Efficient synthetic method for medicinal high-purity dehydrocholic acid

A technology of dehydrocholic acid and synthesis method, applied in steroids, organic chemistry and other directions, can solve the problems of heavy metal residue safety hazards, chlorine leakage, non-conformance and other problems in products, and achieve uniformity, small batch-to-batch variation, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

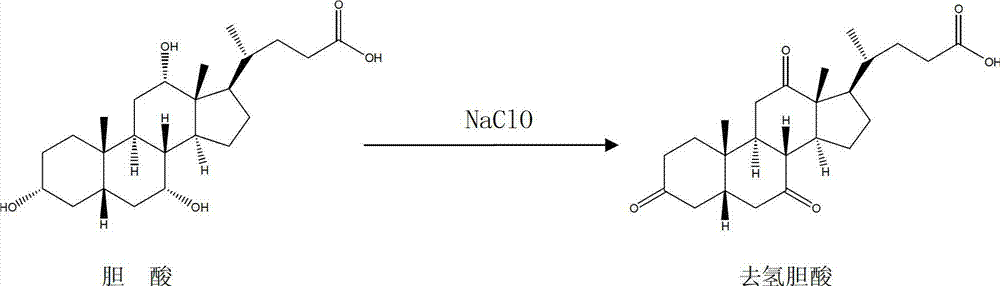

Image

Examples

Embodiment 1

[0047] In a 250ml three-neck round bottom flask, put 10.0g of cholic acid into it, and under the condition of heating in a water bath at 40°C, add 27.5ml of acetone while stirring slowly to disperse the cholic acid evenly, then slowly add 15ml of 65% concentrated sulfuric acid, it can be seen Bile acid gradually dissolves. After the bile acid is completely dissolved, slowly add 100ml of sodium hypochlorite solution dropwise. After the addition, the reaction was incubated for 6 hours, and samples were taken every hour for TLC detection during the period to monitor the reaction process and finally judge the reaction end point. After the reaction was completed, the feed liquid was placed in a 500ml separatory funnel and allowed to stand for stratification. The lower layer was a brine phase, and the upper layer was an acetone phase. The lower layer was discarded, and 275 ml of purified water was added to the upper layer while stirring, and a large amount of white powdery solids w...

Embodiment 2

[0050] In a 50L reactor, put 3kg of cholic acid into it, and under the condition of controlling the temperature of the circulating water in the jacket at 40°C, pump in 8.3L of acetone while stirring slowly to disperse the cholic acid evenly, and then slowly pump in 65% Concentrated sulfuric acid 4.5L, after the cholic acid is completely dissolved, slowly add 30L sodium hypochlorite solution. After the addition, the reaction was incubated for 6 hours, and samples were taken every hour during the process for TLC detection to monitor the reaction progress and finally judge the reaction end point. After the reaction stopped, the layers were left to stand, the lower layer was discarded, the upper layer was transferred to a 200L reactor, 83L of purified water was added, and a large amount of white powdery solids were precipitated. Filter, wash the filter cake with water until neutral, and dry to obtain about 2.6 kg of dehydrocholic acid crude dry powder. The melting point is 236°C-...

Embodiment 3

[0053] In a 50L reactor, put 3kg of cholic acid into it, and under the condition of controlling the temperature of the circulating water in the jacket at 40°C, pump in 8.3L of acetone while stirring slowly to disperse the cholic acid evenly, and then slowly pump in 65% Concentrated sulfuric acid 4.5L, after the cholic acid is completely dissolved, slowly add 30L sodium hypochlorite solution. After the addition, the reaction was incubated for 6 hours, and samples were taken every hour during the process for TLC detection to monitor the reaction progress and finally judge the reaction end point. After the reaction stopped, the layers were left to stand, the lower layer was discarded, the upper layer was transferred to a 200L reactor, 83L of purified water was added, and a large amount of white powdery solids were precipitated. Filter, wash the filter cake with water until neutral, and dry to obtain about 2.6 kg of dehydrocholic acid crude dry powder. The melting point is 236°C-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com