Evaporation cooled lamp

A technology for cooling steam and lamps, which is applied to cooling/heating devices of lighting devices, lampshades, components of lighting devices, etc., and can solve problems such as LED cooling and light output life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This invention relates to LED light fixtures (or other types of light fixtures) that use water or other coolant to evaporate inside a glass bulb to remove heat without the need for an external heat sink or connection to a heat sink.

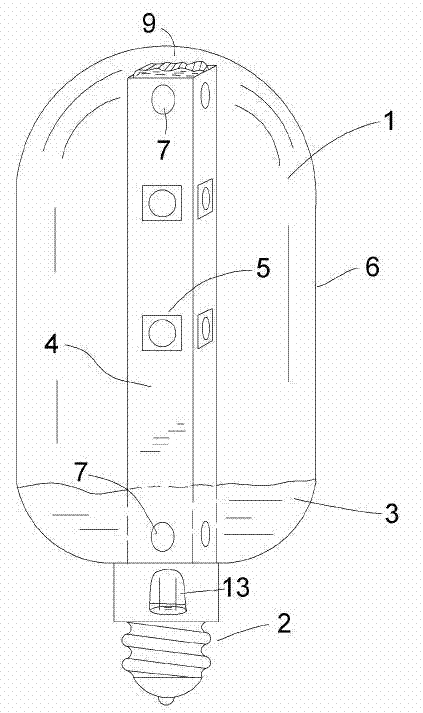

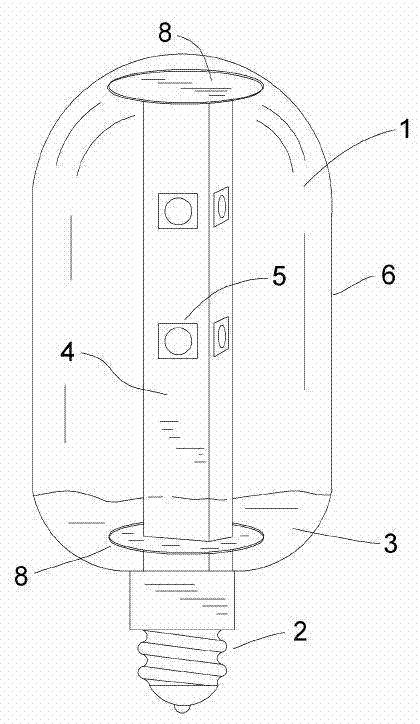

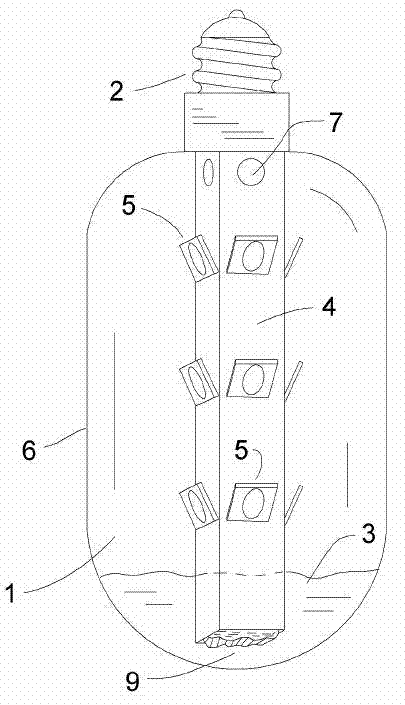

[0027] Usually the pressure inside the fixture is reduced to lower the boiling point of the coolant. figure 1 An example of such a luminaire is shown.

[0028] The glass bulb 6 contains a support structure 4 or light pole for fixing the LED 5 or other light sources. This embodiment of the invention can be as figure 1 Use vertically or upside down as shown. The interior of bulb 1 can be evacuated to a pressure much lower than atmospheric pressure. The coolant collects into a cooling pool 3 at the bottom of the housing. By means of capillary action the wick 9 can guide the coolant upwards through the fixed LEDs. The small hole 7 at the bottom and / or top of the light pole 4 allows the coolant to enter the wick 9 at the position shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com