Condensation heat exchanger for treating waste gas high in moisture content and intensified heat exchanger method

A technology of condensing heat exchangers and high moisture content, which is applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., which can solve the problems of increasing costs, occupying more space, and low removal efficiency, so as to achieve saving The effect of low investment, low investment and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

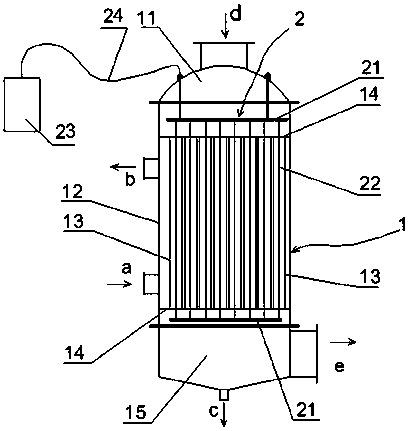

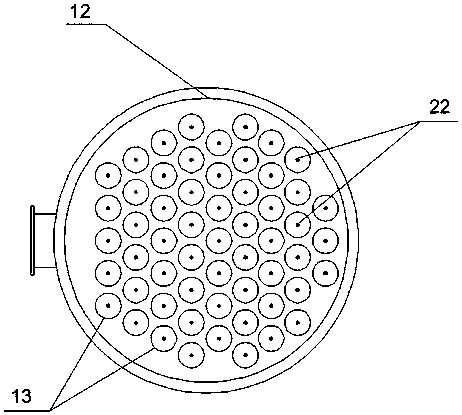

[0024] Such as Figure 1~2 As shown, a condensing heat exchanger for treating waste gas with high moisture content includes a condensing heat exchanger body 1, the condensing heat exchanger body 1 is vertical, and the upper end cover 11 is provided with a waste gas inlet d , the right side wall of the lower end cover 15 is provided with an exhaust gas outlet e, the bottom of the lower end cover 15 is provided with a condensate outlet c, and the bottom of the left side wall of the cylinder 12 is provided with a cooling medium inlet a, and the cylinder 12 A cooling medium outlet b is provided on the top of the left side wall, and a plurality of heat exchange tubes 13 are provided inside the condensing heat exchanger body 1, and the heat exchange tubes 13 are made of conductive metal or non-metallic material. Titanium alloy ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com