Method for improving efficiency of contact oxidation tank in wastewater treatment of neomycin

A contact oxidation pond and wastewater treatment technology, which is applied in natural water treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of difficult treatment, difficult separation of wastewater crystals, large amount of wastewater, etc., and achieve the goal of improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

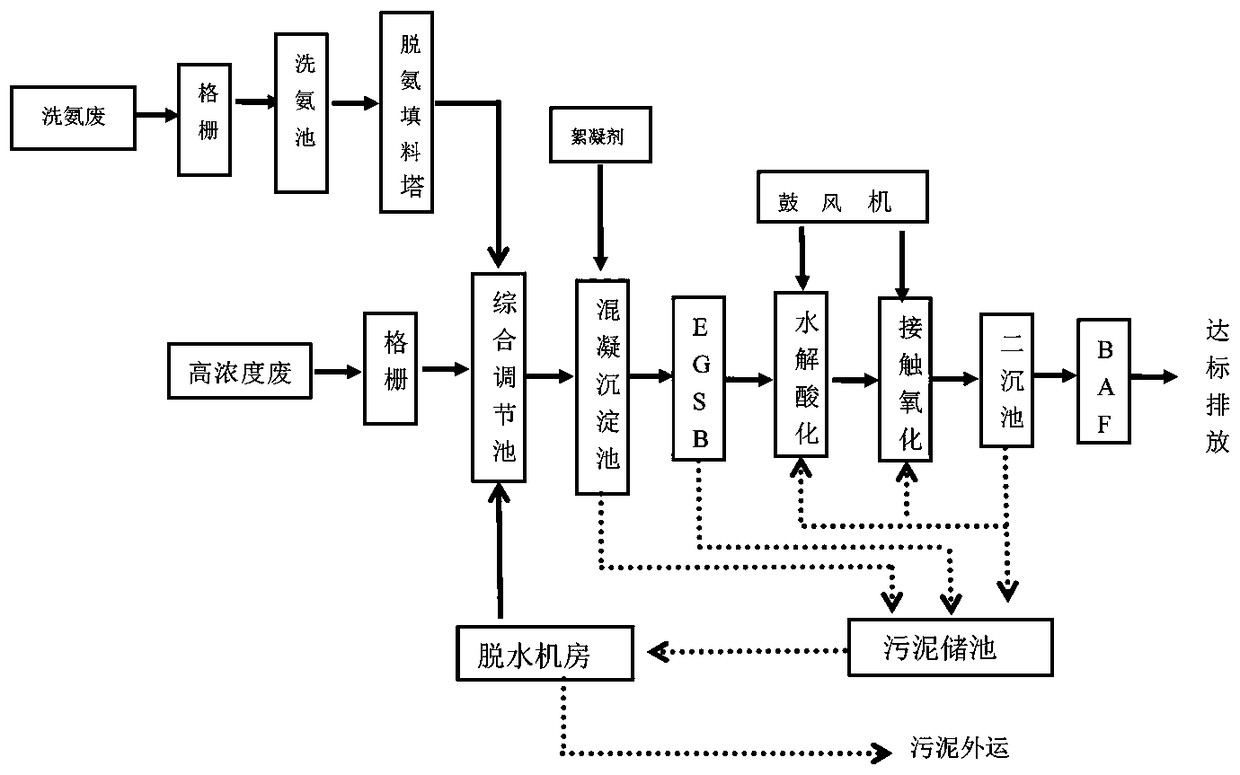

[0016] against attached figure 1 According to the technological process, the incoming water from the workshop is divided into two kinds of wastewater, one is high-concentration wastewater and the other is ammonia washing wastewater. The ammonia washing wastewater is discharged from the workshop into the ammonia washing wastewater grid well of the sewage station to remove large suspended solids, so as not to block the pump and valve, and enter the ammonia washing tank for collection. After being lifted by the pump to the deammonization packing tower, the stripping conditions are controlled, and the After the ammonia is blown off, it enters the comprehensive adjustment tank. The high-concentration wastewater is discharged from the workshop into the high-concentration wastewater grid. After removing the large suspension, it enters the comprehensive adjustment tank to mix with the stripped ammonia washing wastewater. Here, the mixed comprehensive wastewater is pumped up to In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com