High-performance gold-vanadium alloy material as well as preparation method and application thereof

A gold-vanadium alloy and vanadium alloy technology, which is applied in the field of gold-based alloys and their preparation, can solve the problems of easy segregation of components and difficult addition of vanadium elements, and achieve the effects of uniform components, accurate vanadium content and improved comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

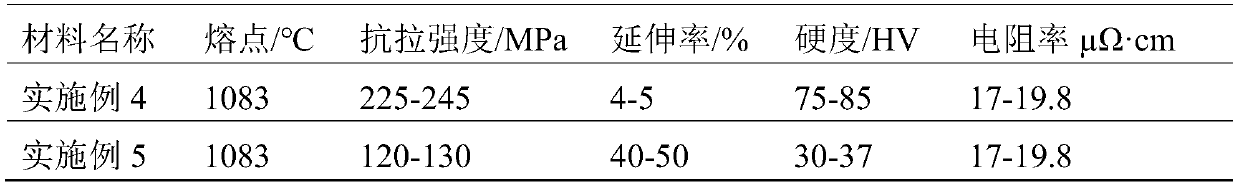

Examples

preparation example Construction

[0053] A method for preparing a gold-vanadium alloy material, using a unique vacuum magnetron doping technology, firstly, preparing a gold-vanadium master alloy with a higher vanadium content; then, combining the gold-vanadium master alloy with a higher vanadium content with gold Melting and refining, the gold vanadium alloy material is prepared. Including the following steps:

[0054] 1) Calculate and weigh high-purity (5N) gold and metal vanadium according to the required proportioning range;

[0055] 2) Use a high-frequency induction vacuum furnace equipped with electromagnetic control, put gold and vanadium in the order of gold and vanadium into a zirconia crucible covered with graphite, then cover the furnace cover and vacuumize;

[0056] 3) Heating up, the power is given to 70%-80% of the rated power of the equipment, the purpose is to quickly heat up;

[0057] 4) After the gold is completely melted, keep the power value unchanged, turn on the magnetic control stirring...

Embodiment 1

[0064] Adopt following preparation method to prepare gold-vanadium master alloy, its composition and mass percent are: V: 5%, Au: surplus (abbreviated AuV 5 ).

[0065] The preparation process is as follows:

[0066] a) Prepare raw materials: Purify gold 4N (99.99%) raw materials by electrolysis to remove impurity elements (mainly control Pb, Sb, In, Bi and rare earth elements), so that the purity of metal gold can reach more than 5N (>99.999 %), purchased metal vanadium raw materials; calculated and weighed according to the above-mentioned composition and mass percentage proportioning.

[0067] b) Using a high-frequency induction vacuum furnace equipped with electromagnetic control, put gold and vanadium in the order of gold and vanadium in a zirconia crucible covered with graphite, then cover the furnace cover and vacuumize;

[0068] c) Heating up, the power is given to 75% of the rated power of the equipment, the purpose is to quickly heat up;

[0069] d) After the gold ...

Embodiment 2

[0074] Adopt the method described in embodiment 1 to prepare gold vanadium master alloy, its composition and mass percent are: V: 10%, Au: balance (being called for short AuV 10 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com