Method for regenerating SCR catalyst by utilizing waste SCR catalyst vanadium extracting solution

A technology of SCR catalyst and extraction liquid, which is applied in the field of regenerating SCR catalysts by utilizing waste SCR catalyst vanadium extraction liquid, which can solve the problems of poor loading effect of active liquid and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

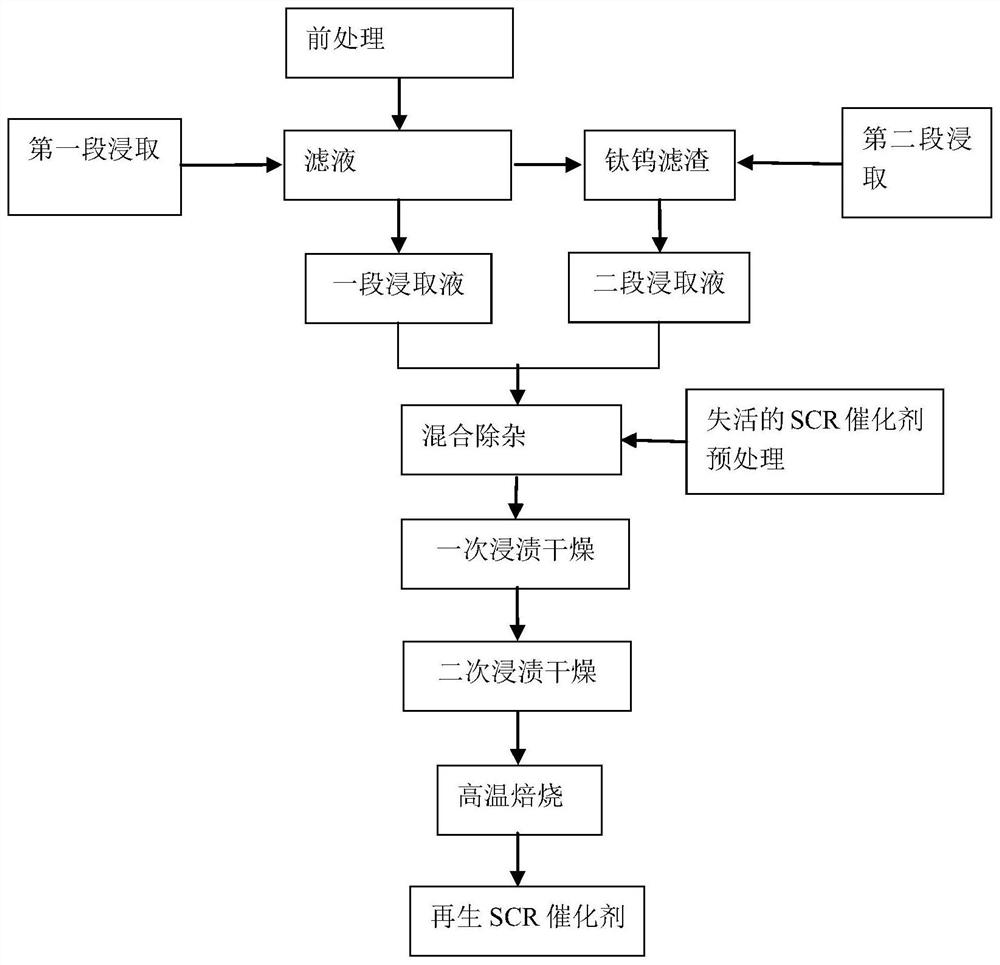

[0037] See attached figure 2 In this embodiment, the method for regenerating the SCR catalyst using the vanadium extraction solution of the waste SCR catalyst includes two parts: the vanadium extraction process of the SCR catalyst and the loading process of the regenerated SCR catalyst, wherein,

[0038] The SCR catalyst vanadium extraction process includes the following steps: A1, pretreatment: the waste SCR catalyst is pretreated with the cleaning agent and method in the publication number CN105032504A, and is obtained through ash cleaning and water cleaning, chemical cleaning and rinsing, and grinding and pulping. Slurry; A2, the first section of leaching: add the first section of acid leaching agent to the slurry obtained in step A1, the acid leaching agent is oxalic acid, the concentration of oxalic acid is 2%, the leaching temperature is 55 ° C, the liquid-solid ratio 3:1, the leaching time is 0.5h, and the first section of leaching solution and filter residue are obtai...

Embodiment 2

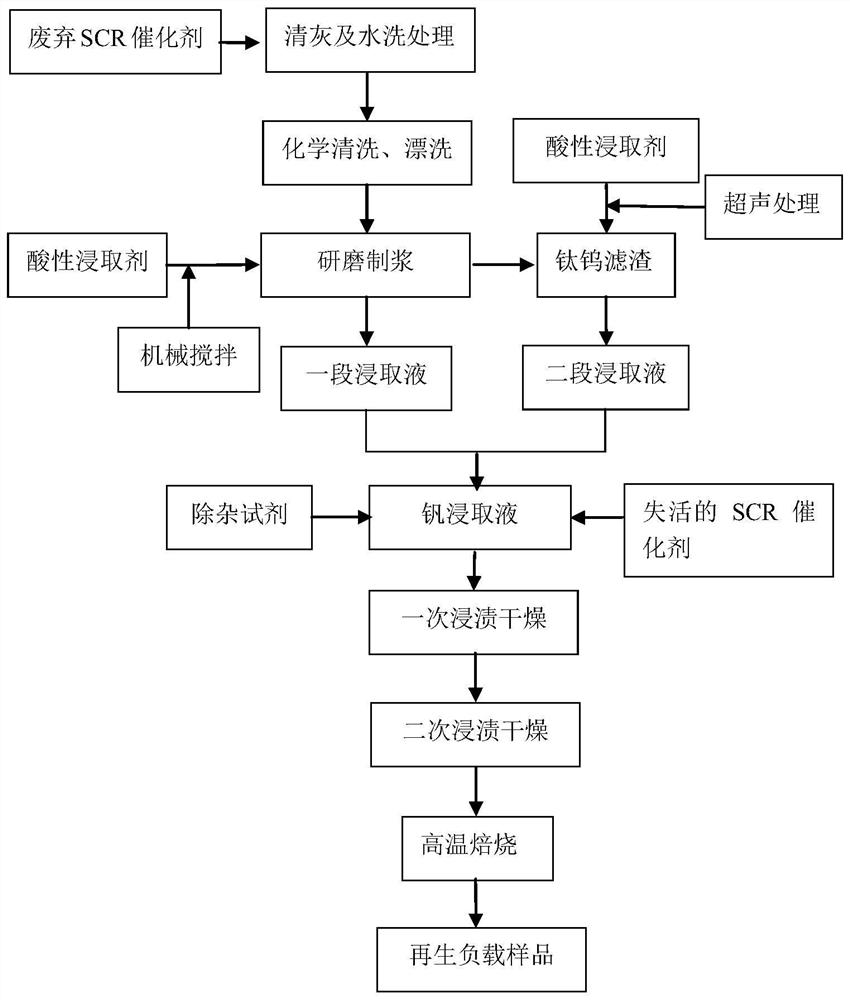

[0041] In this embodiment, the method for regenerating the SCR catalyst by using the vanadium extraction solution of the waste SCR catalyst, the specific technical scheme includes two parts: the SCR catalyst vanadium extraction process and the regenerated SCR catalyst loading process, wherein,

[0042] The SCR catalyst vanadium extraction process includes the following steps: A1, pretreatment: the waste SCR catalyst is pretreated by using the cleaning agent and method in the publication number CN105032504A, and is obtained through ash cleaning and water cleaning, chemical cleaning and rinsing, and grinding and pulping. Slurry; A2, the first section of leaching: add the first section of acid leaching agent to the slurry obtained in step A1, the acid leaching agent is sulfuric acid, the concentration of sulfuric acid is 4%, the leaching temperature is 65 ° C, liquid-solid Ratio 3:1, leaching time is 1.5h, after filtering, obtain the first stage leaching solution and filter residu...

Embodiment 3

[0045] In this embodiment, the method for regenerating the SCR catalyst by using the vanadium extraction solution of the waste SCR catalyst, the specific technical scheme includes two parts: the SCR catalyst vanadium extraction process and the regenerated SCR catalyst loading process, wherein,

[0046] The SCR catalyst vanadium extraction process includes the following steps: A1, pretreatment: the waste SCR catalyst is successively subjected to ash removal and water cleaning, chemical cleaning and rinsing, grinding and pulping to obtain a slurry; A2, the first stage of leaching: to step A1 obtained Add the first section of acid leaching agent to the slurry, the acid leaching agent is sulfuric acid, the concentration of sulfuric acid is 3%, the leaching temperature is 60°C, the liquid-solid ratio is 3:1, and the leaching time is 1h. After filtering, the first One-stage leaching solution and filter residue; A3, second-stage leaching: add the second-stage acid leaching agent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com