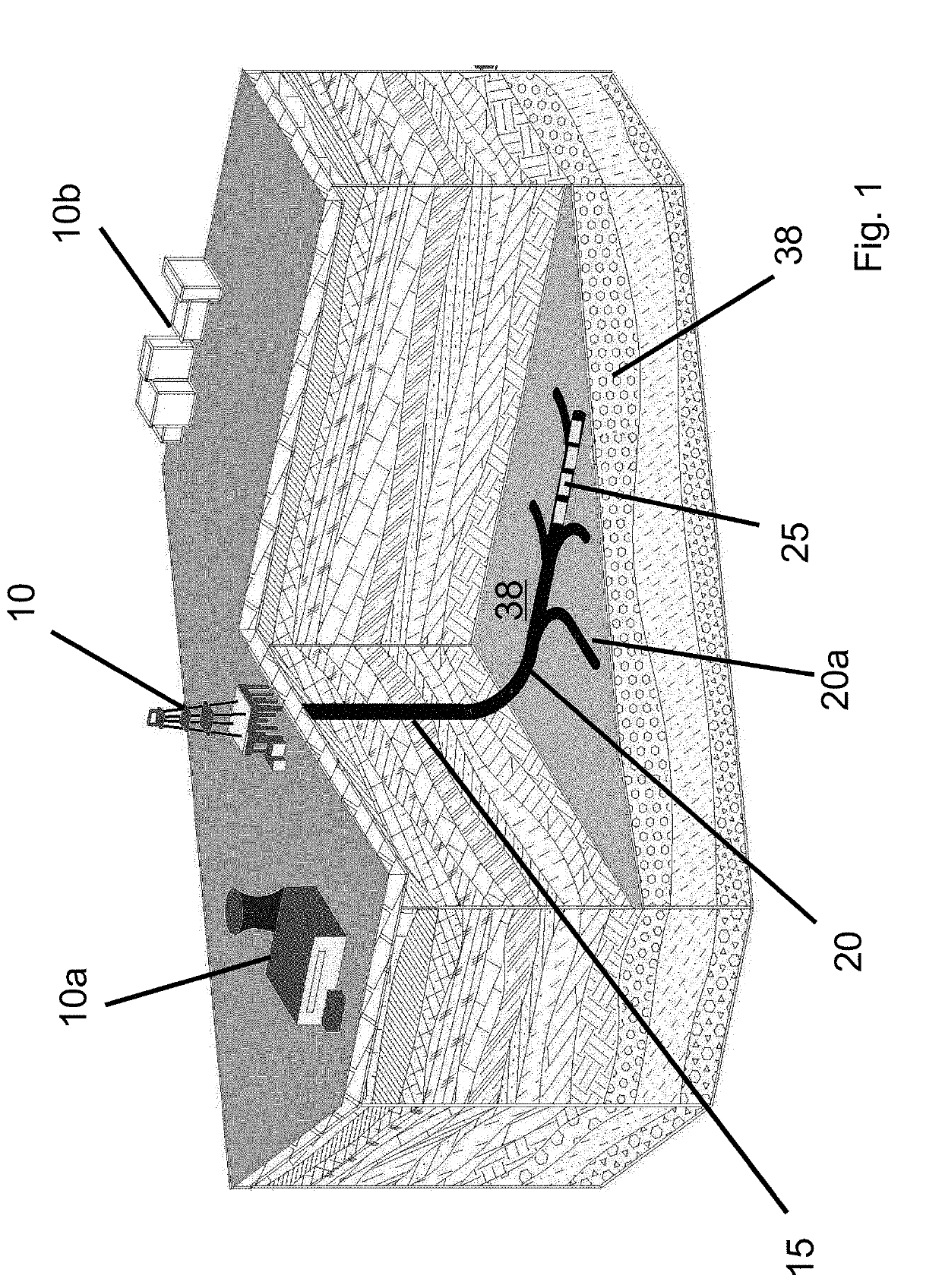

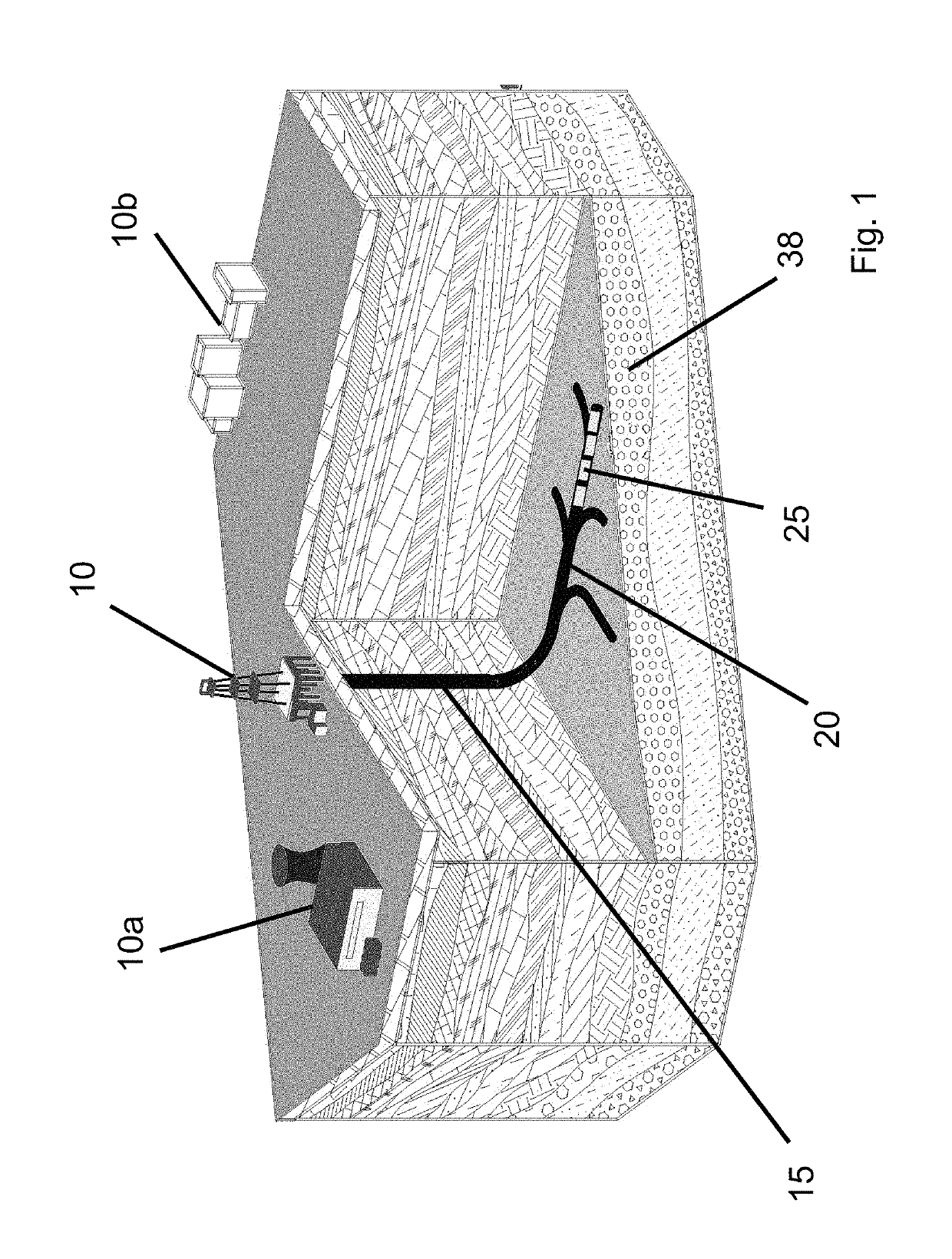

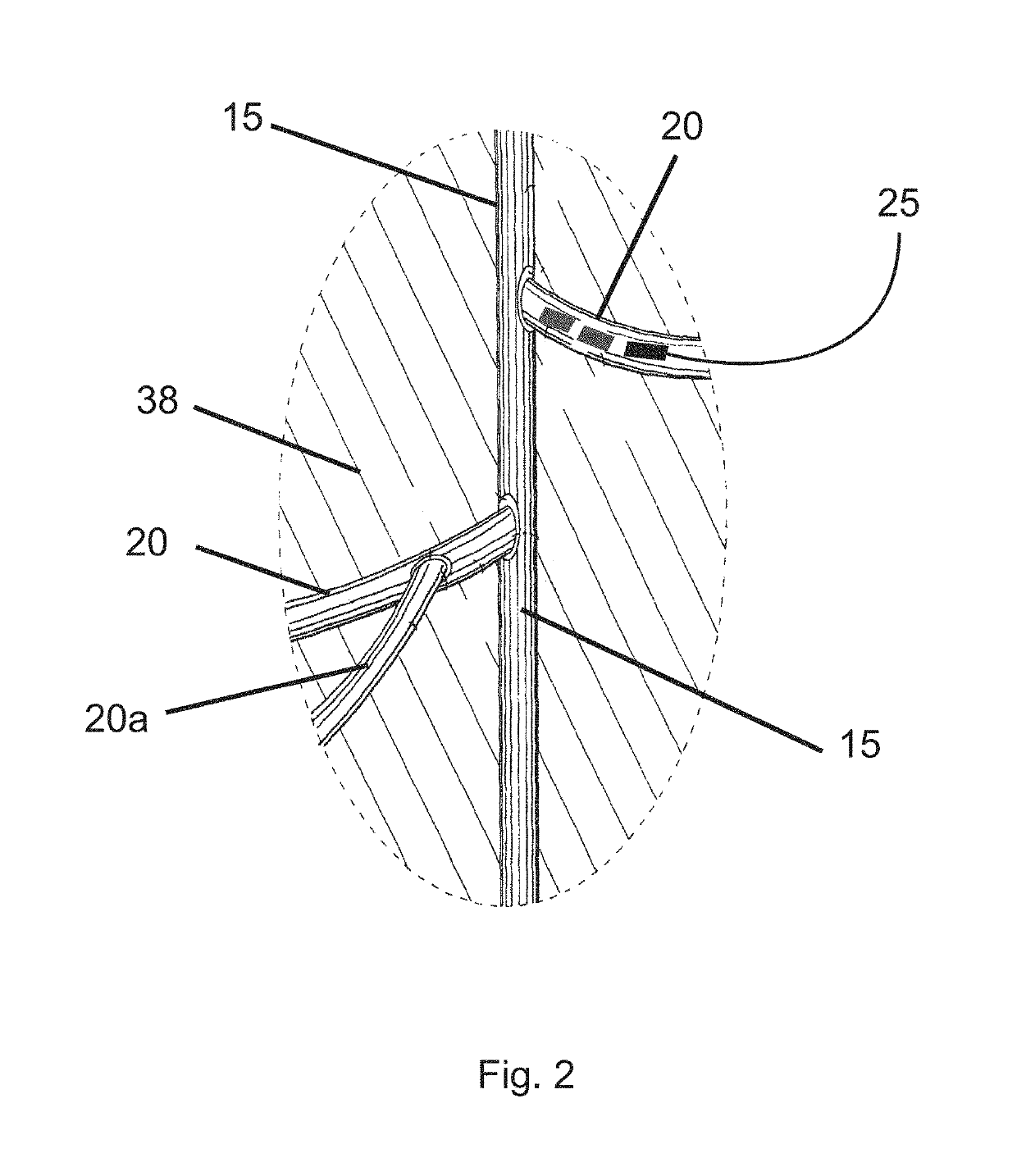

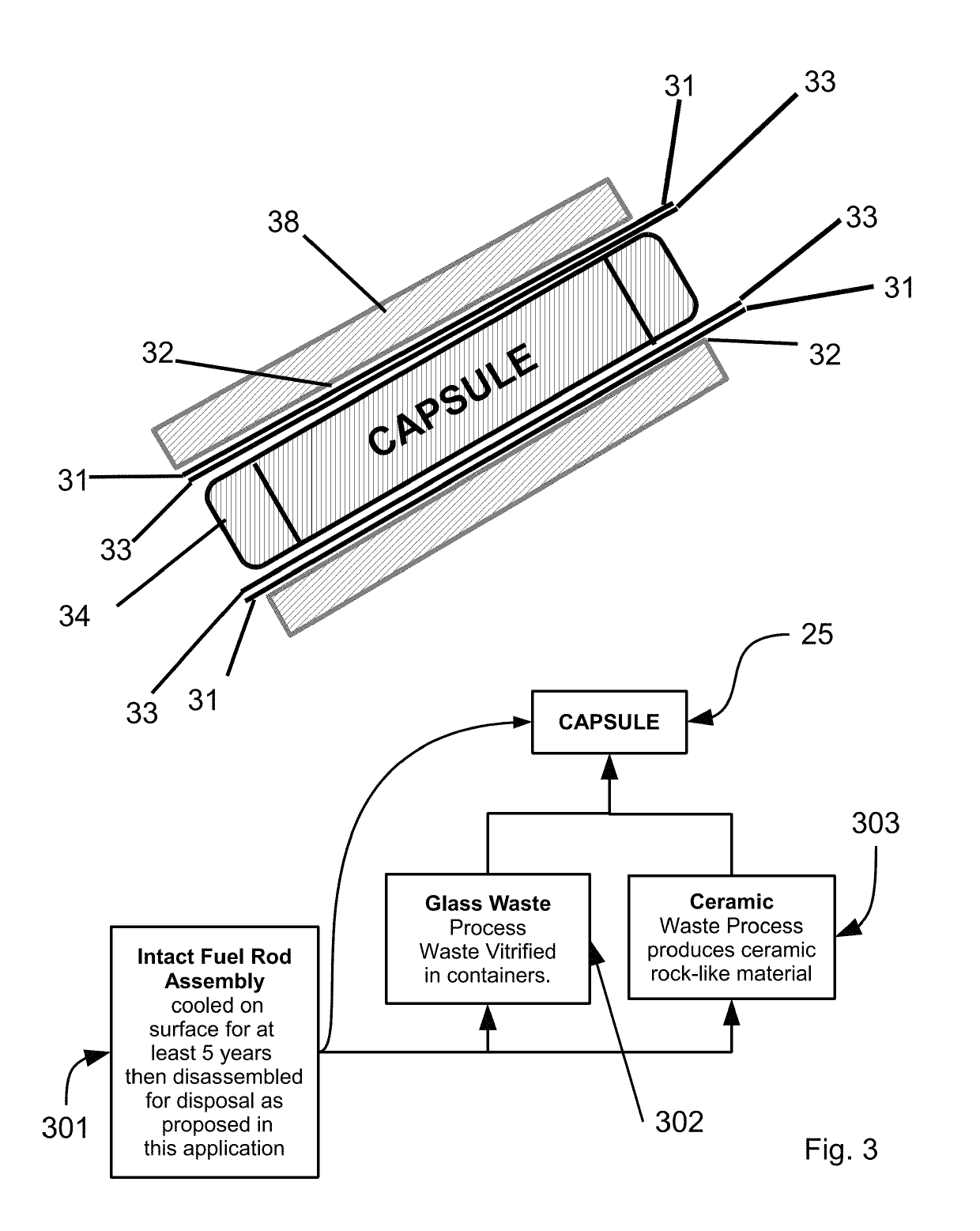

Capsule system for deep geologic disposal of nuclear waste

ActiveUS20190295735A1Increase capacitySafer and economical and long lasting disposalSolid waste disposalPortable shielded containersGeological structureCooling pond

Systems and methods for long-term disposal of high-level nuclear waste in deep geologic formations are described. Such systems and methods may include largely intact spent nuclear fuel rod assemblies that may be placed into waste-capsules (e.g., carrier tubes); which may then be placed into various well boreholes. Example embodiments may provide waste-capsules capable of containing and disposing of nuclear waste generated from spent nuclear fuel; including means for harvesting the nuclear waste from cooling pools and / or surface storage; and operationally processing the waste fuel assemblies for inclusion in the waste-capsules with various engineered barriers; along with storage in relatively large substantially horizontal well boreholes; which may be drilled into closed deep geologic formations.

Owner:CRICHLOW HENRY

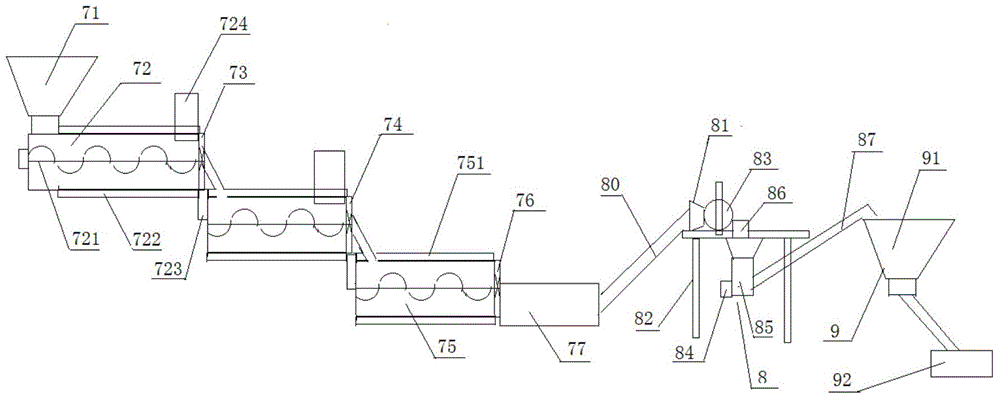

Waste paper-plastic composite paper-plastic separation and plastic-sheet granulation production system

InactiveCN104816400ALow removal efficiencyReduce labor intensitySievingScreeningMolded pulpChemical solution

The invention discloses a waste paper-plastic composite paper-plastic separation and plastic sheet granulation production system, and belongs to the technical field of waste carton processing. The waste paper-plastic composite paper-plastic separation and plastic-sheet granulation production system comprises a paper-plastic separation device, an extrusion molding device and a granulation device, and further comprises a pulp processing unit and a smoke processing unit, wherein the paper-plastic separation device, the extrusion molding device and the granulation device are sequentially connected; the pulp processing unit is connected with the paper-plastic separation device, and the smoke processing unit is connected with the extrusion molding device; the paper-plastic separation device comprises a feeding hole A, a material pushing mechanism, an extruder and a friction mechanism; the extrusion molding device comprises a feed hopper, an extrusion molding mechanism, a filtering mechanism and a cooling pool; the granulation device comprises a granulating mechanism and a packaging mechanism; the pulp processing unit comprises a pulp impurity removing mechanism and a pulp extruding mechanism; the smoke processing unit comprises a chemical solution processing tank, a spray tower and an adsorption tank, and the chemical solution processing tank, the spray tower and the adsorption tank are sequentially communicated. The waste paper-plastic composite paper-plastic separation and plastic-sheet granulation production system performs paper-plastic separation on waste cartons and comprehensive processing on separated crushed plastic sheets and pulp, and is suitable for paper-plastic separation of domestic dually-classified waste paper-plastic composites and comprehensive utilization of separated waste-paper-plastic composites.

Owner:马鞍山华盛环保科技有限公司

Deep geologic disposal of nuclear waste

ActiveUS10427191B2Increase volumeQuantity minimizationSolid waste disposalPortable shielded containersTectonicsCooling pond

Systems and methods for long term disposal of high level nuclear waste in deep geologic formations are described. Such systems and method may include largely intact spent nuclear fuel rods in a disassembled form that may be placed into waste-capsules (e.g., carrier tubes); which may then be placed into various well boreholes. Example embodiments may provide waste-capsules capable of containing and disposing of waste generated from spent nuclear fuel, including means for harvesting the nuclear waste from cooling pools and operationally processing the waste fuel assemblies for inclusion in the waste-capsules with various engineered barriers; along with storage in horizontal well boreholes drilled into closed deep geologic formations.

Owner:CRICHLOW HENRY

Pipeline type running water culture pond

The invention belongs to the technical field of aquaculture and particularly relates to a pipeline type running water culture pond. The pipeline type running water culture pond comprises a culture pond, cleaning ponds, a total culture zone, a hollow cavity, a high-position filtering pond, and a dump pump. The culture pond comprises a square culture pond body, a first wellhole and a second wellhole, a plurality of flexible culture tubes which are circuitously arranged between the first wellhole and the second wellhole, and blocking nets which are arranged at water inlet ends and water outlet ends of the flexible culture tubes, wherein the first wellhole and the second wellhole are formed in two sides inside the culture pond body, and a water inlet end of the flexible culture tube at the head position and a water outlet end of the flexible culture tube at the tail position are respectively connected with a first outlet and a second outlet in a sealed mode. The cleaning ponds are arranged at connection positions of heads and tails of adjacent flexible culture tubes. The first wellhole, the plurality of flexible culture tubes, the plurality of cleaning ponds, and the second wellhole are connected to form the total culture zone. The hollow cavity for containing water is formed between the outer wall of the total culture zone and the culture pond body. The high-position filtering pond is communicated with the first wellhole. The dump pump is arranged between the second wellhole and the high-position filtering pond. With the pipeline type running water culture pond, the problems that still water culture is low in density and yield, feces and remnant are inconvenient to clean, and a lot of water resources are wasted are solved.

Owner:WEIFANG XINLIMENG AQUATIC TECHN

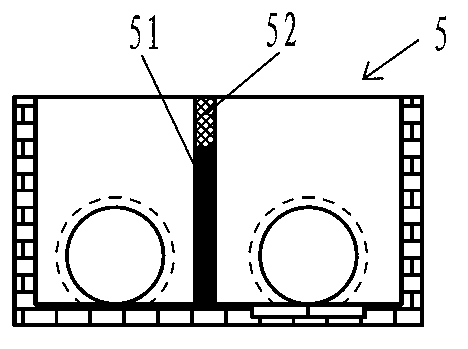

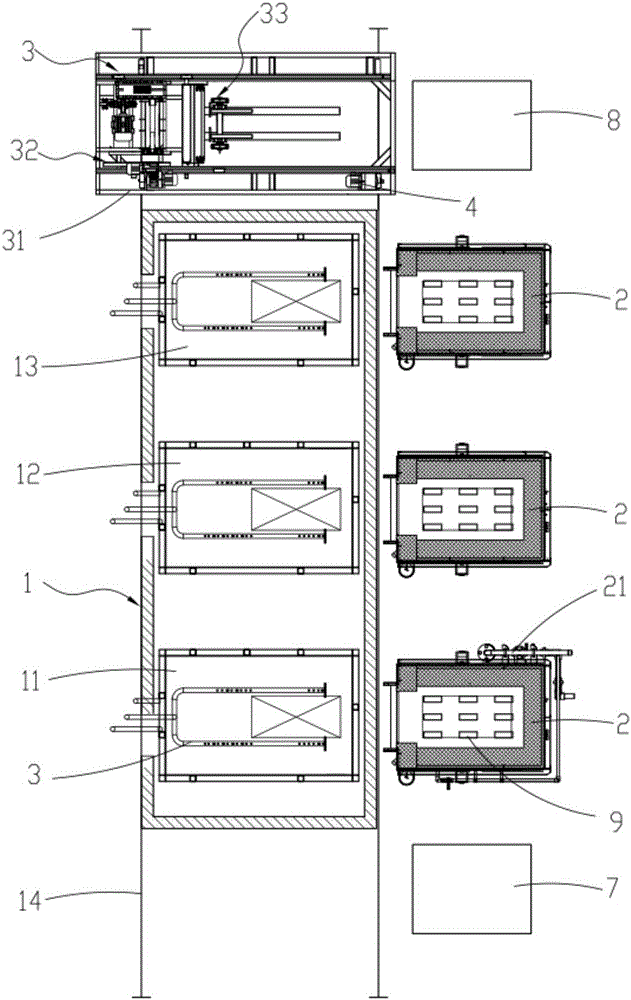

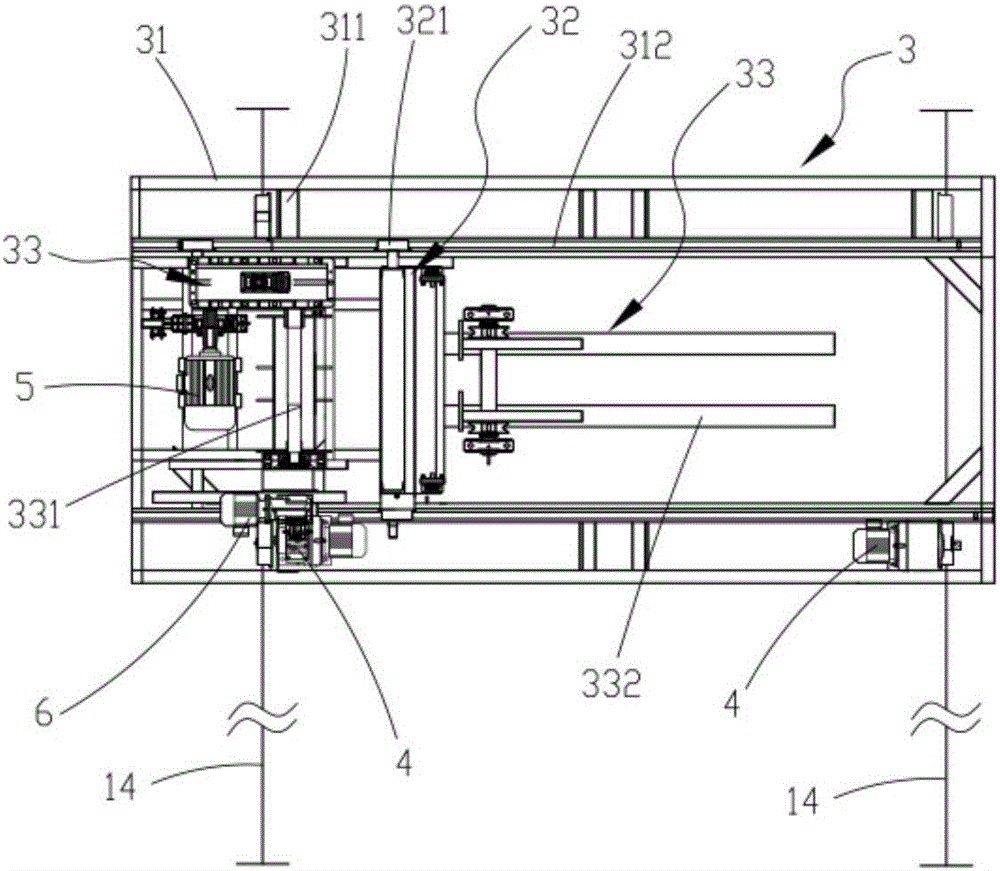

Hot workpiece fast transfer quenching system

InactiveCN105936959ASimple structureGuaranteed uptimeFurnace typesHeat treatment furnacesThermal treatmentQuenching

The invention relates to a hot workpiece fast transfer quenching system which comprises a cooling tank and at least one thermal treatment furnace, wherein the cooling tank and the thermal treatment furnaces are arranged in a split type. Each thermal treatment furnace is provided with a furnace door which can be opened or closed. A material box containing hot workpieces is arranged in each thermal treatment furnace. The hot workpiece fast transfer quenching system is characterized in that a transfer device is arranged between the cooling tank and each thermal treatment furnace and used for transferring the material box in the corresponding thermal treatment furnace into the cooling tank; the whole cooling tank is rectangular, and a water sink, an oil sink and a rinse tank are arranged inside the cooling tank side by side at intervals; and each transfer device is mounted at the upper edge of the cooling tank and reciprocates in the longitudinal direction to take in the material box of the corresponding thermal treatment furnace. By means of the transfer devices, the multiple thermal treatment furnaces are matched with the same cooling tank, the transfer time of the hot workpieces between a thermal treatment process and a cooling process is reasonably utilized, continuous quenching treatment can be conducted on the different hot workpieces, the work efficiency is improved, and energy consumption is lowered.

Owner:浙江宇清热工科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com