Patents

Literature

48results about How to "Low removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

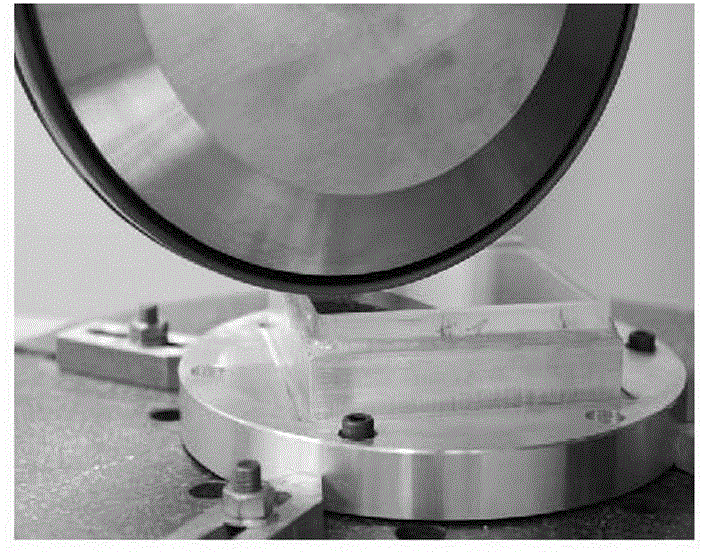

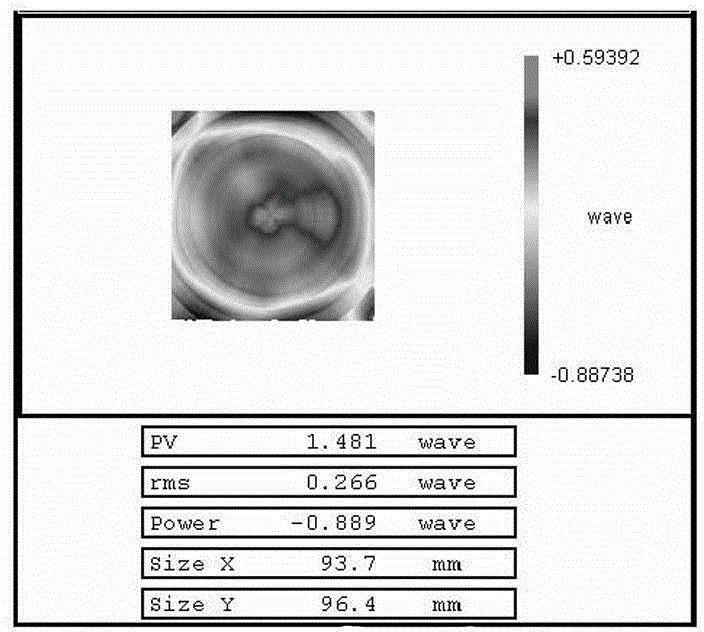

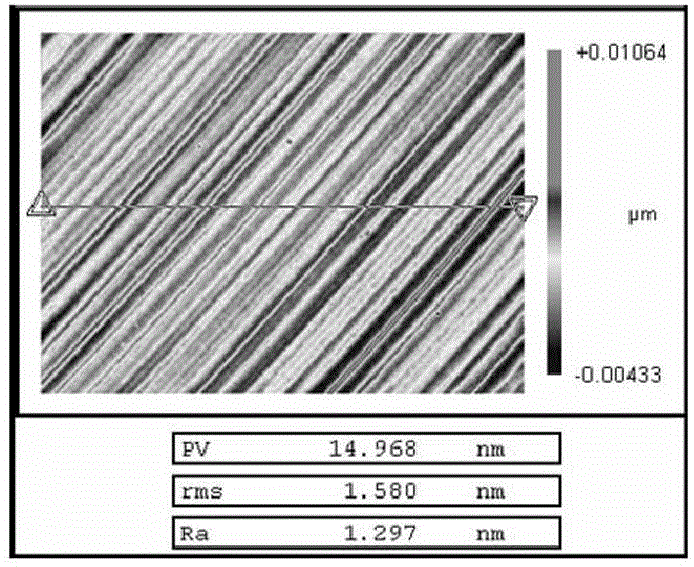

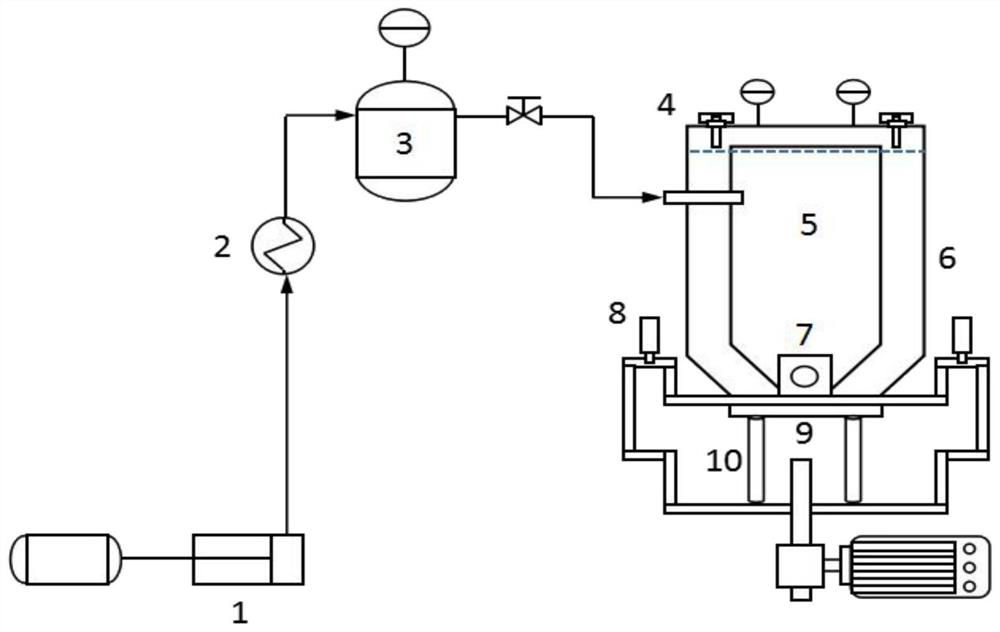

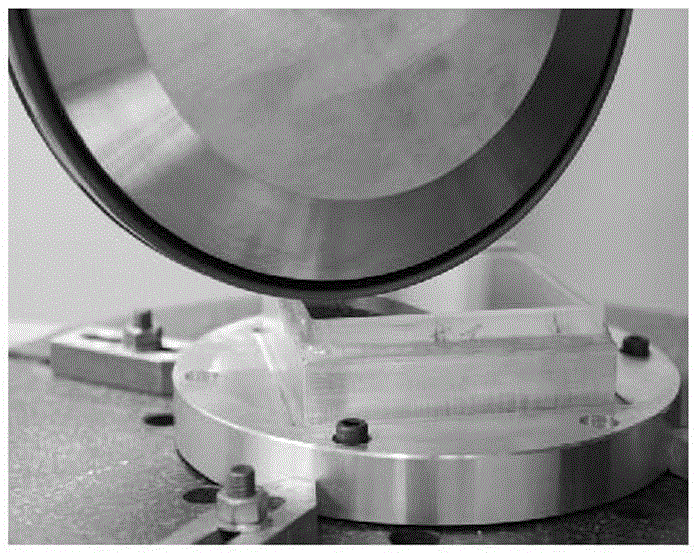

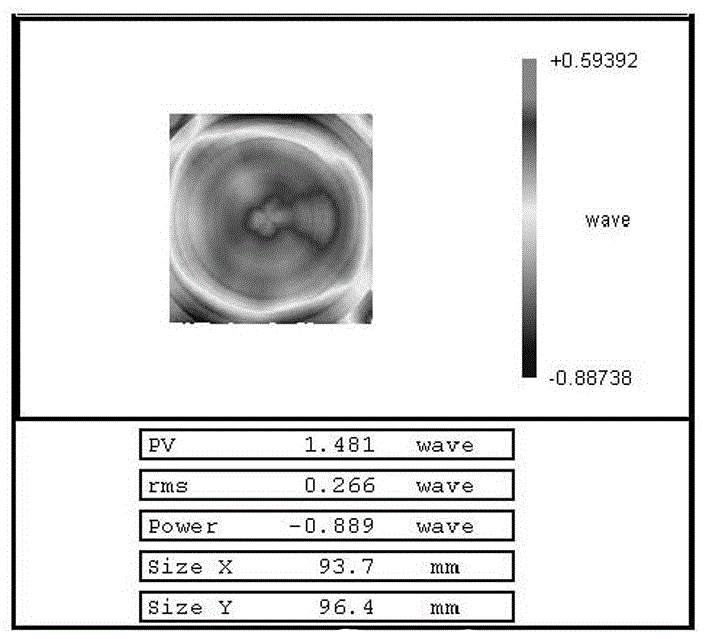

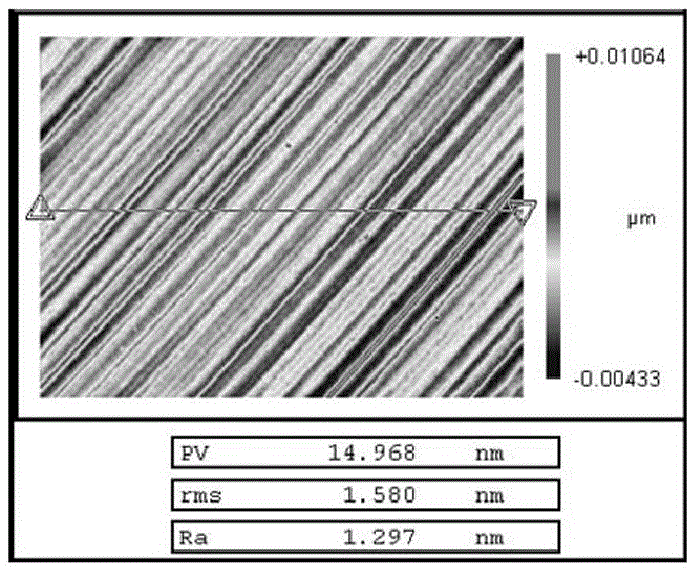

Magneto-rheological finishing method of easy-deliquescence crystals

ActiveCN104084849AImprove rheologyLow magnetic field viscosityPolishing compositions with abrasivesLow frequency bandEngineering

The invention discloses a magneto-rheological finishing method of easy-deliquescence crystals. The method includes the steps of firstly, preparing non-aqueous magneto-rheological finishing solution; secondly, adding the non-aqueous magneto-rheological finishing solution into a magneto-rheological machine tool circulating system for magneto-rheological finishing twice; thirdly, then using aromatic hydrocarbon to clean the easy-deliquescence crystals fast so as to complete the finishing. The method is simple in process flow and high in operability, and high-precision and ultra-smooth easy-deliquescence crystals which can satisfy the high, medium and low frequency band requirements of a strong-light optical system.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing HCN hydrolysis catalyst

InactiveCN104190429AReduce manufacturing costHarm reductionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrolysis

The invention discloses a method for preparing an HCN hydrolysis catalyst, belonging to the field of control of gaseous pollutants. The catalyst is prepared by adopting a sol-gel method, elements such as Fe, Cu, Ni or Mn serving as hydrolytic active ingredients are loaded onto TiO2, and rare earth metals such as La and Ce are added, so that the hydrothermal stability of the catalyst is improved. The catalyst can be hydrolyzed to remove the HCN under the low-temperature and oxygen-free conditions and is finally converted into NH3 and CO, the toxicity of the HCN is greatly reduced, and the preparation method of the catalyst is simple in process and low in cost.

Owner:KUNMING UNIV OF SCI & TECH

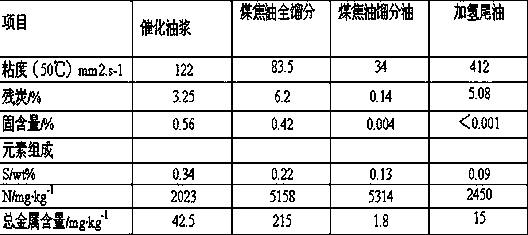

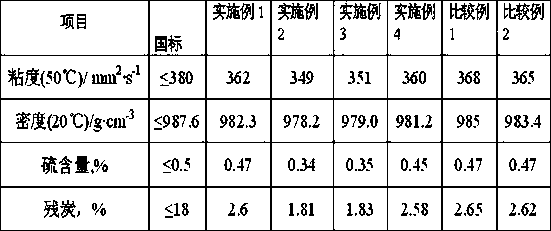

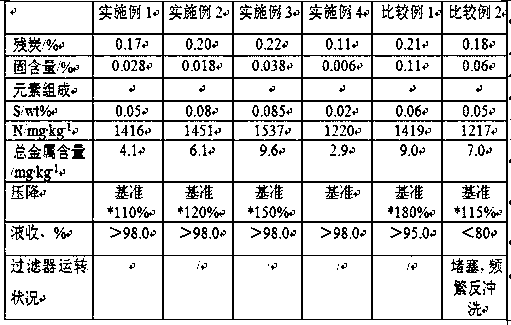

Production method of low-sulfur marine fuel oil

PendingCN111088068ARealize purificationImprove use valueTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses a production method of a low-sulfur marine fuel oil. The production method comprises the following steps: mixing catalytic slurry oil with a first additive, carrying out settling separation after the mixing treatment, obtaining a first material and residues after the separation; introducing the first material into a hydro-processing unit, carrying out a hydrogenation reaction under the action of a hydro-processing catalyst and hydrogen, introducing a liquid-phase effluent obtained after the reaction into a clarification unit, subjecting clarified oil to solid-liquid separation to obtain purified oil slurry, and mixing the purified oil slurry with an inferior raw material (hydrogenation tail oil) to obtain the low-sulfur marine fuel oil. According to the method, thesolid content and the sulfur content of the catalytic slurry oil can be reduced, high-quality purified slurry oil is produced, and the high-quality purified slurry oil is blended with residual oil toproduce the insufficient low-sulfur marine fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

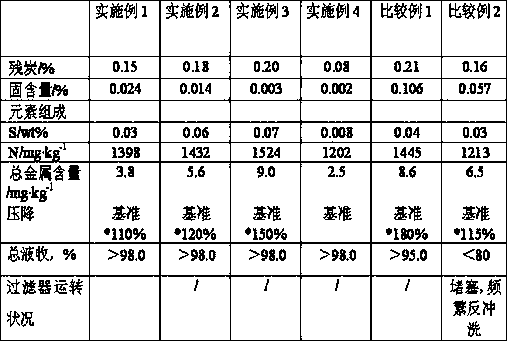

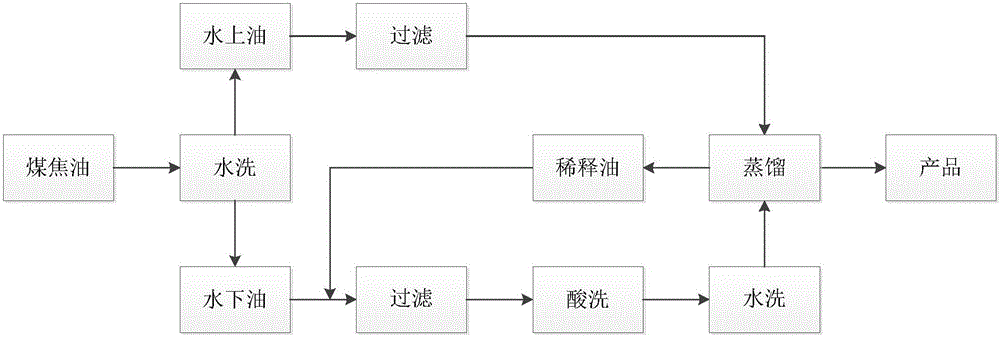

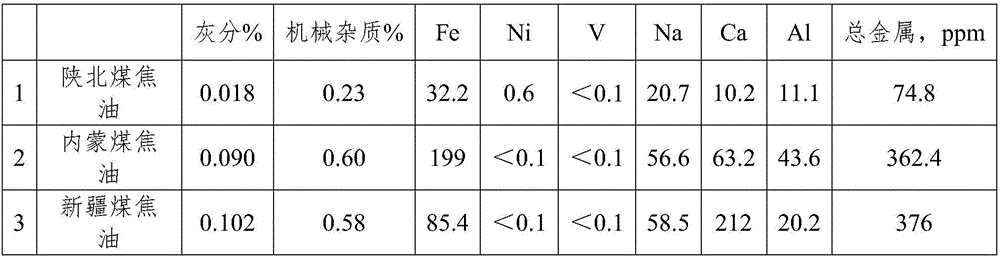

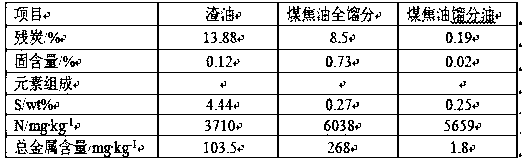

Coal tar pretreatment method

InactiveCN106398735AQuality assuranceHigh selectivityTar working-up by distillationTar working-up by chemical refiningPretreatment methodBoiling point

The invention discloses a coal tar pretreatment method. The method comprises the following steps: 1, fully mixing a coal tar raw material with water, salt and a de-emulsifier A, and using an oil-water separation device to separate the coal tar raw material at 50-200 DEG C under 0.1-5.0 Mpa into oil above water, water and oil under water, wherein the addition amount of water is 5-50% of the weight of the coal tar raw material, the addition amount of the de-emulsifier A is 0.003-0.05% of the weight of the coal tar raw material, and the addition amount of the salt makes the density of the salt in water reach 1.001-1.015 g / cm<3>; 2, treating the oil above water obtained in step 1 to obtain refined coal tar I; 3, treating the oil under water obtained in the step 1 to obtain standing coal tar II; and 4, mixing the refined coal tar I obtained in step 2 with the standing coal tar II obtained in step 3 to obtain refined coal tar, adding the refined coal tar to a distillation system, separating to obtain a fraction with the boiling point being smaller than 150 DEG C and a fraction with the boiling point being greater than 150 DEG C, and mixing a part of the fraction with the boiling point being smaller than 150 DEG C with the fraction with the boiling point being greater than 150 DEG C to obtain pretreated coal tar.

Owner:特思锐能源科技(北京)有限责任公司

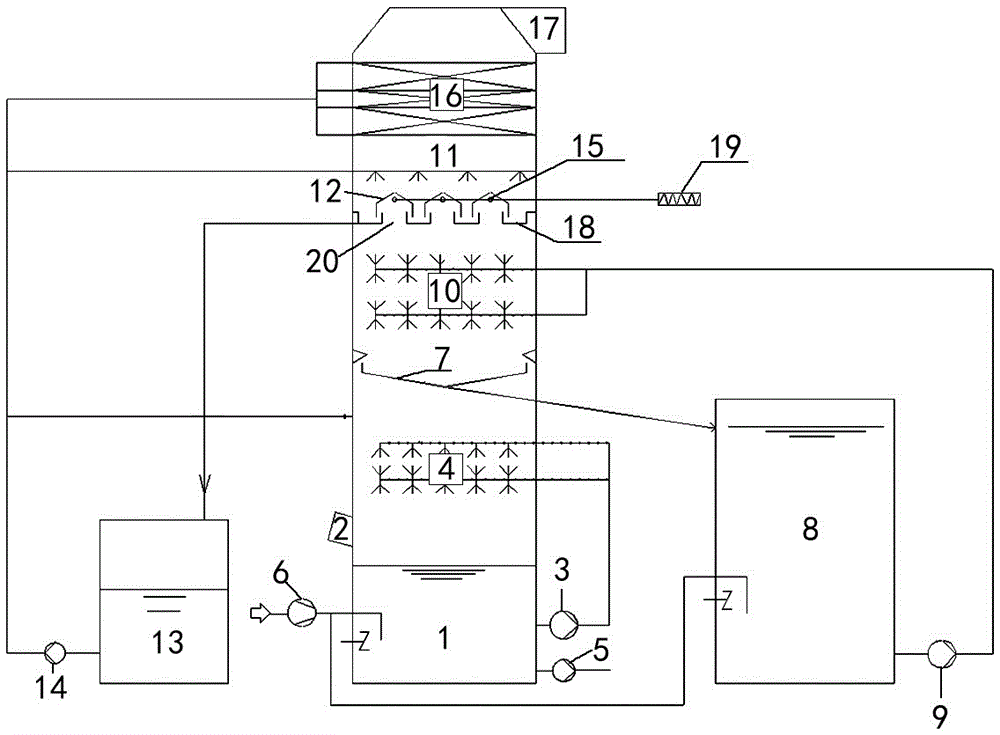

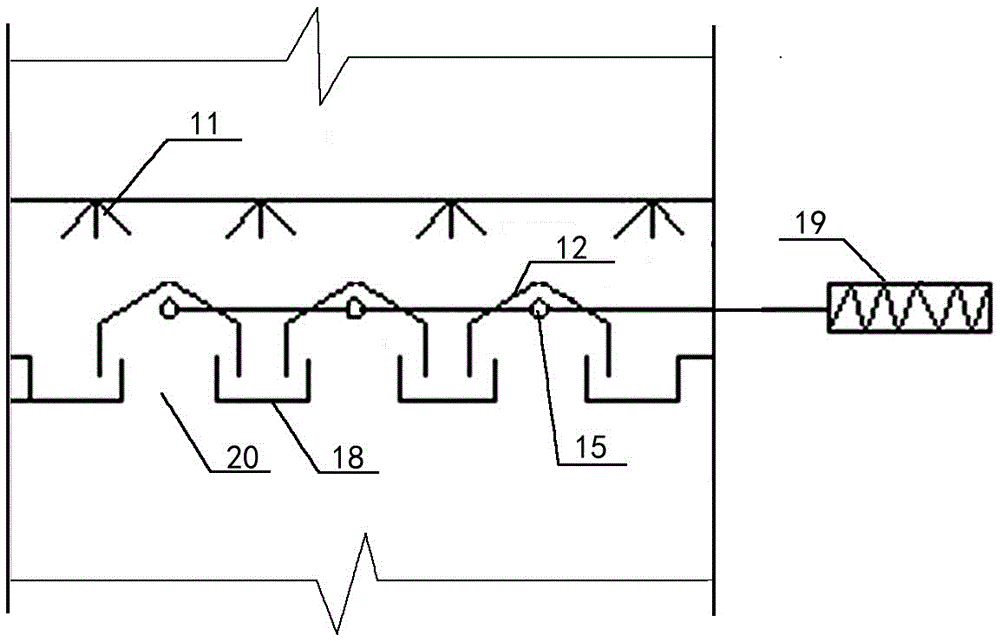

Integral device and method for efficient removal of flue gas pollutants through multistage washing wet process

PendingCN106215679AReduce concentrationImprove removal efficiencyGas treatmentUsing liquid separation agentSlurryCoal

The invention discloses an integral device and method for efficient removal of flue gas pollutants through multistage washing wet process. Slurry partitioning and multistage washing are conducted, primary washing of flue gas is conducted with low-pH slurry so that the content of SO2 in flue gas can be reduced, then secondary washing is conducted on the flue gas with high-pH slurry, and finally the flue gas enters a ternary ultrasonic showering layer and enters an ultrasonic agglomeration chamber through a gas ascending channel; under the action of an acoustic amplifier in an inverse-V-shaped gas ascending cap, frequent collision occurs between particles to cause agglomeration, particles with size increased enter a water collection disc under clear water spraying of an ultrasonic showering disc, and then SO3 and fine particles are removed and efficient desulfurization is achieved. By means of the calcium-based wet desulphurization technique, ultra-low emission is achieved through synergism of desulphurization and dust removal, applicability to coal property is high, SO2, SO3 and particles are effectively removed, SO2 removing rate reaches 99.5%, SO3 removing rate reaches 80%, and particle removing rate reaches 85%.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

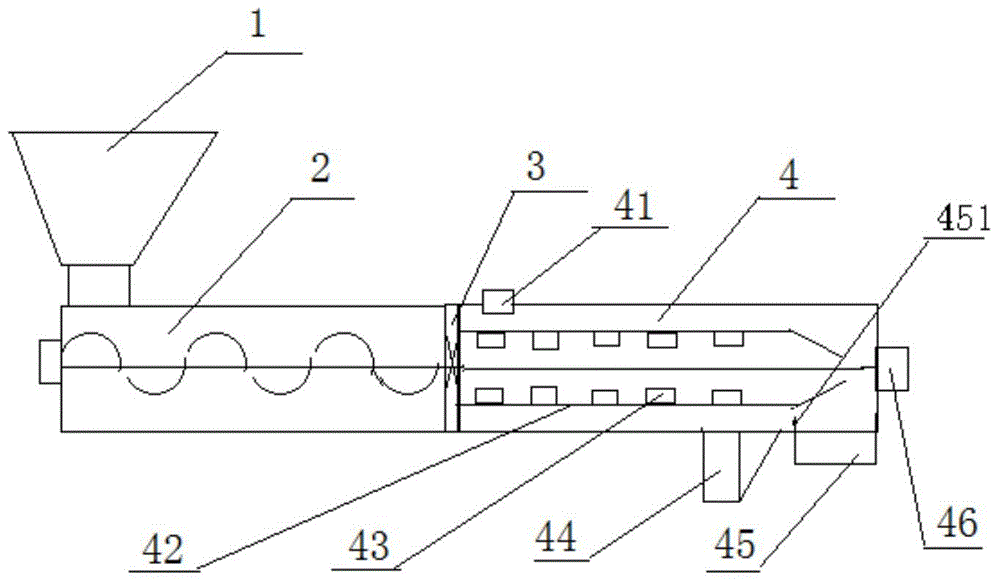

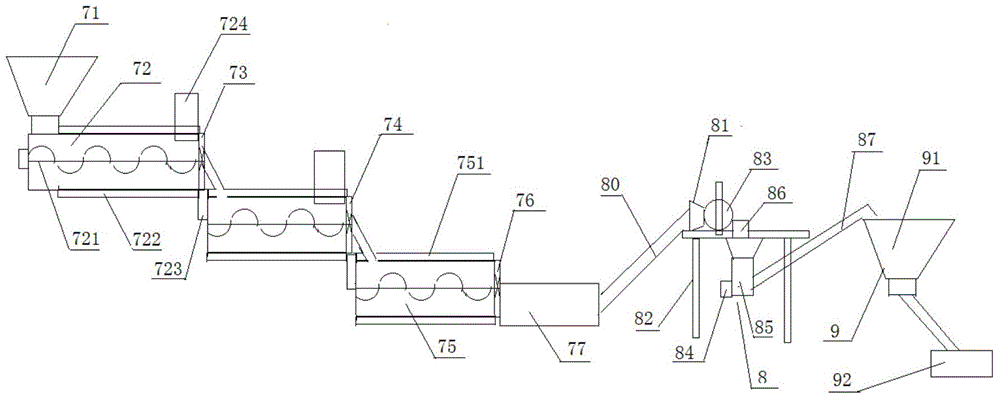

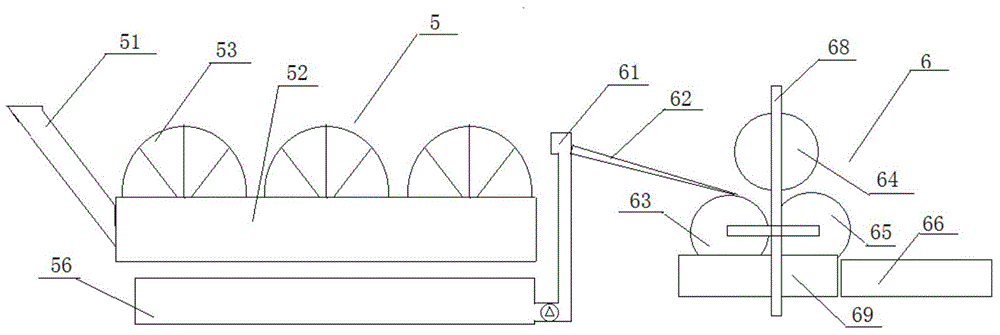

Waste paper-plastic composite paper-plastic separation and plastic-sheet granulation production system

InactiveCN104816400ALow removal efficiencyReduce labor intensitySievingScreeningMolded pulpChemical solution

The invention discloses a waste paper-plastic composite paper-plastic separation and plastic sheet granulation production system, and belongs to the technical field of waste carton processing. The waste paper-plastic composite paper-plastic separation and plastic-sheet granulation production system comprises a paper-plastic separation device, an extrusion molding device and a granulation device, and further comprises a pulp processing unit and a smoke processing unit, wherein the paper-plastic separation device, the extrusion molding device and the granulation device are sequentially connected; the pulp processing unit is connected with the paper-plastic separation device, and the smoke processing unit is connected with the extrusion molding device; the paper-plastic separation device comprises a feeding hole A, a material pushing mechanism, an extruder and a friction mechanism; the extrusion molding device comprises a feed hopper, an extrusion molding mechanism, a filtering mechanism and a cooling pool; the granulation device comprises a granulating mechanism and a packaging mechanism; the pulp processing unit comprises a pulp impurity removing mechanism and a pulp extruding mechanism; the smoke processing unit comprises a chemical solution processing tank, a spray tower and an adsorption tank, and the chemical solution processing tank, the spray tower and the adsorption tank are sequentially communicated. The waste paper-plastic composite paper-plastic separation and plastic-sheet granulation production system performs paper-plastic separation on waste cartons and comprehensive processing on separated crushed plastic sheets and pulp, and is suitable for paper-plastic separation of domestic dually-classified waste paper-plastic composites and comprehensive utilization of separated waste-paper-plastic composites.

Owner:马鞍山华盛环保科技有限公司

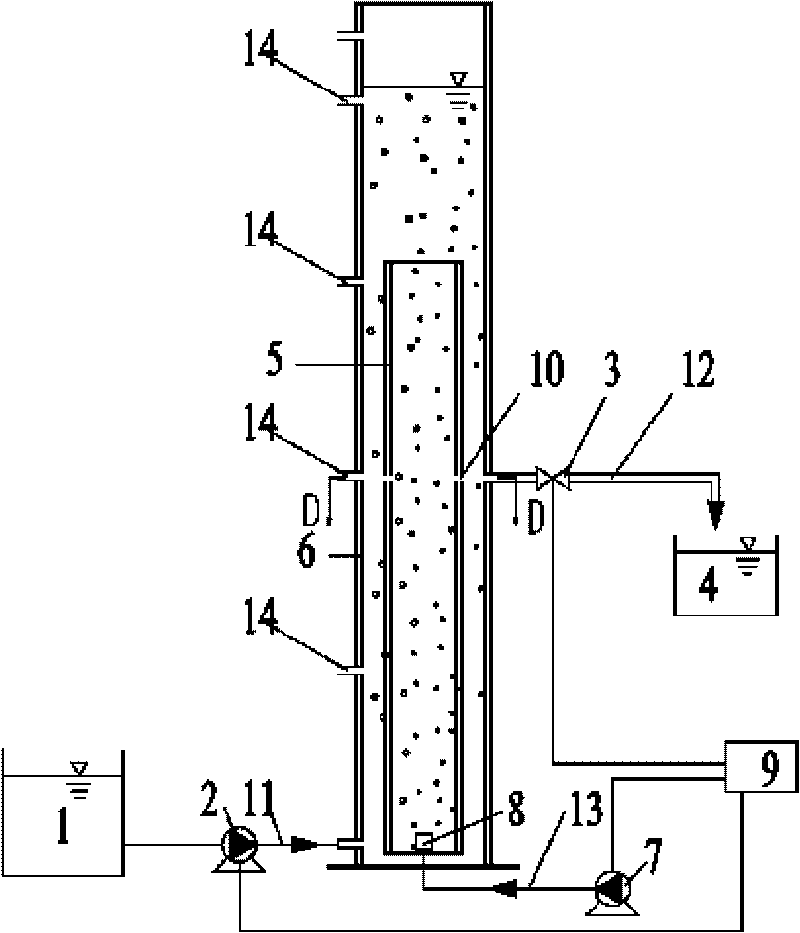

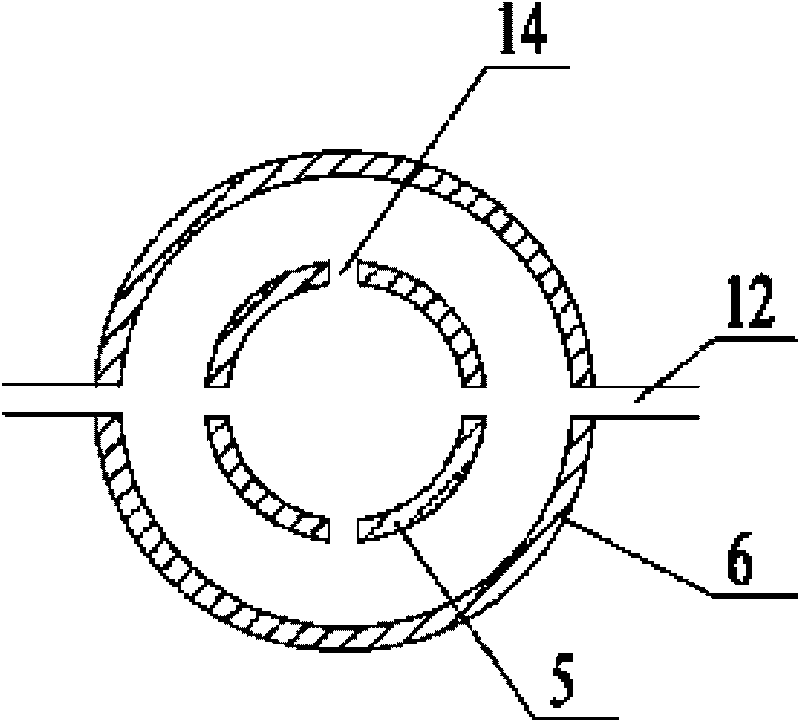

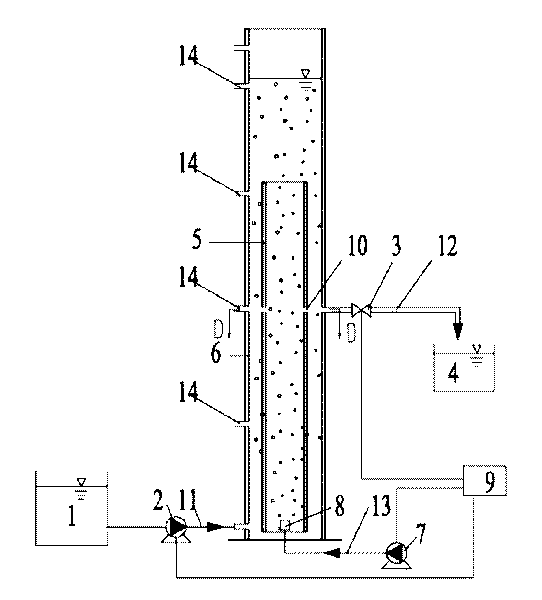

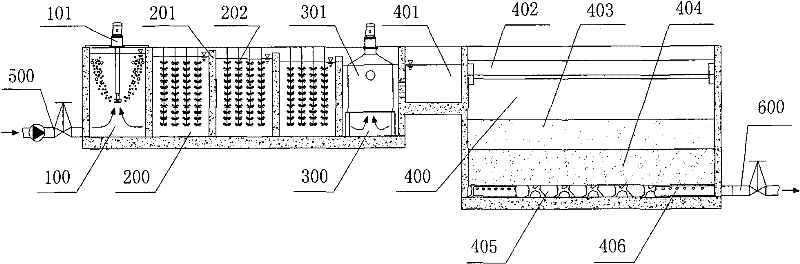

Aerobic granular sludge reactor for treating low-temperature sewage and water treatment method thereof

InactiveCN101698533AEasy to operateRun smoothlyTreatment with aerobic and anaerobic processesSustainable biological treatmentSewageStart up

The invention relates to an aerobic granular sludge reactor for treating sewage and a water treatment method thereof, in particular to an aerobic granular sludge reactor for treating sewage and a water treatment method thereof. The invention solves the problems that the aerobic granular sludge reactor has poor performance in start-up and stable operation, the aerobic sludge has poor properties and the sludge is prone to expansion at low temperature under the existing low-temperature conditions. The aerobic granular sludge reactor of the invention is characterized in that a riser thereof is co-axially sleeved with a downcomer thereof; an aerator is arranged at the bottom of the riser and communicated with an air compressor; a water outlet pipe is mounted at he height position which is 2 / 5-3 / 5 of a reactor body; a connecting hole is formed at the height position which is1 / 4-3 / 4 of the reactor body from the bottom thereof; and the ratios between the height and the inner diameter of the riser and the downcomer are both 9-15. The water treatment method of the invention mainly comprises the steps of inflowing, aerating, sludge / water separating, discharging and idling. The invention provides an effective method for controlling the discharge of nitrogen and phosphorus in low-temperature sewage, which is widely applicable to the synchronous removal of nitrogen and phosphorus from low-temperature sewage and has good environmental benefit.

Owner:HARBIN INST OF TECH

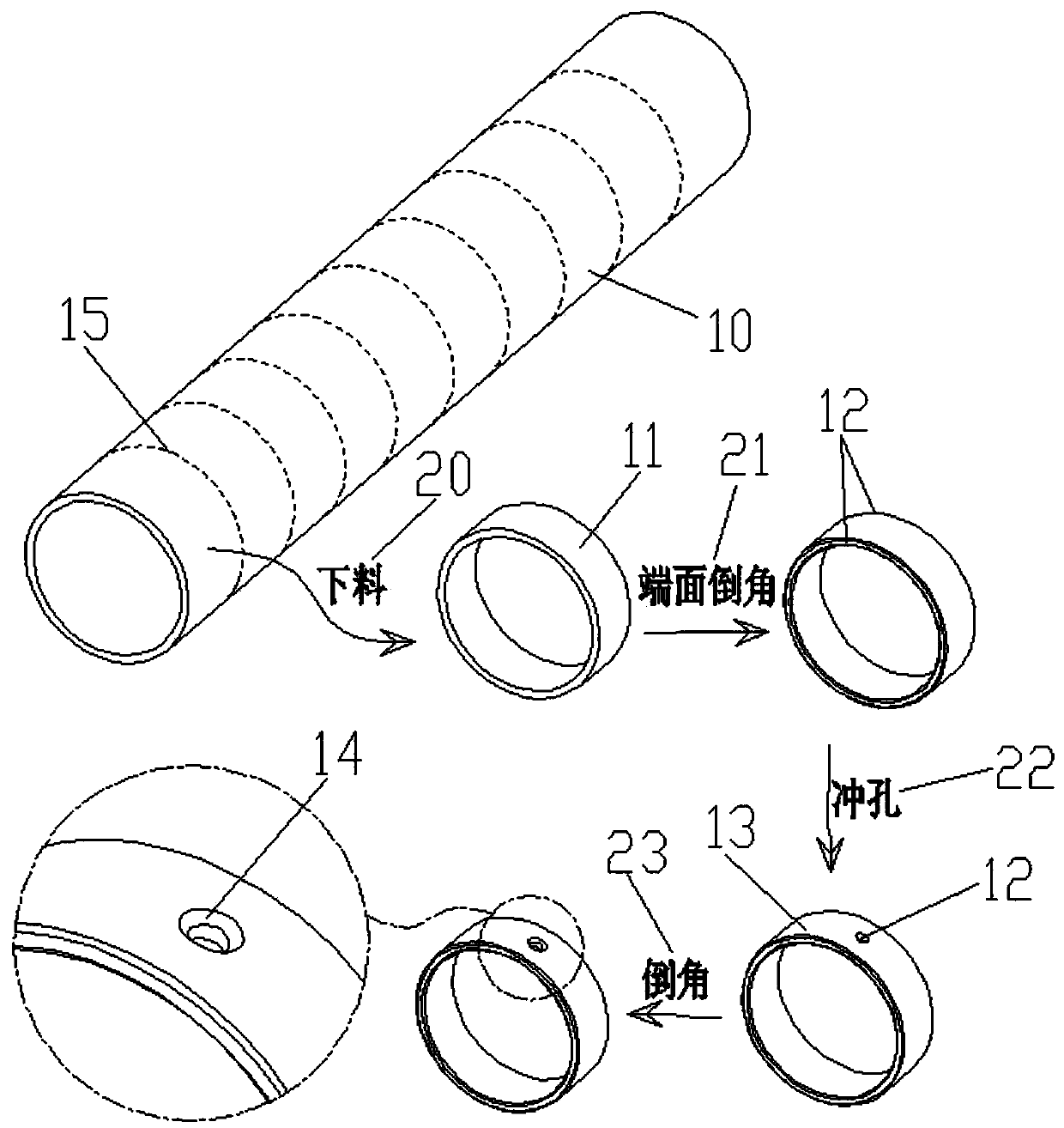

Sliding bearing machining process

The invention relates to a mechanical manufacturing process, and in particular relates to a process of manufacturing and material processing of sliding bearings. The invention discloses a sliding bearing machining process, comprising the following steps: blanking, end surface chamfering, end surface grinding, punching, chamfering of an oil filling hole, quenching and tempering, centerless grinding, squeezing, and surface grinding. Through the sliding bearing machining process, a sliding bearing is used for lowering frictional resistance of machine running, and is high in machining precision. On the premise of satisfying the machining precision of the sliding bearing, the efficiency and the product quality can be improved by the machining process.

Owner:余晓娜

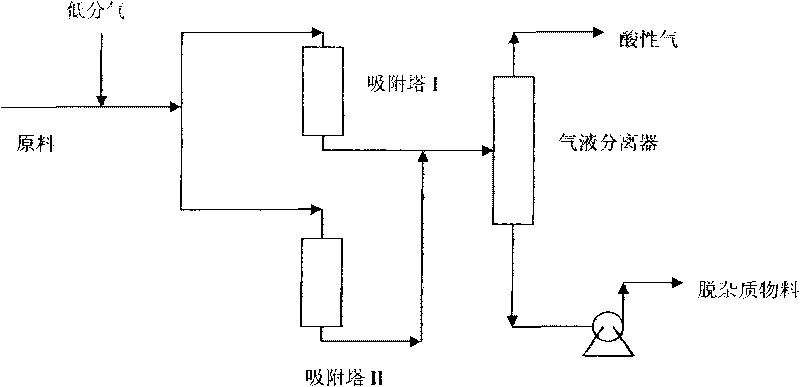

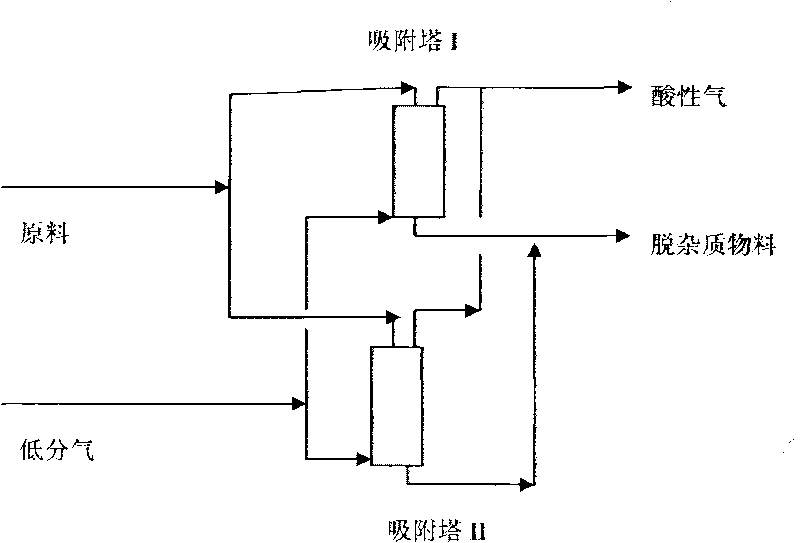

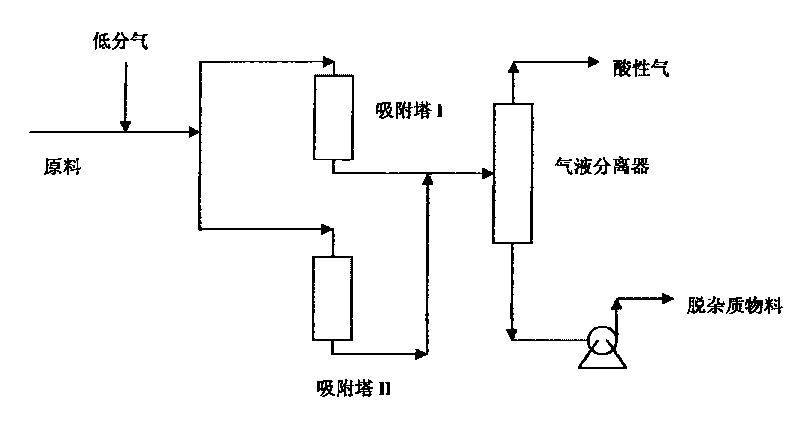

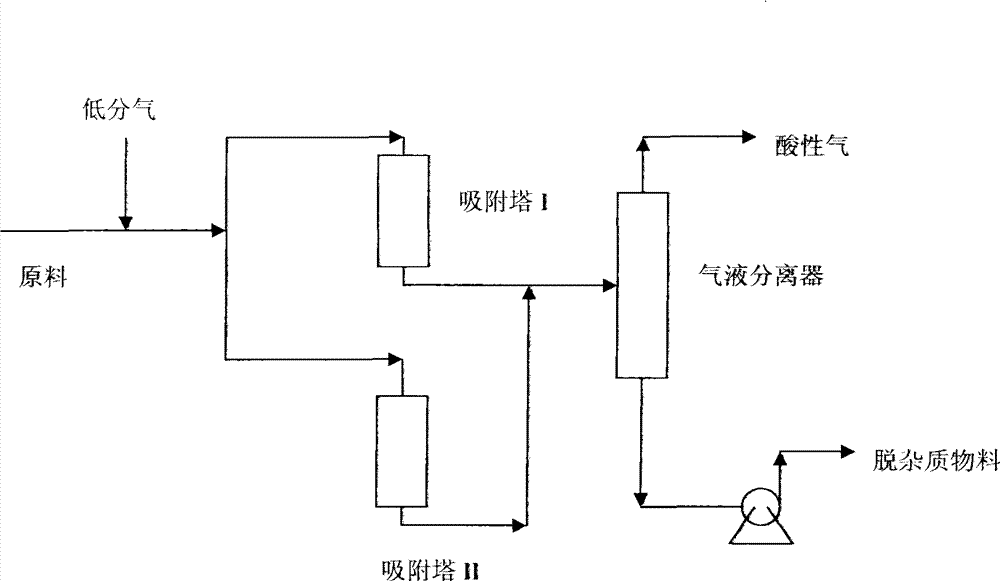

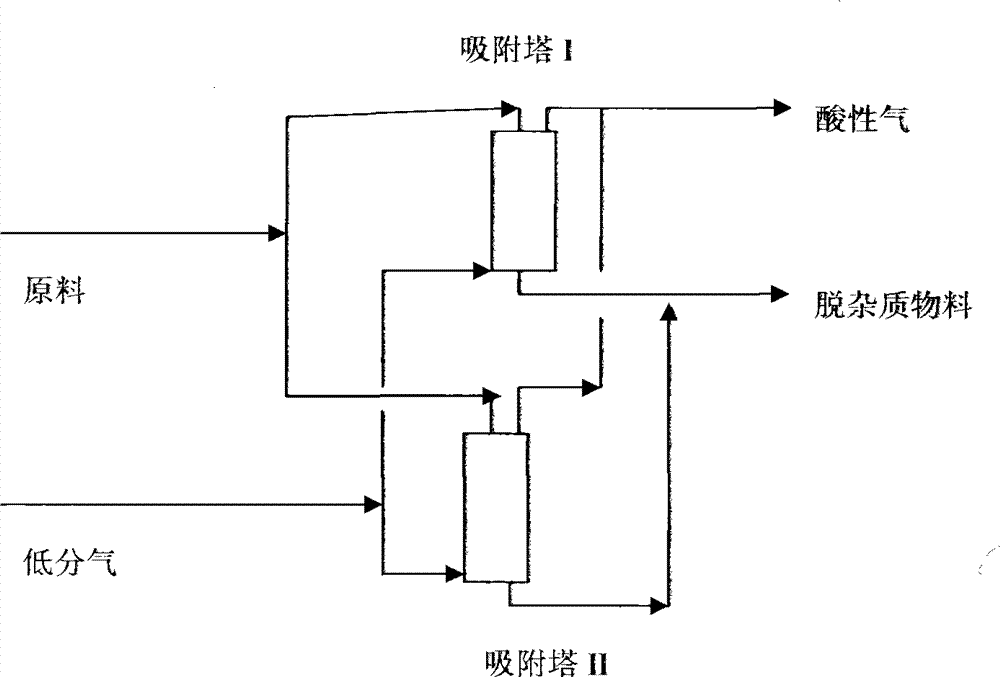

Method for purifying materials containing metal impurities

ActiveCN101724434ALow removal rateRemoval is suitable forHydrocarbon oils refiningFilter materialFixed bed

The invention relates to a method for purifying materials containing metal impurities, in particular to a method for removing at least one metal impurity of iron, sodium and calcium from hydrocarbon materials, which comprises that the materials containing metal impurities are mixed with flash gas (low grade gas) in a low-pressure separator of a hydrogenation unit to obtain the materials with a higher impurity removal rate by a fixed bed layer of filtering materials, absorbent or catalyst. Compared with the prior art, the method in the invention has mild operation conditions and high impurity removal rate, and can be used in processing various materials containing metal impurities.

Owner:CHINA PETROLEUM & CHEM CORP +1

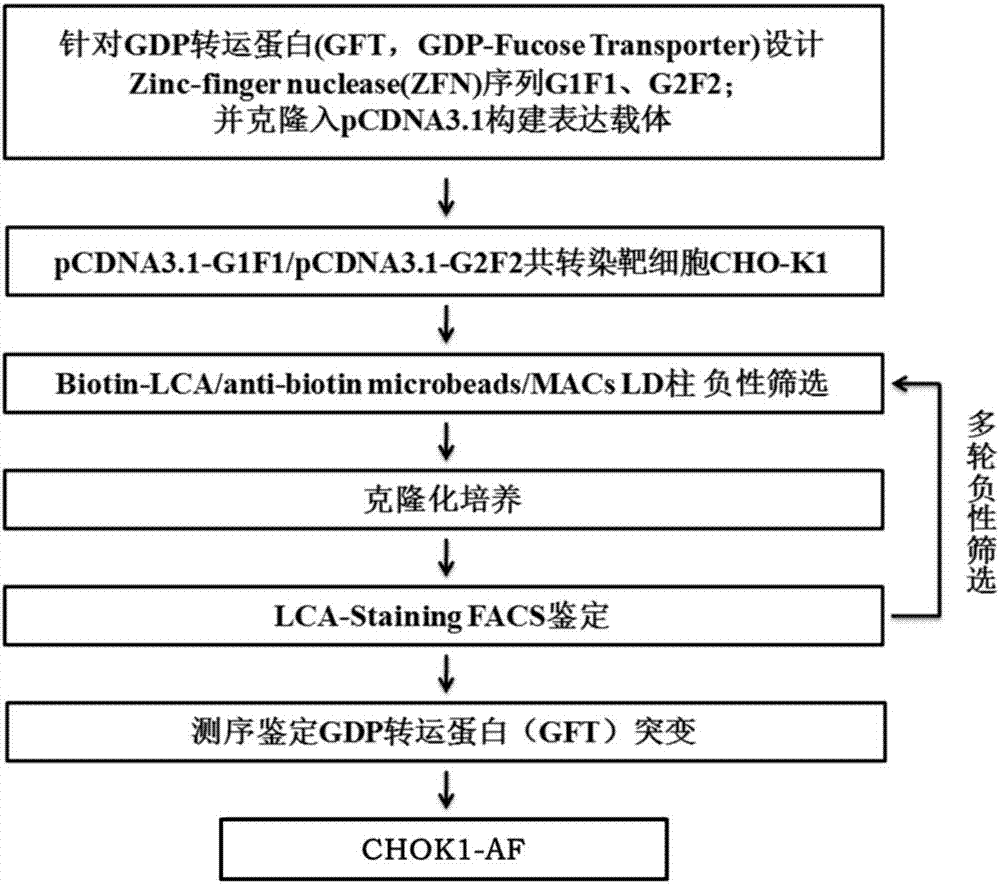

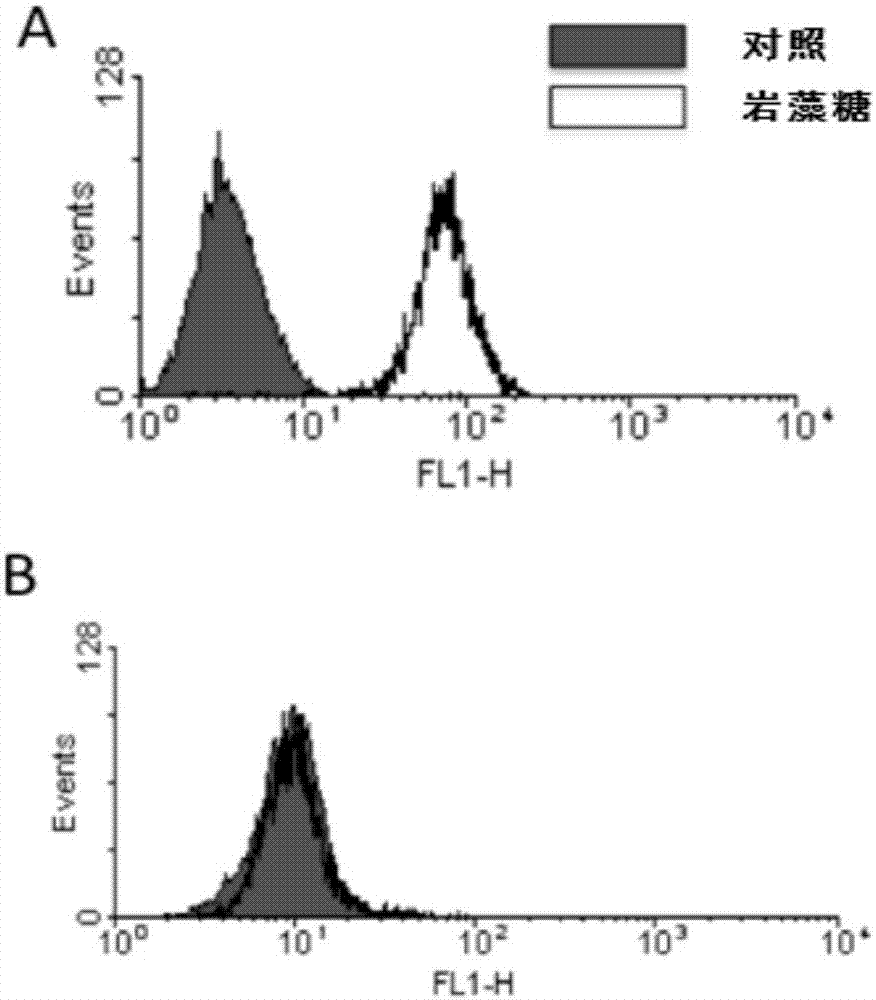

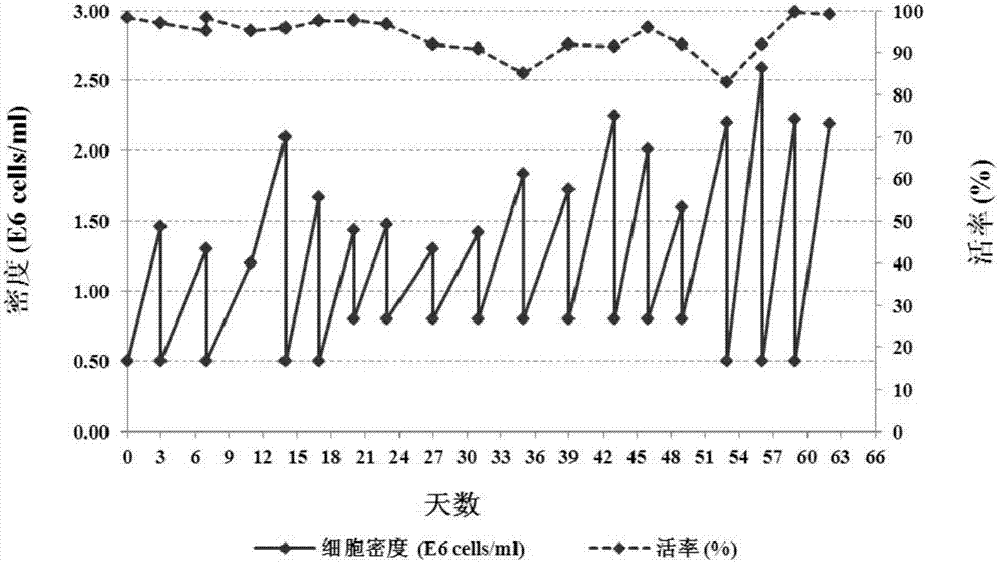

Antibody for resisting human epidermal growth factor receptor 2 (HER2), as well as medical composition and use of antibody

InactiveCN107446045AGood curative effectGood tumor suppressor effectCompounds screening/testingImmunoglobulins against cell receptors/antigens/surface-determinantsHigh cellAntigen

The invention belongs to the field of tumor treatment and the field of molecular immunology, and relates to an antibody for resisting human epidermal growth factor receptor 2 (HER2), as well as a medical composition and use of antibody, in particular to the antibody for resisting Her2 or an antigen binding fragment of the antibody for resisting Her2. The antibody for resisting Her2 comprises a first heavy chain and a second heavy chain, wherein according to the first heavy chain, a variable region of heavy chain (VH) of the first heavy chain comprises a complementarity-determining region (CDR) of which the amino acid sequence is SEQ ID No: 1-3, and the amino acid sequence of the CH of the first heavy chain is as shown in SEQ ID No: 7; according to the second heavy chain, a variable region of heavy chain (VH) of the second heavy chain comprises a complementarity-determining region (CDR) of which the amino acid sequence is SEQ ID No: 4-6, and the amino acid sequence of the CH of the first heavy chain is as shown in SEQ ID No: 8. Compared with the combination of two antibodies of trastuzumab and pertuzumab, the antibody disclosed by the invention has higher cell direct killing activity and higher antibody dependent cellmediated cytotoxicity (ADCC) activity; the complement-dependentcytotoxicity (CDC) activity of the two antibodies of trastuzumab and pertuzumab is equivalent to that of the antibody disclosed by the invention; the antibody disclosed by the invention adopts a structure of a normal antibody; and fucose is also knocked out, so that the ADCC activity is improved.

Owner:BEIJING MABWORKS BIOTECH

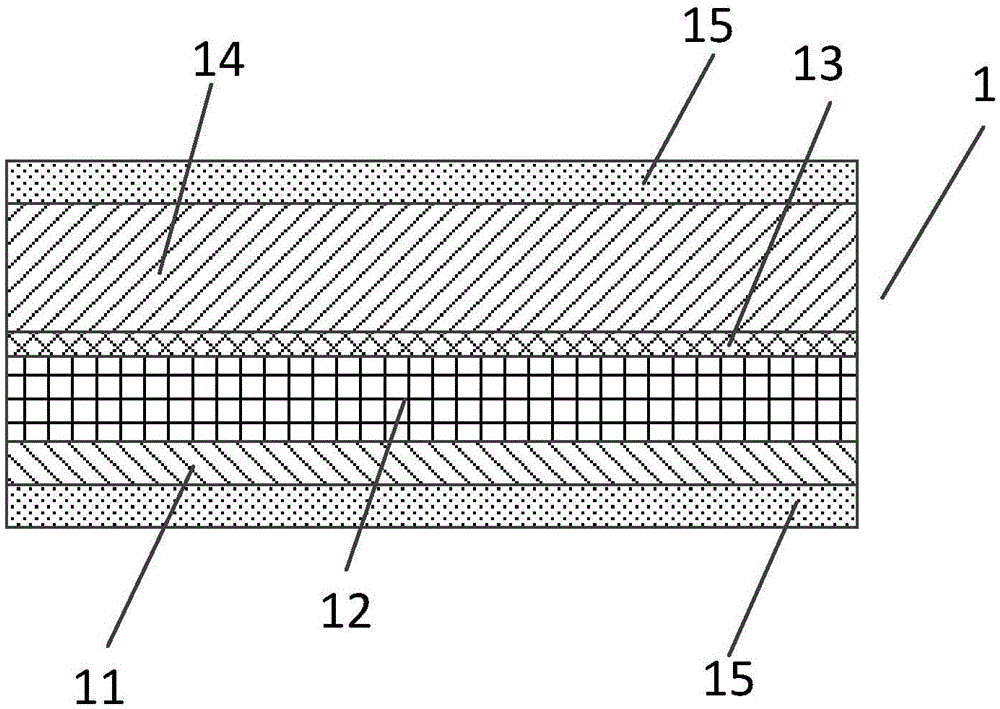

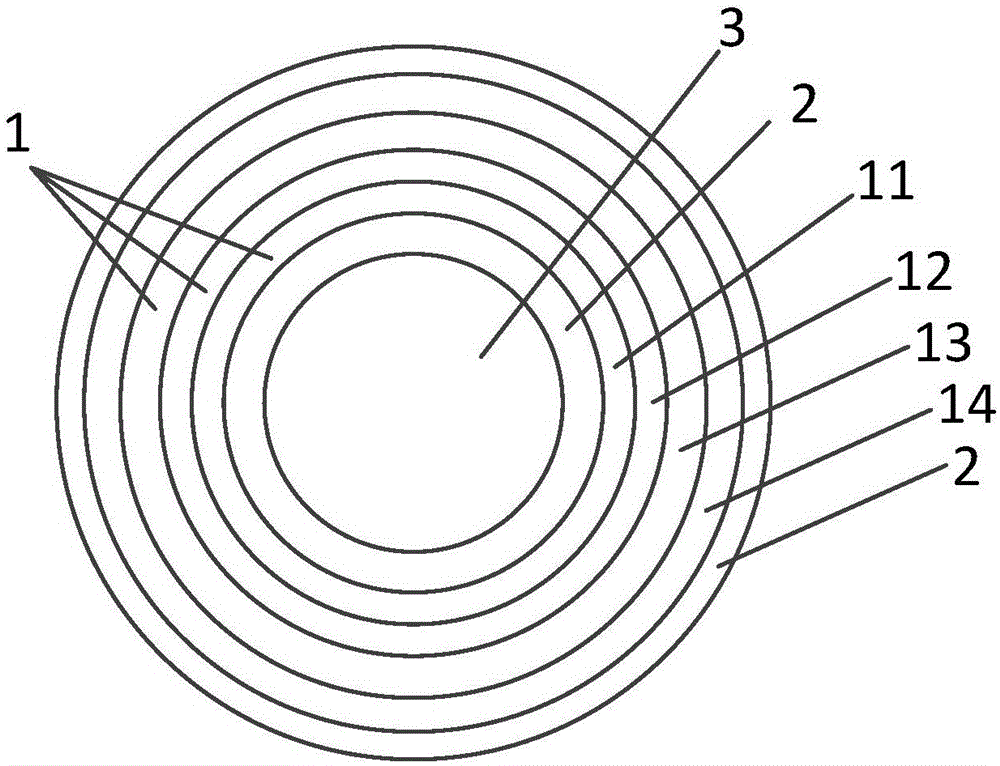

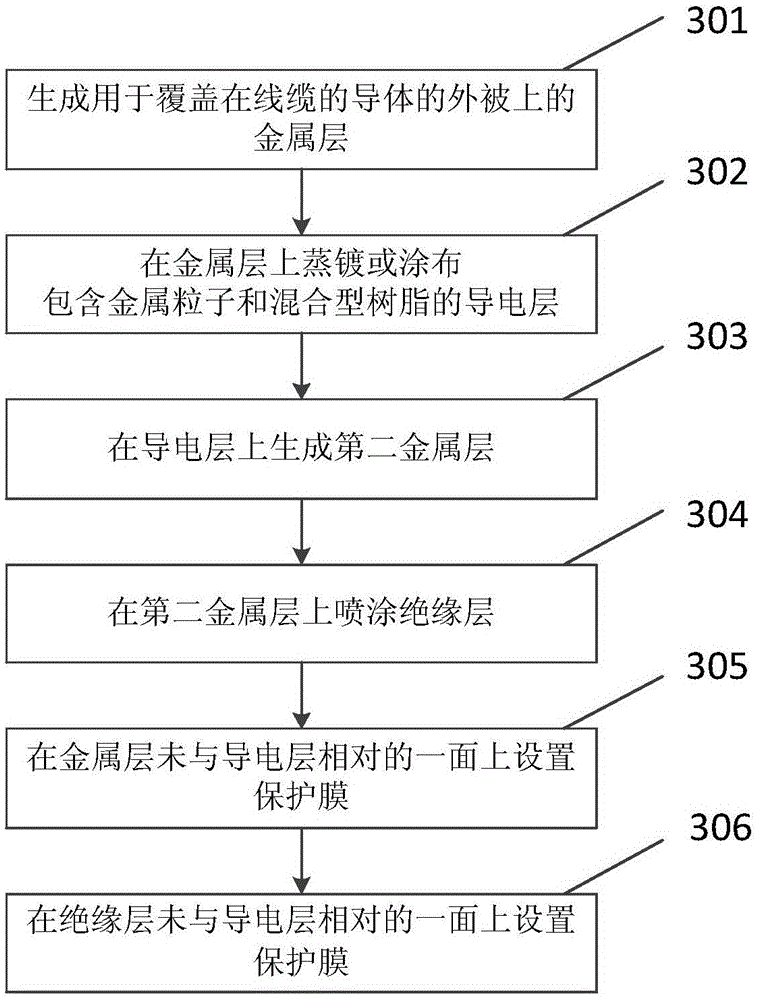

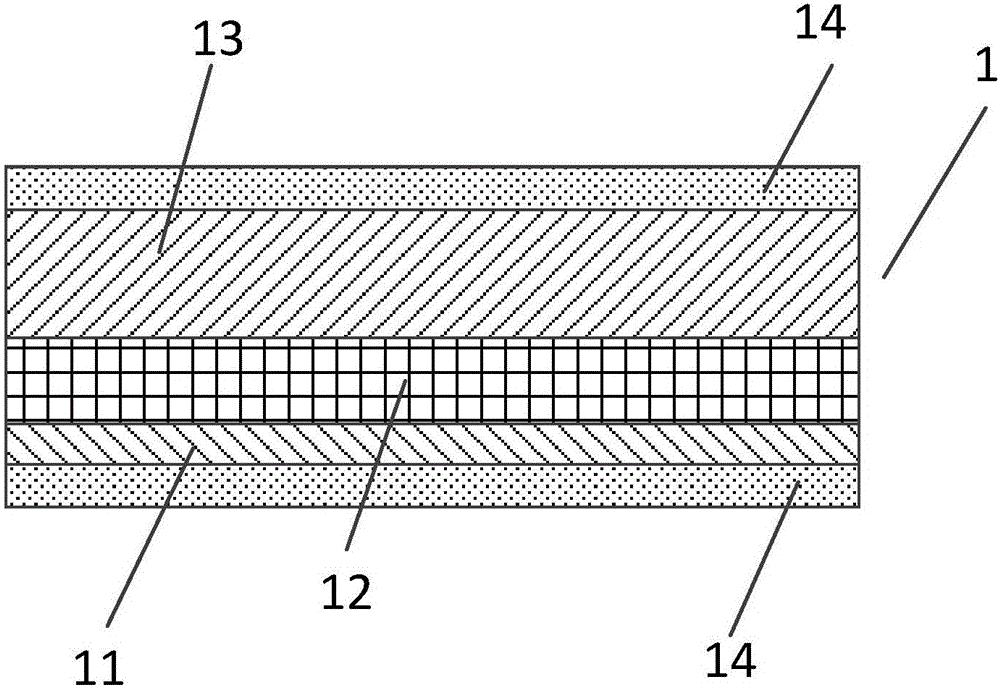

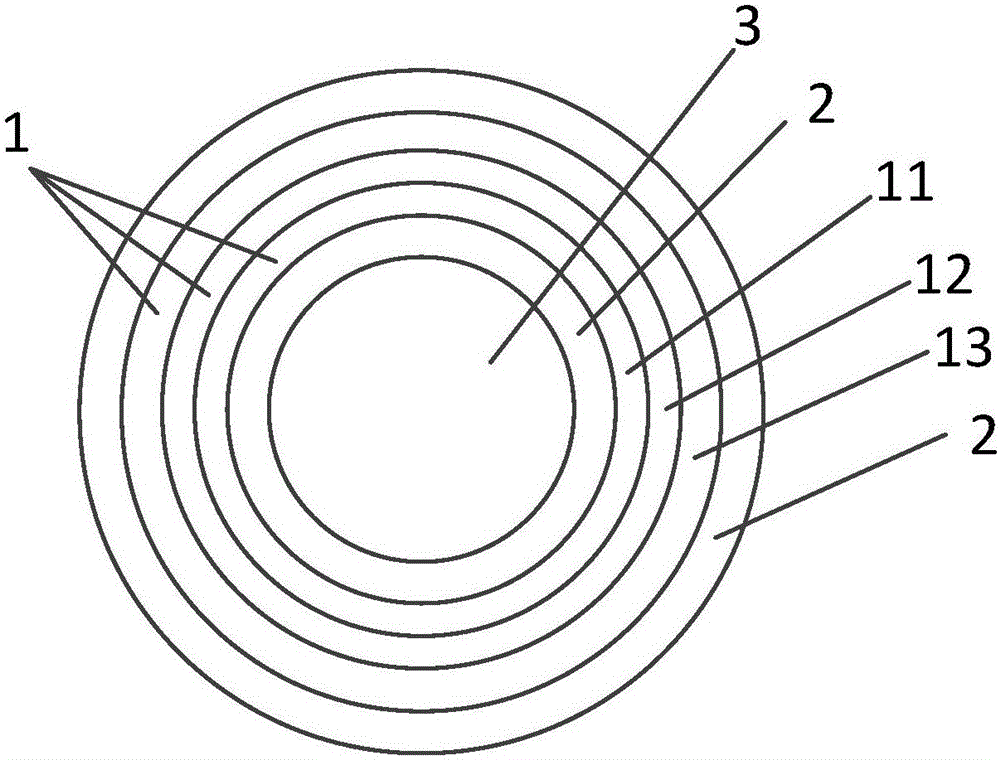

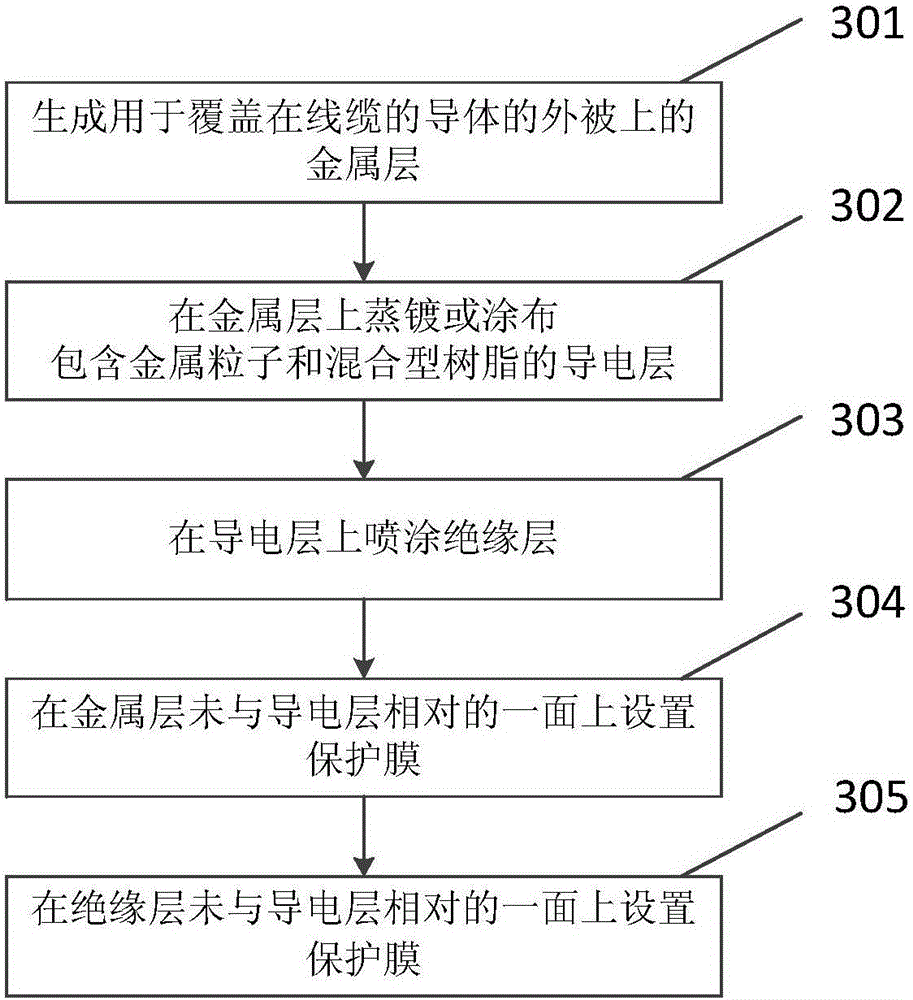

Shielding film used for cable, manufacturing method of shielding film, and manufacturing method of wire rod

InactiveCN105139923AEliminate energyReduce consumptionConductive layers on insulating-supportsInsulated cablesElectrical conductorElectromagnetic interference

The embodiment of the present invention discloses a shielding film used for a cable, a manufacturing method of the shielding film, and a manufacturing method of a wire rod. The shielding film comprises a first metal layer used for shielding the electromagnetic interference, and the first metal layer is used to cover the ecderon of a conductor of the cable and is equipped with a conductive layer. The conductive layer is equipped with a second metal layer used for cooperating with the conductive layer to shield, and the second metal layer is equipped with an insulating layer which cooperates with the ecderon of the conductor to enable the conductive layer and the first metal layer to be insulating with the conductor and the outside world. According to the embodiment of the present invention, a same or better effect can be realized by changing a conventional process of needing multiple wrapping and braiding operations into a process of just needing to wrap the shielding film once, thereby reducing the consumption of the raw materials substantially, and reducing the production cost. Because of the reduction of technologies, the production efficiency also can be improved substantially, and the equipment investment is reduced. In addition, the processes, such as an electroplate process, etc., are not needed, so that an environment is not polluted.

Owner:NANCHANG UNITETEC TECH CO LTD

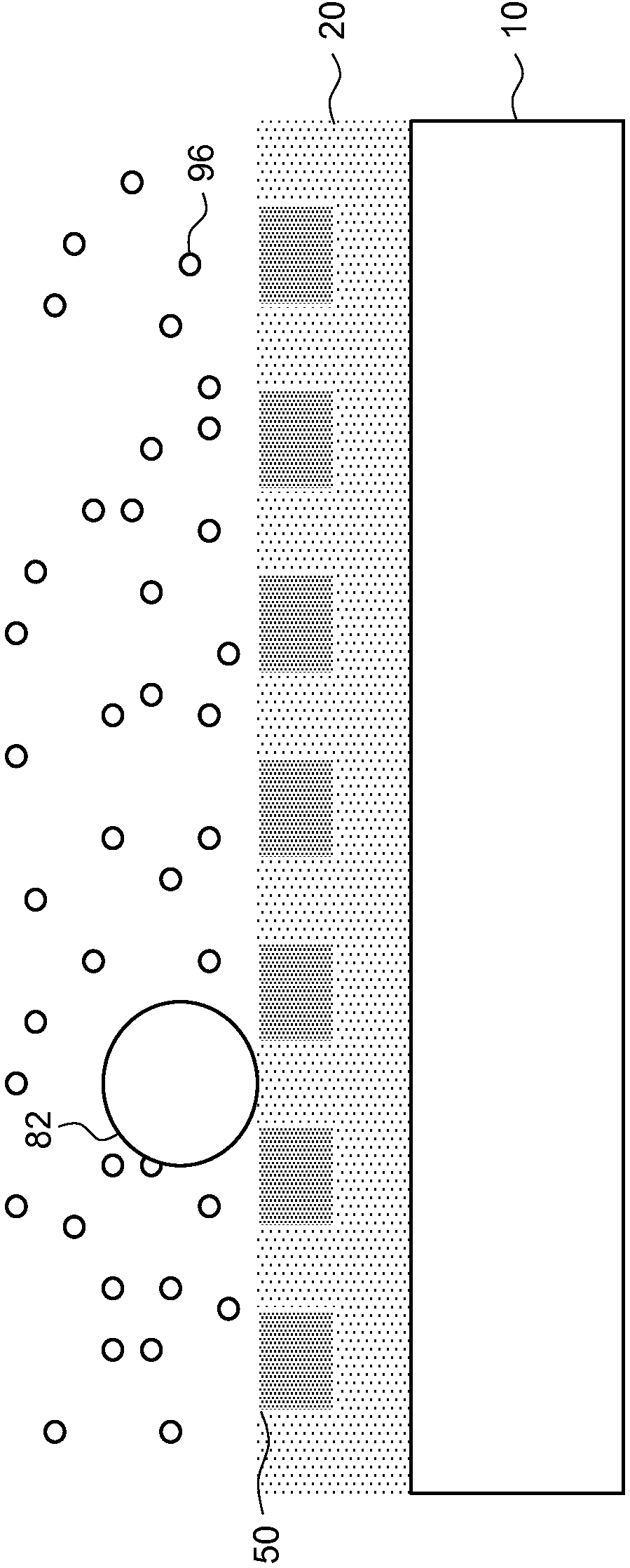

Method of forming conductive films with micro-wires

InactiveCN105518531AReduce distortionReduce uniformityPhotomechanical apparatusMetal/alloy conductorsLithographic artistNanoparticle

A pattern of conductive micro-wires as in a conductive pattern can be prepared using photo-lithography, or imprint technology. A photocurable composition is cured to form a pattern of photocured micro-channels. A conductive composition comprising metal nano-particles is added to the photocured micro-channels and excess conductive composition outside the photocured micro-channels is removed. The conductive composition in the photocured micro-channels is then dried at a temperature of less than 60 DEG C. The dried conductive composition in the photocured micro-channels is treated with hydrogen chloride vapor to form conductive micro-wires in the photocured micro-channels at a temperature of less than 60 DEG C. The outer surface of the conductive micro-wires is then polished in the presence of water, to form a micro-wire pattern.

Owner:EASTMAN KODAK CO

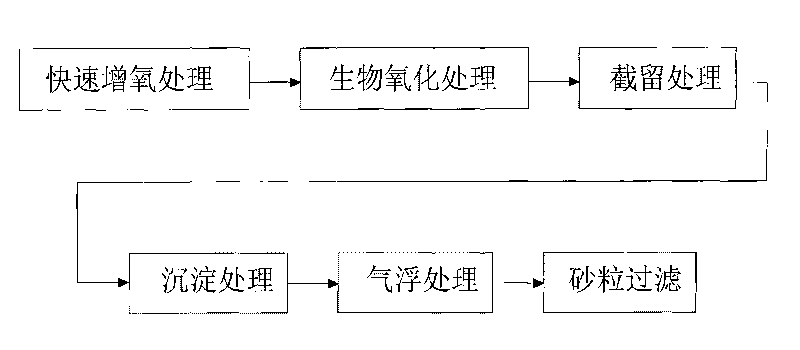

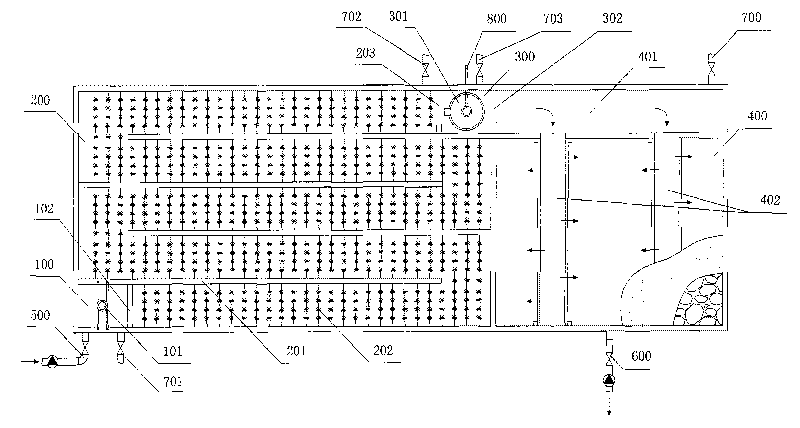

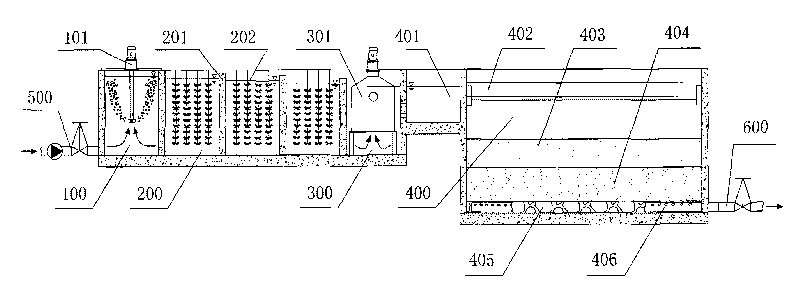

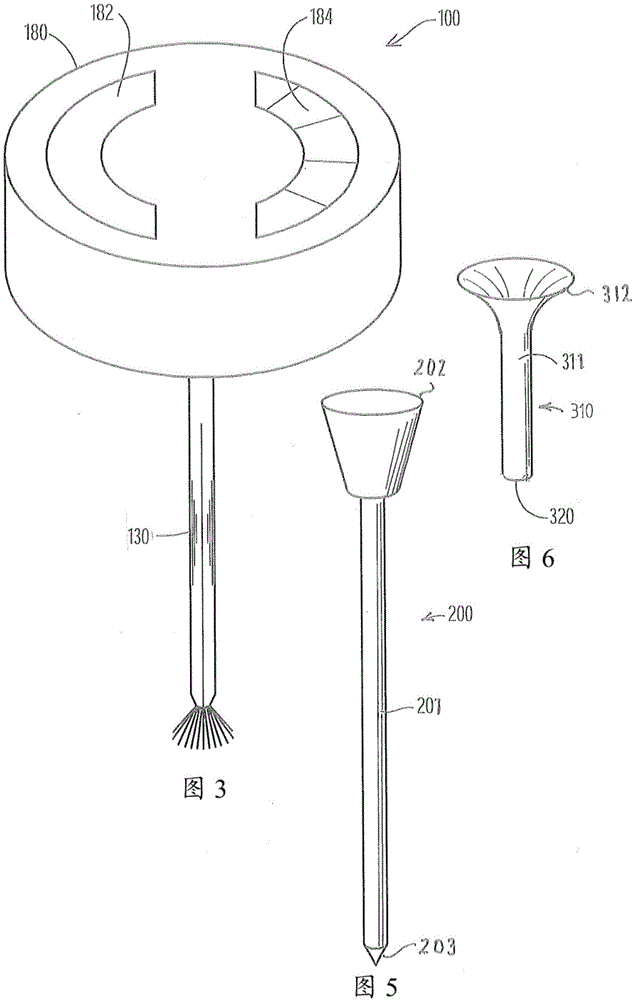

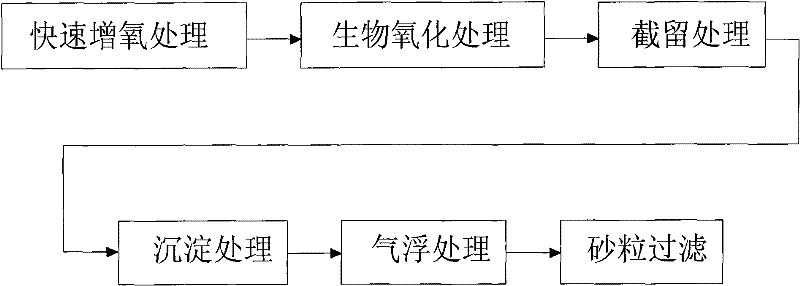

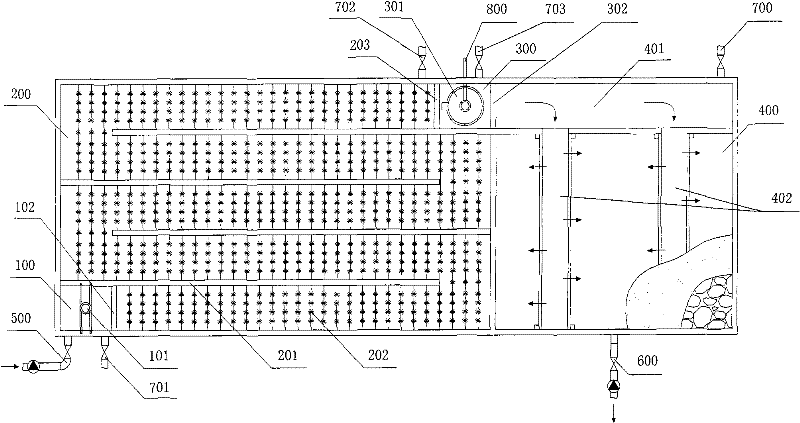

Method for treating underground seawater used for aquiculture

InactiveCN101717172AImprove processing powerImprove efficiencySeawater treatmentMultistage water/sewage treatmentCinderChemistry

The invention belongs to a technological method for removing iron and manganese in underground seawater out of marine culture water. The method for treating underground seawater used for aquiculture comprises the following steps of: quick oxygenation treatment: carrying out oxygenation treatment by an oxygenation appliance and maintaining the pH value of a water body to be 7.0-7.8, wherein [O2] is not less than 0.40[Fe2+]; biological oxidation treatment: hanging a hairbrush-shaped three-dimensional elastic filtering material of a PE material in a corridor of a reaction pool and forming a biologic filter membrane at the surface of a filler; detention treatment: detaining an insoluble substance in the elastic filtering material by the elastic filtering material in the reaction pool; precipitation treatment: precipitating in the corridor with the average water flow rate of 10-20m / h and the oxidation time of 1.5-3h; floatation treatment: treating by a floatation device, removing the fine particles of the iron and the manganese, carrying out secondary oxygenation and separating and removing most of insoluble compounds; and sand grain filtration treatment: filtering cinder and quartz sand by a two-section type filtering material filtration pool. The invention can ensure the content of dissolved oxygen in water, maintains the balance and the stability of microorganisms in the biologic filtering material and the water quality, has lower investment and running cost and increases the benefit of a culture system.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

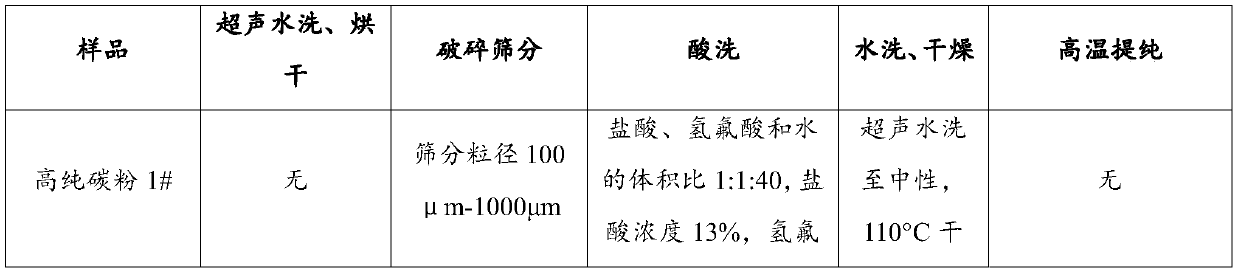

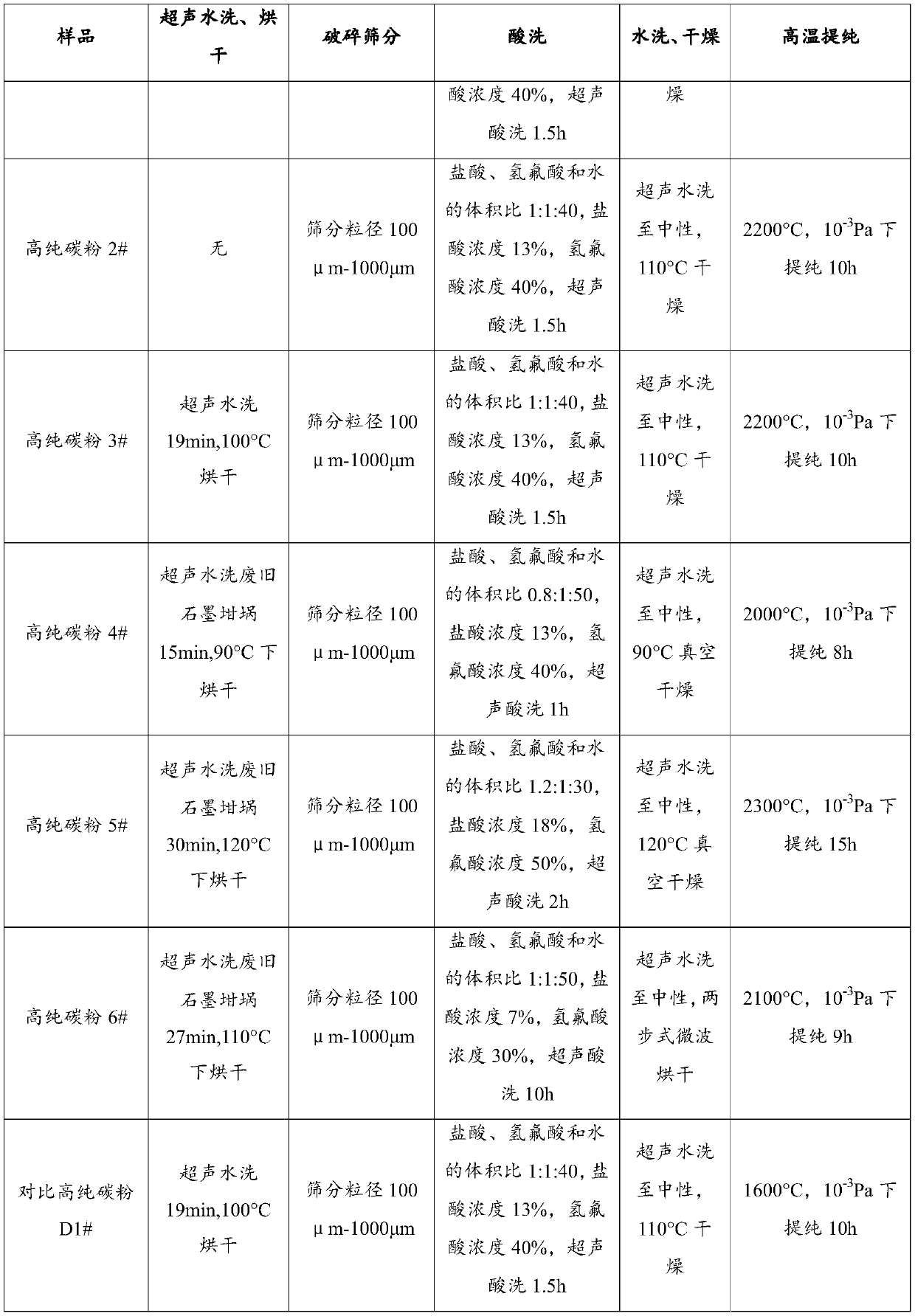

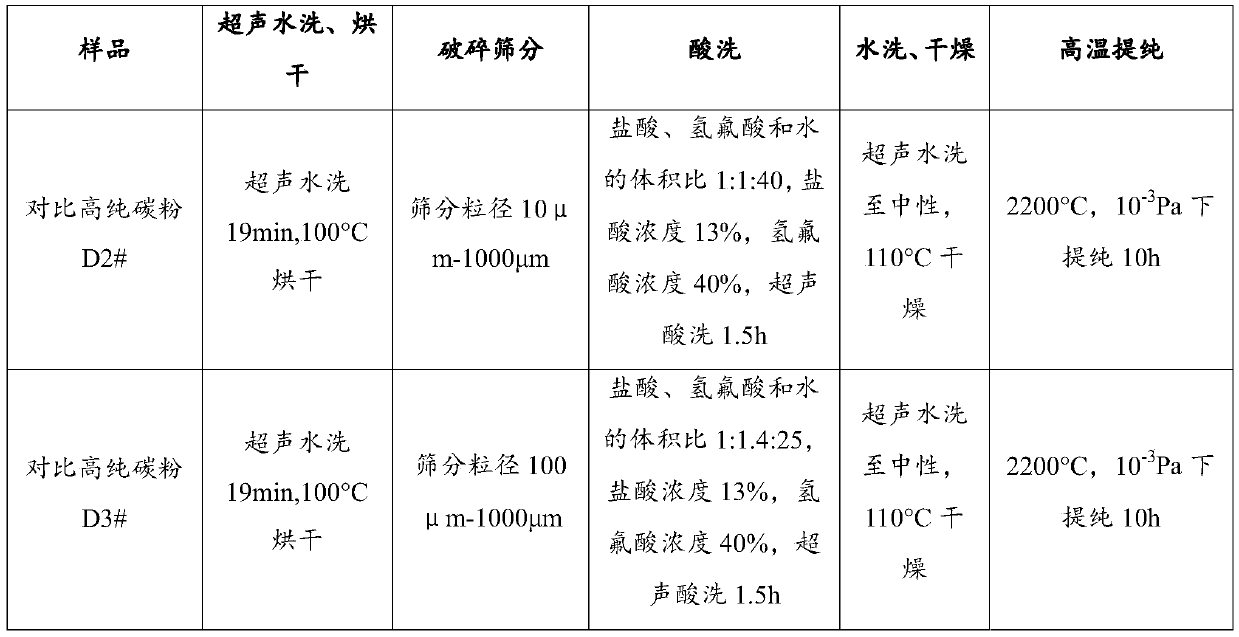

Recovery of waste graphite crucibles and high-purity carbon powder

PendingCN109775700ASolving Recycling ProblemsTake advantage ofCarbon compoundsRecovery methodSemiconductor materials

The invention relates to a recovery method of waste graphite crucibles and high-purity carbon powder, and belongs to the field of semiconductor materials. The method includes crushing waste graphite crucibles, sieving the crushed crucibles, and performing acid washing, water washing and drying to obtain high-purity carbon powder. A problem of recovering the waste graphite crucibles is solved so that resources are more fully utilized, and the cost of the high-purity carbon powder is reduced. The method is low-carbon, environmentally friendly and energy-saving. The waste graphite crucibles are low in impurity content after a plurality of times of application at high temperature, and the prepared high-purity carbon powder is low in cost, high in purity, and wide in particle size distributionand can be used for preparing semiconductor-grade silicon carbide powder.

Owner:SICC CO LTD

Catalytic reduction denitration method for sintering flue gas of vanadium titano-magnetite

ActiveCN107649002AImprove removal efficiencyReduce manufacturing costGas treatmentDispersed particle separationSlagFlue gas

The invention belongs to the technical field of flue gas denitration, and particularly relates to a catalytic reduction denitration method for sintering flue gas of vanadium titano-magnetite. The catalytic reduction denitration method for the sintering flue gas of the vanadium titano-magnetite aims at solving the problems that in existing flue gas denitration methods, costs are high, processes arecomplex, and industrial operation is uneasy to implement. The method comprises the following step of spraying catalysts into the sintering flue gas of the vanadium titano-magnetite for a reaction at140-160 DEG C for 10-15 s. The content of CO in the flue gas is higher than that of NO, and the catalysts are selected from one or more of blast furnace slag, vanadium-refined tail slag and titanium-refined tail slag. Without adding reducing substances, by adding side products of the vanadium titano-magnetite to convert NO in the flue gas into N2, the denitration efficiency can reach 60% or above,the production cost is low, and great convenience is provided for industrial implementation.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Shielding film used for cable, manufacturing method of shielding film, and manufacturing method of wire rod

InactiveCN105139922AReduce consumptionWill not polluteConductive layers on insulating-supportsInsulated cablesElectrical conductorElectromagnetic interference

The embodiment of the present invention discloses a shielding film used for a cable, a manufacturing method of the shielding film, and a manufacturing method of a wire rod. The shielding film comprises a metal layer used for shielding the electromagnetic interference, the metal layer is used to cover the ecderon of a conductor of the cable and is equipped with a conductive layer used for shielding, and the conductive layer is equipped with an insulating layer which cooperates with the ecderon of the conductor to enable the conductive layer and the metal layer to be insulating with the conductor and the outside world. According to the embodiment of the present invention, a same or better effect can be realized by changing a conventional process of needing multiple wrapping and braiding operations into a process of just needing to wrap the shielding film once, thereby reducing the consumption of the raw materials substantially, and reducing the production cost. Because of the reduction of technologies, the production efficiency also can be improved substantially, and the equipment investment is reduced. In addition, the processes, such as an electroplate process, etc., are not needed, so that an environment is not polluted.

Owner:NANCHANG UNITETEC TECH CO LTD

Processing technology of bearing

InactiveCN108067836AImprove corrosion resistanceImprove the efficiency of subsequent processing stepsInterference fitBall bearing

The processing method of a bearing comprises (1) a step of preparation, and tempering a inner ring and an outer ring of the bearing; (2) a step of processing and forming the inner ring and outer ringof the bearing; (3) a step of fixing the inner ring and outer ring of the bearing by a clamping hoop; (4) piercing a through hole at the outer ring of the bearing in a axial direction; (5) a step of grinding and machining towards the inner and outer ring of the bearing; (6) adopting wire cutting to cut out a clamping block , and the cut clamping block enabling the through hole to be divided into afirst through hole and a second through hole which is arranged at both sides of a fracture of the outer ring of the bearing; (7) installing a ball bearing at a position between the outer ring of thebearing and the inner ring of the bearing; and (8) loading the clamping block into the fracture, and inserting a bolt into the first through hole and the second through hole for interference fit. Tempering towards the inner ring and outer ring of the bearing is carried out before the process, so that the ductility and toughness of the bearing are enhanced. The bearing has high bearing capacity, the service life compared with the existing full ball bearing is greatly prolonged, and the safety is high.

Owner:贵州弘润实业发展有限公司

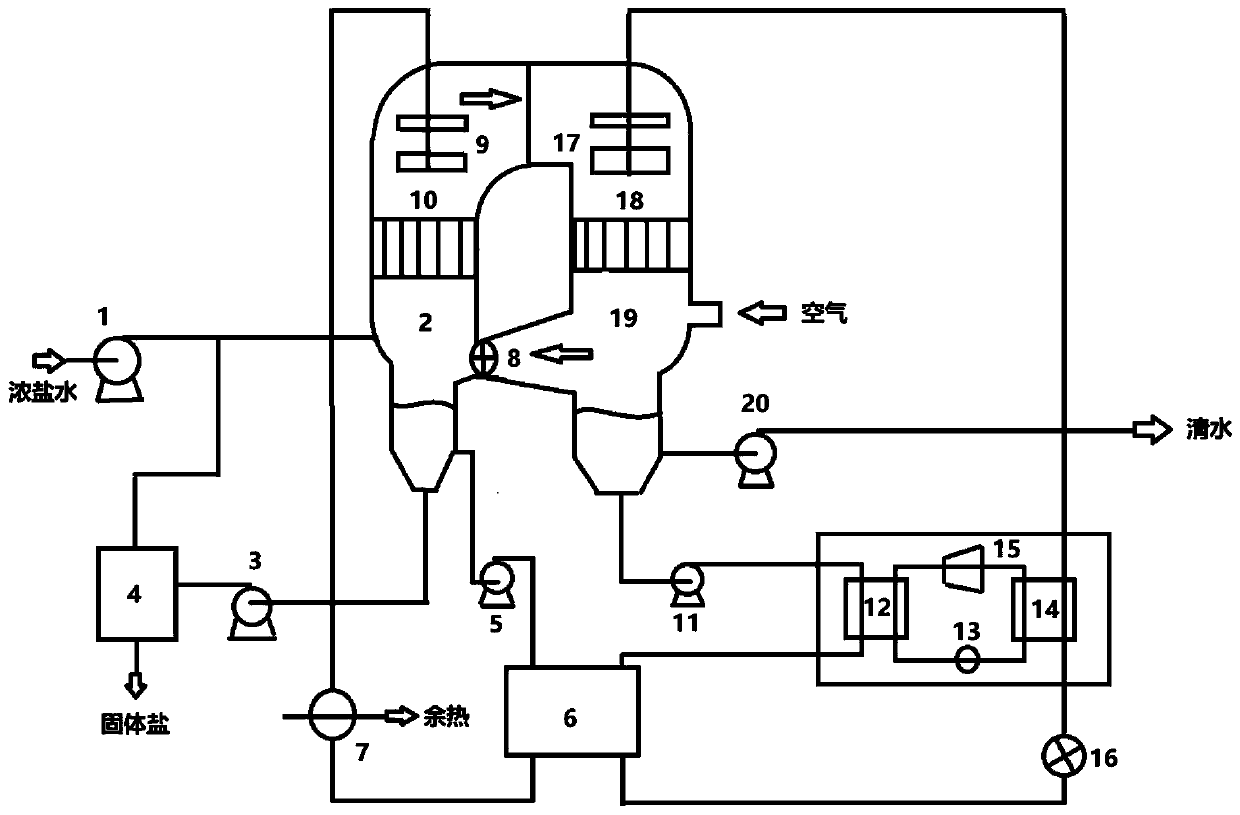

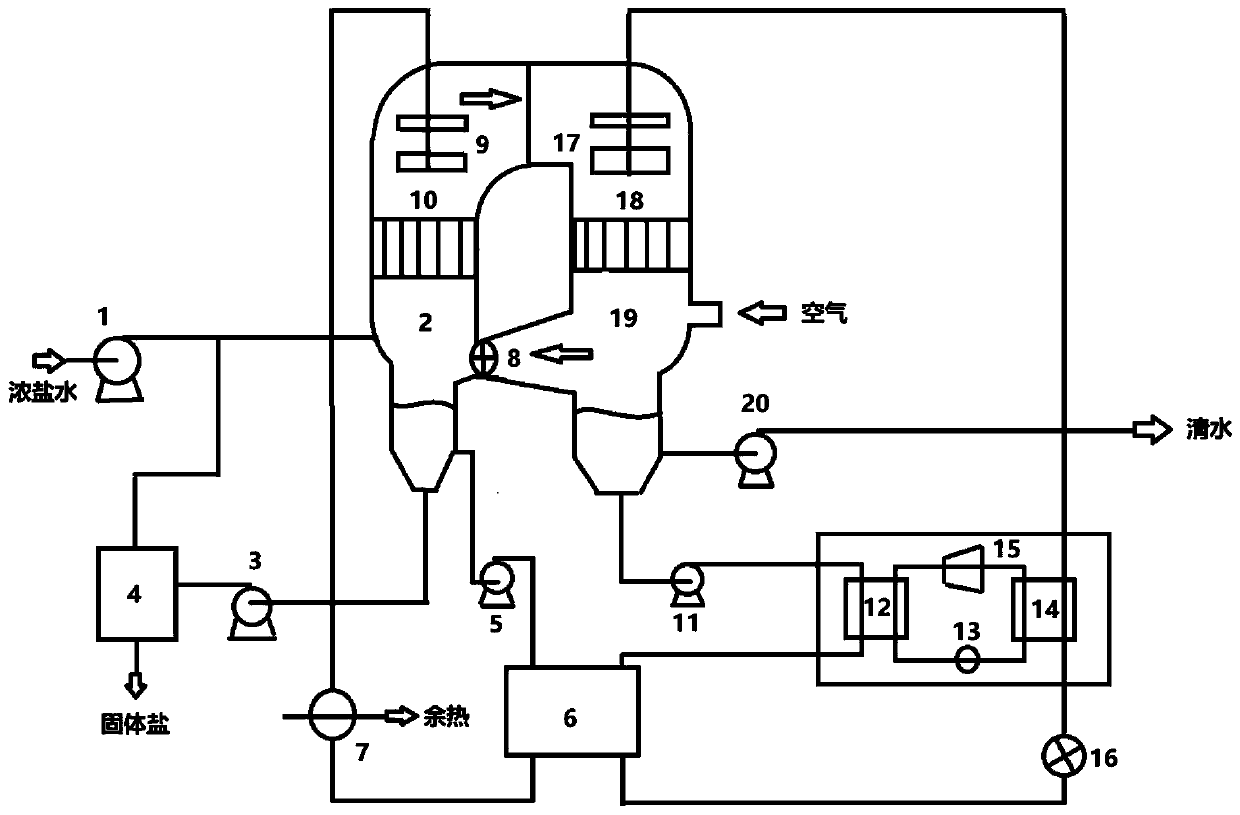

Energy-saving zero-emission low-temperature normal-pressure evaporation and crystallization system and working method thereof

PendingCN111153543ARealize energy saving and consumption reductionEasy to handleMultistage water/sewage treatmentWater/sewage treatment by heatingSaline waterZero emission

The invention discloses an energy-saving zero-emission low-temperature normal-pressure evaporation and crystallization system and a working method thereof, and belongs to the technical field of high-concentration brine zero emission. The system comprises an evaporation chamber, a crystallization kettle, an evaporation and condensation heat exchanger, a condensation chamber and a refrigeration chamber unit. Concentrated crystallization of strong brine and collection of condensate are achieved through circulation in the evaporation chamber and the condensation chamber according to the characteristic that the moisture carrying capacity of air at different temperatures is different, and high-concentration brine zero-discharge treatment at normal temperature and normal pressure is achieved. Thesystem is reasonable in design, high in automation degree, low in energy consumption, low in cost, zero in pollutant discharge, high in salinity and COD removal efficiency and remarkable in energy-saving effect, strong brine is treated into solid salt and clear water, and the system has good economic benefits, obvious environmental protection advantages and good application prospects.

Owner:HUANENG CLEAN ENERGY RES INST

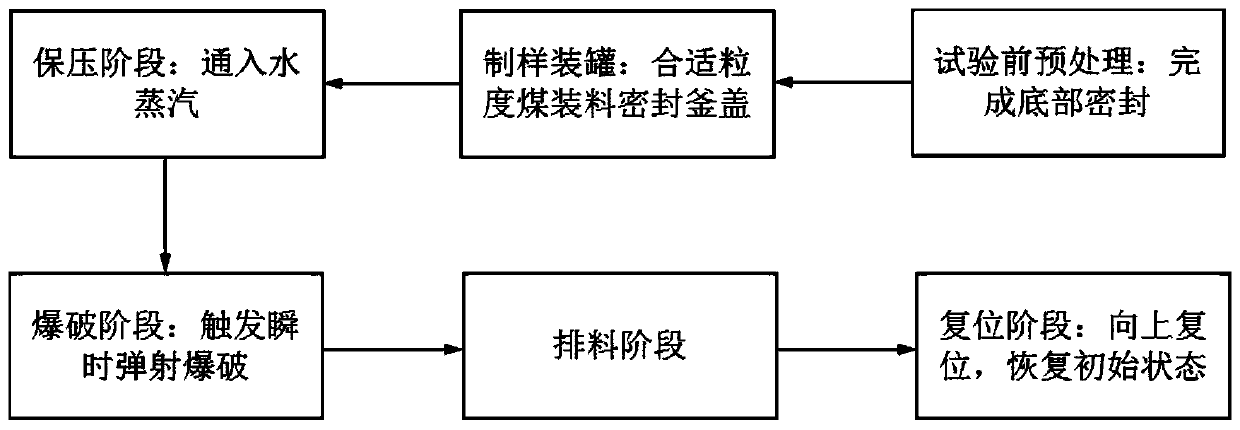

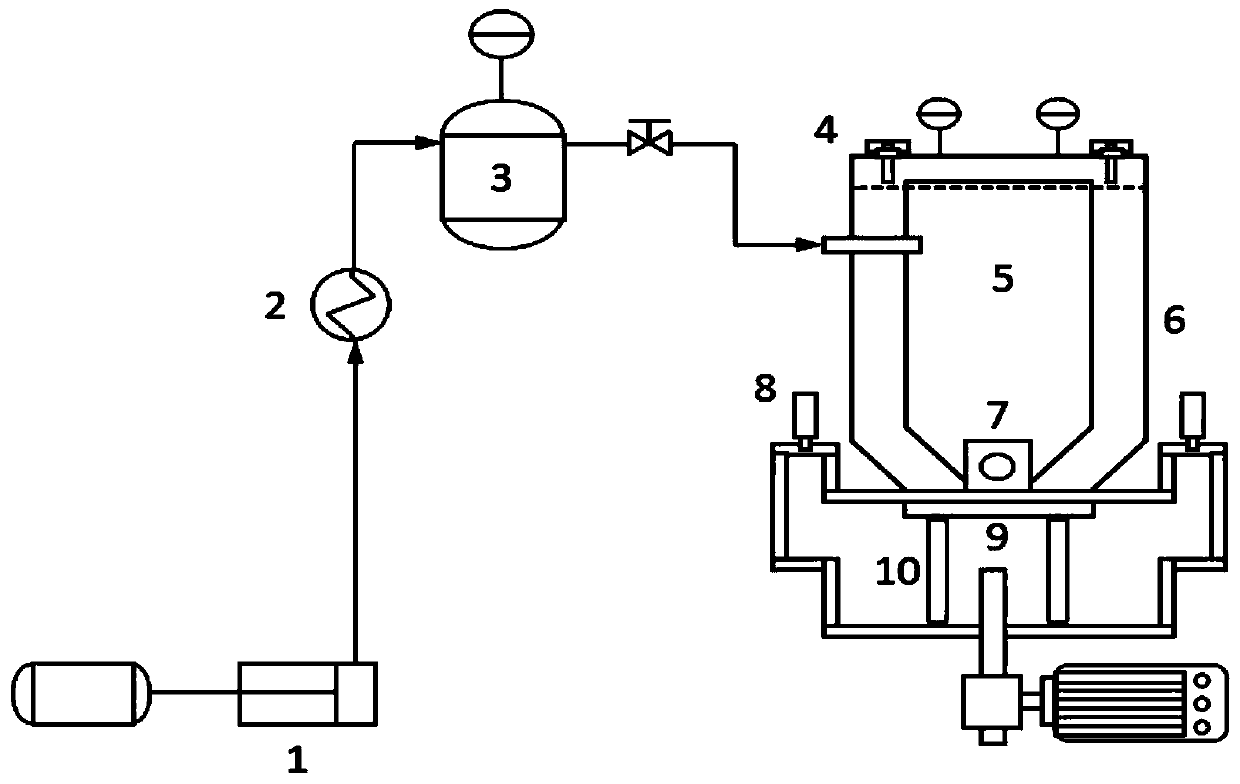

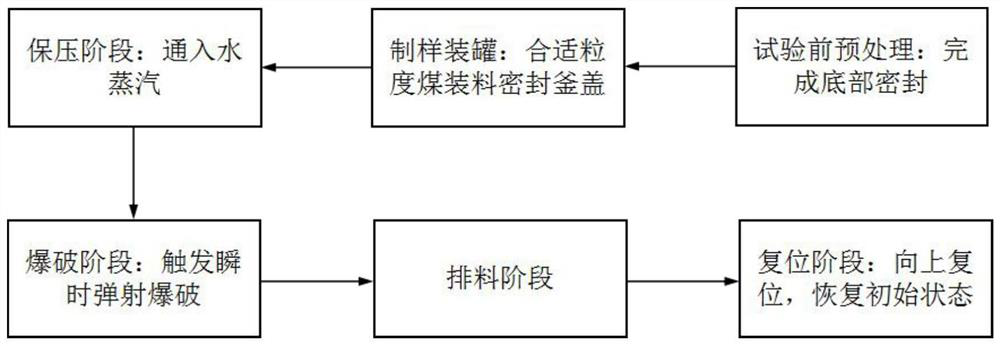

Device and method for removing water in coal

The invention discloses a device and a method for removing water in coal, and belongs to the field of coal dehydration. Firstly, a coal sample is put into a reaction kettle and the reaction kettle isthen sealed; then high-pressure and high-temperature water vapor is introduced into the reaction kettle, and pressure maintaining is conducted; then a lower sealing piston is controlled to be opened to punish instantaneous ejection blasting, and the water vapor in the reaction kettle and water difficult to remove in the coal sample are discharged together. The reaction time is short, the operationis safe and stable and the cost is low. The device and method is suitable for large-scale production, so that the invention provides a new process breakthrough for further deep dehydration of coal.

Owner:CHINA UNIV OF MINING & TECH +1

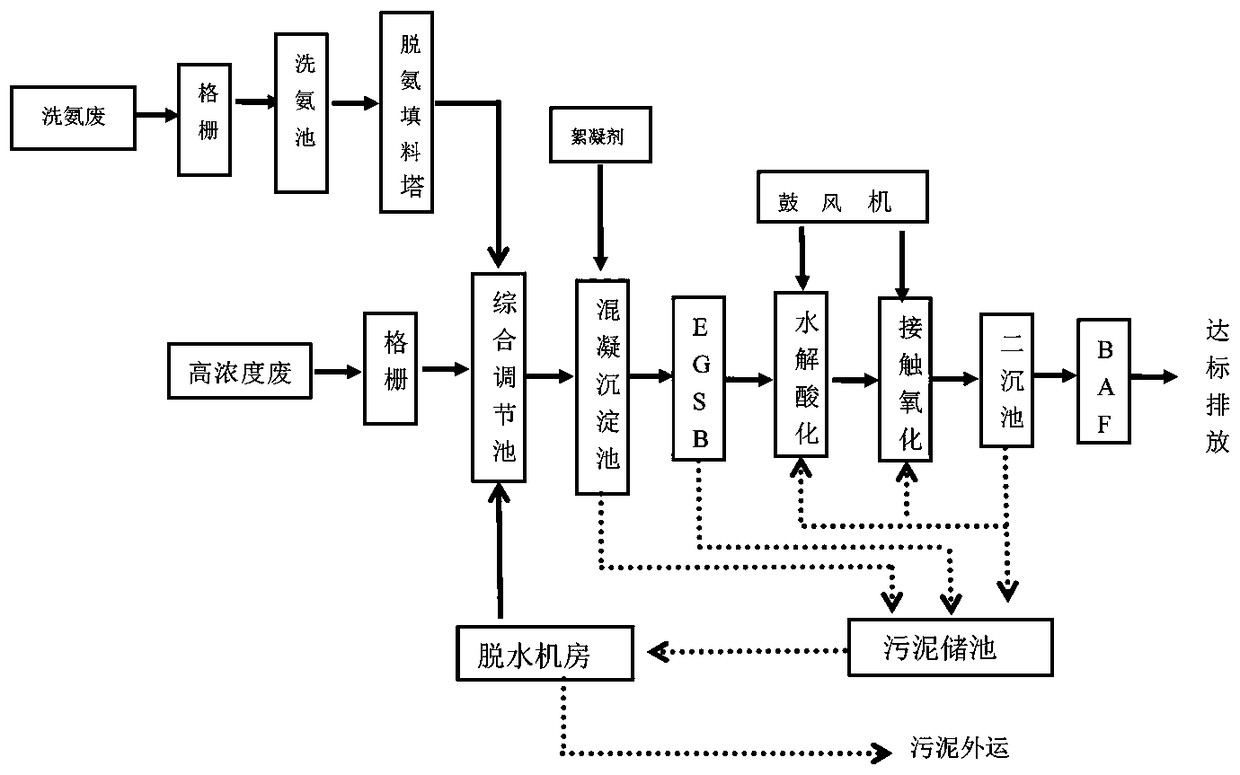

Method for improving efficiency of contact oxidation tank in wastewater treatment of neomycin

InactiveCN109399873AImprove efficiencyLow removal efficiencyWater treatment parameter controlWater treatment compoundsHigh concentrationEnvironmental resistance

The invention relates to a method for improving the efficiency of a contact oxidation tank in the wastewater treatment of neomycin. The method includes making neomycin wastewater pass through a hydrolysis acidification tank and then enter the contact oxidation tank, adding glucose, opening the reflux of a secondary sedimentation tank, opening inflow of the contact oxidation tank and adjusting to intermittent inflow; adding sodium carbonate to the contact oxidation tank and adjusting the pH of sludge in the contact oxidation tank to 8-8.5; introducing air to the bottom of the contact oxidationtank for aeration to control dissolved oxygen in a water outlet of the contact oxidation tank to be 2-4 mg / L to improve the efficiency of the contact oxidation tank. By means of the technical scheme,the environmental protection problem of the wastewater treatment in the production of the neomycin is solved, the difficulty in the treatment of high-concentration ammonia nitrogen is solved, the wastewater discharge meets the standard comprehensively, continuous stable operation reaching the standard is achieved, and the environmental risks are reduced. Key process steps in the wastewater treatment are found, and the suitable process is determined. A method for improving the sedimentation performance of the sludge and a method for increasing the retention time of nitrifying bacteria in the contact oxidation tank are found.

Owner:YICHANG SANXIA PHARMA

Inferior heavy oil treatment method

PendingCN111088070AIncrease profitHigh economic valueTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses an inferior heavy oil treatment method. The treatment method comprises the following steps: introducing inferior heavy oil into a first hydro-processing unit; carrying out a hydrogenation reaction in the presence of hydrogen and a first hydro-processing catalyst, directly introducing a liquid phase effluent obtained after the reaction into a catalytic cracking unit withoutfractionation, separating a reaction product to obtain catalytic slurry oil, mixing the catalytic slurry oil with a first auxiliary agent, carrying out settlement separation after the mixing treatment, obtaining a first material and residues after separation; introducing the first material into a second hydro-processing unit, carrying out a hydrogenation reaction under the action of a second hydro-processing catalyst and hydrogen, introducing a liquid-phase effluent obtained after the reaction into a clarification unit, obtaining clarified oil after separation, and subjecting the clarified oilto further solid-liquid separation to obtain purified oil slurry. According to the treatment method, heavy oil is cleaned, catalytic slurry oil generated by catalytic cracking can be purified, solidsand sulfur in catalytic slurry oil are removed, and the economic value of the catalytic slurry oil is greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

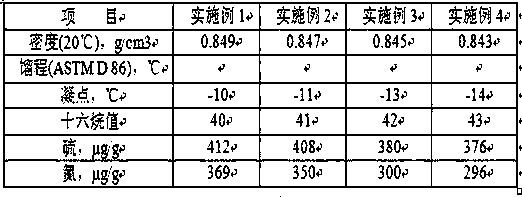

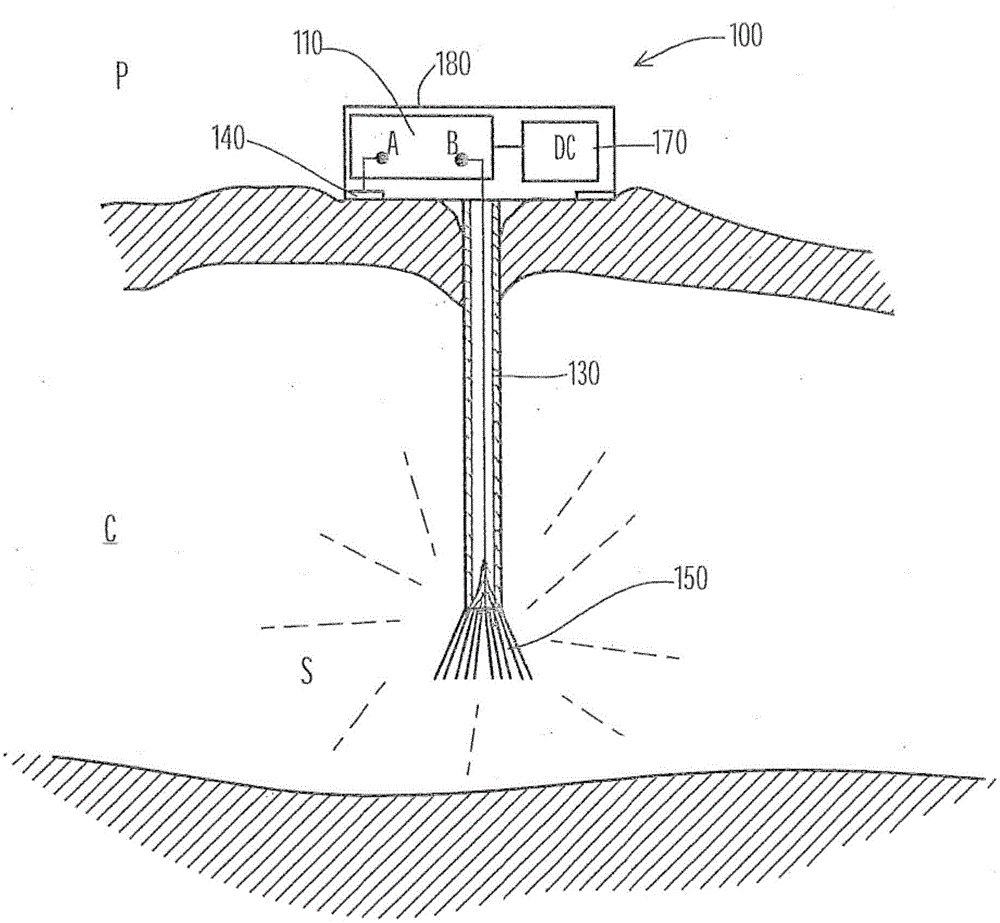

Improvements in and relating to the reduction or removal of particles within an enclosed corporeal atmosphere

ActiveCN103957830AReduce in quantityLow removal efficiencyElectrotherapySurgical instruments for heatingBiomedical engineeringAtmosphere

Owner:ALESI SURGICAL

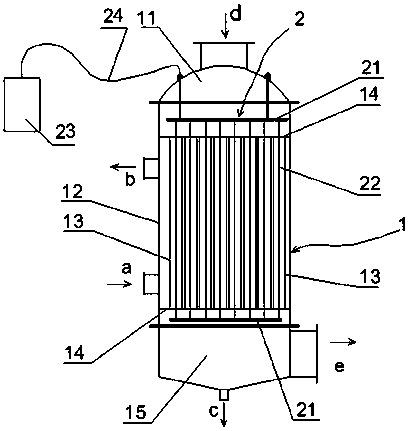

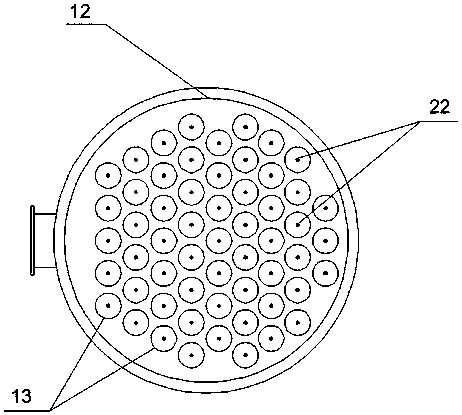

Condensation heat exchanger for treating waste gas high in moisture content and intensified heat exchanger method

PendingCN109405599AReduce contentEfficient dust removalStationary tubular conduit assembliesExternal electric electrostatic seperatorCondensation processEngineering

The invention discloses a condensation heat exchanger for treating waste gas high in moisture content and an intensified heat exchanger method. The condensation heat exchanger comprises a condensationheat exchanger body (1). The condensation heat exchanger body (1) is internally provided with multiple heat exchange tubes (13). The heat exchange tubes (13) are made of electrically-conductive metalor non-metal materials. The heat exchanger further comprises a static electricity generating device (2). The static electricity generating device (2) comprises a cathode fixing bracket (21), cathodewires (22), a power source (23) and a connecting wire (24). The cathode wires (22) are arranged in the heat exchange tubes (13). The cathode wires (22) form a cathode, and the heat exchange tubes (13)form an anode. The cathode wires (22) and the heat exchange tubes (13) form a static electric field in the heat exchange tubes (13), so that the waste gas flows in the heat exchange tubes (13), and acooling medium flows outside the heat exchange tubes (13). By means of the condensation heat exchanger, the dedusting / defogging efficiency can be improved in the condensation process; and the condensation heat exchanger has the advantages that the investment is low, the heat exchange efficiency and the dedusting / defogging efficiency are high, and the equipment space is saved.

Owner:江苏双良冷却系统有限公司

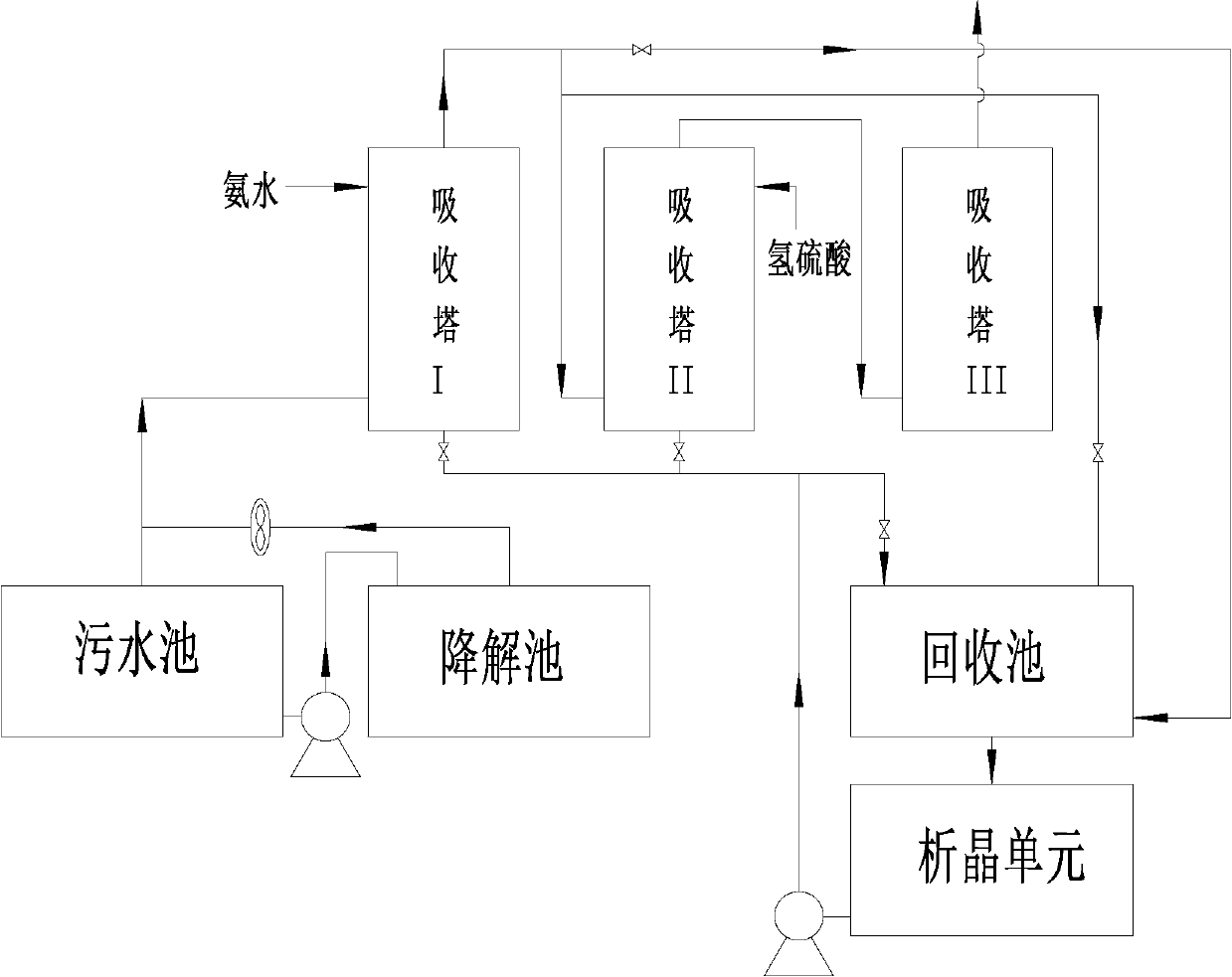

Wastewater treatment system

PendingCN107827248ALow costAvoid secondary generationGas treatmentAmmonium sulfides/polysulfidesExhaust gasTreatment effect

A wastewater treatment system comprises a wastewater tank, a degradation tank, absorption columns, a recycling tank and a crystallization unit and is technically characterized in that the wastewater tank is connected with the bottom intake end of the absorption column I, the top exhaust end of the absorption column I is communicated with the bottom intake end of the absorption column II, the top exhaust end of the absorption column II is communicated with the bottom intake end of the absorption column III, the top exhaust end of the absorption column III is communicated with the air, the bottom drain end of the absorption column I and the bottom drain end of the absorption column II are communicated with the recycling tank, the top exhaust end of the absorption column I is communicated with the bottom intake end of the recycling tank, the topo exhaust end of the absorption column II is communicated with the top intake end of the recycling tank, and the bottom drain end of the recyclingtank forms a crystallization cycle with the top inflow end of the recycling tank through the crystallization unit and pump block II. The wastewater treatment system has the advantages of simple compact structure, low setup cost, good convenience of use, high treatment efficiency, good treatment effect and the like.

Owner:SHENYANG PARAFFIN CHEM

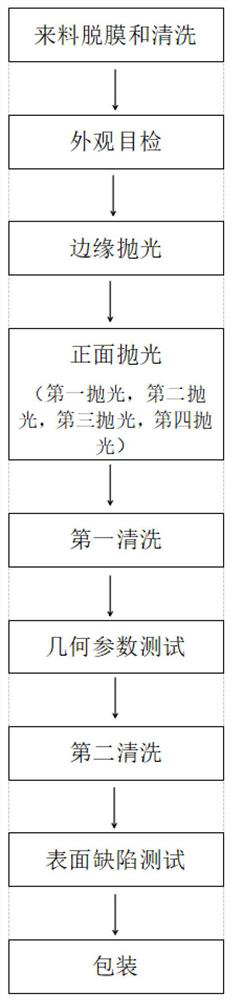

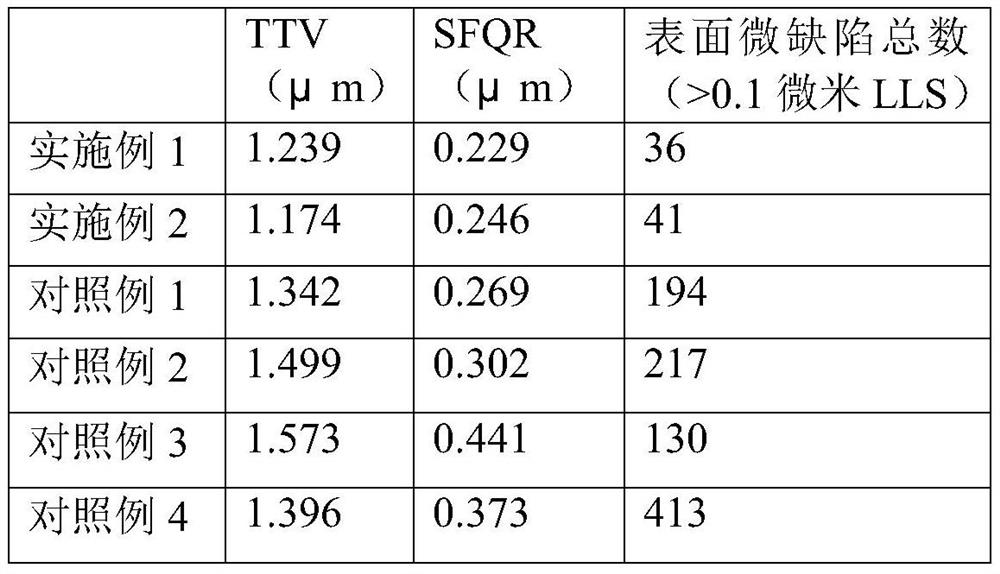

Regeneration processing method of substrate slice after SOI bonding process

ActiveCN113192823ALow costImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention belongs to the technical field of recycling and processing of monocrystalline silicon polished wafers of integrated circuits, and particularly relates to a regeneration processing method of a substrate slice after an SOI bonding process. The method comprises the following steps: demoulding and cleaning a recovered SOI substrate slice, polishing the front surface of the substrate slice, cleaning the substrate slice for the first time, testing the flatness uniformity and thickness of the substrate slice, and cleaning the substrate slice for the second time. According to the regeneration processing method disclosed by the invention, the recovery of the substrate slice after the SOI bonding process is realized, so that the substrate slice reaches a substrate silicon slice with a high surface quality level again, the substrate slice can be circularly used for multiple times in the SOI bonding process, and the processing cost is far lower than the price of purchasing a new substrate silicon slice.

Owner:MCL ELECTRONICS MATERIALS

Method for removing residual monomers from styrene-acrylic emulsion

The invention provides a method for removing residual monomers from styrene-acrylic emulsion and relates to the technical field of emulsion polymerization. The method comprises the following steps: mixing propylene glycol methyl ether acetate and emulsion into a reaction kettle; and inserting a vapor guide pipe and a rod-like ultrasonic generator into the reaction kettle at 85 DEG C, opening a vapor valve, blowing saturated water vapor into the emulsion, staring the ultrasonic generator simultaneously to bubble and oscillate the emulsion, cooling the emulsion in the kettle to 40 DEG C after bubbling, and discharging to obtain the residual monomer-removed styrene-acrylic emulsion, wherein the gas outlet of the vapor guide pipe and the ultrasonic generator need to be completely immersed below the liquid level. Through low-frequency ultrasonic oscillation, the residual monomers and the propylene glycol methyl ether acetate enter an aqueous phase from the internal parts of colloidal particles and are driven by the saturated water vapor to be separated from the aqueous phase, so that the residual monomer content of the emulsion system is reduced. The method has the characteristic of high residual monomer removing efficiency.

Owner:海安常州大学高新技术研发中心

Method for treating underground seawater used for aquiculture

InactiveCN101717172BGuaranteed dissolved oxygen contentEfficient removalSeawater treatmentPisciculture and aquariaFiltrationManganese

The invention belongs to a technological method for removing iron and manganese in underground seawater out of marine culture water. The method for treating underground seawater used for aquiculture comprises the following steps of: quick oxygenation treatment: carrying out oxygenation treatment by an oxygenation appliance and maintaining the pH value of a water body to be 7.0-7.8, wherein [O2] is not less than 0.40[Fe2+]; biological oxidation treatment: hanging a hairbrush-shaped three-dimensional elastic filtering material of a PE material in a corridor of a reaction pool and forming a biologic filter membrane at the surface of a filler; detention treatment: detaining an insoluble substance in the elastic filtering material by the elastic filtering material in the reaction pool; precipitation treatment: precipitating in the corridor with the average water flow rate of 10-20m / h and the oxidation time of 1.5-3h; floatation treatment: treating by a floatation device, removing the fine particles of the iron and the manganese, carrying out secondary oxygenation and separating and removing most of insoluble compounds; and sand grain filtration treatment: filtering cinder and quartz sand by a two-section type filtering material filtration pool. The invention can ensure the content of dissolved oxygen in water, maintains the balance and the stability of microorganisms in the biologic filtering material and the water quality, has lower investment and running cost and increases the benefit of a culture system.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Method for purifying materials containing metal impurities

Owner:CHINA PETROLEUM & CHEM CORP +1

A device and method for removing moisture from coal

Owner:CHINA UNIV OF MINING & TECH +1

Magnetorheological Polishing Method for Deliquescent Crystals

ActiveCN104084849BImprove rheologyLow magnetic field viscosityPolishing compositions with abrasivesAromatic hydrocarbonOptic system

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com