Device and method for removing water in coal

A moisture removal technology, applied in the petroleum industry, solid fuels, fuels, etc., can solve the problems of removal, inability to remove, and other moisture removal to be studied, and achieve high efficiency and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

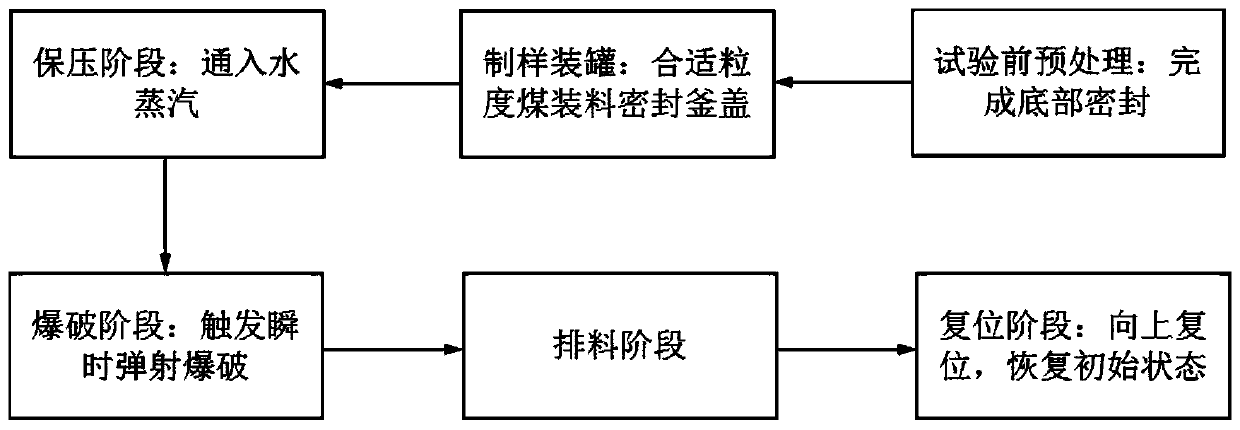

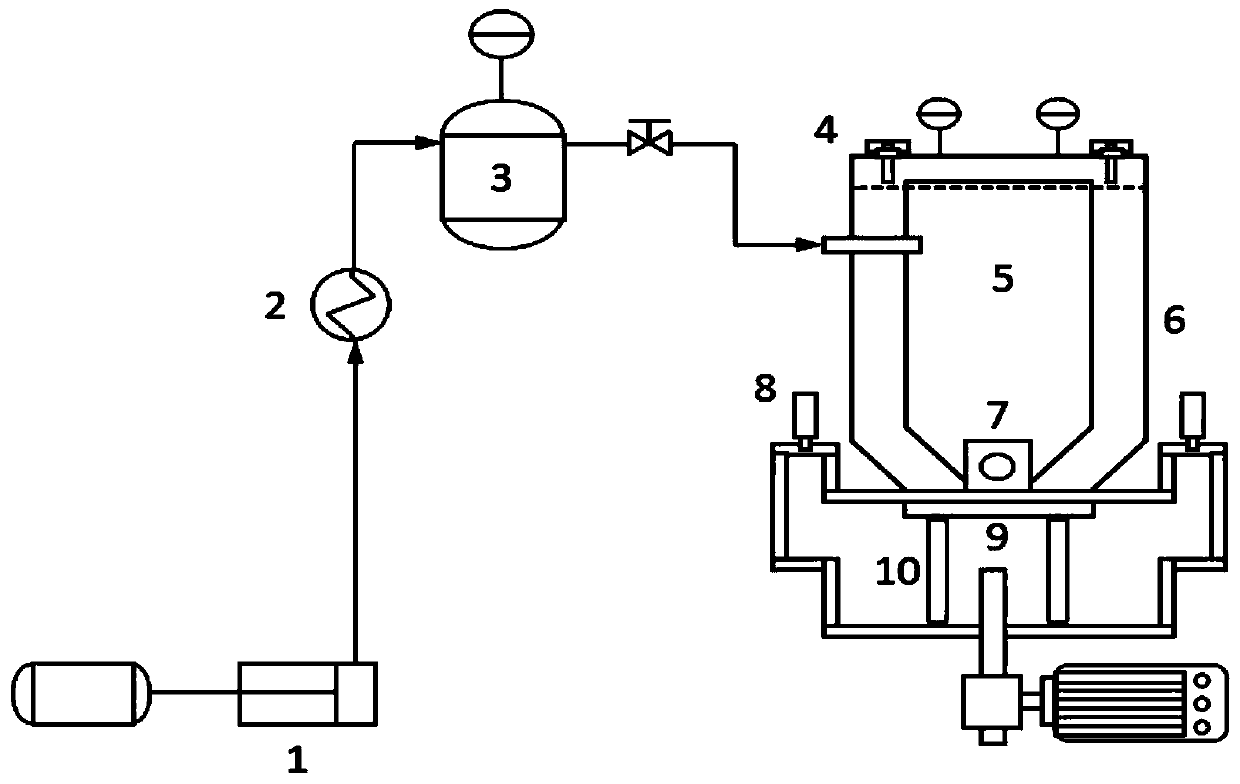

[0025] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0026] Such as figure 1 and figure 2 Shown, moisture removal device in coal of the present invention, 1. a moisture removal device in coal, is characterized in that: it comprises dehydration reaction kettle, and dehydration reaction kettle comprises still body 6, and still body 6 outsides are provided with high temperature protection laminated to reduce heat leakage loss, the kettle body 6 is provided with a material frame 5, and a steel perforated material bucket with a cover is also provided in the material frame 5 to hold the coal sample to be dehydrated to ensure that the water vapor It can enter and discharge the reaction kettle, and the coal sample will not leak out. One side of the material frame 5 passes through the kettle body 6. There is a pipeline interface for introducing water vapor, and the pipeline interface is connected to the energy storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com