Regeneration processing method of substrate slice after SOI bonding process

A processing method and a bonding technology, which are applied in the field of recycling and processing of integrated circuit single crystal silicon polished wafers, can solve problems such as roughness, surface damage, and ineffective recycling of substrate wafers, and achieve the effects of reducing costs and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

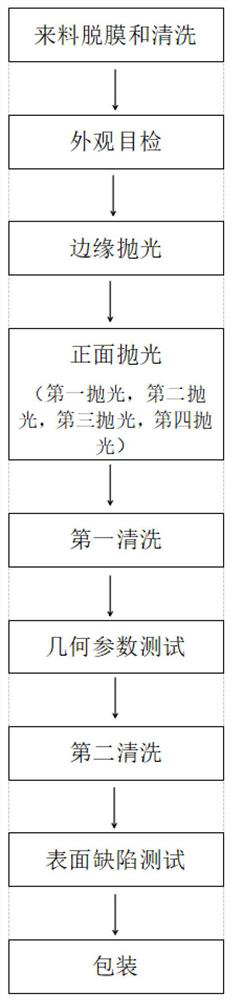

Method used

Image

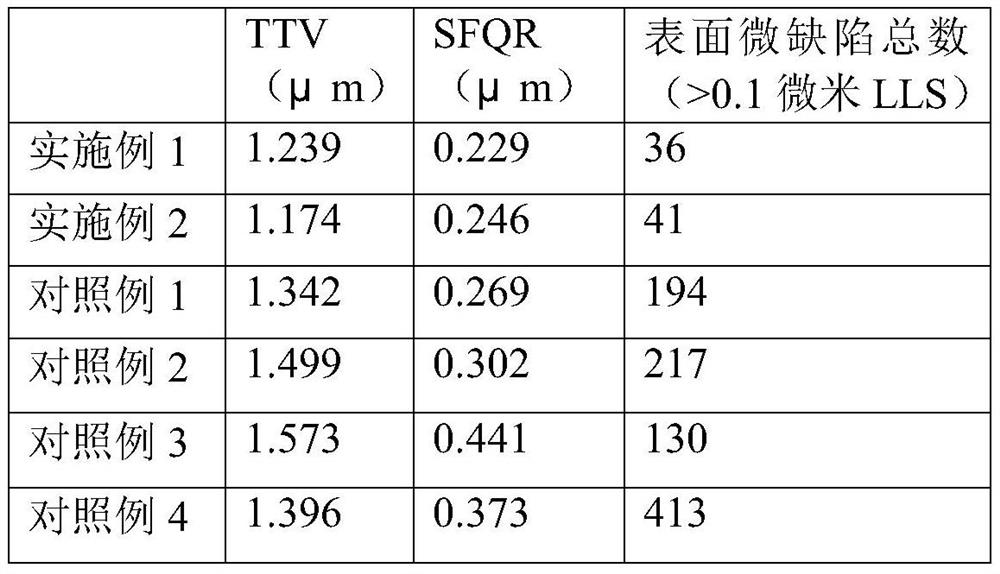

Examples

Embodiment 1

[0034] 1) Put the substrate sheet into the tetrafluoro film box, use HF solution to soak and remove the film for 5 minutes in the etching machine, the volume ratio of hydrofluoric acid and pure water in the HF solution is 1:20; then use ammonia water, The mixture of hydrogen peroxide and pure water was washed for 5 minutes at a temperature of 50° C., and the volume ratio of ammonia water, hydrogen peroxide and pure water was 1:2:20.

[0035] 2) Carry out manual appearance visual inspection under a strong light with a light intensity of 160,000 LX to confirm that the oxide film has been completely peeled off, and pick out edge chips that may cause fragments in subsequent processing.

[0036] 3) The edge of the substrate is polished, and the substrate is fixed on the vacuum chuck during the edge polishing process, and the polishing cloth with a hardness of 60 is used to polish the substrate, the polishing inclination angle is 50 degrees, the edge polishing pressure is 80N, and th...

Embodiment 2

[0050] 1) Put the substrate sheet into the tetrafluoro film box, and use HF solution to soak and remove the film for 10 minutes in the etching machine. The volume ratio of hydrofluoric acid and pure water in the HF solution is 1:30; then use ammonia water, The mixture of hydrogen peroxide and pure water was washed for 10 minutes at a temperature of 80° C., and the volume ratio of ammonia water, hydrogen peroxide and pure water was 1:1:30.

[0051] 2) Carry out manual appearance visual inspection under a strong light with a light intensity of 160,000 LX to confirm that the oxide film has been completely peeled off, and pick out edge chips that may cause fragments in subsequent processing.

[0052] 3) The edge of the substrate is polished, the substrate is fixed on the vacuum chuck during the edge polishing process, and the polishing cloth with a hardness of 80 is used to polish the substrate, the polishing inclination angle is 50 degrees, the edge polishing pressure is 120N, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com