Waste paper-plastic composite paper-plastic separation and plastic-sheet granulation production system

A paper-plastic separation and composite material technology, applied in solid separation, filter screen, grille, etc., can solve the problems of complex smoke components, unsuitable for granulation, high production cost, etc., and achieve suitable for granulation, low labor intensity, The effect of less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

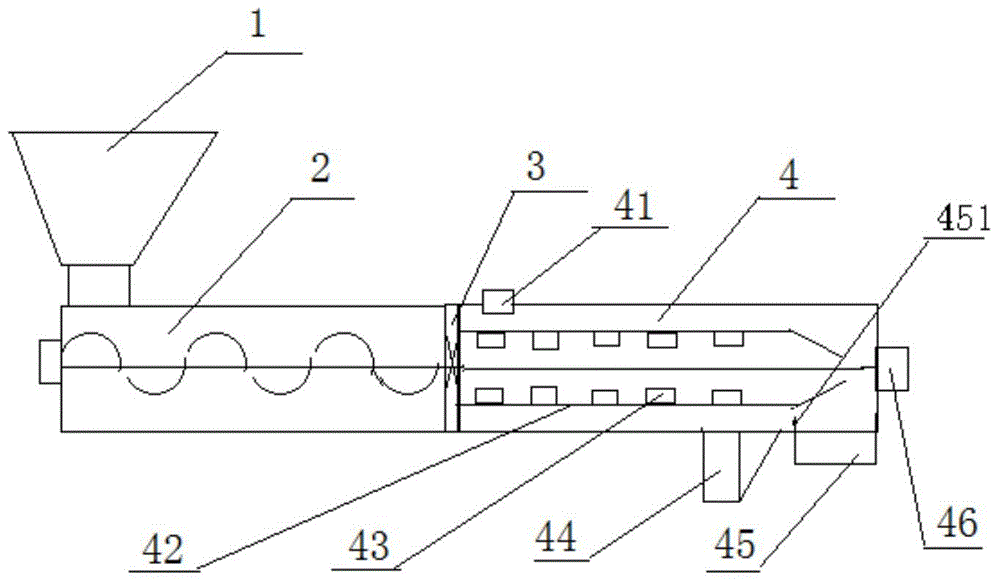

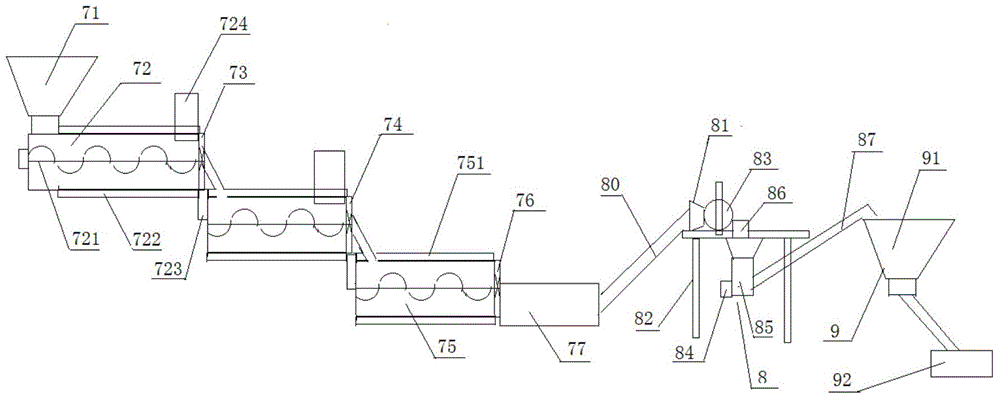

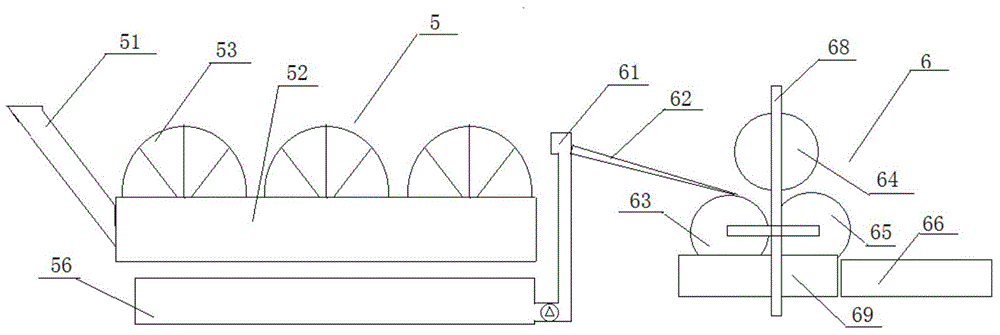

[0044] A paper-plastic separation-plastic-skin granulation production system for waste paper-plastic composite materials in this embodiment includes a paper-plastic separation device, an extrusion molding device, and a granulation device connected in sequence, and also includes a pulp Treatment units and fume treatment units connected to extrusion molding units; e.g. figure 1 As shown, the paper-plastic separation device includes a feed inlet A1, a material pushing mechanism 2, an extruder 3 and a friction mechanism 4. Both the material pushing mechanism 2 and the friction mechanism 4 are barrel structures, and the feeding inlet 1 is set on the material pushing mechanism. 2 and communicate with it, the extruder 3 is detachably installed on the other end of the material pushing mechanism 2; the friction mechanism 4 is connected with the discharge end of the extruder 3; as figure 2 As shown, the extrusion molding device includes a feed hopper 71, an extrusion mechanism 72, a fi...

Embodiment 2

[0053] The paper-plastic separation-plastic-skin granulation production system of waste paper-plastic composite material in this embodiment has the same basic structure as that of embodiment 1, except that the extruder 3 is a cross-knife structure; the material pushing mechanism 2 is a screw propulsion Type structure; friction mechanism 4 comprises water inlet 41, vertical angle screen 42, slurry outlet 44, plastic outlet 45 and motor A46, and water inlet 41 is arranged on the position above the left end of friction mechanism 4, and the volume of water in friction mechanism 4 is 60%% of the total capacity; the vertical angle sieve 42 and its motor A46 are inside the vertical angle sieve 42, and the motor A46 is fixedly arranged on the friction mechanism 4 axis at the right end. Friction blocks 43 are evenly arranged on the inner network wall; the pulp outlet 44 and the plastic outlet 45 are respectively arranged at the bottom of the friction mechanism 4 from left to right, and ...

Embodiment 3

[0062] A paper-plastic separation-plastic-skin granulation production system for waste paper-plastic composite materials in this embodiment, the basic structure is the same as that of embodiment 2, the difference is that the volume of water in the friction mechanism 4 is 70% of the total capacity; The inclination angle of the sieve 53 is 30 degrees, the number of revolutions is 2 revolutions per second, and the mesh number of the screen is 20 meshes; an automatic pounding rod is set on the feed hopper 71 to avoid blanking in the feed hopper 71 due to the relatively light plastic skin; The heater 722 is an electromagnetic heater; the extruding mechanism is provided with a temperature detection and monitoring mechanism connected to the PLC. The packaging mechanism 9 includes a collecting hopper 91 and a weighing and packaging platform 92. The upper end of the collecting hopper 91 communicates with the discharge pipe 87, and the outlet at the bottom end communicates with the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com