Patents

Literature

38results about How to "Meet the requirements of the preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

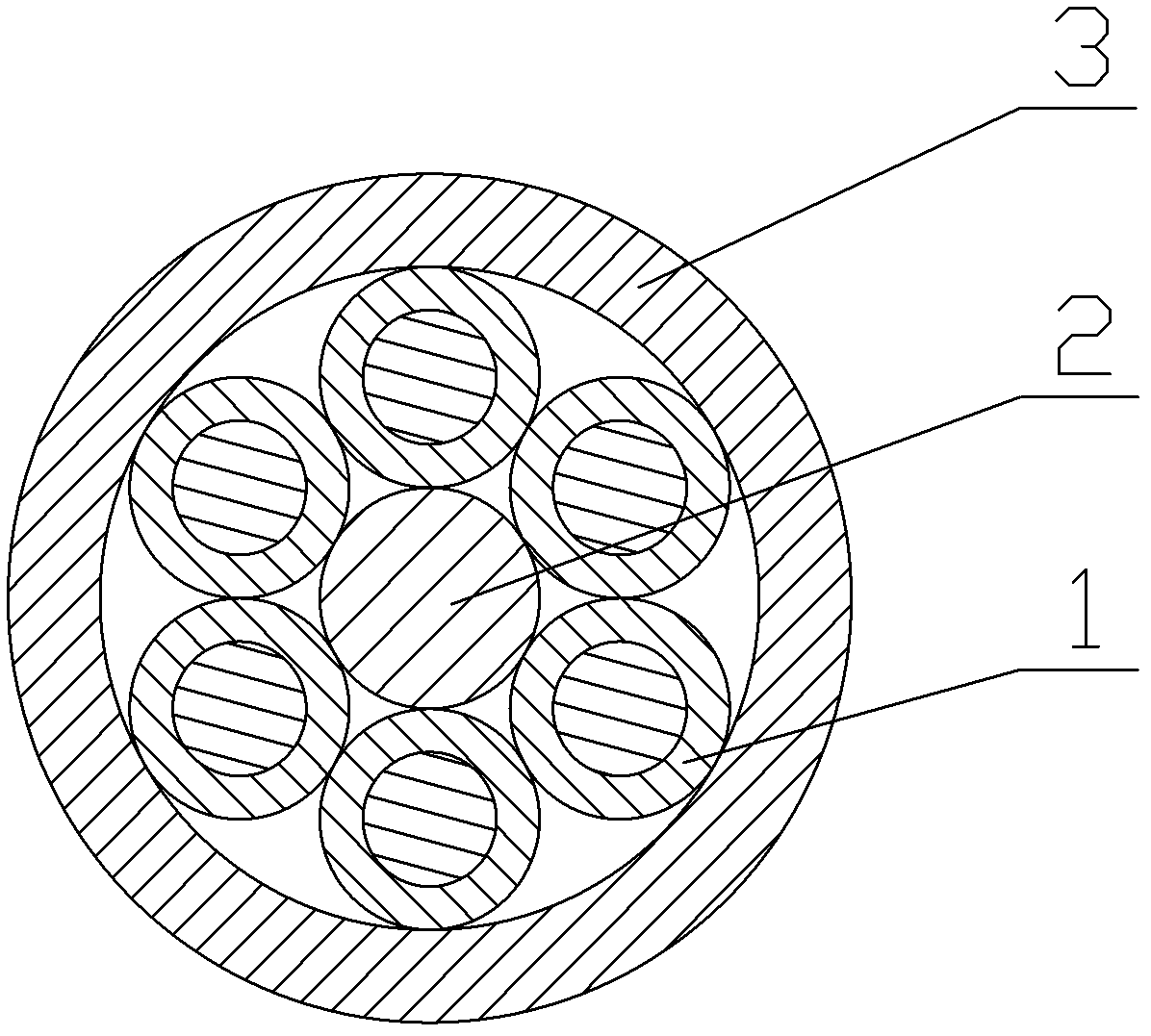

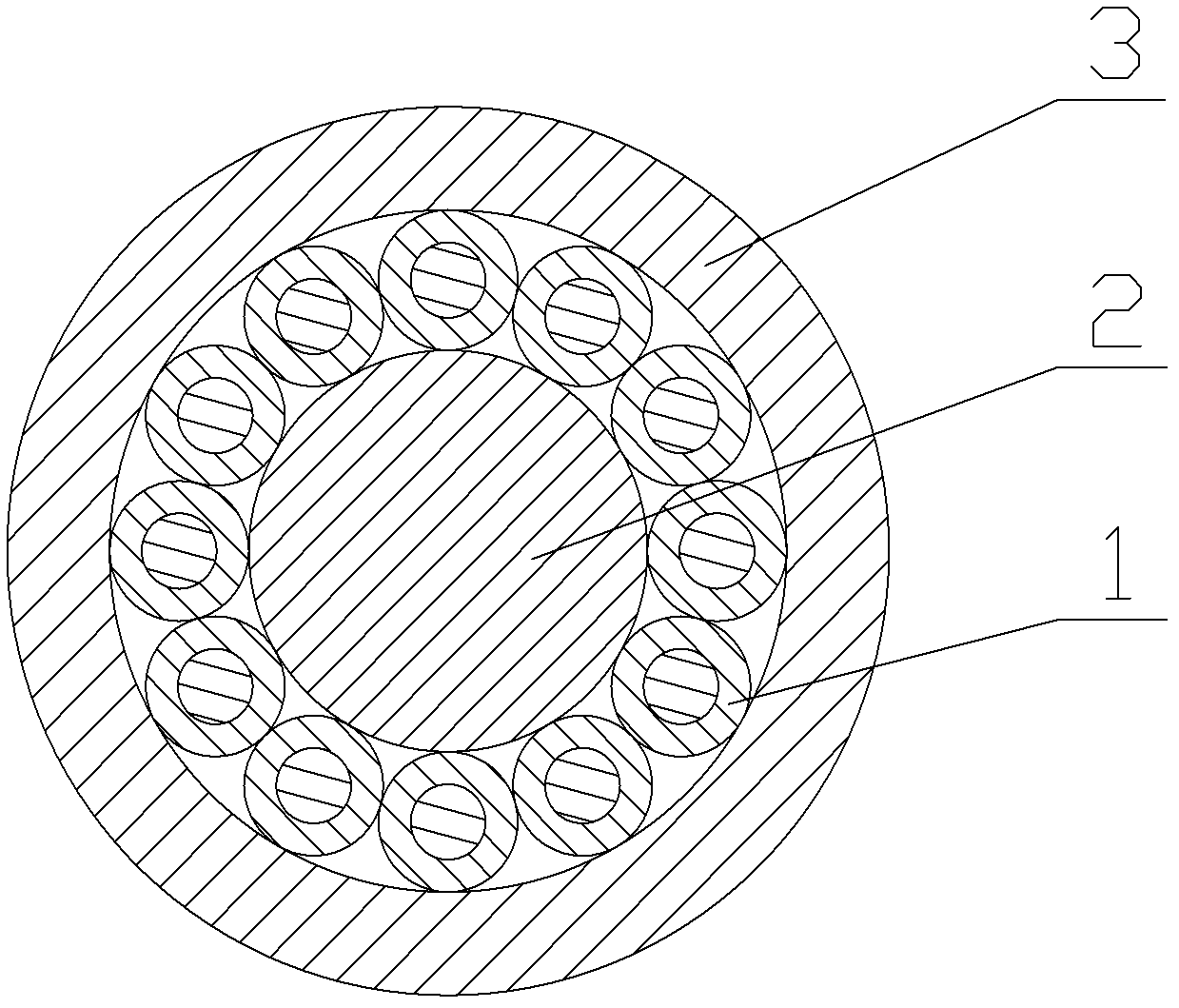

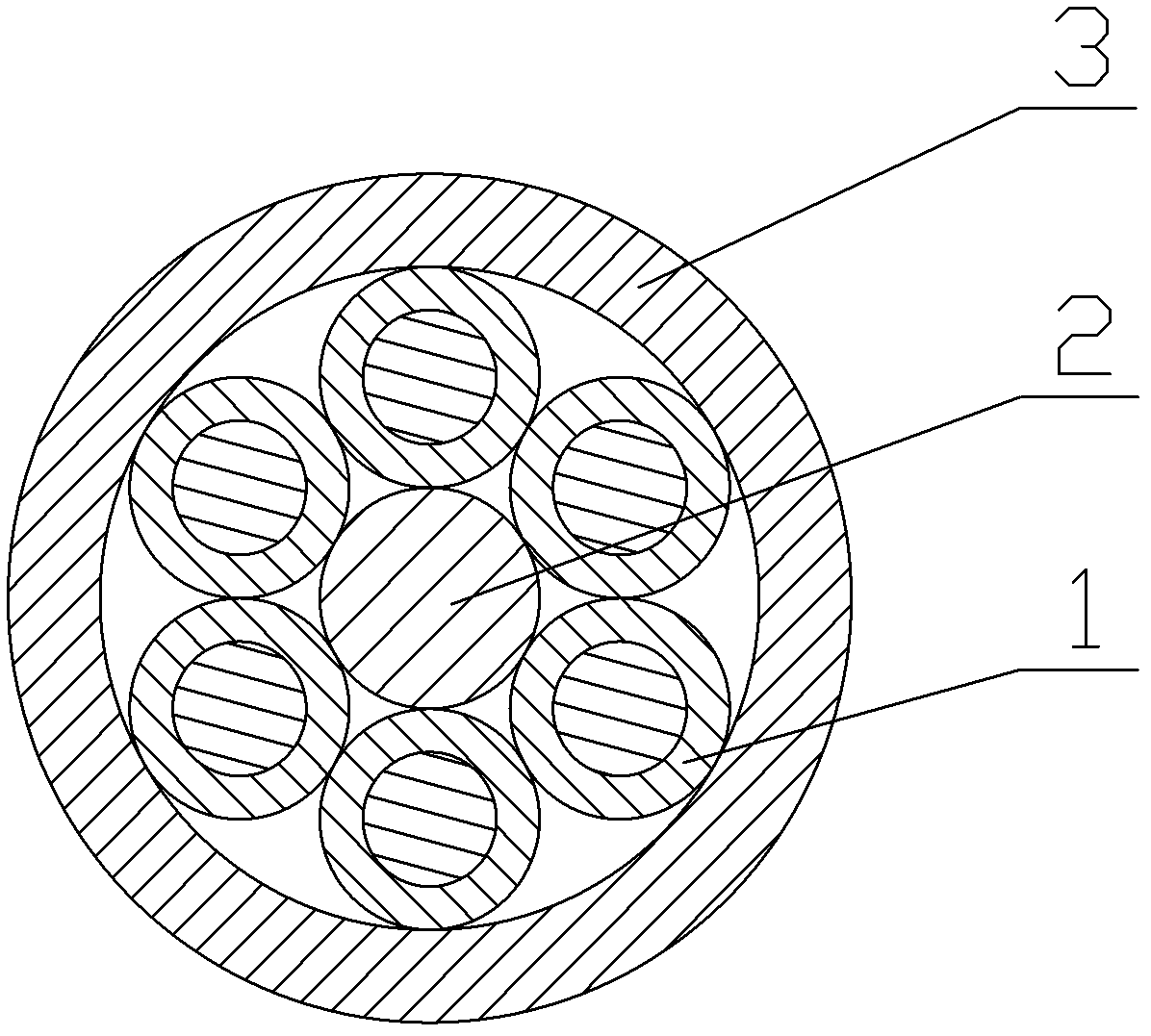

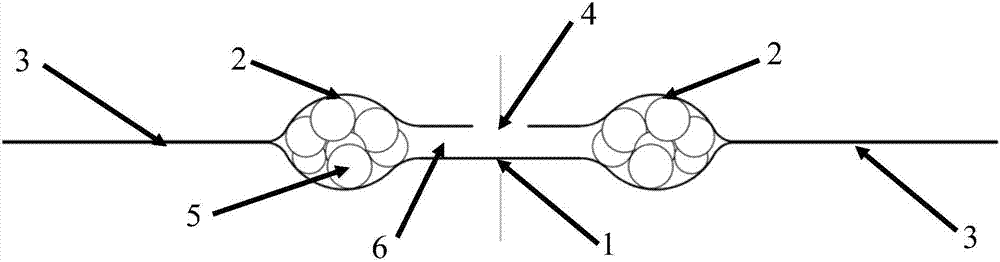

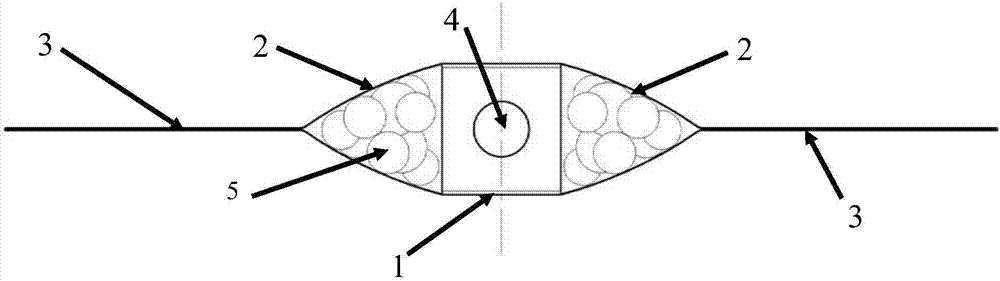

Preparation method of multi-core MgB2 superconducting wire

ActiveCN102522153AHigh degree of compoundHigh densitySuperconductors/hyperconductorsSuperconductor devicesSwagingUltimate tensile strength

The invention discloses a preparation method of a multi-core MgB2 superconducting wire. The method comprises: first, precursor power is prepared; second, the precursor power is placed in a Ta tube to prepare a tubulation complex; third, groove rolling is carried out on a single core wire; fourth, a NbTi / Cu composite rod and a plurality of single core wires are placed in an oxygen-free copper tubefor assembling so as to obtain a secondary composite rod; fifth, rotary swaging and drawing are carried out on the secondary composite rod, groove rolling is carried out and rotary swaging and drawing are carried out again, so that a multi-core wire is obtained; and sixth, heat treatment is carried out on the multi-core wire to obtain a multi-core MgB2 superconducting wire. According to the invention, processes of rotary swaging, drawing and groove rolling are combined and employed; therefore, not only is density of the multi-core wire improved, but also connectivity between crystal grains can be improved; it is beneficial to prepare a multi-core MgB2 superconducting wire with high performances; and the prepared wire has high mechanical strength and can bear great stress and strain without obvious reduction of the superconductive current carrying performance, so that a superconducting wire practical requirement can be well met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Electrochemical polishing method of nickel-tungsten alloy base-band for coated conductor

The invention discloses an electrochemical polishing method of a nickel-tungsten alloy base-band for a coated conductor. The method comprises the following steps: preparing an electrochemical polishing solution by utilizing sulphuric acid, water and propanetriol according to a certain volume ratio; taking an Ni-5at.%W base-band as an anode, taking stainless steel as a cathode, submerging the anodeand the cathode in the electrochemical polishing solution, switching on a power supply, and polishing under the voltage of 5 to 8 V and the current density of 1 to 1.3A*cm<2>, wherein the temperatureof the polishing solution is kept between 0 DEG C and the room temperature, time is controlled between 30 to 60 s, and polishing polar distance is controlled between 30 to 40 mm; and repeatedly washing and drying the base-band by alcohol and deionized water. The invention has the advantages of stable component of the polishing solution, stable polishing effect and low cost. The method can effectively reduce the roughness of the surface of the base-band on the basis of maintaining the original texture sharpness of the base-band, and is applicable to the scale polishing treatment of the Ni-5at.% base-band.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

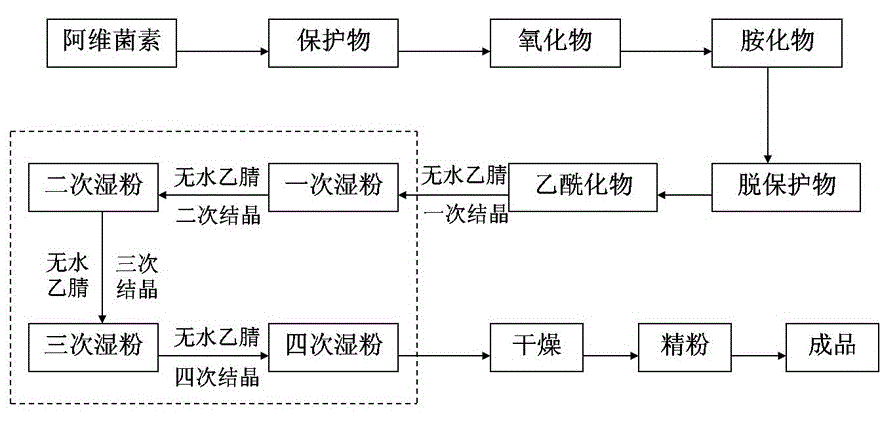

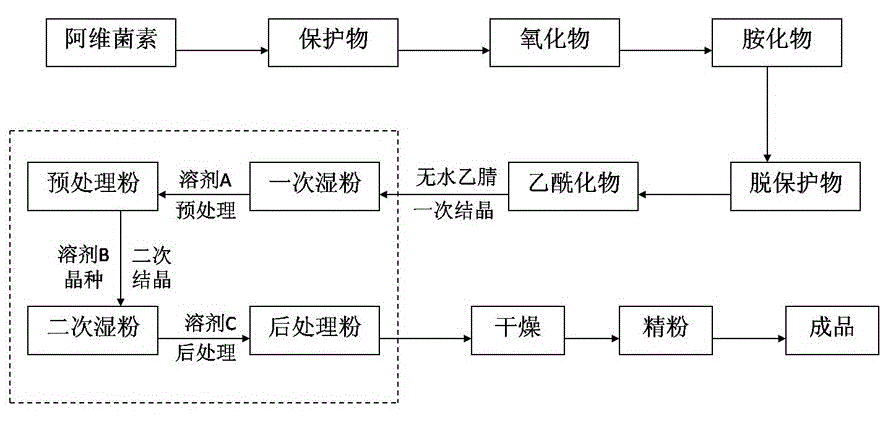

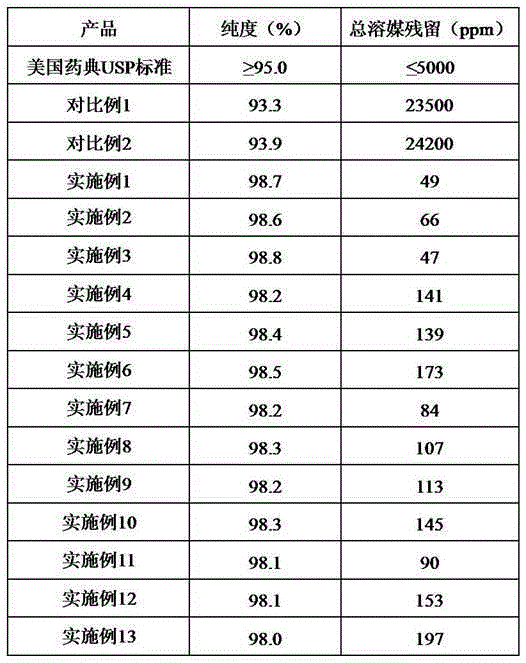

Eprinomectin refining method

ActiveCN105001289AHigh purityReduce solvent residueSugar derivativesSugar derivatives preparationAcetone / EthanolSolvent

The invention provides an eprinomectin refining method. The eprinomectin refining method comprises the following steps: primary eprinomectin wet powder is pre-treated by a solvent A at first; then the obtained product is dissolved in a solvent B; eprinomectin seed crystals are added for crystallization; then a solvent C is adopted for aftertreatment; finally, the obtained product is subjected to vacuum drying to acquire eprinomectin refined powder, wherein the solvent A is a mixed solution of one or more of n-hexane, ethyl acetate and water at any proportion; the solvent B is a mixed solution of two or more of acetone, ethanol and water at any proportion; the solvent C is a mixed solution of one or more of ethyl ether and water at any proportion. The obtained product has the purity of 98% or above, the solvent residue is reduced to be within 200 ppm, the consumption of acetonitrile is greatly reduced, the manufacturing cost is lowered, environmental pollution is reduced, the work environment is greatly improved for workers, and the body health of employees is guaranteed.

Owner:NORTH CHINA PHARMA GROUP AINO

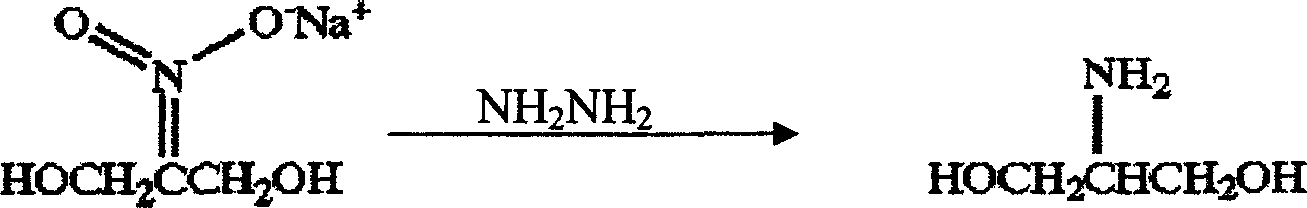

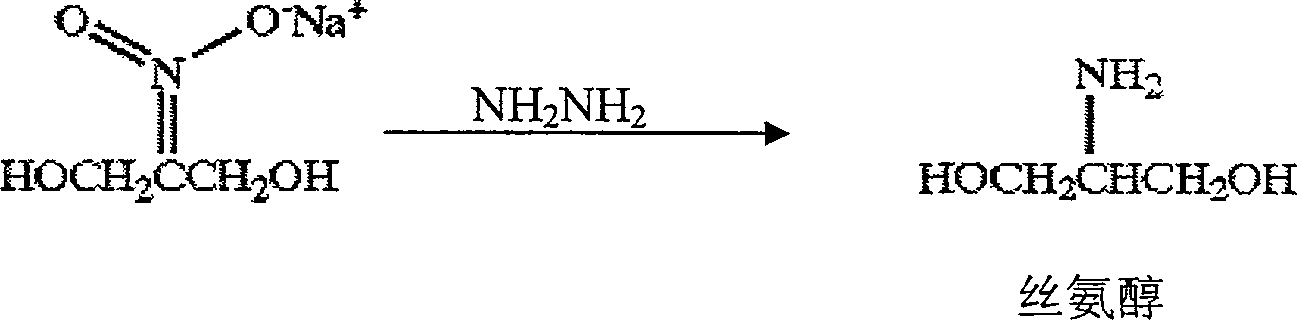

Preparation method of serinol

InactiveCN1948272AHigh product purityAvoid High Pressure Catalytic HydrogenationOrganic compound preparationAmino-hyroxy compound preparationPalladiumHydrazine compound

The present invention relates to a preparation method of serinol, belonging to the field of serinol preparation technology by using reduction reaction. Said serinol is an important intermediate body for preparing nonionic X-ray contrast agent iopamidol. Said invention uses 2-nitro-1,3-propanediol sodium salt as raw material, uses hydrazine hydrate as reducing agent and uses palladium / carbon as catalyst to prepare serinol at normal pressure.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

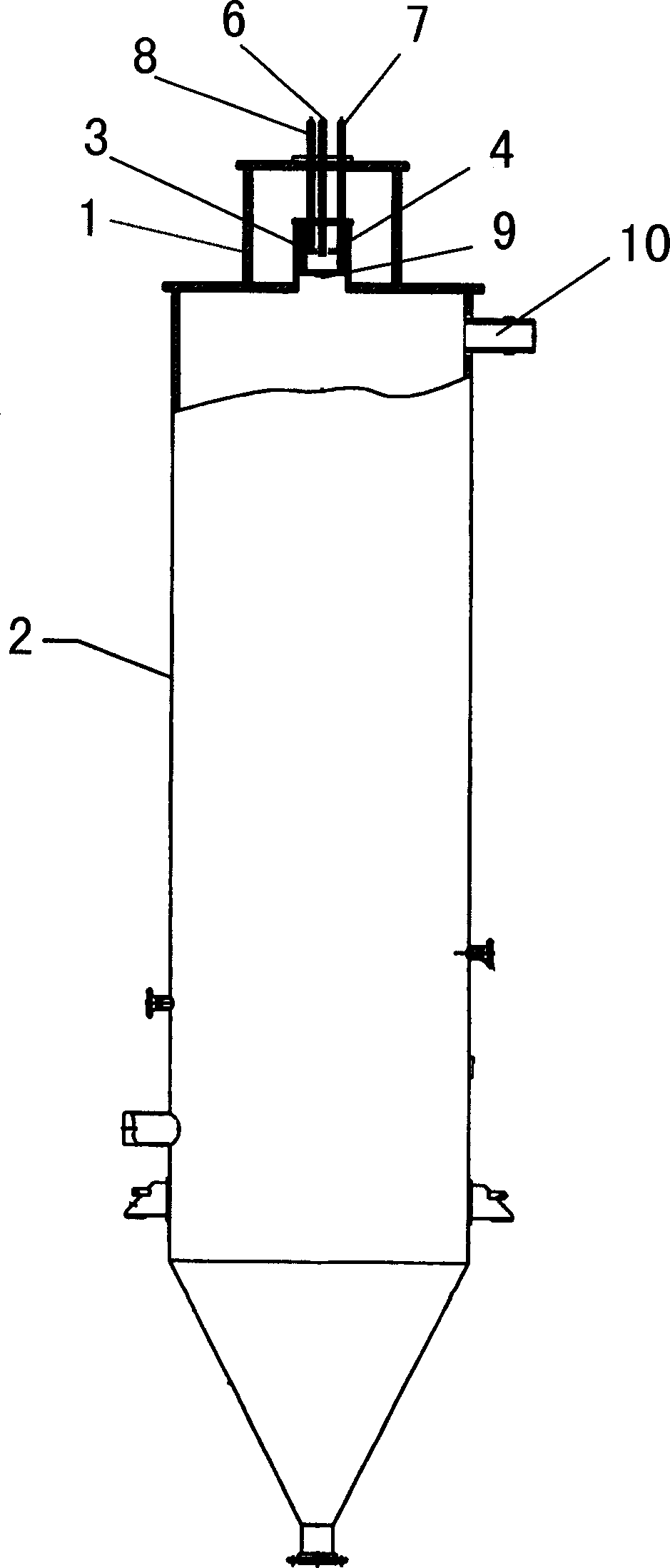

Method and equipment for preparing nano grade biological powder material

This invention relates to preparation method and equipment for nano-level biological-power raw material which comprises, employing microwave to assist abstraction of continual flow liquid at low temperature, condensing thin membrane and decompressing, and carrying out low temperature supersonic jet spray drying; fit to large range material, and can make obtain needed constituent activity with no damage.

Owner:西安邦肽实业有限公司

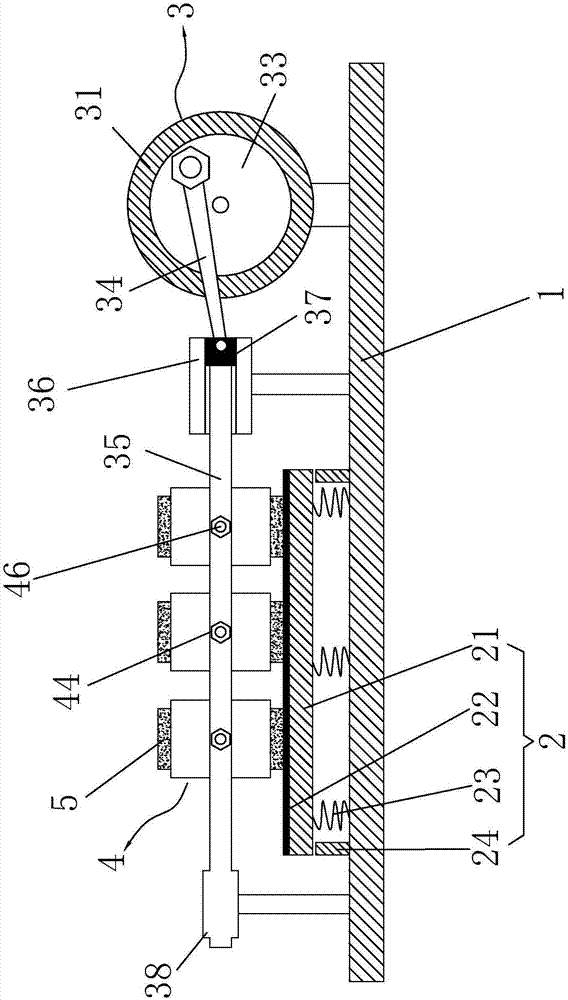

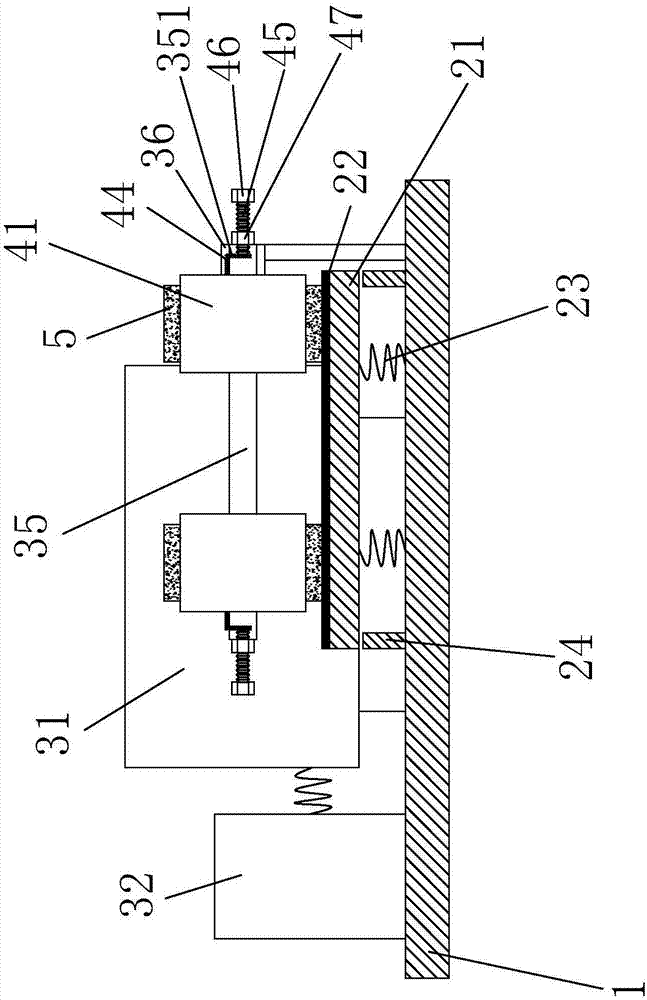

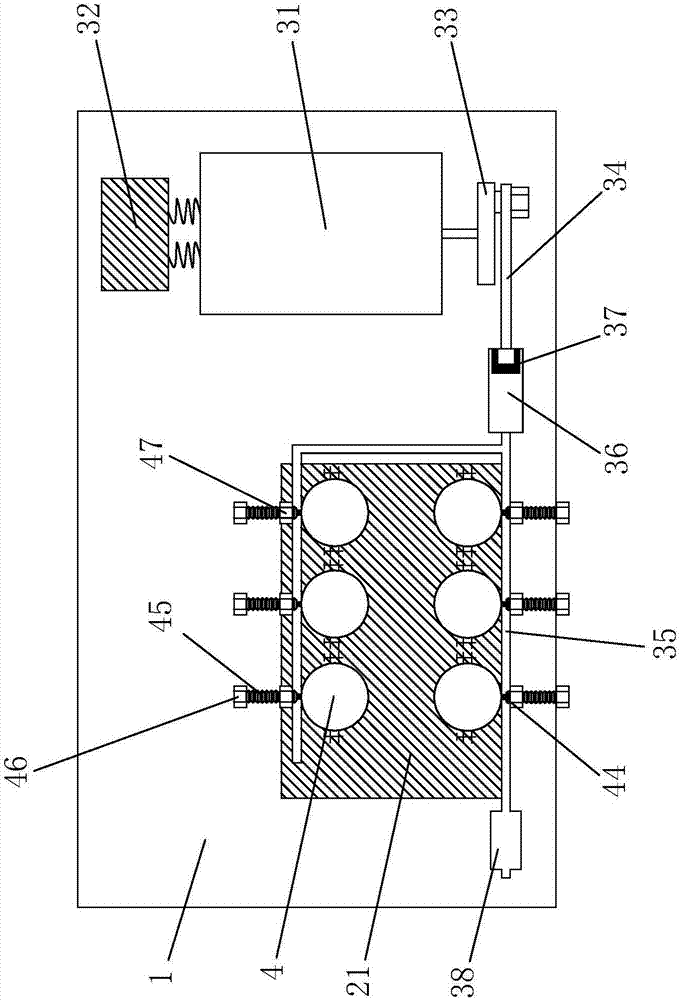

Fragile transverse plane grinding machine used for rock test

ActiveCN107044931AMeet the requirements of the preparationContact stabilityPreparing sample for investigationReciprocating motionCrank

The invention discloses a fragile transverse plane grinding machine used for a rock test. The fragile transverse plane grinding machine comprises a pedestal, a workbench mechanism, an actuating mechanism and a clamping mechanism, a workbench is connected with the pedestal through an elastic component and is limited to a press height by a stop block, sand paper is arranged on the workbench, the actuating mechanism uses a crank slide block principle to realize linear repetitive motion from motor rotation to a guide rod, the clamping mechanism is connected with the guide rod for clamping a rock sample, the rock sample is driven by the motion mechanism, the bottom performs reciprocating motion on the sand paper, and thereby polishing is realized. The grinding machine realizes the stable contact of the rock sample and the sand paper as well as automatic grinding, requirement of rock mechanics test on the extremely fragile rock sample can be satisfied, rate of section edge damage of the rock sample is reduced, and a traditional form of preparation of the fragile rock by artificial operation can be avoided. The structure is simple, the application of the grinding machine is convenient, and the grinding machine is convenient for popularization to the field of the preparation of the rock sample used for indoor rock mechanics test.

Owner:HUAQIAO UNIVERSITY

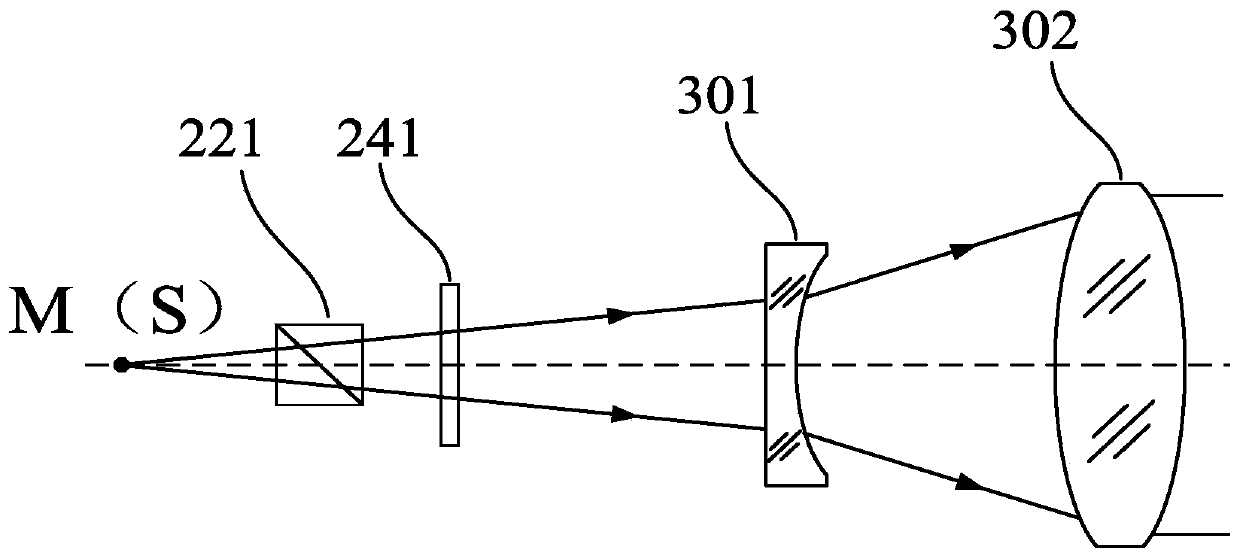

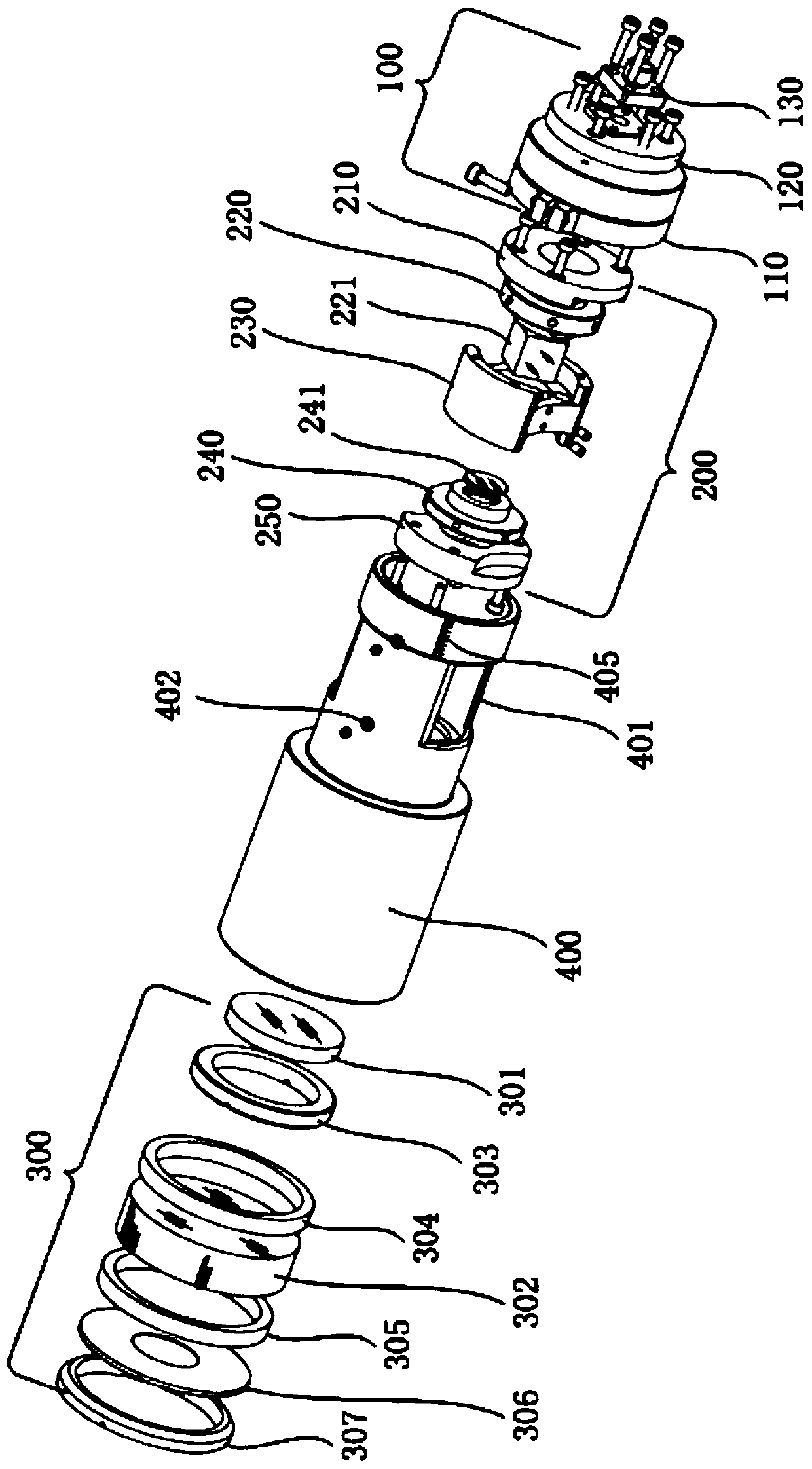

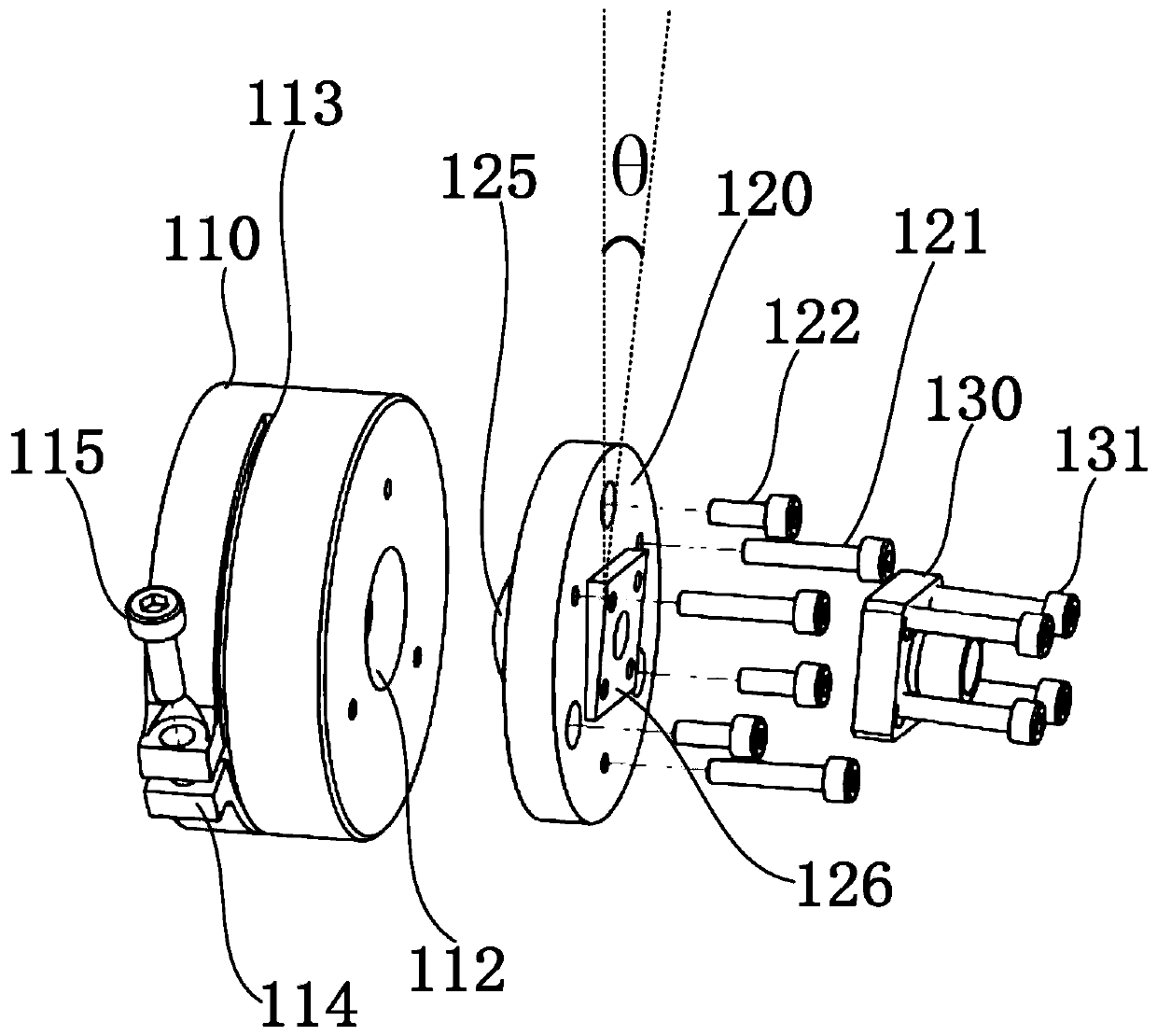

Polarization-adjustable laser beam expansion collimator

PendingCN110568625AAccurate adjustment effectKeep properlyOptical devices for laserOptical elementsPolarization-maintaining optical fiberLight beam

In order to overcome the defect that the polarization of an input laser beam cannot be accurately adjusted and maintained by an existing beam expansion collimator, the invention provides a polarization-adjustable laser beam expansion collimator employing magnetic optical trap, optical trap and other structure cold atomic physical experiment systems. A polarization prism and a slide of which polarization axis can be independently and accurately adjusted are arranged in an optical path, the polarization state of a light beam input from a polarization-maintenance optical fiber can be accurately adjusted and maintained, the fluctuation of a laser power is reduced, the change of the polarization state of an emergent light beam caused by the polarization-maintenance optical fiber is eliminated,and the requirement of high-quality ultracold atom preparation is met.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

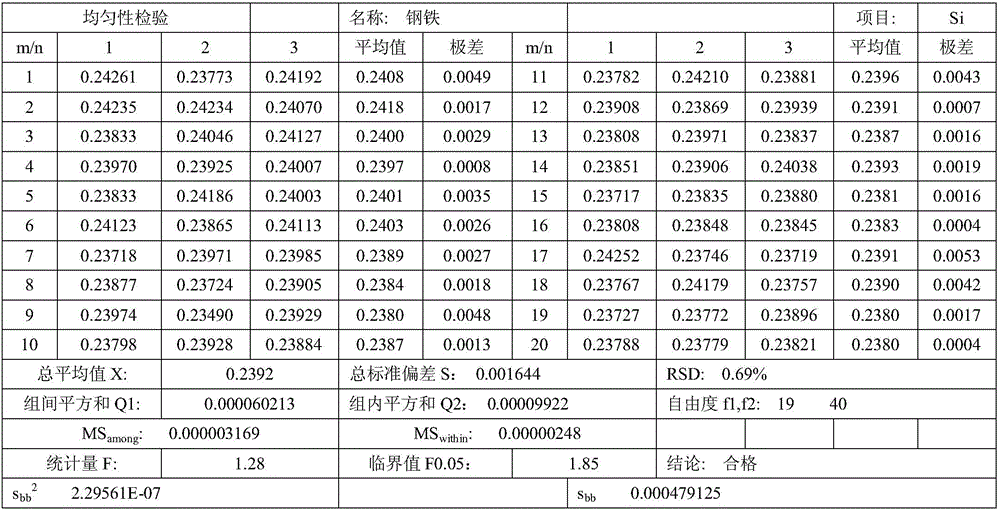

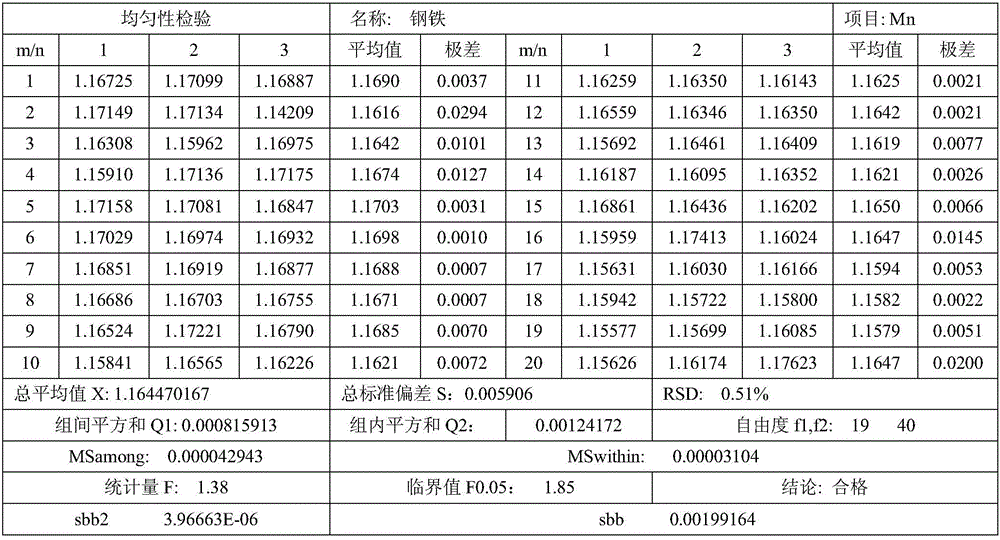

Preparation method for standard spectral sample and application of standard spectral sample

InactiveCN105928754AImprove uniformityUniformityPreparing sample for investigationAnalysis by material excitationSpectral analysisStandard samples

The invention specifically relates to a method for developing or producing a standard spectral sample and application of the standard spectral sample to a spectral analysis instrument, belonging to the technical field of analytical chemistry. The method provided by the invention comprises the following steps: a, material acquisition: cutting off a piece of a blank material from a large finished section and carrying out peeling; b, cold forging and molding: subjecting the peeled blank material obtained in the step a to cold forging so as to obtain a sample meeting requirements of spectral testing; and c, later processing: subjecting the sample obtained in the step b to surface peeling, polishing and cutting so as to obtain the standard sample meeting requirements of spectral testing. The method provided by the invention has the characteristics of easy operation, short preparation flow, good uniformity and qualified rate of products, low cost, capacity of realizing large-batch rapid production, etc., and overcomes the problem of nonuniform segregation in traditional preparation of the standard spectral sample and disadvantages of conventional methods.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

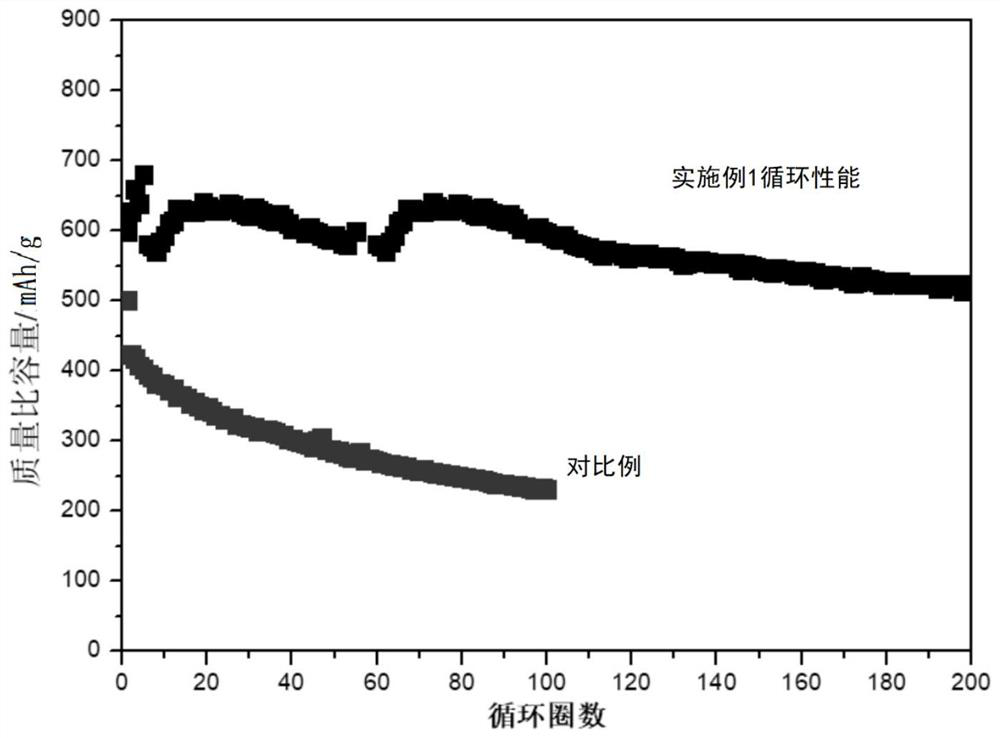

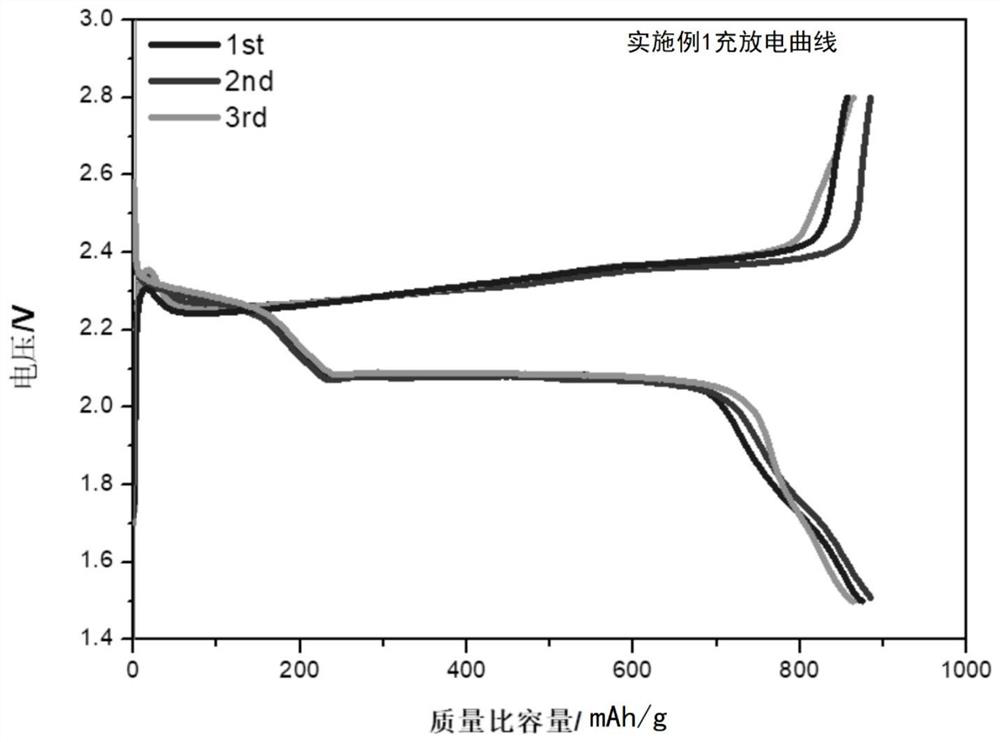

Poly-sulfur positive electrode material and lithium-sulfur secondary battery prepared from same

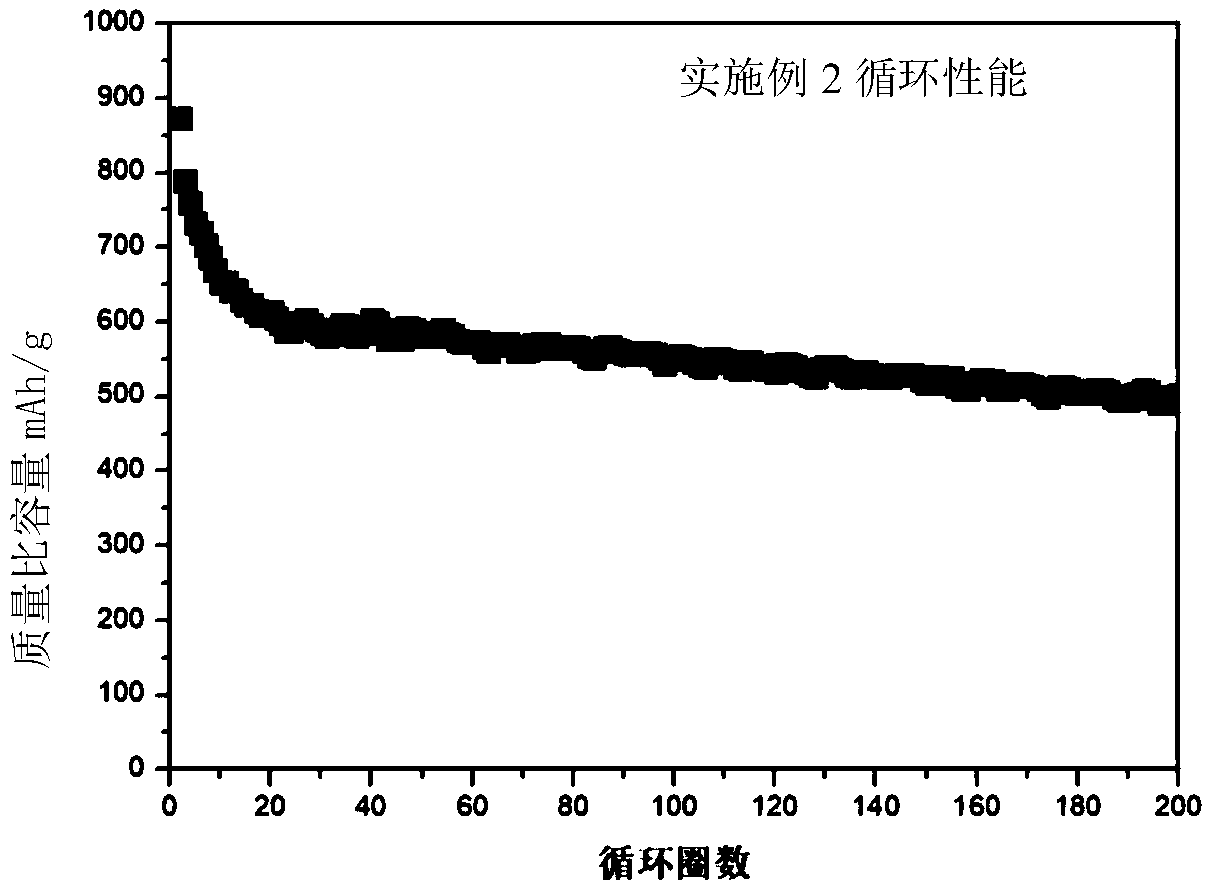

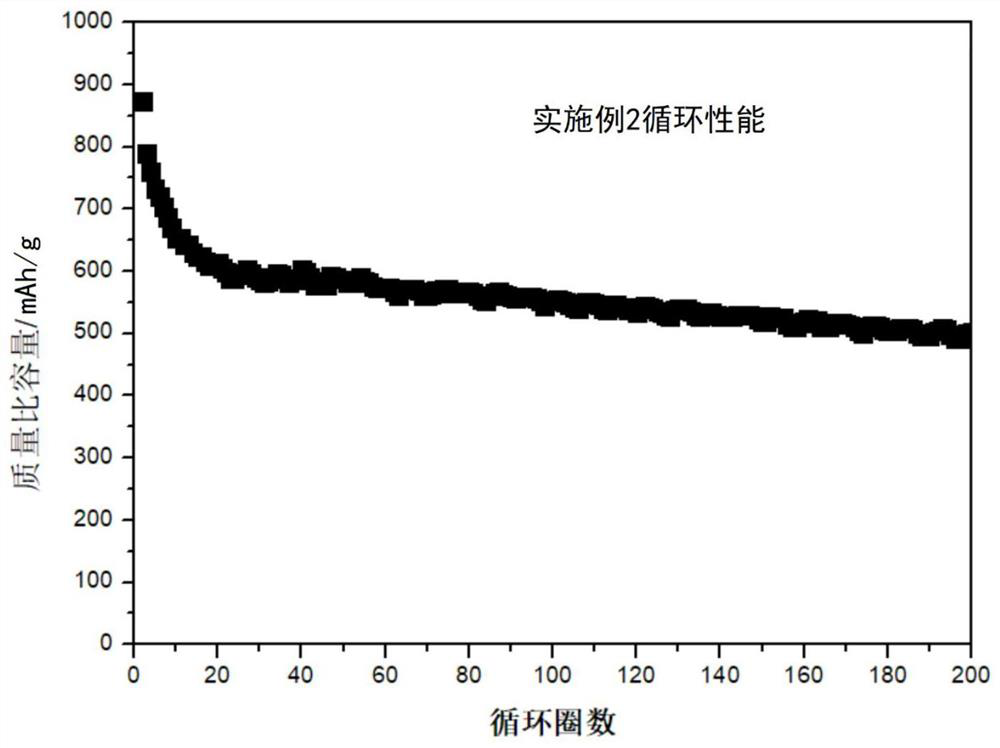

ActiveCN109575288AMeet the requirements of the preparationLow priceCell electrodesLi-accumulatorsMolten stateMaterials preparation

The invention provides a poly-sulfur positive electrode material. Steps for preparing the poly-sulfur positive electrode material include 1), carrying out polymerization reaction on simple sulfur substances in molten states and thiuram organic polymerizing agents; 2), grinding and smashing reaction products after the polymerization reaction is completely carried out. The thiuram organic polymerizing agents are a type or a plurality of types of thiuram monosulfide, thiuram disulfide and thiuram polysulfide. The invention further provides a lithium-sulfur secondary battery prepared from the poly-sulfur positive electrode material. The poly-sulfur positive electrode material and the lithium-sulfur secondary battery have the advantages that the material preparation requirements can be met by simple heating equipment, processes for producing the poly-sulfur positive electrode material are convenient to operate and are simple, thiuram is extremely low in cost, and accordingly the poly-sulfurpositive electrode material is low in synthesis cost; macromolecular polymerized sulfide can be polymerized, the related problems such as poly-sulfur dissolution and shuttling of lithium-sulfur batteries can be solved when poly-sulfur is used as a positive electrode of the lithium-sulfur secondary battery, and the lithium-sulfur secondary battery is stable in cycle performance and long in cycle life.

Owner:BEIHANG UNIV

Method for purifying cefazolin acid

ActiveCN104610282APrevent precipitationAvoid degradationOrganic chemistryPurification methodsCefazolin Sodium

The invention discloses a method for purifying a cefazolin acid, which is implemented by preparing a crude cefazolin acid product with a content of less than 97% into a sodium salt firstly; then, carrying out adsorption on the sodium salt by using a macroporous resin so as to remove impurities; and finally, reducing the sodium salt to an acid, so that the content, individual impurity and color grade of the obtained cefazolin acid satisfy the demands of being directly used for preparing cefazolin sodium by using a freeze-drying method; and the cefazolin acid can be directly used. The method disclosed by the invention overcomes the defects that single purification in existing purification methods can not meet the requirements of use.

Owner:石药集团中诺药业(石家庄)有限公司

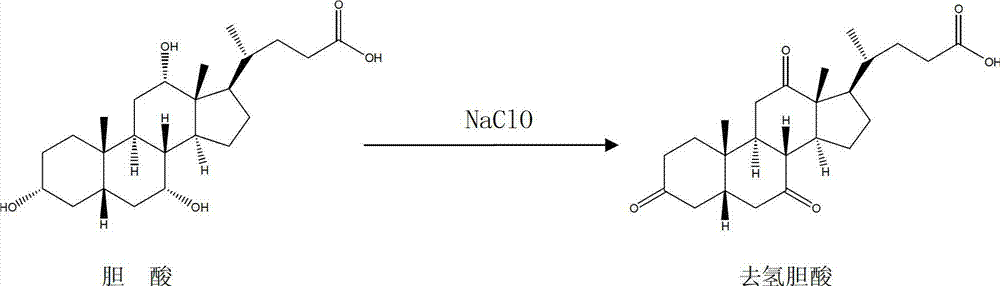

Efficient synthetic method for medicinal high-purity dehydrocholic acid

The invention discloses an efficient synthetic method for medicinal high-purity dehydrocholic acid. The method is characterized by comprising the following steps: A, cholic acid is evenly dispersed by using acetone, then concentrated sulfuric acid is added for dissolving; sodium hypochlorite is dripped, after the reaction is finished, water is added for mixing and filtering, and is used for washing until the neutral property is obtained, and then the drying is implemented to obtain a crude redox product; and B, after the acetone is added in the crude product of the step A for dissolving, enough silica gel is added for absorbing acid and cholic acid derivative of the crude product, after the absorption is finished, acetone solution of the dehydrocholic acid is obtained through filtering, the acetone solution is dried by distillation, and is added with sodium hydroxide solution for dissolving, then acetic acid solution is dripped, and is crystallized to separate out a dehydrocholic acid crystal, and then the filtration and the drying are implemented to obtain the finished product. The invention aims to overcome the defects in the prior art, and provides the efficient synthetic method for the medicinal high-purity dehydrocholic acid; and the method has the advantages of simple technique, high product purity, high yield, lower production cost, safety and reliability.

Owner:ZHONGSHAN BAILING BIOTECHNOLOGY CO LTD

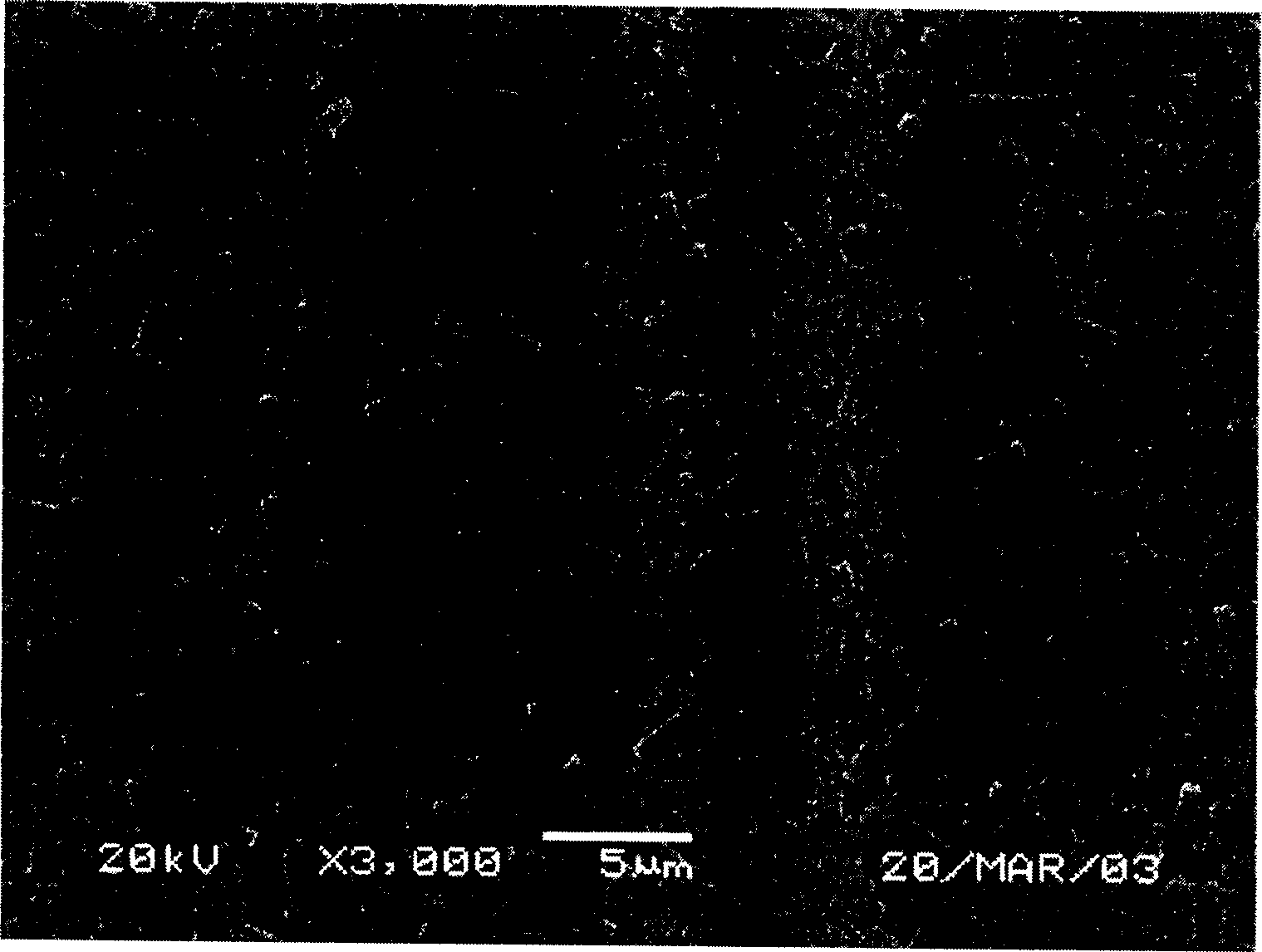

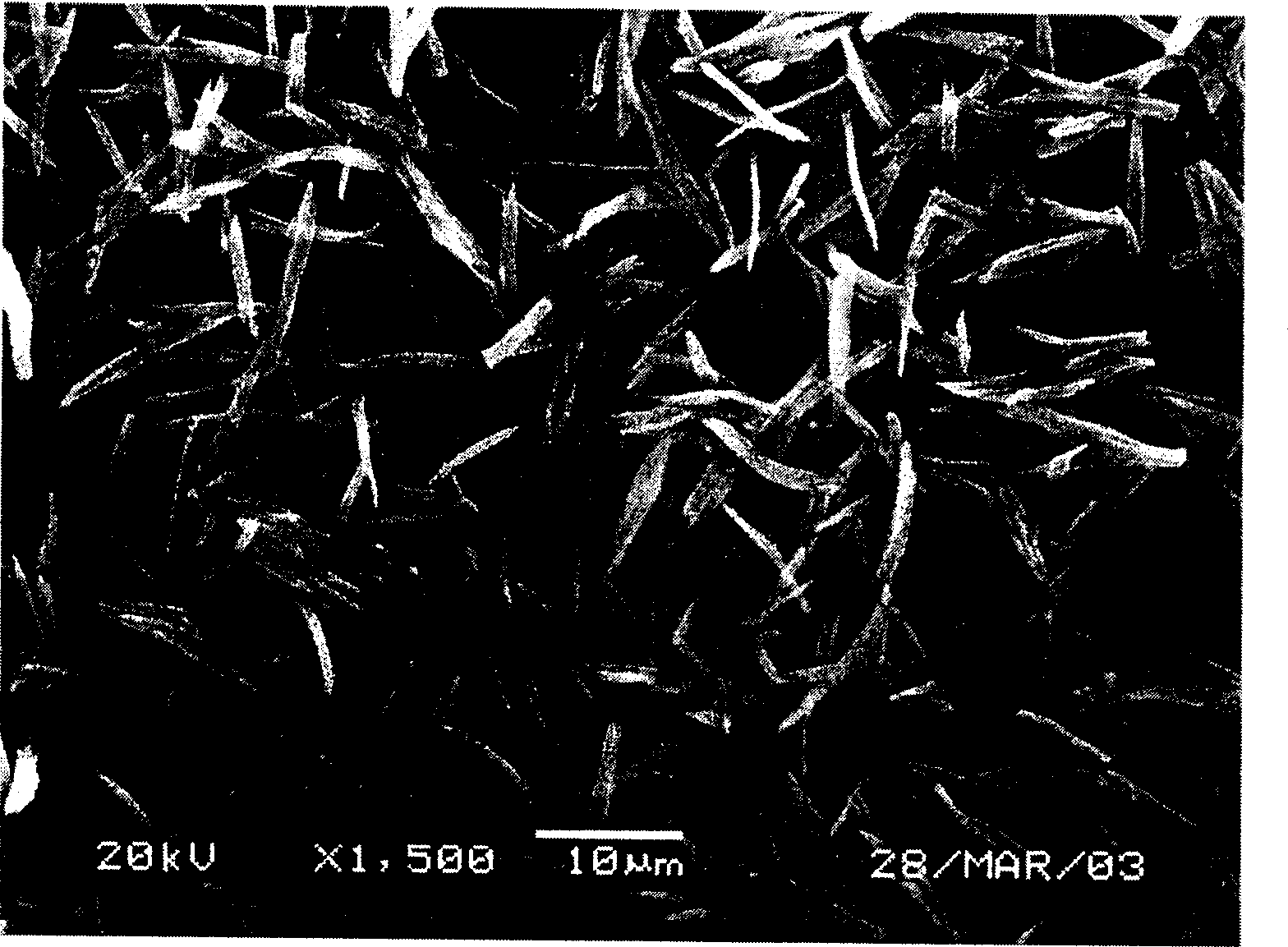

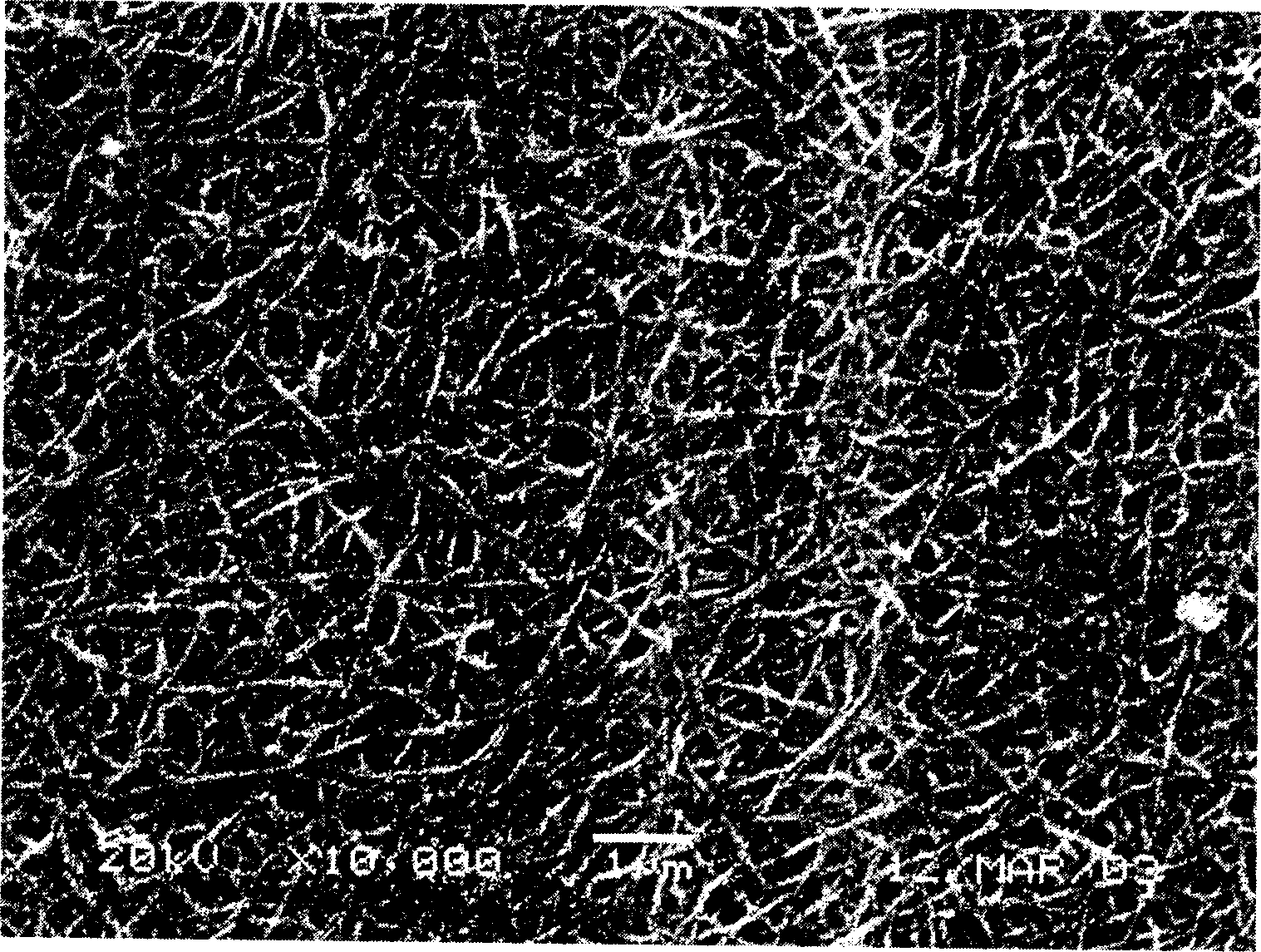

Method for preparing phthalocyanine film

InactiveCN1445873ANo impuritiesThickness can be adjustedLiquid surface applicatorsFinal product manufacturePhthalocyanineOrganic semiconductor

A preparing method for phthalocyanine film includes such steps as: 1) putting phthalocyanine into solvent as mass ratio of 1:1000 to 100000 for mixing to obtain phthalocyanine solution with solid content of 0.001%-0.1% by mass and 2) immersing baseplate into the above-mentioned phthalocyanine solution and carrying on the external field action for one minute to one hour for obtaining the phthalocyanine film on the baseplate, furthremore obtaining the dried phthalocyanine film in thickness of 10nm to 1 mum by removing the solvent.

Owner:ZHEJIANG UNIV

A kind of purification method of cefazolin acid

ActiveCN104610282BMeet the requirements of the preparationReduce manufacturing costOrganic chemistryPurification methodsFreeze-drying

The invention discloses a method for purifying a cefazolin acid, which is implemented by preparing a crude cefazolin acid product with a content of less than 97% into a sodium salt firstly; then, carrying out adsorption on the sodium salt by using a macroporous resin so as to remove impurities; and finally, reducing the sodium salt to an acid, so that the content, individual impurity and color grade of the obtained cefazolin acid satisfy the demands of being directly used for preparing cefazolin sodium by using a freeze-drying method; and the cefazolin acid can be directly used. The method disclosed by the invention overcomes the defects that single purification in existing purification methods can not meet the requirements of use.

Owner:石药集团中诺药业(石家庄)有限公司

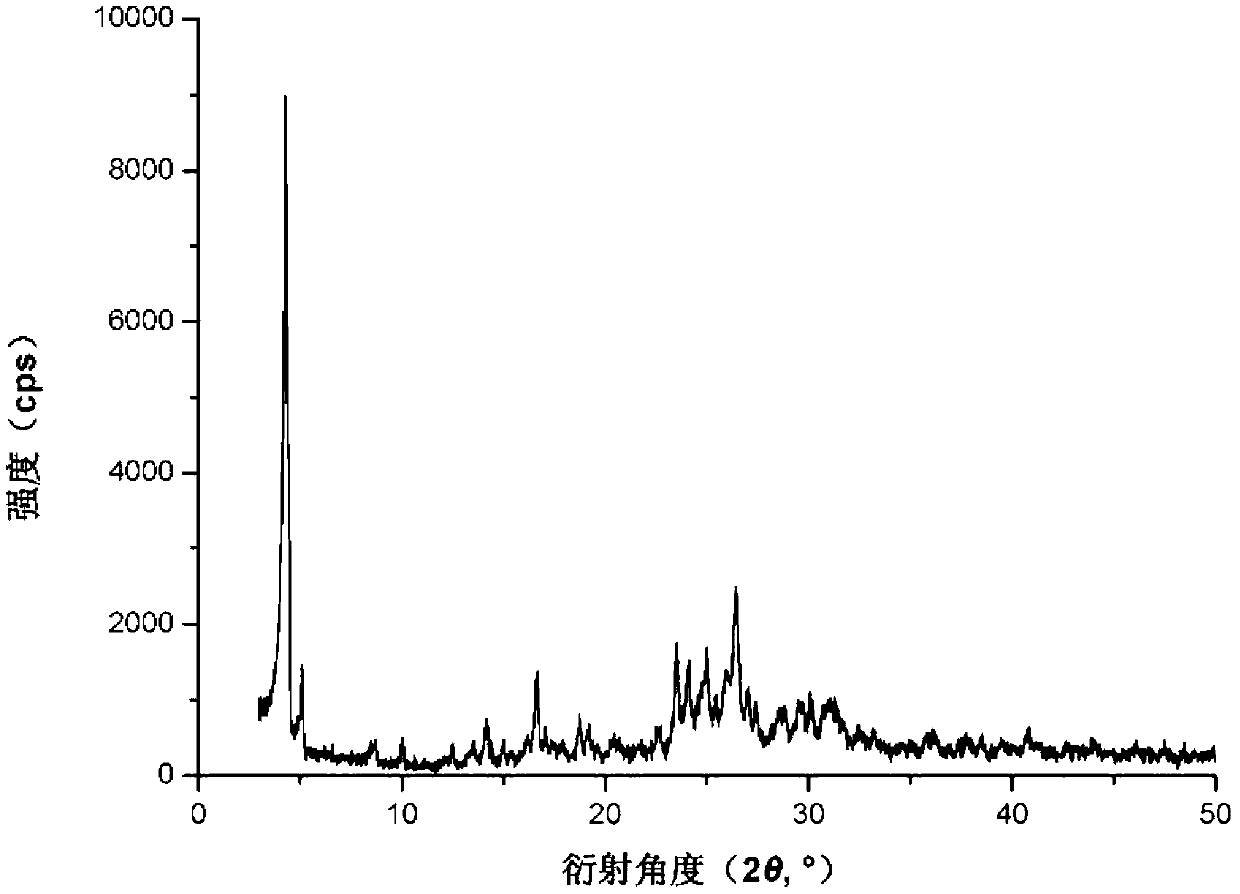

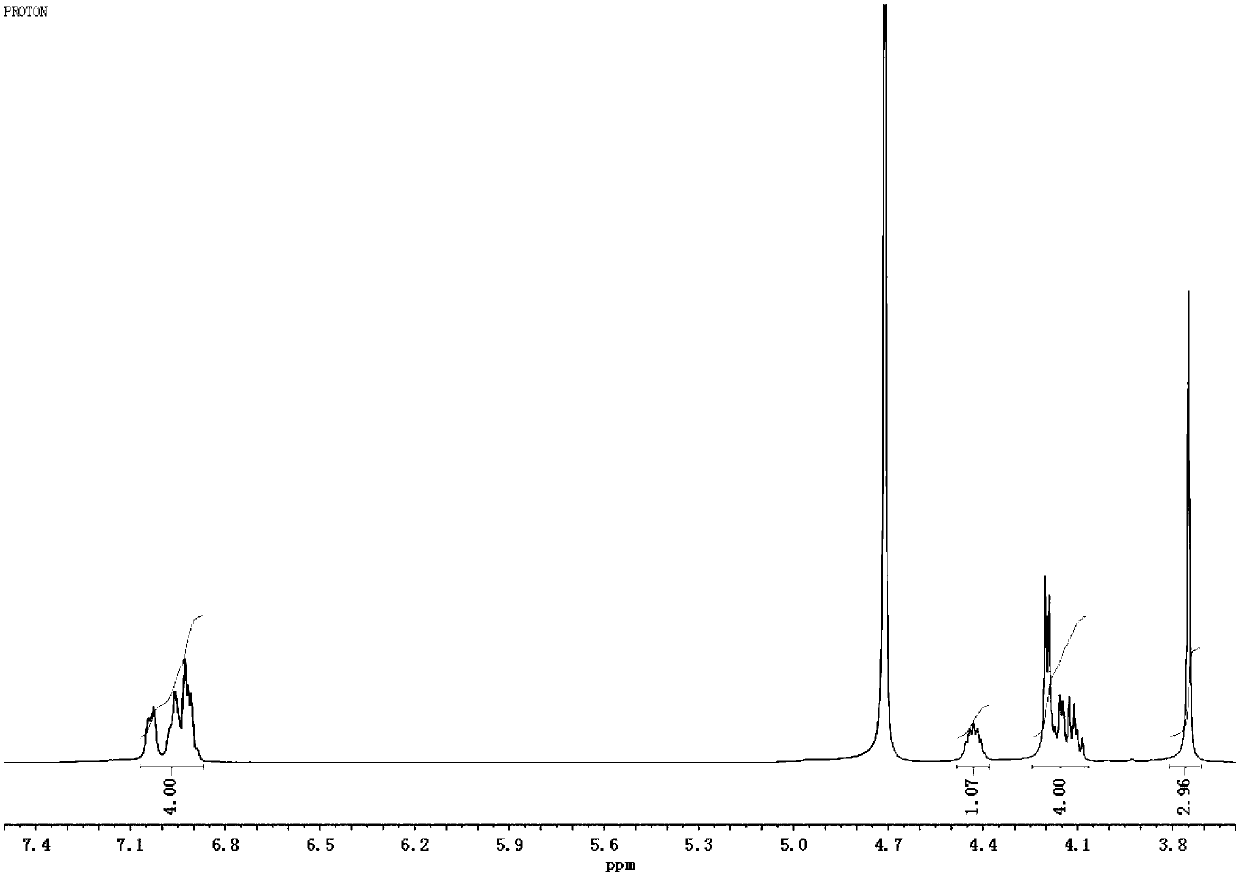

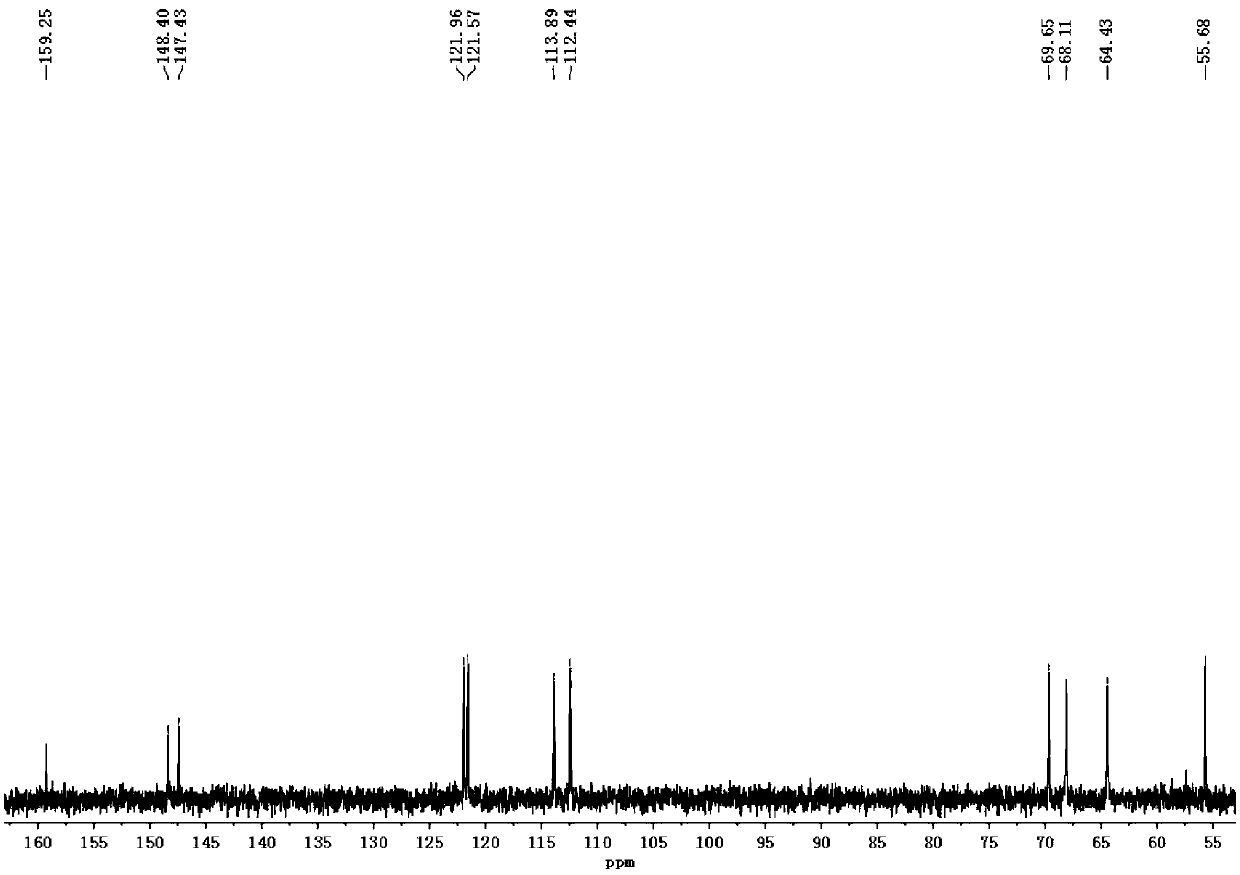

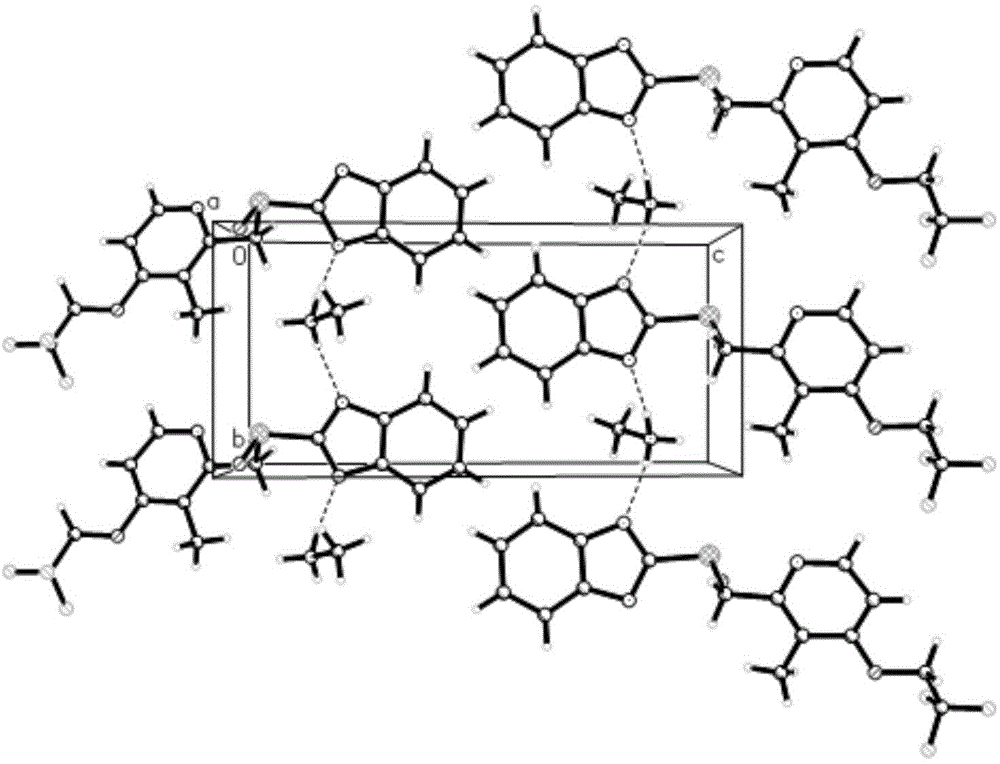

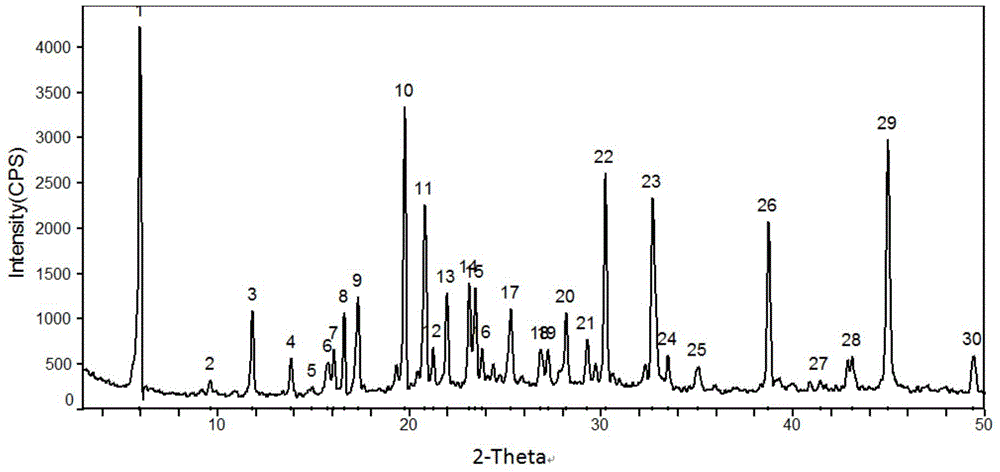

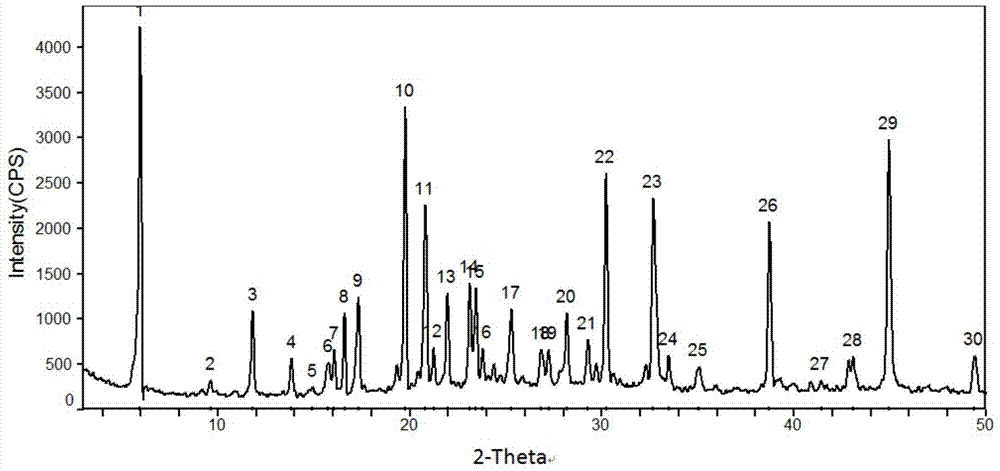

Polymorphism of methocarbamol dipotassium phosphate and preparation method thereof

InactiveCN103130684AMeet the requirements of the preparationEvenly dispersedNervous disorderCarbamic acid derivatives preparationSolubilityX-ray

The invention provides a polymorphism of methocarbamol dipotassium phosphate and a preparation method thereof, and relates to a polymorphism corresponding to 3-(o-methoxyphenoxy)-2-hydroxypropyl amino-acid ester dipotassium phosphate (methocarbamol dipotassium phosphate) and a preparation method thereof. A medicament containing the crystal form can be used for treating muscle sprain, lumbar muscle strain and ischialgia. The crystal form is specified by characterization results of an X-ray powder diffraction pattern (shown as Figure 1), nuclear magnetic resonance absorption spectra (shown as Figures 2-4), a thermogravimetry-differential thermal analysis curve (shown as Figure 5), an infrared spectrum absorption curve (shown as Figure 8) and liquid chromatography / mass spectrometry. The powder of the polymorphism is fine and uniform in dispersion; the stability is increased; the water solubility is 1:1; and the crystallization process is simple and convenient to implement production / transportation / storage, and conforms to the requirements for medicament preparation.

Owner:NANKAI UNIV

High-performance gold-vanadium alloy material as well as preparation method and application thereof

InactiveCN110029244AIncreased vanadium contentUniform vanadium contentVacuum evaporation coatingSputtering coatingCast ironHeat treating

The invention relates to a high-performance gold-vanadium alloy material as well as a preparation method and application thereof. The alloy is mainly applied to preparation of a metallization system in silicon microwave power transistors. The gold-vanadium alloy is composed of 0.1-9.9 wt% of V, and the balance Au. After the materials are proportioned, high-frequency induction vacuum furnace equipment with electromagnetic control is used, magnetic control stirring is started in the smelting process, so that the metal vanadium is fully melted; a furnace body is filled with argon; heating is stopped, the molten metal is poured into a cast iron mold, cooled with the furnace and then taken out, and then an intermediate alloy ingot with relatively high vanadium content is obtained; and the obtained gold-vanadium intermediate alloy is melted and refined together with gold through the same method so as to obtain the gold-vanadium alloy with relatively low vanadium content. The alloy is subjected to drawing, rolling and heat treatment process to obtain a wire material, a target material and a strip material. The gold-vanadium intermediate alloy disclosed by the invention has relatively highvanadium content, and is small in error range and uniform in vanadium content; and the requirement for preparation of the metallization system in the silicon microwave power transistor is met.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

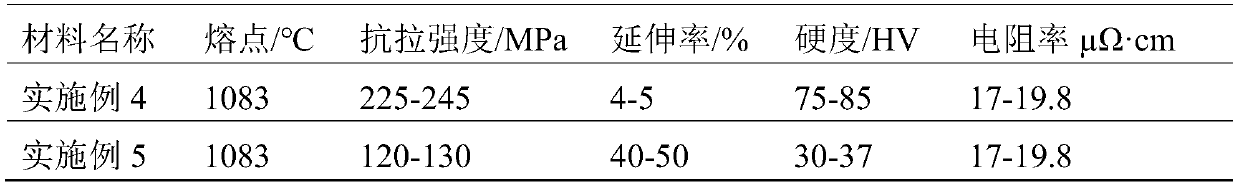

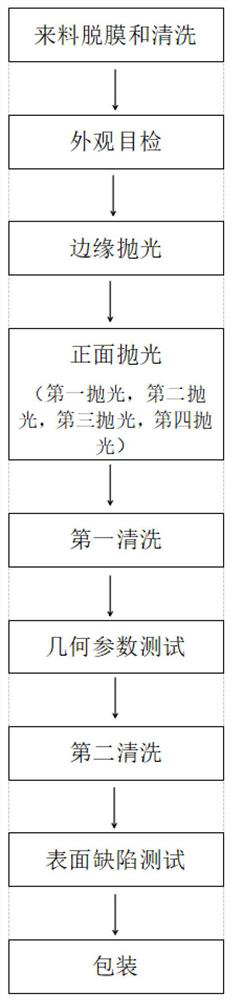

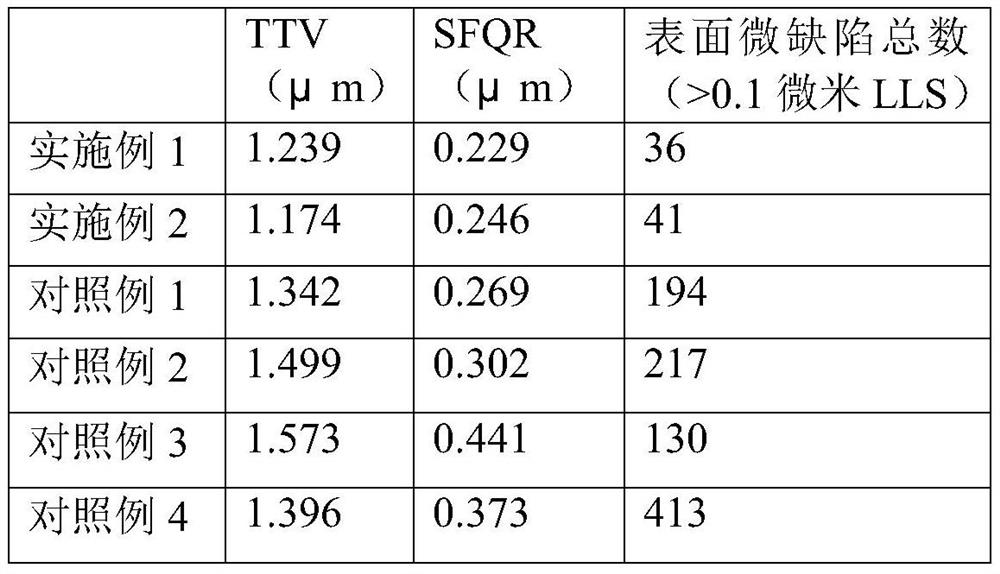

Regeneration processing method of substrate slice after SOI bonding process

ActiveCN113192823ALow costImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention belongs to the technical field of recycling and processing of monocrystalline silicon polished wafers of integrated circuits, and particularly relates to a regeneration processing method of a substrate slice after an SOI bonding process. The method comprises the following steps: demoulding and cleaning a recovered SOI substrate slice, polishing the front surface of the substrate slice, cleaning the substrate slice for the first time, testing the flatness uniformity and thickness of the substrate slice, and cleaning the substrate slice for the second time. According to the regeneration processing method disclosed by the invention, the recovery of the substrate slice after the SOI bonding process is realized, so that the substrate slice reaches a substrate silicon slice with a high surface quality level again, the substrate slice can be circularly used for multiple times in the SOI bonding process, and the processing cost is far lower than the price of purchasing a new substrate silicon slice.

Owner:MCL ELECTRONICS MATERIALS

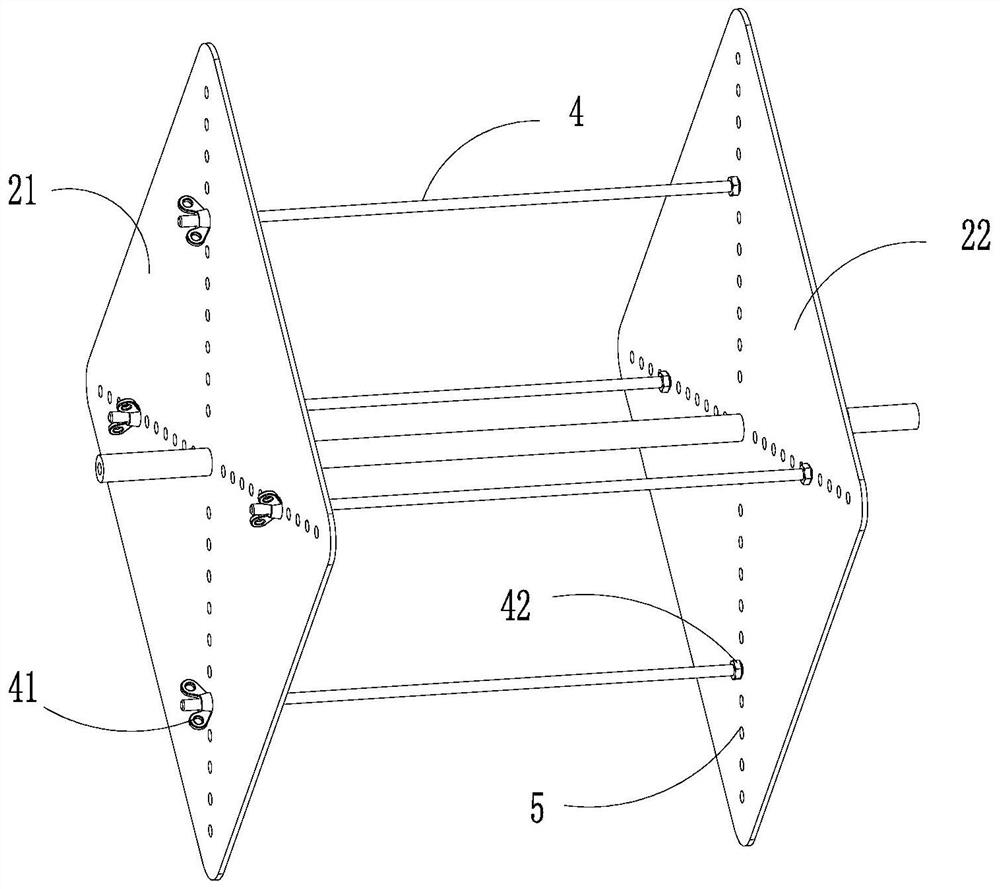

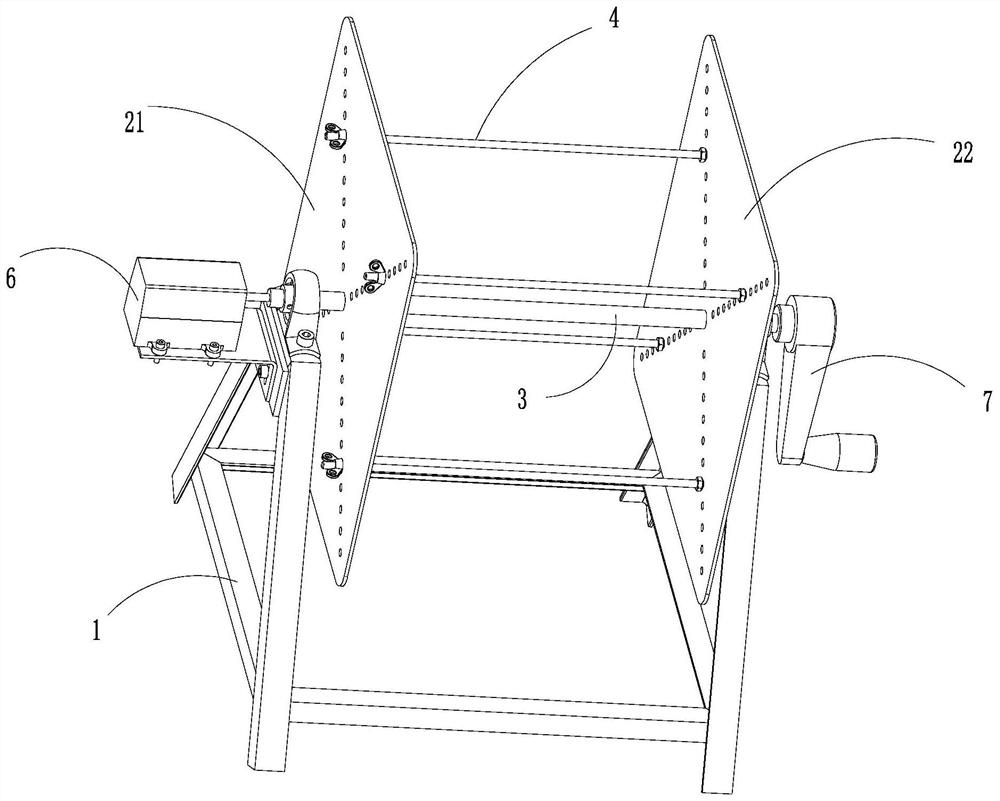

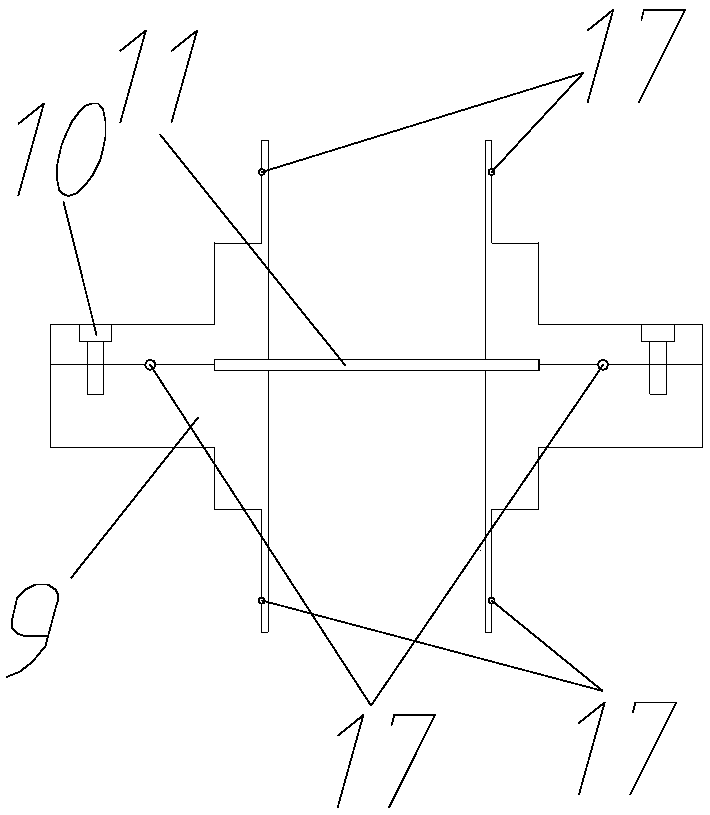

Continuous carbon fiber composite material forming winding machine

InactiveCN112374299AMeet the requirements of rectangular tube preparationMeet the requirements of the preparationWinding machineCarbon fiber composite

The invention relates to a continuous carbon fiber composite material forming winding machine which comprises a support and a winding frame. Bearing seats are arranged at the two ends of the support respectively. The two ends of the winding frame are connected with the bearing seats correspondingly. A carbon fiber composite material can be wound, and the winding size can be adjusted, so that the requirements of small and medium-sized enterprises for the preparation of carbon fiber composite material rectangular pipes are met.

Owner:江苏赛愽智能制造研究院有限公司

Preparation method of serinol

InactiveCN100408547CMeet the requirements of the preparationHigh purityOrganic compound preparationAmino-hyroxy compound preparationHydrazine compoundX-ray

The present invention relates to a preparation method of serinol, belonging to the field of serinol preparation technology by using reduction reaction. Said serinol is an important intermediate body for preparing nonionic X-ray contrast agent iopamidol. Said invention uses 2-nitro-1,3-propanediol sodium salt as raw material, uses hydrazine hydrate as reducing agent and uses palladium / carbon as catalyst to prepare serinol at normal pressure.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

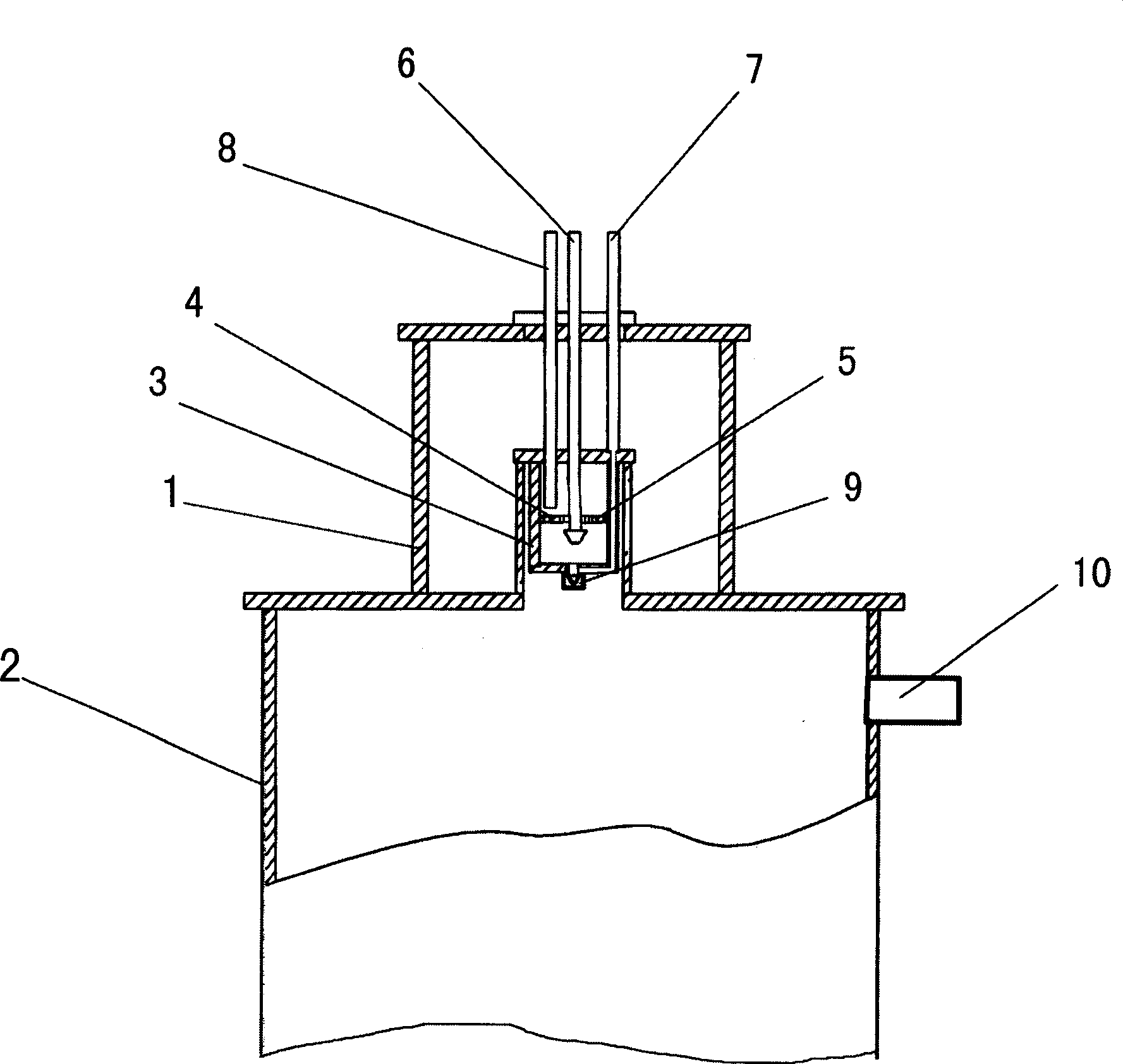

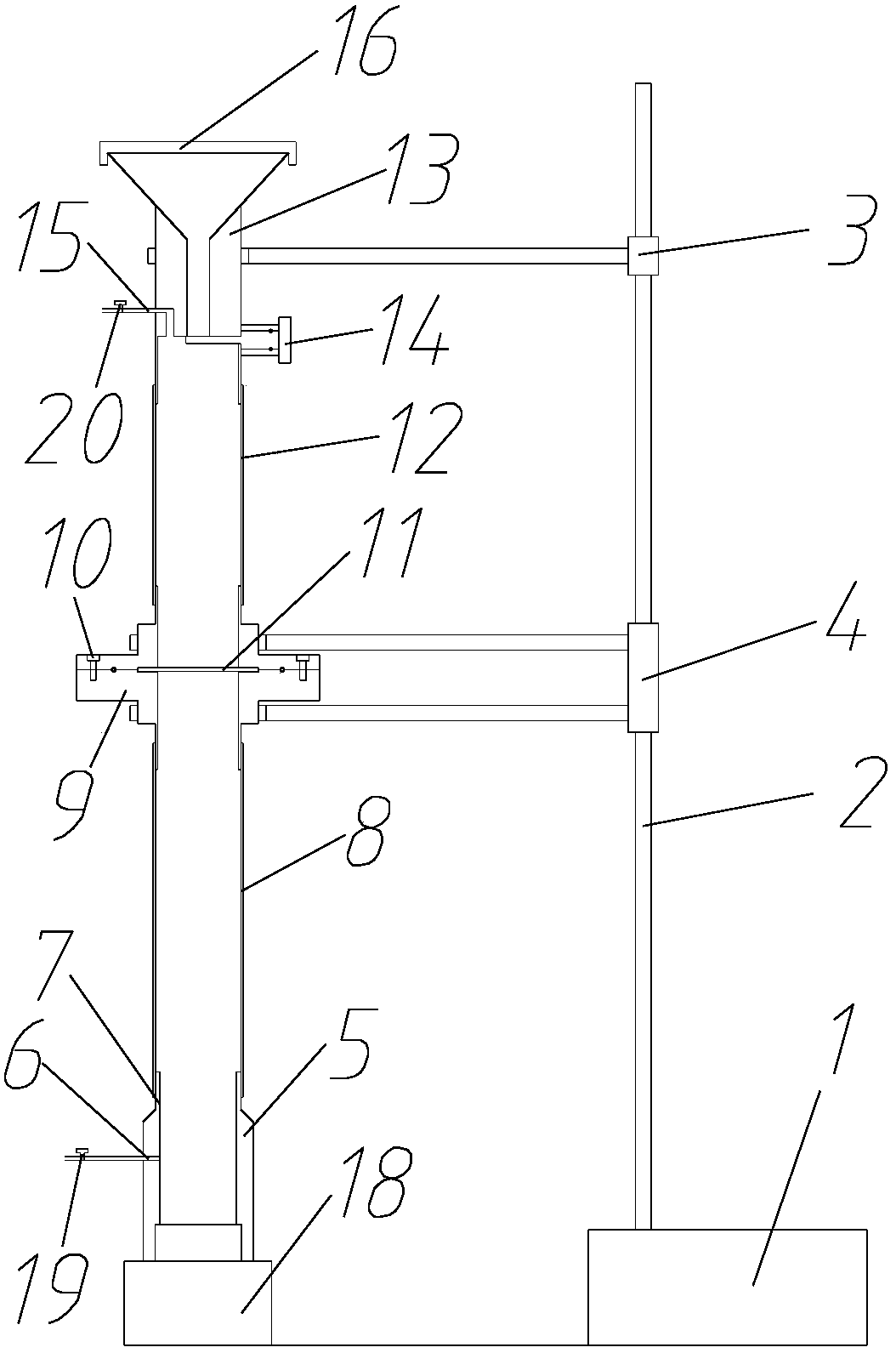

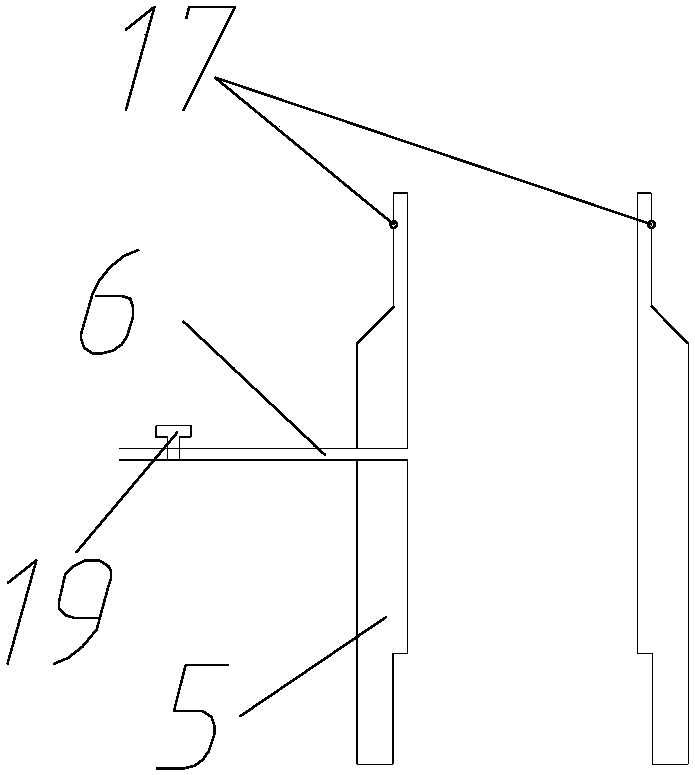

A device for preparing geotechnical triaxial sand samples

ActiveCN105910872BImprove uniformityMeet the requirements of the preparationPreparing sample for investigationOrganic glassSand sample

The invention belongs to the field of civil engineering and relates to a preparation device of a geotechnical three-axis sand sample. The preparation device comprises a funnel, a sand falling switch, an upper organic glass pipe, a dispersion device, a dispersion sheet, a lower organic glass pipe, a splitting mold and a three-axis chamber base, wherein the lower organic glass pipe is arranged on the three-axis chamber base through the splitting mold; the splitting mold is provided with a lower air exhausting hole; the dispersion device comprises an upper dispersion device and a lower dispersion device, each having a convex-shaped section; the upper dispersion device sleeves the outer part of the upper organic glass pipe and the lower dispersion device sleeves the outer part of the lower organic glass pipe; the dispersion sheet is embedded between the upper dispersion device and the lower dispersion device; the upper dispersion device and the lower dispersion device are arranged back to back and are connected through a connection bolt; the upper organic glass pipe is communicated with the lower organic glass pipe through the dispersion sheet in the dispersion device; the funnel is arranged at the top of the upper organic glass pipe and is communicated with the upper organic glass pipe through the sand falling switch; and the upper organic glass pipe is provided with an upper air exhausting hole. The preparation device of the geotechnical three-axis sand sample has the advantages that the sand sample with good uniformity can be prepared and the operation is convenient.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

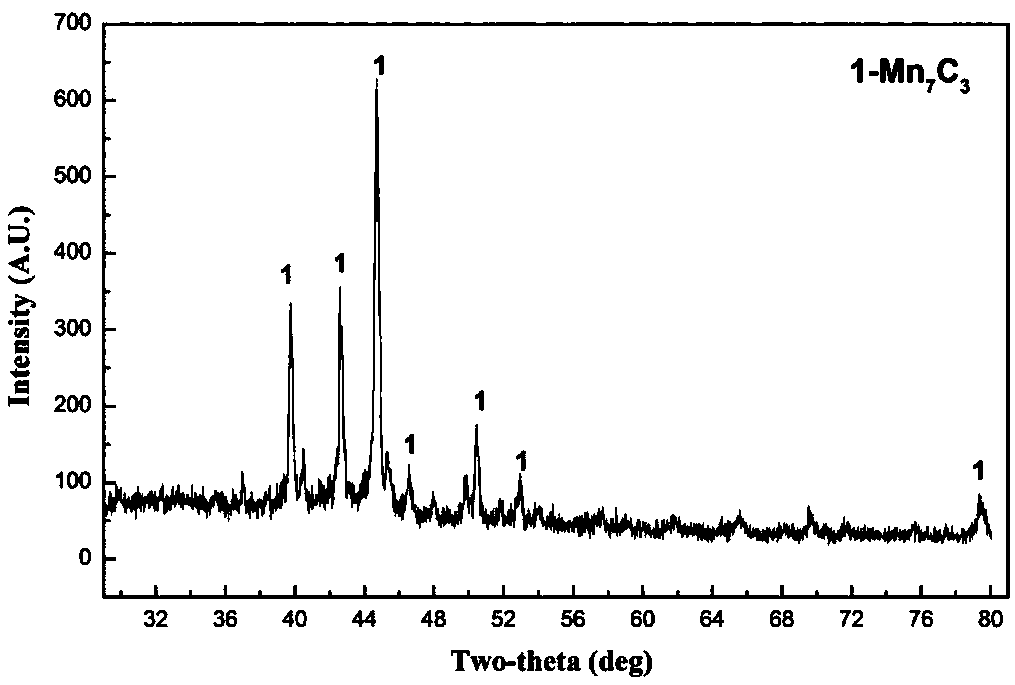

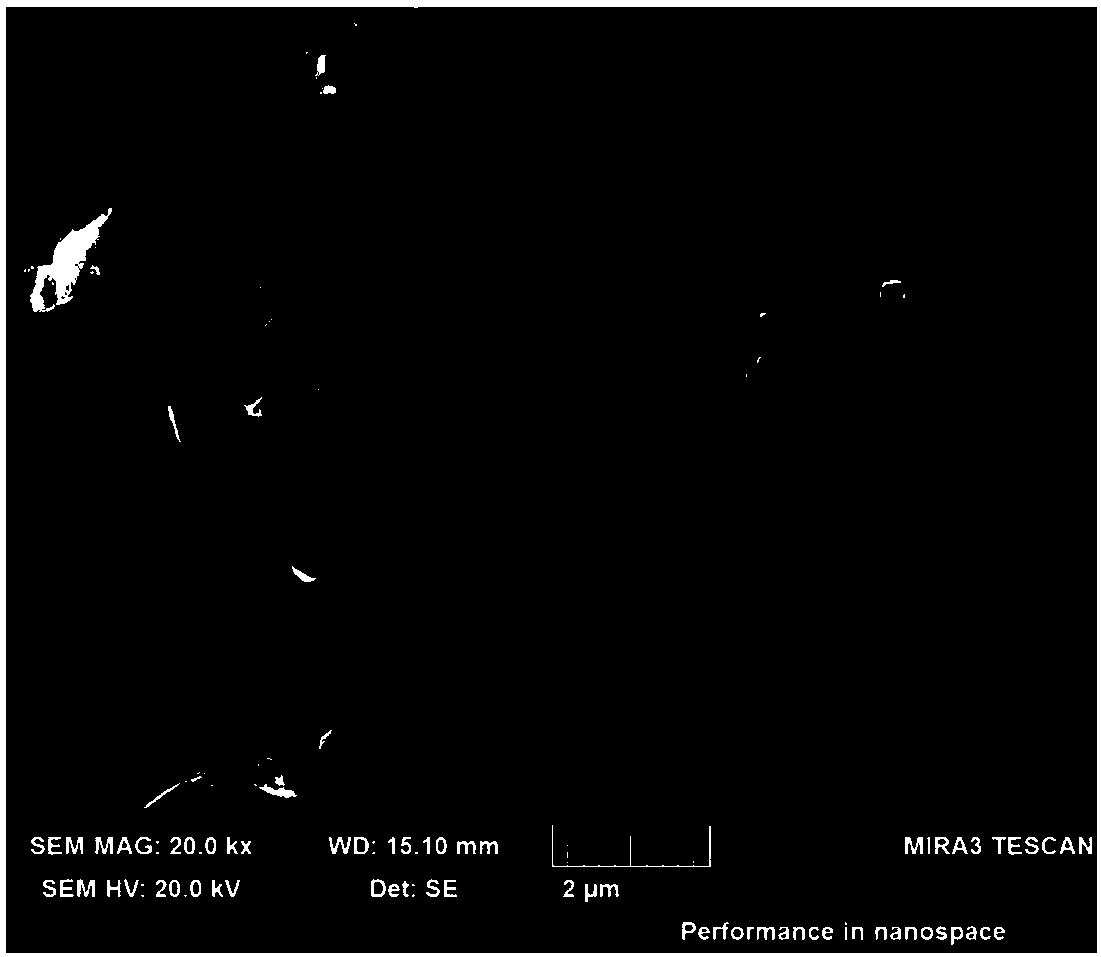

A kind of method that manganese oxide gas-based reduction prepares manganese carbide

ActiveCN106430196BReduce the reduction roasting temperatureReduce energy consumptionCarbon compoundsCarbideGraphite

The invention discloses a method for preparing manganese carbide by gas-based reduction of manganese oxides. The method comprises the following steps of mixing the manganese oxides, a bonding agent and water uniformly, agglomerating and drying, putting dry blocks into mixed atmosphere containing H2, CH4, CO and N2, calcining to obtain a manganese carbide product. Compared with the traditional method for preparing the manganese carbide by high-temperature smelting of manganese metal and graphite, the method disclosed by the invention has the characteristics of moderate reaction condition, low cost and simple process flow, and the prepared manganese carbide is high in purity and is applicable to requirements for preparing precursors of various functional materials.

Owner:CENT SOUTH UNIV

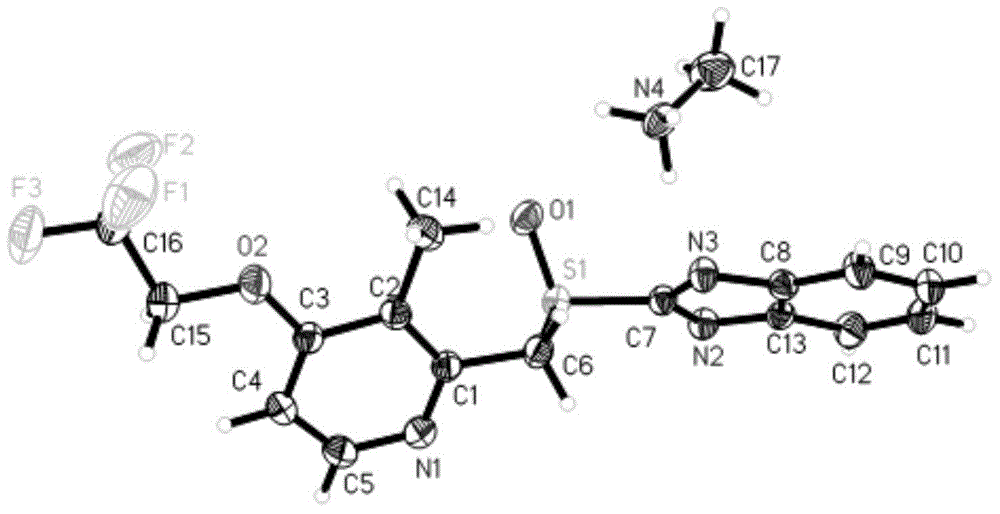

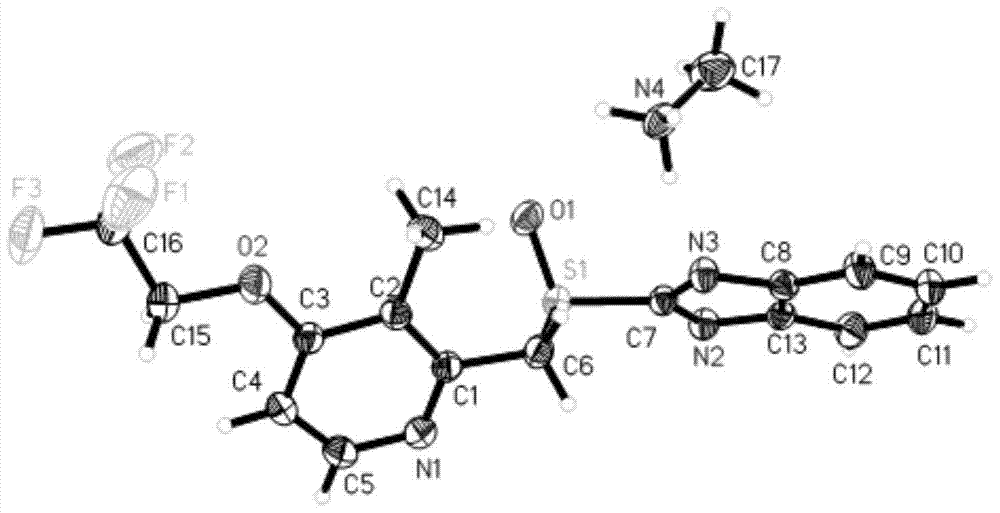

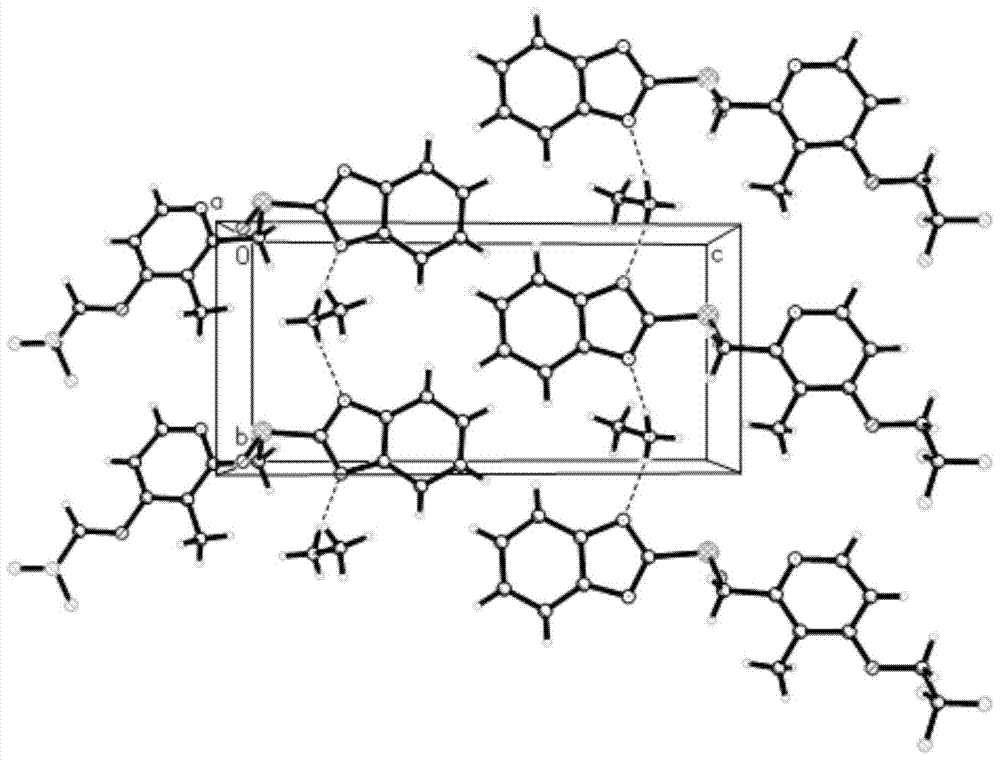

R-lansoprazole methylamine salt compound and preparation method and pharmaceutical composition thereof

ActiveCN104130244AGood water solubilityHigh optical purityAntibacterial agentsOrganic active ingredientsDiseaseSolubility

The invention provides an R-lansoprazole methylamine salt compound and a preparation method thereof, and absolute configuration of the molecule is determined by single crystal X-ray diffraction. Compared to R-lansoprazole, the compound has stable melting point, higher stability and greater water solubility, and is more suitable for pharmaceutical use. At the same time, the invention also provides a drug composition containing R-lansoprazole methylamine salt for the prevention and treatment of gastric acid related diseases.

Owner:SHANGHAI RIGHTHAND PHARMTECH

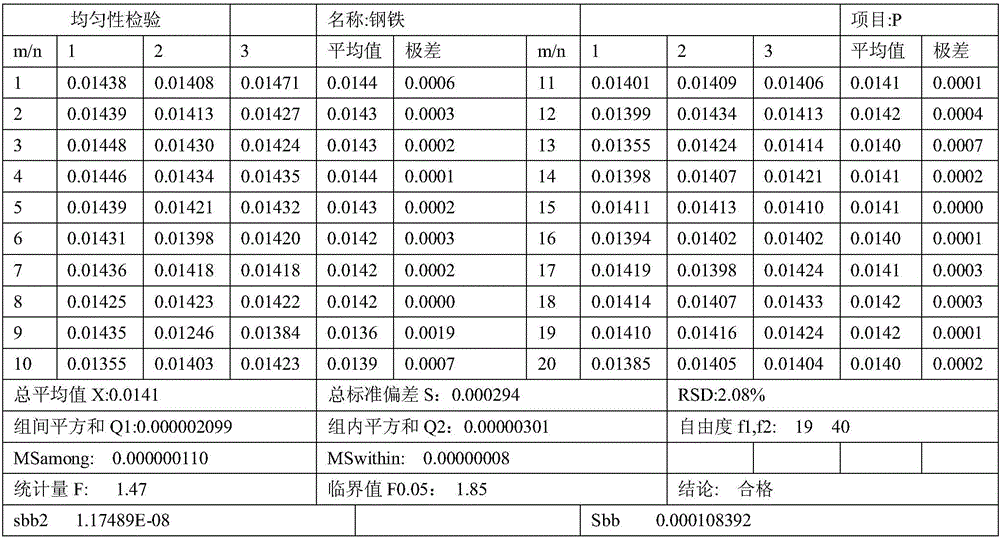

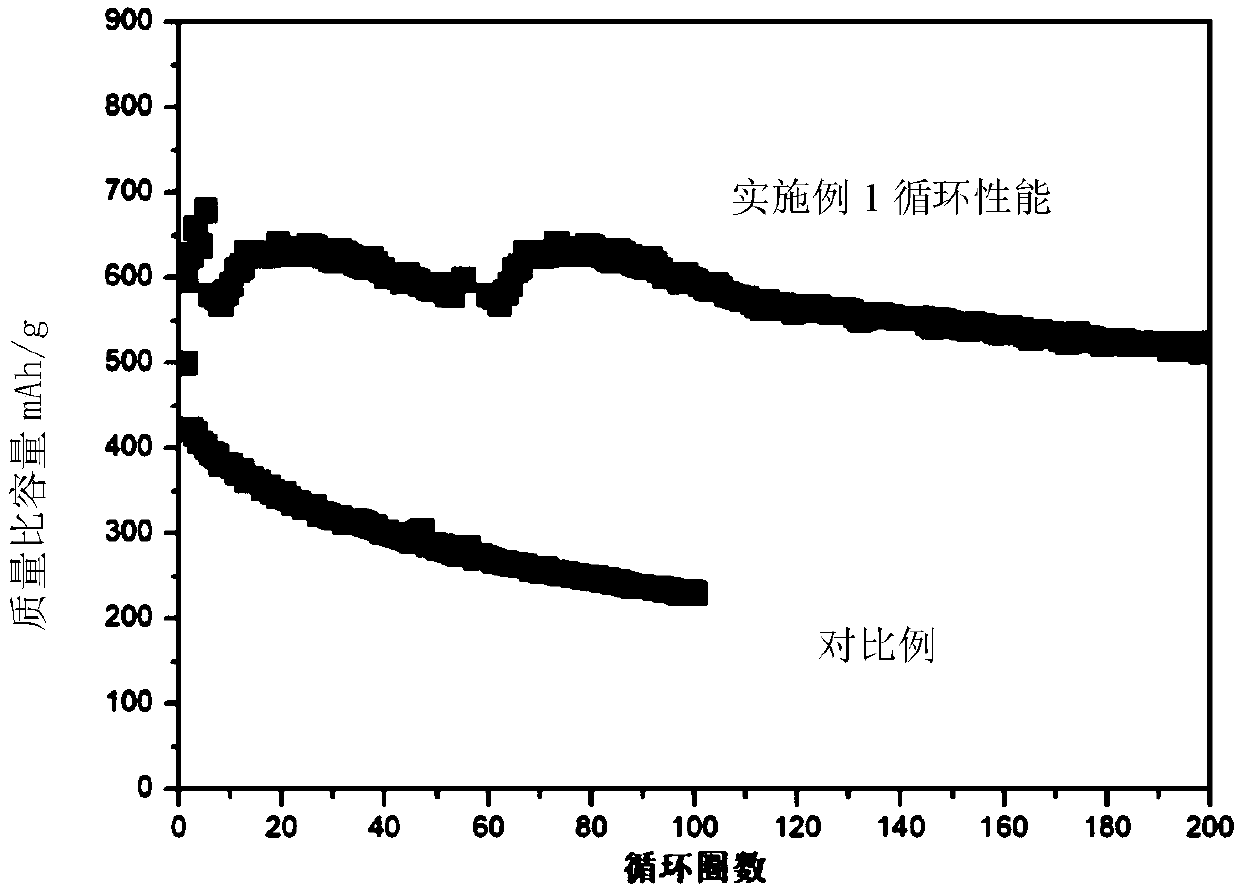

A kind of polymerized sulfur cathode material and lithium-sulfur secondary battery made of it

ActiveCN109575288BMeet the requirements of the preparationLow priceCell electrodesLi-accumulatorsElectrical batteryPolysulfide

The invention provides a poly-sulfur positive electrode material. Steps for preparing the poly-sulfur positive electrode material include 1), carrying out polymerization reaction on simple sulfur substances in molten states and thiuram organic polymerizing agents; 2), grinding and smashing reaction products after the polymerization reaction is completely carried out. The thiuram organic polymerizing agents are a type or a plurality of types of thiuram monosulfide, thiuram disulfide and thiuram polysulfide. The invention further provides a lithium-sulfur secondary battery prepared from the poly-sulfur positive electrode material. The poly-sulfur positive electrode material and the lithium-sulfur secondary battery have the advantages that the material preparation requirements can be met by simple heating equipment, processes for producing the poly-sulfur positive electrode material are convenient to operate and are simple, thiuram is extremely low in cost, and accordingly the poly-sulfurpositive electrode material is low in synthesis cost; macromolecular polymerized sulfide can be polymerized, the related problems such as poly-sulfur dissolution and shuttling of lithium-sulfur batteries can be solved when poly-sulfur is used as a positive electrode of the lithium-sulfur secondary battery, and the lithium-sulfur secondary battery is stable in cycle performance and long in cycle life.

Owner:BEIHANG UNIV

Dexlansoprazole methylamine salt compound and its preparation method and pharmaceutical composition

ActiveCN104130244BGood water solubilityHigh optical purityAntibacterial agentsOrganic active ingredientsDexlansoprazolePharmaceutical drug

The invention provides an R-lansoprazole methylamine salt compound and a preparation method thereof, and absolute configuration of the molecule is determined by single crystal X-ray diffraction. Compared to R-lansoprazole, the compound has stable melting point, higher stability and greater water solubility, and is more suitable for pharmaceutical use. At the same time, the invention also provides a drug composition containing R-lansoprazole methylamine salt for the prevention and treatment of gastric acid related diseases.

Owner:SHANGHAI RIGHTHAND PHARMTECH

Nickel alloy seamless evaporator for preparing photocathode coatings, and machining method

PendingCN107058959ASimple processing technologyEasy to mechanizeVacuum evaporation coatingSputtering coatingPhotocathodeEngineering

The invention relates to the evaporation field of photocathode coatings for night vision devices, and provides a nickel alloy seamless evaporator for preparing the photocathode coatings. The seamless evaporator is formed by machining seamless evaporating pipes with trapezoidal cross sections, and comprises a middle flat part, material holding parts and electrodes; a round hole is formed in the center of the upper bottom edge or the lower bottom edge of the middle flat part; the material holding parts are arranged at both ends of the middle flat part; and the electrodes are arranged at the side, far away from the middle flat part, of the material holding parts. The invention also provides a making method of the evaporator. The method comprises the steps of firstly, slightly flattening the part near the round hole in the center of the trapezoidal seamless evaporating pipe, and leaving a gap as a steam discharging channel; then, putting evaporating materials which are equal in mass into both ends of the evaporating pipe; and finally, flattening both ends of the evaporating pipe as the electrodes. The evaporator and the method provided by the invention have the beneficial effects of simple processing technology and easy realization of mechanization; the coatings are easy to form on the photocathode uniformly and stably, and the photoelectric conversion rate of the photoelectric surface of a low light level image intensifier is improved; and the requirements for preparation of various photocathode coatings can be met.

Owner:UNIV OF SCI & TECH BEIJING

A kind of aluminum niobium tantalum ternary alloy and preparation method thereof

The invention discloses an aluminum columbium tantalum ternary alloy and a preparation method thereof. The aluminum columbium tantalum ternary alloy comprises the following elements by weight percent: 40%-50% of Al, 35%-45% of Nb, and 5%-25% of Ta. The preparation method comprises the following steps of: step one, building a square graphite brick smelting furnace with a graphite brick; step two, placing the built graphite brick smelting furnace in a dry kiln; step three, burdening by using a burdening machine controlled by a computer; step four, igniting the loaded furnace burden with a magnesium chip to carry out smelting, wherein smelting temperature is 2700-3000 DEG C, and smelting time is 1 minute; step five, finishing the alloy by using a grinding machine to remove an oxide skin on the surface of the alloy; and step six, crushing the finished alloy by using a jaw crusher. The alloy and the preparation method of the alloy have the beneficial effects that production cost is low, energy is saved, and the alloy is low in impurity content; and the melting point of the alloy is reduced to be lower than 1650 DEG C, which is capable of fully meeting the requirements for the preparation of a titanium alloy.

Owner:肖景波

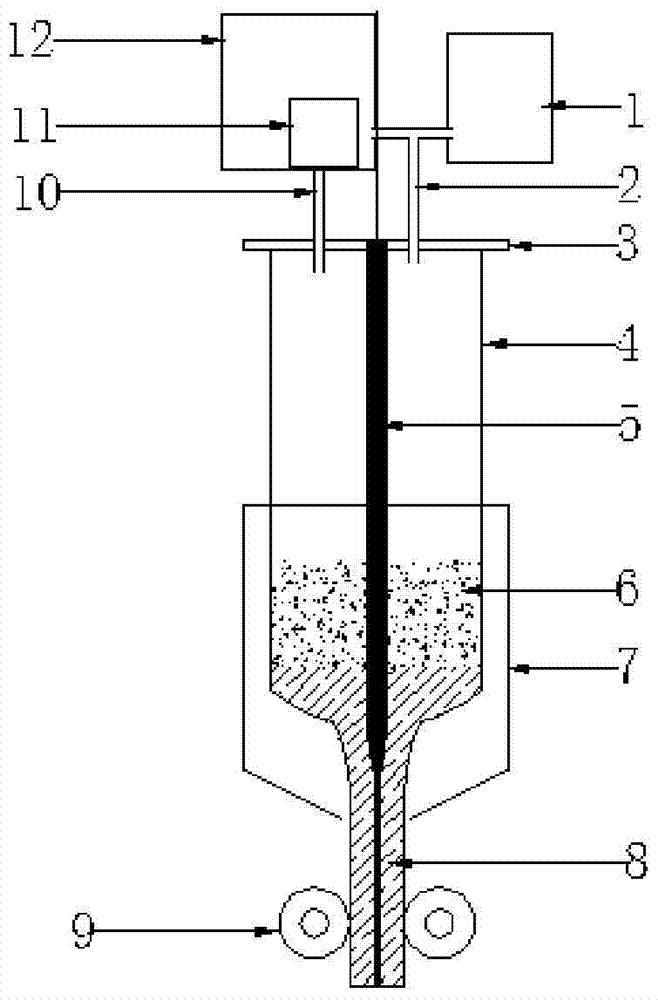

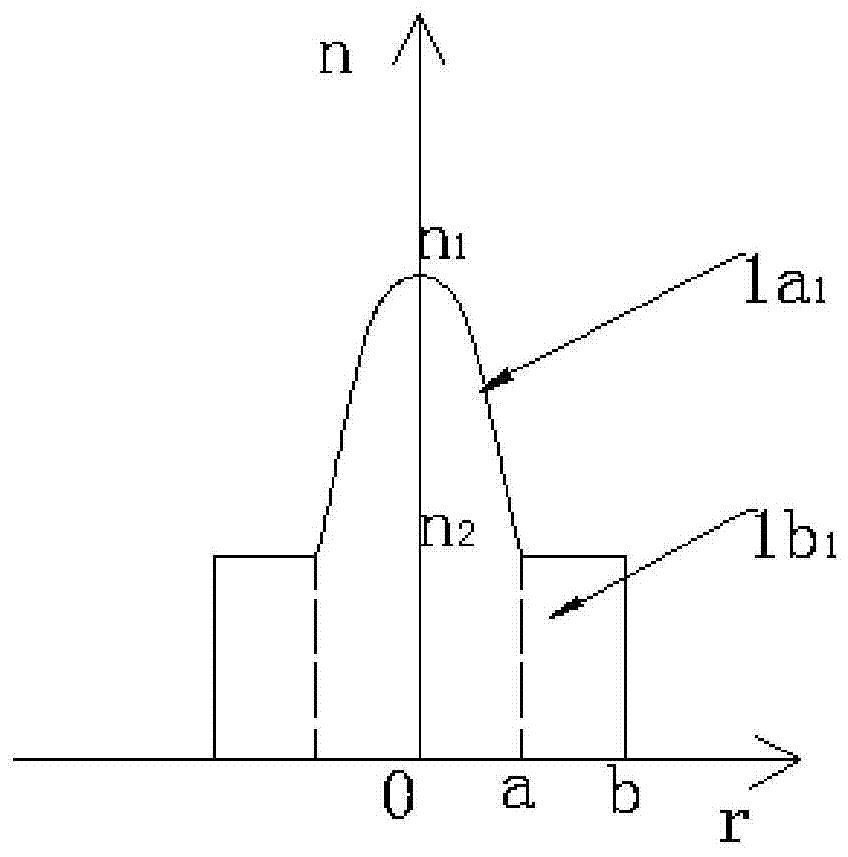

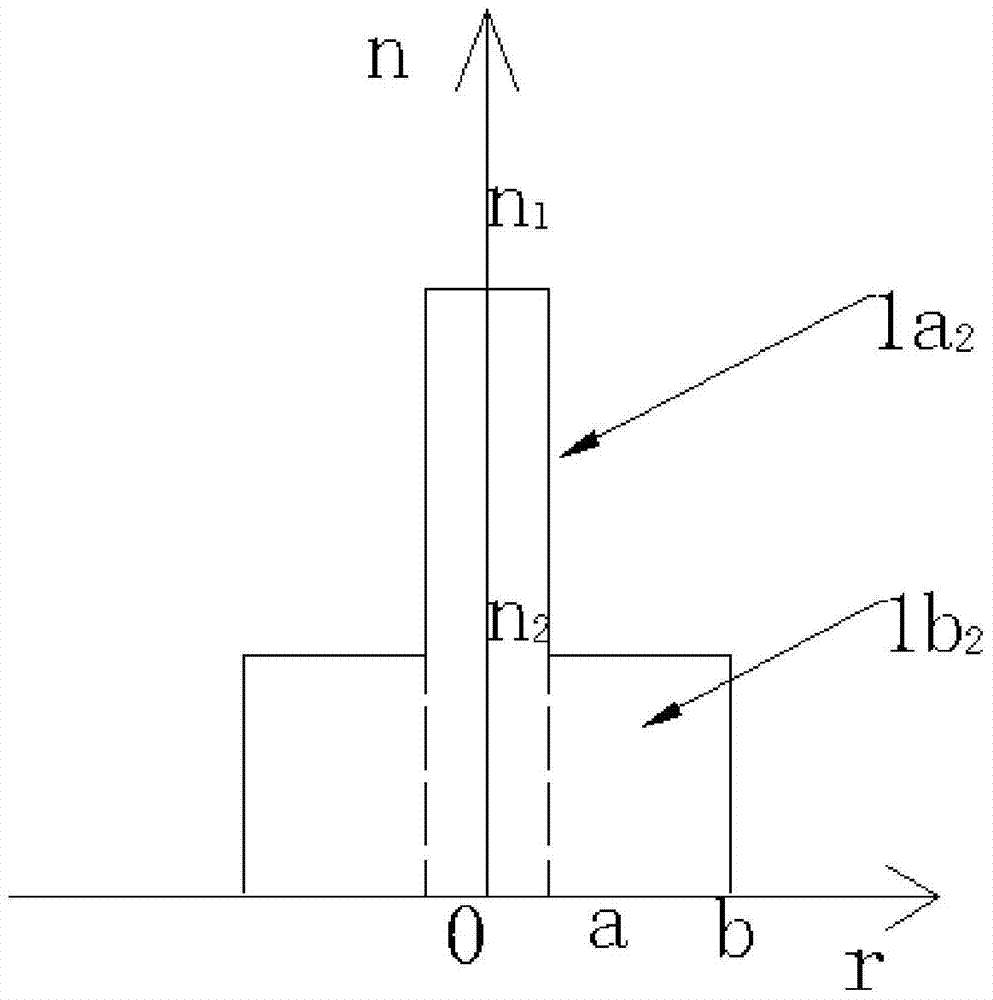

A method for preparing an optical fiber preform and drawing an optical fiber

The invention relates to a method for preparing an optical fiber preform rod and drawing an optical fiber. It uses a heating furnace device as a heat source, and a quartz crucible container containing SiO 2 A glass-based rod is filled with high-purity quartz sand or a mixture of quartz sand doped with F or B and other elements into the aforementioned container, melted at high temperature and drawn out of the SiO core containing the core. 2 The outer periphery of the glass rod has SiO 2 Optical fiber preforms with cladding or quartz sand mixture outer cladding doped with elements such as F or B can also be directly drawn out of optical fiber products by adjusting the drawing process parameters.

Owner:久智光电子材料科技有限公司 +1

Preparation method of low-chlorine refined bleached shellac

PendingCN110862771AQuality improvementImprove securityNatural resin purificationPreservativeSodium hypochlorite

The invention discloses a preparation method of low-chlorine refined bleached shellac. The preparation method includes: firstly dissolving granular shellac with a sodium carbonate solution to obtain ashellac resin alkali dissolution solution; then carrying out deslagging, temperature adjustment and concentration adjustment sequentially on the shellac resin alkali dissolution solution, and then conducting medium-concentration sodium hypochlorite bleaching to obtain a semi-bleached slurry; then adding assistants into the semi-bleached slurry for adjustment, and then conducting medium-concentration hydrogen peroxide supplementary bleaching by a hydrogen peroxide bleaching solution to obtain a bleached shellac resin solution; carrying out diatomite adsorption filtration on the bleached shellac resin solution, then carrying out acidification precipitation treatment with dilute sulfuric acid or dilute hydrochloric acid with a mass concentration of not higher than 6% to separate out shellacresin; and finally, washing the precipitated shellac resin with water to neutral, then carrying out centrifugal dehydration, crushing and drying, and performing cooling to obtain the low-chlorine refined bleached shellac. The method provided by the invention solves the technical problems of combination of traditional shellac bleaching method with other green bleaching methods, and the prepared low-chlorine refined bleached shellac can meet the preparation requirements of fruit preservatives and even drugs, and is environment-friendly and economical.

Owner:安宁戴科生物科技有限公司

Clean preparation method of hydrocracking catalyst

ActiveCN103785447BRealize cleaner productionEvenly dispersedMolecular sieve catalystsHydrocarbon oil crackingOrganic acidActive component

The invention relates to a clean preparation method of a hydrocracking catalyst. The clean preparation method comprises following steps of: (1) preparing a carrier of the hydrocracking catalyst; (2) preparing a dipping solution containing hydrocracking active components that are metal salts, wherein the hydrocracking active components comprise W and / or Mo in the VIB group and Ni and / or Co in the VIII group, the VIII metal salt is a salt of an organic acid, a dissolution process is performed under stirring at high temperature, the solution is placed in an ultrasonic wave environment and is cooled to the room temperature; and (3) dipping the carrier prepared in the step (1) into a measured amount of the metal salt dipping solution prepared in the step (2) with the dipping process being in an ultrasonic wave environment; performing solid-liquid separation after the dipping step, drying the dipped catalyst and calcinating to obtain a catalyst product. According to the clean preparation method, a pollution problem in the catalyst production process is overcome under the premise of guaranteeing the using performances of the catalyst, thus achieving clean production of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high alloy tool and die steel hollow tube billet

ActiveCN110125408BSmall and uniform tissueCrystal fine and denseMetal-working apparatusEngine componentsCarbideIngot

The invention provides a high alloy tool and die steel hollow steel ingot injection molding method and hollow steel ingot and high alloy tool and die steel hollow tube billet preparation method, the hollow steel ingot spray forming method of the present invention includes rolling a steel plate to meet the inner diameter and height requirements The top-closed core cylinder is fixed on the rotatable collection tray in the spray chamber, and the refined high-alloy tool and die steel molten steel is sprayed to the rotating collection tray and core cylinder for atomization deposition, and the spray is used The collecting tray is continuously moved downwards to gradually deposit the sprayed ingots, and the sprayed ingots are air-cooled and then annealed and air-cooled out of the furnace. The hollow steel ingot preparation method of the present invention can make the hollow steel ingot uniform and fine in structure, dense in crystallization, greatly improved in chemical composition and carbide segregation, close to the quality of products obtained by powder metallurgy forming method, and can realize the preparation of hollow steel ingot of high alloy tool and mold steel, and The prepared hollow steel ingot can meet the requirements for the preparation of high-alloy tool and die steel hollow pipes.

Owner:HEYE SPECIAL STEEL

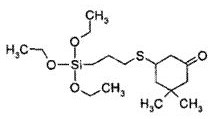

A kind of modified silica fume wool and its preparation method and application

ActiveCN111004273BImprove friction resistanceMeet the requirements of the preparationGroup 4/14 element organic compoundsSolid waste managementPolymer sciencePolymer chemistry

The invention discloses a modified silica fume wool and a preparation method and application thereof. The modified silica fume wool is prepared by joint modification of 3-isocyanatopropyltrimethoxysilane and a silane coupling agent as described in formula I. The modified silica fume wool prepared by the invention is modified jointly by two silane coupling agents, which greatly improves the friction resistance of the material. The friction coefficient of the disc brake pad prepared by using the modified silica fume wool as a raw material reaches 0.63, which meets the requirement of Current requirements for the preparation of disc brake pads.

Owner:大冶市启发矿产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com